Fundamental Analysis of Electrochemical Copper Deposition for

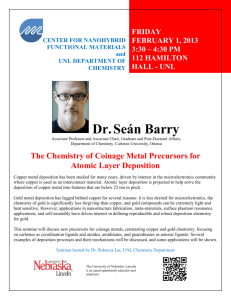

advertisement