613 KB

advertisement

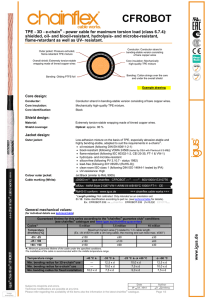

CF99 TPE - e-chain® - control cable for maximum load requirements (class 7.5.4): especially for small radii up to 4xd, shielded, oil- and biooil-resistant, PVCand halogen-free, hydrolysis- and microbe-resistant as well as UV-resistant. Conductor: Conductor strand in highly bending-stable version consisting of a special alloy Outer jacket: Pressure extruded, halogen-free TPE mixture Inner jacket: Pressure extruded, gusset filling TPE mixture Overall shield: Highly bending-stable braid made of special alloy wires Strain relief (7 cores ( ≥ 0,25 mm² → 4 cores) or more): Centre element for high tensile stresses Core insulation: Mechanically high-quality TPE mixture Example drawing (For a detail overview see construction table) Core design: Conductor: Conductor strand in highly bending-stable version consisting of a special alloy. Core insulation: Mechanically high-quality TPE mixture. Core identification: Basically: Colour code in accordance with DIN 47100. (see colour code table) CF99.X.X.INI: Colour code in accordance to INI-Standard. (see colour code table) Shield design: Material: Highly bending-stable braid made of tinned copper wires. Shield coverage: Linear: approx. 70 % Optical: approx. 90 % +++ chainflex® cable works +++ Jacket design: ® Inner jacket: TPE mixture adapted to suit the requirements in e-chains . Outer jacket: Low-adhesion mixture on the basis of TPE, especially abrasion-stable and ® highly bending-stable, adapted to suit the requirements in e-chains . oil-resistant (following DIN EN 60811-2-1) biooil-resistant (following VDMA 24568 (tested by DEA with Plantocut 8 S-MB)) PVC- and halogen-free (following DIN EN 50267-2-1) hydrolysis-resistant (following DIN VDE 0282 Part 10 - A) microbe-resistant (following DIN EN 50396) silicon-free (following PV 3.10.7 - status 1992) lead-free (following 2011/65/EU (RoHS-II)) clean room ISO class 1 (following DIN ISO 14644-1 tested by IPA) UV-resistance: High Colour outer jacket: Steel blue (similar to RAL 5011) Cable marking (White): „00000 m“* igus chainflex CF99.--.-- ----- 300/300V CE RoHS-II conform www.igus.de +++ chainflex cable works +++ * Length printing: Not calibrated. Only intended as an orientation aid. / : Cable identification according to part no. (see technical table for details). Ex.: CF99.01.02: …igus chainflex CF99.01.02 (2x0,14)C 300/300V… General mechanical values: (for individual details see technical table) ® Double strokes Temperature (from/to) [°C] igus® chainflex® CF99 -35 / -25 -25 / +80 +80 / +90 Image exemplary 5 million Travel distance (TD) 7,5 million 10 million Min. bending radius for e-chain® use [Factor multiplied by outer diameter (d)] (Ex.: CF99.01.02 at 20°C: 4,0 x 5,5 mm Min. bending radius 22,0 mm) ≤ 100 m 5,0 4,0 5,0 5,0 4,0 5,0 5,0 4,0 5,0 : Minimum guarantee lifetime of the cable under the specified conditions. The installation of the cable is recommended within the middle temperature range. Temperature range Min. bending radius for fixed installation Torsion (at 1 m cable length) -40 °C 6,8 x d --- -35 °C 4,0 x d ±0 ° -25 °C +80 °C 3,0 x d ±30 ° Date Subject to misprints and errors. Technical modifications are possible at any time. 10 May. 2014 Maybe older batches do not have all or other features. Please refer regarding the availability of the items especially the information in the latest chainflex® catalogue. +90 °C 4,0 x d ±0 ° Author D. Borsberg Page 1/4 www.igus.de Guaranteed lifetime for this series according to the "chainflex guarantee club" conditions ® (see chainflex catalogue and www.igus.eu/chainflex-guarantee) CF99 TPE - e-chain® - control cable for maximum load requirements (class 7.5.4): especially for small radii up to 4xd, shielded, oil- and biooil-resistant, PVCand halogen-free, hydrolysis- and microbe-resistant as well as UV-resistant. General electrical values: (for individual details see technical table) Nominal voltage: 300 / 500 V Test voltage: 1,5 kV Guidelines: CE, EAC Dynamic values: Max. speed ® for e-chain use:** Unsupported: v = 10 m / s Max. acceleration ® for e-chain use:** a = 100 m / s ** Gliding (up to 100 m): v = 6 m / s 2 These values are based on specific applications or tests. They do not represent the limit of what is technically feasible. Typical lab test setup for this cable group: Test bending radius R: approx. 15 - 28 mm Test travel S: approx. 1 - 15 m Test period: min. 20 - 30 million double strokes Test speed: approx. 0,5 - 2 m / s Test acceleration: approx. 0,5 - 1,5 m / s +++ chainflex® cable works +++ 2 e-chain® - control cable for maximum load requirements at radii up to 4xd: especially abrasion stable almost unlimited resistance to oil, also with biooils especially for short, very fast applications with small radii and tight design UV-resistant CE, RoHS-II, EAC www.igus.de igus® chainflex® CF99 Typical application areas: Indoor and outdoor applications. Automatic insertion machines, automatic doors, clean room, very quick handling. Image exemplary Date Subject to misprints and errors. Technical modifications are possible at any time. 10 May. 2014 Maybe older batches do not have all or other features. Please refer regarding the availability of the items especially the information in the latest chainflex® catalogue. Author D. Borsberg Page 2/4 CF99 TPE - e-chain® - control cable for maximum load requirements (class 7.5.4): especially for small radii up to 4xd, shielded, oil- and biooil-resistant, PVCand halogen-free, hydrolysis- and microbe-resistant as well as UV-resistant. Technical tables: Mechanical values: Part no. Number of cores & nominal cross section*** [mm²] External diameter (d)**** [max. mm] Copper index [kg / km] Weight [kg / km] CF99.01.02 (2x0,14)C 5,5 14 33 CF99.01.03 (3x0,14)C 6,0 17 37 CF99.01.04 (4x0,14)C 6,0 21 43 CF99.01.07 (7x0,14)C 7,5 32 62 CF99.01.08 (8x0,14)C 8,0 36 69 CF99.02.03.INI (3x0,25)C 6,5 25 48 CF99.02.04 (4x0,25)C 6,5 30 56 CF99.02.07 (7x0,25)C 8,0 48 85 CF99.02.08 (8x0,25)C 8,5 54 93 CF99.03.03 (3x0,34)C 6,5 27 51 CF99.03.04.INI (4x0,34)C 7,0 35 62 CF99.03.08 (8x0,34)C 9,0 64 105 *** **** Due the alloy of the conductor, the mechanical cross section is larger than the nominal cross section. Therefore it can be necessary, with the use of ferrules, to choose the next larger size of ferrules. External diameters are maximum values and may tend toward lower tolerance limits. Nominal cross section [mm²] Conductor resistance [approx. Ω / km] at 20 °C (following) DIN IEC 60344 Max. current rating [A] at 30 °C DIN VDE 0298- 4 0,14 140 2,5 0,25 80 5 0,34 65 7 The max. current rating depends on factors such as the individual environmental conditions and the type of installation. DIN 47100 colour code: No. 01 02 03 04 05 06 07 08 09 10 11 12 Colour white brown green yellow grey pink blue red black violet greypink redblue No. 13 14 15 16 17 18 19 20 21 22 23 24 Colour whitegreen browngreen whiteyellow yellowbrown whitegrey greybrown whitepink pinkbrown whiteblue brownblue whitered brownred No. 25 26 27 28 29 30 31 32 33 34 35 36 Colour whiteblack brownblack greygreen yellowgrey pinkgreen yellowpink greenblue yellowblue greenred yellowred greenblack yellowblack www.igus.de +++ chainflex® cable works +++ Electrical values: INI Standard colour code: igus® chainflex® CF99 Part no. Image exemplary Colour code CF99.02.03.INI brown, blue, black CF99.03.04.INI brown, blue, black, white Date Subject to misprints and errors. Technical modifications are possible at any time. 10 May. 2014 Maybe older batches do not have all or other features. Please refer regarding the availability of the items especially the information in the latest chainflex® catalogue. Author D. Borsberg Page 3/4 CF99 TPE - e-chain® - control cable for maximum load requirements (class 7.5.4): especially for small radii up to 4xd, shielded, oil- and biooil-resistant, PVCand halogen-free, hydrolysis- and microbe-resistant as well as UV-resistant. Construction table: Part no. No. of cores Core stranding Part no. No. of cores CF99.XX.02 CF99.XX.03 / .INI 2 3 CF99.XX.04 / .INI CF99.XX.07 4 7 Core stranding CF99.XX.08 Image exemplary www.igus.de igus® chainflex® CF99 +++ chainflex® cable works +++ 8 Date Subject to misprints and errors. Technical modifications are possible at any time. 10 May. 2014 Maybe older batches do not have all or other features. Please refer regarding the availability of the items especially the information in the latest chainflex® catalogue. Author D. Borsberg Page 4/4