®

THE HYSTER ADVANTAGE

PRODUCTIVITY

ERGONOMICS

COST OF OWNERSHIP

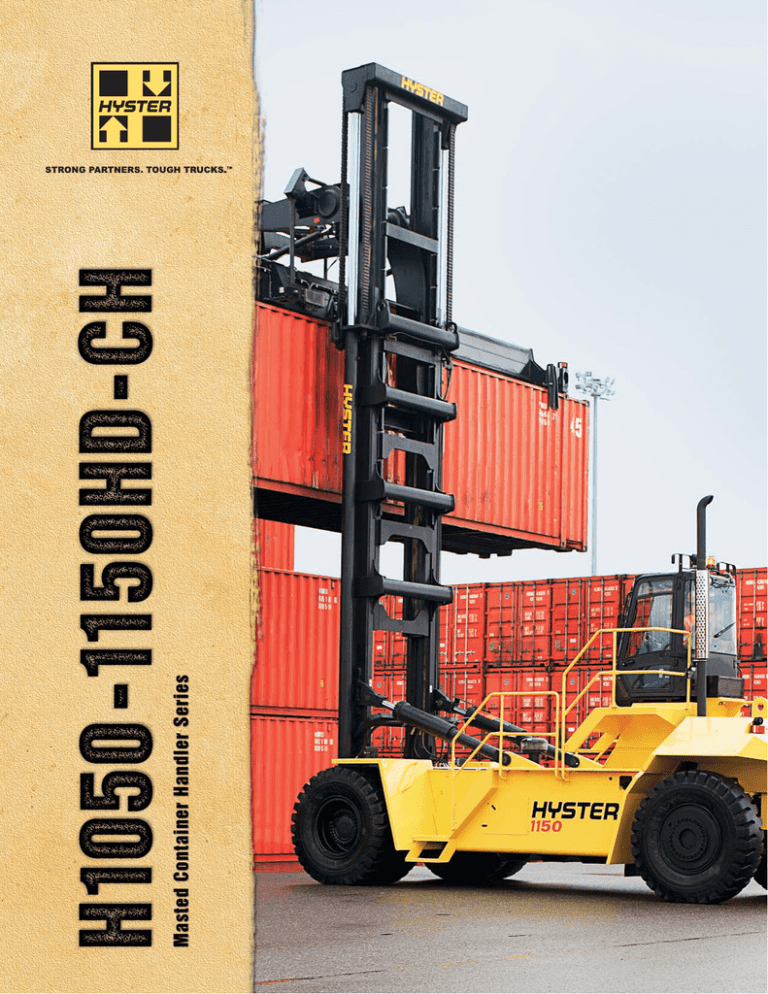

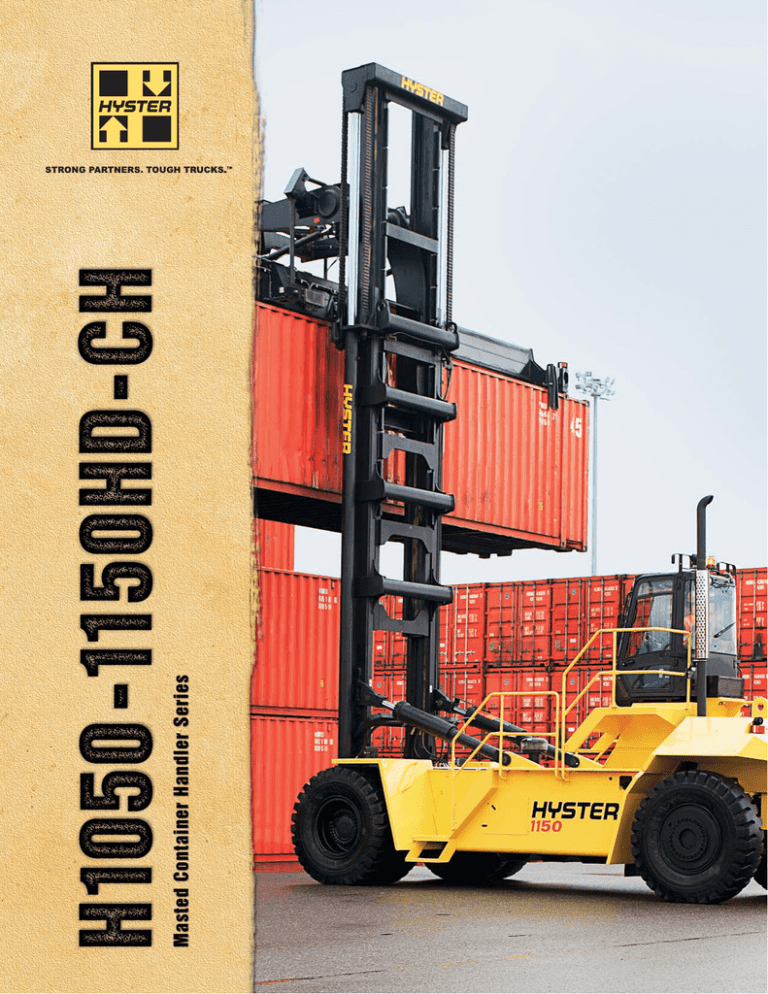

The outstanding lift capacity of the new

H1050-1150HD-CH Container Handler

series is a combination of the latest

engine, transmission and hydraulic

technologies, offering superior

performance in all facets of

container handling.

■ Increased lift/lower speeds equal

increased container moves per hour.

■ Superb visibility in all directions due to:

– Positioning of mast cross-members

– Placement of cab

– Design of cab structure

– Counterweight design

A spacious, comfortable operator

environment and unmatched functionality

are the hallmarks of the new Hyster

H1050-1150HD-CH series. The operator

interface with intuitive controls elevates

productivity levels like no other truck in

its class.

Service on the new H1050-1150HD-CH

series is facilitated by the easy

accessibility of all internal elements.

■ Industry-leading lift/lower speeds

maximize the number of laden

containers moved per hour.

- 51.0 ft./min. lifting speed (Laden)

- 59.0 ft./min. lifting speed (Unladen)

- 98.0 ft./min. lowering speed

(Laden or Unladen)

■ ComforCab II design provides superior

work environment and visibility of twist

locks at all heights, significantly adding

to the number of container placements

per hour for a better bottom line.

■ Certified leak-free O-ring face seal

(ORFS) hydraulic system fittings

dramatically improve uptime.

■ Redesigned steer axle geometry cuts

down on overall steer tire wear to

significantly reduce cost of ownership.

■ Twist Lock With Indicator Signals

and Tones (TWIST) module is

ergonomically located to facilitate

monitoring of twist lock status.

■

■

■

■

Increased hydraulic tank capacity for

improved hydraulic performance and

cooler operating temperatures.

The 175-gallon fuel tank supplies in

excess of 30 hours of run time.

Rugged truck frame design has wide

drive and steer axles capable of

handling 33-inch tires.

New counterweight design reduces

overall truck length by 20 inches on the

H1150HD (13 inches on the H1050HD).

A shorter truck equals a shorter turning

radius, equals greater manuverability,

equals improved productivity.

■

■

■

■

■

■

■

■

Front-to-rear 3-point access from either

side contributes to easy entry and exit.

ComforCab II™ offers an open,

uncluttered floor plan with an easy

3-pedal configuration for maximized

operator efficiency.

Full-suspension 3-way adjustable seat

has left armrest and infinitely adaptable

right-hand control console with loweffort pilot hydraulic controls to provide

naturally personalized operator position

that lessens fatigue.

Cab design creates excellent

all-around visibility.

Air conditioning system, combined

with top and rear sunshades, keeps

operators cool during extended shifts.

Cab air filtration system yields a

dust-free environment.

ComforCab II soundproofing makes

for a quiet working environment.

Right-hand dash display allows

complete performance monitoring

at a glance.

When it comes to container handling, the H1050-1150HD-CH series

rules the roost. This line of masted top-pick trucks can handle up to

88,185 pounds (40,000 kg) under the spreader, giving you the strength to move even the heaviest cargo anywhere it needs to go. The

trucks’ lift capabilities allow true 5-high stacking for increased container density. Engineering advances have made these container

handlers one of the most rugged and reliable on the market. But, as with every Hyster lift truck, your operators will feel right at home

in the comfortable, ergonomically advanced ComforCab II™. Outstanding productivity, durability and comfort. No matter how you look

at it, the H1050-1150HD-CH series from Hyster Company is the only smart choice for container handling.

■ ComforCab II™: Easy 3-point

access. Air filtration, adjustable seat and

armrest control module combine to give

operators the most comfortable working

environment possible.

■ Radiator: Side-by-side

core placement boosts airflow

to lower operating temperatures

and ease cleaning.

■ Battery

Access:

Fully enclosed and

conveniently located for

ground level access.

■ Steer

Axle: Less wear on the steer

tires due to the redesigned steer axle

geometry, improving tire life.

■ Fuel

Tank: Greater capacity allows more

work to be done on a single tank of fuel.

■ VISTA®

Mast: Redesigned

cross-member location to

optimize visibility of twist

locks and corner castings

at all lift heights.

■ Spreader

Attachment:

Simplified solid-state electrical

control system.

Sealed Electrical Connectors

No matter what your business, time is money,

which is why your lift truck doesn’t get sick

days. That’s where the H1050-1150HD-CH

Container Handler comes in. More than 6,000

hours of application testing have proven this

tough, rugged series doesn’t need them.

■

Engine / Transmission

Management System

New Frame Design

■

■

“Deutsch” sealed electrical connectors

throughout the entire truck shield

components against the elements.

■

The new frame was designed using the

latest technologies and testing to deliver

a stronger, simpler box-type structure.

Drive axle is bolted on to eliminate

frame fatigue.

The electronically managed system offers

the most protection against engine/

transmission damage. If temperatures rise

too high or pressures get too low, the engine

will throttle back or shut down.

Reduced Steer Tire Wear

New Radiator Design

■

■

■

Cores are placed side-by-side for

improved airflow, which lowers operating

temperatures and facilitates cleaning.

Rubber-mounted design lessens

vibration fatigue.

Spreader Attachment Upgrades

■

■

Hydraulic System

■

■

■

■ Frame: The redesigned frame

features a stronger, simpler box-type

structure with bolted-on drive axle to

eliminate frame fatigue.

■ Hydraulic

■

■

Heavy-duty tandem pumps ensure longer life.

Filtration system is designed to enhance

cleanliness throughout.

Fewer fittings, shorter hoses and

conveniently located hydraulic

components reduce complexity.

ORFS fittings contribute to leak-free

operation.

Optional heater elements are available

for use in cold weather applications.

■

The spreader has been upgraded with the

use of solid-state printed circuit boards.

Wire harnesses have replaced the aluminum

interface boxes, further increasing reliability.

Hydraulic relief system diminishes risk of

damage to extension beams.

Centrally mounted hydraulic valves

simplify hose and tube routing and

reduce the number of fittings.

System:

Heavy-duty tandem pumps ensure

longer life, and maximum hydraulic

performance while ORFS fittings

eliminate leaks.

■ TWIST Module

(Twist Lock With Indicator

Signals and Tones):

LED illumination stays bright, day or

night. Audible tone for seated signal

and override activation comes with

volume control for customization.

The position of the steer axle pivot reduces

tire wear.

Simple, box-type construction

yielding a stronger, more

durable platform for

container handling.

Through the combination of engine,

transmission and hydraulic technologies,

the H1050-1150HD-CH provides superior

performance in all facets of container handling,

lowering the cost of a container move.

■

A significant improvement in cycle speeds

enables the movement of more containers

per hour, combined with a true 5-high

stacking capability for the most efficient

use of yard capacity.

■

■

■

■

■

The overall design of the H1050-1150HD-CH

series simplifies service to minimize downtime

during periodic and routine maintenance.

■

■

Hyster Company is known for tough lift

trucks, but we’re also recognized for

ergonomically advanced lift trucks. The

H1050-1150HD-CH series builds on this

reputation by simplifying container moves

with intuitive controls while providing the

quietest, most comfortable work

environment possible.

■

■

■

Operator ComforCab II™

■

■

Easy 3-point access, via steps, is

provided on both sides of the cab.

A 3-way adjustable seat combines with a

6-way adjustable armrest control module

to ensure minimum fatigue and precise

controllability throughout a shift.

Superb visibility allows easy positioning of

containers at any height for more precise

and efficient load handling.

Rugged truck frame design has wide drive

and steer axles, significantly increasing

durability, reliability and uptime in all

operating environments.

Fuel tank capacity of 175 gallons allows

more than 30 hours of run time for

maximum productivity and throughput.

Increased hydraulic tank capacity allows

full functionality and improved cooling.

The top deck is covered with easily

removable aluminum cover plates secured

with quick disconnect latches. When plates

are removed, all major components –

including the drivetrain and hydraulic

systems – are easily accessible.

All serviceable components are positioned

for easy maintenance.

Well-positioned sight gauges facilitate

daily checks.

An air filtration system and high-volume

air conditioning control cab environment.

Top and rear sunshades further

enhance comfort.

The cab is large and uncluttered,

allowing the operator ample room for

auxiliary options.

The soundproofing achieved on the

ComforCab II creates a quiet and relaxed

working environment, reducing fatigue

and ensuring alertness for the operator.

■

■

■

■

■

■

Located in a module at the operator’s

right hand, the intuitive joystick option

was designed for simplicity to ensure easy,

precise operation of the mast and spreader.

Newly designed cooling system is centered

around an easily cleaned multi-core

radiator. The cores are aligned side-by-side

and are individually removable for servicing.

The operator cab is a fully self-contained,

sealed unit and does not need to be

removed to service major components.

Hydraulic tank includes two 3-inch

shut-off valves for ease of maintenance.

Visibility

■

Joystick

■

Designed for intuitive truck operation,

state-of-the-art cab ergonomics

increase productivity.

High-Intensity Discharge (HID option)

lights offer excellent visibility for

nighttime operations.

New counterweight design reduces truck

length and turning radius by 4.4%,

improving manuverability and productivity.

■

Mast design changes have repositioned

cross-members away from critical

container lift heights, allowing ultimate

forward vision while keeping twist locks

and rear obstacles in view at all times.

The cab’s structural design creates

the best all-around visibility available.

Rearward visibility is further enhanced

by counterweight profile.

TRUCK FEATURE

Cummins ® QSM-11 290 HP Engine (Tier II) and

Dana® Spicer ® HR TE-27 AutoShift ® Transmission

Cummins ® QSM-11 330 HP Engine (Tier II) and

Dana® Spicer ® HR TE-32 AutoShift ®Transmission

474" Wide VISTA ® 2-Stage Mast (Height under Twist Lock)

592" Wide VISTA ® 2-Stage Mast (Height under Twist Lock)

18" x 25" - Radials (Michelin ® XZM)

18" x 25" - 40 Bias Ply Treaded (E4-ELS-2)

18" x 25" - 40 Bias Ply Slick (STMS LS5)

18" x 25" - Radials Slick (VSMS L5)

18" x 33" - 40 Bias Ply Treaded (E4-ELS-2)

Integral Suspended Attachment (Spreader) with

Mechanical Pile Slope

Integral Suspended Attachment (Spreader) with

Power Pile Slope

Mechanical, Full Suspension Cloth Seat

Mechanical, Full Suspension Cloth Seat (High Backrest)

Air Ride, Full Suspension Cloth Seat

Air Ride, Full Suspension Cloth Seat (High Backrest)

Air Conditioning

Steer Wheel Nut Guards

Halogen Light Package

High-Intensity Discharge (HID) Light Package

Audible Signaling Device

Visual Signaling Device

Hydraulic Lever Control, Seatside

Hydraulic Joystick Control, Seatside

Accumulator

Truck Installation Assistance (See Price List)

6-degree Forward / 10-degree Back Tilt

Intermittent Front Wipers

Top and Rear Wipers

Top and Rear Sunshades

Map Reading Light

Monitoring System Mounting Platform

Multifunctional Display Panel

Engine Compartment Light

Lights by Stairs

12 Volt DC to DC Converter

Container Guides (Bumpers)

Hydraulic Wet Disc Brakes

Mechanical Tilt Indicator

Mast Lifting Eyes

Electronic Twist Lock Position Indicator with

LED Signals and Audible Tone (TWIST Module)

H1050HD-CH

H1150HD-CH

OPTIONAL

H1050HD-Container Handler

Truck Capacity

88,185 lbs. (40 000 kg)

STANDARD

OPTIONAL

STANDARD

x

—

—

x

—

x

x

—

Max. Lifting

Speed - Laden

47.0 ft./min.

(0.24 m/s)

x

—

x

—

—

—

—

x

—

x

—

x

x

x

x

—

—

x

—

—

—

—

x

—

x

—

x

x

x

x

—

x

Max. Lifting

Speed - Unladen

51.0 ft./min.

(0.26 m/s)

—

x

x

—

x

—

—

—

x

x

x

—

x

x

x

—

—

—

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

—

x

x

x

—

—

—

x

—

—

—

x

x

x

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

x

—

—

—

x

x

x

—

x

x

x

—

—

—

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

—

x

x

x

—

—

—

x

—

—

—

x

x

x

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

Wheelbase

232.0 inch (5 895 mm)

OATL*

420.4 inch (10 678 mm)

Load Center

59.0 inch (1 500 mm)

Max. Travel

Speed - Laden

12.0 mph

(19.3 kmh)

Max. Travel

Speed - Unladen

14.0 mph

(22.5 kmh)

Specifications are for a truck equipped as

described as Standard Equipment in the

Technical Guide for the H1050-1150HD-CH.

*Overall truck length

H1150HD-Container Handler

Truck Capacity

88,185 lbs. (40 000 kg)

Wheelbase

232.0 inch (5 895 mm)

OATL*

420.4 inch (10 678 mm)

Load Center

59.0 inch (1 500 mm)

Max. Lifting

Speed - Laden

51.0 ft./min.

(0.26 m/s)

Max. Lifting

Speed - Unladen

59.0 ft./min.

(0.30 m/s)

Max. Travel

Speed - Laden

12.4 mph

(20.0 kmh)

Max. Travel

Speed - Unladen

14.9 mph

(24.0 kmh)

Specifications are for a truck equipped as

described as Standard Equipment in the

Technical Guide for the H1050-1150HD-CH.

*Overall truck length

HYSTER CAPITAL

FLEET SERVICES

A Division of NMHG Financial Services, Inc.

It’s not just about the lift trucks.

Rental Products

Automated Warehouse Solutions

Any company worth its weight knows

success has just as much to do with the

support before and after the sale as the sale

itself. We pride ourselves on being more than

just a lift truck manufacturer. Through our

Dealer Network, we’re also fleet managers,

parts suppliers, capital procurement

specialists and trainers. You’ll find that

when it comes to service, there’s not

much we don’t do.

At Hyster Company, we’re always looking

for ways to help you keep your productivity

up. Through the Hyster Dealer Network, you

can access rental equipment for the times

when leasing or buying isn’t a practical

option. Your local Hyster Dealer has access

to over 14,000 units that are available for

short- or long-term rental. Whether you need

one truck to substitute for a vehicle that’s

being serviced or several lift trucks to

accommodate seasonal changes in your

business, we’ll help you maintain output

in a cost-effective manner.

As society’s technological capabilities

advance, we strive to find practical

applications. One of our most recent

innovations in that pursuit is our

development of automated warehouse

solutions. We can help you determine if

your operation would benefit from this

type of system, which improves inventory

accuracy, warehouse productivity and

safety records, as it reduces maintenance

and overtime.

Hyster® Fleet Services

As much as we’d like for your entire fleet to

be Hyster, we know that’s not always the

case. But just because you also operate other

brands doesn’t mean we can’t manage your

lift truck maintenance and replacement plan.

We can analyze your current fleet or provide

a summary of your fleet history and a costeffective proposal for replacement and

scheduled maintenance of all your vehicles.

Once this initial review is complete, we’ll

continue to monitor your fleet to ensure

it’s performing optimally.

UNISOURCE™ Parts Program

In addition to providing fleet management

for a variety of brands, we can also serve as

your source of parts for all your lift trucks.

With the Hyster UNISOURCE parts and

service program, we offer approximately

2 million part number crosses for most

brands of materials handling and other

in-plant mobile equipment. UNISOURCE

also has remanufactured parts that provide

the same quality and guarantee but at a lower

price. And we can deliver parts to you in less

than 24 hours, any day of the week. How’s

that for convenience?

Hyster Company

P.O. Box 7006

Greenville, North Carolina

27835-7006

Part No. H1150HDC/B

1/2006 Litho in U.S.A.

Hyster Capital

We know that financing new additions to

your fleet can sometimes be challenging.

That’s why your Hyster Dealer has a long

list of ways for you to fund your purchase.

We are skilled in arranging solutions for

special financing requirements, taking the

difficulties out of buying the equipment you

need. Whether you purchase or lease a new

or used lift truck, Hyster Capital offers better

service and competitive rates, ensuring

you receive the value you deserve.

Operator and Service Training

Hyster Company recognizes that proper

training is a key element of a profitable

company. That’s why your local Authorized

Hyster Dealer offers a training program for

your lift truck operators as well as those

who maintain your vehicles. Proper education

in running and servicing lift trucks cuts

down on the number of repairs and risk of

injuries due to accidents while increasing

productivity. All of our trainers are professionals

with experience in materials handling.

Special Products

Engineering Department (SPED)

In a perfect world, every application could

be handled with a standard lift truck.

However, in the real world, different materials

require different handling. That’s why Hyster

Company’s Special Products Engineering

Department works with you to customize*

your lift trucks. From strobe lights to specially

made forks, SPED can provide you with the

tools you require to get the job done right.

* May be subject to an additional charge. Contact your local Authorized

Hyster Dealer for more information.

Visit us online at www.hysterusa.com or call us at 1-800-HYSTER-1.

Hyster,

and VISTA are registered trademarks of Hyster Company.

ComforCab II and

are trademarks of Hyster Company.

Hyster products are subject to change without notice.

AutoShift, Cummins, Dana, Michelin and Spicer are registered trademarks of their respective companies.

©2006 Hyster Company. All rights reserved.