The Crazy World of LEDs and Controlling Them

advertisement

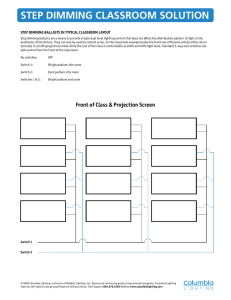

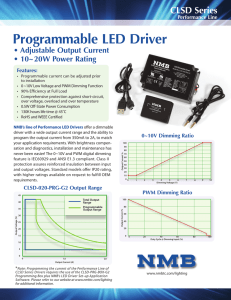

Saturday, October 12, 2013 The Crazy World of LED’s and How to Control Them James R Benya, PE, FIES, FIALD Benya Burnett Consultancy Davis, CA Continuing Education Credits NECA has been accredited as an Authorized Provider by the International Association for Continuing Education and Training (IACET) and is authorized to offer IACET CEUs for its programs that qualify under the ANSI/IACET Standard. This session is eligible for 0.2 IACET CEUs To earn these credits you must: • Have your badge scanned at the door • Attend 90% of this presentation • Fill out the online evaluation for this session 2 Learning Objectives • Important understanding of how LED’s are made and how they work • Critical understanding of how LED color, dimming, flicker and control issues • Clear understanding of capabilities, issues and options of LED’s used as directional lighting • Clear understanding of capabilities, issues and options of LED’s used as linear display lighting The lighting industry used to be a plodding business, slow to change and with rare new technologies. But no longer! Solid state lighting, principally light emitting diodes, have totally revolutionized lighting. LED lighting fixtures, LED replacement lamps, and all kinds of special new products are part of lighting today. And with them has come a revolution in lighting controls, with wireless controls, network controls, and everything is dimmable – if you can get it to work. This workshop will explain how to plan, install and troubleshoot LED control devices and systems. It will include dimmers, switches, sensors, small systems, large systems, networked controls, wireless controls, and the world of drivers, dimmers, and other components now part of everyday LED installations. It will include teaching how to stay current, where to get more education, and how to get assistance from manufacturers, agents and other resources, especially when things aren’t working the way they were planned. The program will include troubleshooting and fixes for common LED lighting system control issues. Breakout sessions will allow groups to identify and discuss particular problems. 1 Saturday, October 12, 2013 Please note • This program is intended for a wide audience • Many of you will find portions to repeat things you already know • Don’t worry – there is some new stuff in here for everyone LED Anatomy PART ONE What is Solid State Lighting (SSL) and How is it Fundamentally Different? Conventional Lighting Generates light by either • Incandescence (heating) • Low intensity mercury discharge • High intensity mercury discharge • Fluorescence (phosphor conversion of discharge spectrum) to create white light or to improve color LED • Generates a specific narrow band of colored light by passing DC current through a diode • Fluorescence or combinations of R, G, B (and other colors) to create white light Brief History of SSL Year Event 1962 First visible light LED (red) Through 1990 Evolution of red, orange and yellow LED mostly for indicator lights and similar low wattage applications, based largely on gallium arsenic and gallium phosphorus 1992 Development of Indium Gallium Nitride technology, allowing for short wavelength LED 1995 High Brightness Blue LED and Green LED (Shuji Nakamura) 1996 White LED using RGB 1997 White LED using phosphor coating 2000 Commercially viable white LED, 10 lumens per watt 2010 Commercially viable white LED, >100 lumens per watt, wide choice of color temperatures and CRI values 2 Saturday, October 12, 2013 Evolution of LED What is a DIODE? 200 • Electronic device • Allows electricity to pass one direction, not the other • Used to rectify AC electricity to DC >150 lm/W First > 100 lm/W Red Native Substrate 100 Shaped AlInGaP/GaP Red-Orange-Yellow Fluorescent Lamp Green Transparent Substrate AlInGaP/GaP Red-Orange-Yellow Unfiltered Incandescent Lamp Yellow Filtered Incandescent Lamp Luminous Efficacy (lm/W) 10 AlGaAs/AlGaAs Red Red Filtered Incandescent Lamp GaAsP:N Red-Orange-Yellow Edison’s First Light Bulb 1 Holonyak’s First Commercial LED White AlInGaP/GaAs Red-Orange-Yellow Blue AlGaAs/GaAs Red – Power supplies – Radio circuits InGaN GaP:N Green GaP:Zn,O Red • Specific types emit light when this happens. SiC GaAsP Red Ga0.6As0.4P Red 0.1 1960 1970 1980 1990 2000 2010 Dupuis and Krames, IEEE J. Lightwave Tech. 26, 1154 (2009). Real Diode Forward Voltage Real Diode • Some forward resistance • Almost infinite backward resistance • Won’t conduct forward current until a minimum voltage is achieved – LED 1.8 to 3.1 volts + + Battery or DC power supply - V Current flow Current flow = ∞ if V > Vf Current flow = 0 otherwise 3 Saturday, October 12, 2013 Real Circuit Forward Voltage Parallel Diode Circuit Forward Voltage I = (V-Vf)/R Pdiode = I x Vf Presistor = I2 x R I = (V-Vf)/(R/3) Pdiode = (I/3) x Vf Presistor = (I/3)2 x R + + Battery or DC power supply - Resistor in ohms R V + + + - - - + Battery or DC power supply V Current flow ~ (V-Vf)/R if V > Vf Current flow = 0 otherwise Parallel Circuit Resistor in ohms Series Diode Circuit Forward Voltage • Divide the amps among the diodes – Less amps per diode means less power per diode – Three diodes do the work of one – Each runs cooler – Heat can be spread out • Very Low Voltage (like 2-3 volts) means heavy gauge wires R Current flow ~ (V-Vf)/R if V > Vf Current flow = 0 otherwise I = (V-3Vf)/R Pdiode = I x Vf Presistor = I2 x R + + Battery or DC power supply - V Resistor in ohms Current flow ~ (V-3Vf)/R if V > 3Vf Current flow = 0 otherwise R 4 Saturday, October 12, 2013 Series Circuit • • • • • • Increase the voltage, drop the amps Divide the power among the diodes Each diode operates at less amps Diodes operate cooler Distribute heat more evenly Higher voltage means smaller gauge wires Series Parallel Diode Circuit Forward Voltage I = 2(V-3V )/R f Pdiode = I/2 x Vf Presistor = (I/2)2 x R + + Battery or DC power supply V Resistor in ohms Current flow ~ (V-3Vf)/R if V > 3Vf Current flow = 0 otherwise R Series Parallel Circuit • Increase the voltage, drop the amps • Increase total output by adding series groups • Best of both worlds The Ideal LED for lighting is often a point source. Making a number of LED’s appear as a point source is a challenge. 5 Saturday, October 12, 2013 Real Circuit Forward Voltage AC with LED I = (V-Vf)/R Pdiode = I x Vf Presistor = I2 x R + Current and light “pulse” – creating flicker or “shimmer” - Battery or DC power supply + + Vf for most LED’s is around 2.5 volts - V - Resistor in ohms Current flow ~ (V-Vf)/R if V > Vf Current flow = 0 otherwise R Pulse Width Dimming Voltage Dimming BRIGHT + Jittery behavior as V approaches Vf then it stops abruptly DIM Very fast switch + Battery or DC power supply - Efficiency drops as voltage goes up Color changes as current goes up Battery or DC power supply + + - Good behavior to below ~1% light Efficiency constant Color constant Flicker free Flicker increases as light dims 6 Saturday, October 12, 2013 Constant Voltage Systems Pros • Simple • Low cost • Easy to wire • Secondary side dimming and/or color changing with PWM • Keep adding diodes in parallel (or series parallel) to capacity of circuit Cons • Challenging performance at the low end of dimming • Dimming flicker • Less efficient Integrated Power Supply/driver Ballast-like product • Plenty of room • Cool enclosure • Removed from lamp heat source Lamp Integrated • Not much room • Hot location Constant Current Systems Pros • Better dimming performance • Reduced dimming flicker • More efficient Cons • Hard to wire (series circuit) • To add diodes, add in series –limited ability due to voltage climb • More expensive Dimming Notes • Non dimming LED systems are easy and inexpensive • Dimming LED systems are complicated and not easily driven by phase cut dimmers 7 Saturday, October 12, 2013 Product Development Notes • LED arrays today are usually series parallel • There is a push to increase acceptable LED system voltage – More devices in series, lower current – Larger lumen packages • There is a push to make the building systems responsible for providing DC power Heat Other light sources • Radiant heat (IR) • Conducted heat through the socket • Convected heat through the ambient air LED • Conducted heat through the socket or surrounding structure – Makes LED systems appear more energy efficient Parts of an LED LED Fabrication LUXEON Rebel 8 Saturday, October 12, 2013 Die Shape and Light Extraction (Al,Ga)InP + window layer wb pad (Al,Ga)InP GaAs DBR GaAs (a) Thin AS (b) Thick AS GaAs (c) Thick AS + DBR p-GaP n-GaP substrate host substrate metal n-GaP substrate p-GaP (d) Thick TS (e) Shaped TS (f) Thick RS InGaN-GaN-Al2O3 Basic Commercial LED Package 100 Light Extraction (%) Light extractionEfficiency, efficiency, C ext ext (%) (Al,Ga)InP-GaAs or GaP 90 TFFC 80 CC(PS/ITO) low power VTF 70 Shaped TS 60 CC (PS) Thick RS 50 CC (PS/ITO) high power FC (Al) 40 Improved TS 30 CC TS 20 10 FC (Ag) Thick AS + DBR Thick AS Thin AS into silicone or epoxy (n ~ 1.5) 0 p-spreader p-wb pad 1990 1995 2000 2005 2010 p-type Al 2O3 n-type n-type n-wb pad Al 2O3 n contact p-type (a) Conventional Chip - CC (b) Flip Chip - FC reflective p contact Year Year after Krames et al., IEEE J. Display Technology 3, 160 (2007) n-wb pad light extraction features n-type p-type host substrate reflective metal bond n contact n-type p-type reflective p contact (c) Vertical Thin Film - VTF (d) Thin Film Flip Chip - TFFC Commercial Multi-die Arrays Phosphor-based White LEDs Cree Lumileds • Blue LED + Y3Al5O12:Ce3+ (“YAG”) – Efficient use of blue pump light – Limited to ~ 4000-10000K – CRI < 80 typically – Currently, >> 100 lm/W @6500K – “Valley of Cyan” 490-515 nm – Limited red From Soraa, after Krames et al., IEEE J. Display Technology 3, 160 (2007) 9 Saturday, October 12, 2013 Where is the phosphor? Hot Phosphor vs Cold Phosphor a. Hot phosphor, in direct contact with LED b. Cold phosphor, physical distance from LED Diffuser or optical lens White LED or Mixture of White and other colors Phosphor Coated lens UV, Violet, Blue or Green LED Luger Research. eU Making LED products Most important in order 1. Thermal management 2. LED quality – – Color rendering CCT 3. Optics 4. Driver quality – – – – Reliability Flicker control Dimming Power quality Parts of a “point source” LED Luminaire • • • • • • Electrical connection Driver LED Phosphor Optic Housing 10 Saturday, October 12, 2013 Light Engines Parts of a point-source LED replacement lamp • A single apparent “lamp” by traditional standards • Inside: – Driver – LED – Phosphor – Optic – Electrical connections Standardize LED luminaires • Standard thermal interface • Standard electrical interface • Flexible choice of LED and optic • Flexible choice of driver • Flexible design of heat sink and housing Linear LED Luminaires • Alternative to fluorescent fixtures • Distributed heat allows small form factor in low wattage systems GE Cooper Io WAC Color Kinetics Fraqtir 11 Saturday, October 12, 2013 White LED Color Rendering Index • What color temperature of white? 2700K 3500K Kruithof’s curve, 1941, Philips Partially reaffirmed 2009 by Vienot, Durand and Mahler (Fr) with “low CCT most preferred at 150, 300 or 600 lux”. Matches the McCandless Method (“fill warm, key cool”) Color Quality for White LED • Lower efficacy • Higher CRI and improved R9-R15 70 CRI 90 CRI Cree Color Quality 3000K Ra = 80 (CRI) R9= 19 3000K Ra = 98 (CRI) R9 = 98 Xicato XSM 12 Saturday, October 12, 2013 Studying Product Data Color Summary • Choose correlated color temperature – 2700K, 3000K, 3500K, 4000K, or 5000K • Choose color quality – CRI + R9 – Other metrics (CQS, etc.) • Choose color consistency (MacAdam steps) • Try to get a color warranty Linear source applications • • • • • • • • Display cases Freezer cases Coves and Valences Shelf lighting Undercabinet lighting Inside cabinet lighting Wallwashing Wall grazing Linear luminaires • Distributed LED’s all along a linear channel or tube • Modular lengths allow increments of size • Qualities of LED’s and drivers vary 13 Saturday, October 12, 2013 Refrigerated cabinets Cove luminaires • Mostly indirect ambient lighting • Plug together • Line voltage integral driver • 2700K, 3000K, 3500K, 4000K • 80-83 CRI • 350-700 lumens per ft Philips GE Undercabinet and Valences Philips • From 100 lumens per foot up to 700 lumens per foot • 2700K, 3000K, 3500K, 4000K, 5000K • Low voltage remote transformer or line voltage enclosed luminaires • Mostly 70-80 CRI • Designed for vertical and horizontal mounting • 250-500 lumens per foot • 3000K, 4000K and 5000K • 75-80 CRI • Remote DC power supply (size constraints) GE Tape light • From 70 to 250 lumens per foot • 2700K, 3000K, 4000K, 5000K and 6500K • 70-82 CRI • Remote power supply • Optional enclosures and lenses Edge Lighting Elemental LED 14 Saturday, October 12, 2013 Display Case Lighting Wall Washing and Valences GE • • • • • 2 to 6 w/ft 150-500 lumens per ft 3000K, 4000K, 5000K, 6500K 80 CRI typical Remote power supply Sylvania, GE, Lighting Science Group Wall Grazing • Not wallwashing – purposeful gradient and revelation of texture • 700 lumens per ft/14 watts/ft • Integral line voltage driver • 2800K/80CRI • Modular linear wallwash • Symmetric and Asymmetric beams • 300-600 lumens per foot/5-10 watts per foot • Integral 120-277 driver • 2700K, 3000K, 4000K, 80CRI min Backlighting • Various LED lighting systems designed to illuminate the inside of a light box 15 Saturday, October 12, 2013 Dedicated LED Recessed Adjustable Light Engines Light engines* include • Power unit and thermal connector • LED module • Remote phosphor or mixing lens (if used) • Optic *Zhaga is a standard for light engines • Light engine (proprietary or OEM product) • Adjustable engine holder and optic • Driver usually remote USAI Lucifer Dedicated LED Multiples • Several LED luminaires – one housing • Recessed or pendant • Usually derived from track heads Amerlux Dedicated Track Luminaires • Optimized for LED package • Often for high wattage (up to about 50 w) • Driver in separate compartment RSA Lightolie r Contech Amerlux 16 Saturday, October 12, 2013 Dedicated Semi-Theatrical Luminaires • High power and high precision applications • Current products to 4500 lumens, >50 watts, 2700K, 3000K, 4000K • Wide range of optics • Some allow accessory lenses • CRI 80 to 98 Low Voltage Monopoints • Monopoint • Arm mount • Rail mount WAC Lighting Lighting Services Inc. MP Lighting Edge Lighting Times Square Wallwashers • Monopoint • Recessed • Semirecessed • Track Replacement LED lamp products • Install in existing luminaires • Install in new luminaires designed for older technology • Potential for considerable reduced cost Edge Lighting Fraqtir 17 Saturday, October 12, 2013 Replacement MR16 Replacement PAR38 • 15-20 watt class • 2700K and 3000K common • 3500K and 4000K not common • Under $40 and falling • 10 watt class • 50 watt halogen replacement (?) • 2700K and 3000K common • 3500K and above uncommon Replacement GU10 LED Control Basics • Another option • 120 volt GU-10 base • Same optics as the low voltage lamp LED Lighting Devices “Driver” Control device *Not always Power control circuits Line AC to low voltage DC rectifier and filter Dimming Circuits* Communications or power signaling conversion circuits* 18 Saturday, October 12, 2013 Line Voltage Switching Wallbox Dimmers Dimmers of Various Types • Standard forward phase cut • Magnetic forward phase cut • Electronic reverse phase cut • CL rated phase cut • Simple circuit • Inrush to driver is an issue LED replacement lamp OR LED fixture with dimmable driver inside OR Incandescent dimming module in dimming system Line Voltage Dimming Line Voltage Dimming LED’s • With wallbox triac dimmers for incandescent lamps – Most dimmable integrated replacement lamps – Luminaires with forward phase-cut dimmable drivers – Some luminaires with integral transformers and dimmable LED replacement low voltage lamps – Special transformers for dimming LED strips and tape lights Line voltage dimmable driver Dedicated LED luminaire OR Low voltage transformer LED MR16 replacement lamp OR Dimmable “transformer” for LED strips Line Voltage Dimming LED’s • With wallbox reverse phase cut dimmers – Most dimmable integrated replacement lamps – Luminaires with reverse phase-cut dimmable drivers – Some luminaires with integral electronic transformers and dimmable LED replacement low voltage lamps 19 Saturday, October 12, 2013 Line Voltage Dimming LED’s Ten volt Wallbox Dimmers Line voltage dimmable driver • With CL rated phase cut dimmers – Most dimmable integrated replacement lamps – Luminaires with forward phase-cut dimmable drivers – Some luminaires with integral electronic transformers and dimmable LED replacement low voltage lamps – Special transformers for dimming LED strip or tape lights 0-10 Volt DC Dimming LED’s Low voltage transformer Ten Volt Module on Dimming System Ten Volt Dimming Digital Signal from DALI, Ecosystem, or other system • Dimmer includes an on-off switch and 0-10 volt output OR • Dimming module has an on-off relay and 010 volt output Ten Volthas a 0-10 volt line voltage • Lighting system Module on dimming driver Dimming System OR • Lighting system has a transformer and a separate low voltage dimming module Low voltage dimmer Line voltage digital driver Low voltage transformer Low voltage dimmer Ten Volt Module on Dimming System Digital Dimming 20 Saturday, October 12, 2013 Digital Dimming LED’s • Driver on fixture is a digital system driver OR • System dimming module has an on-off relay and 0-10 volt output When Dimming Goes Wrong • Symptoms – Dimming range too limited – Lamps don’t work or strobe and flicker at any setting – Lamps strobe or flicker when dimmed – Weird jumps, starts, etc. – Noise, smoke or flames Dimming and Flicker • Investigate LED and dimmer interactions • Evaluate flicker issues on display When Dimming Goes Wrong • General Solutions – Make sure dimmer is not overloaded • 600 watt dimmer use only 150 watts of LED’s • Make sure transformers and components are properly rated primary and secondary – Check fixture or lamp manufacturer’s compatible dimmer list – Check wiring diagrams and wiring carefully. 21 Saturday, October 12, 2013 When Dimming Goes Wrong • Low voltage solutions – Be sure dimmer or dimming module is rated to match power supply • Magnetic transformer = magnetic phase cut dimmer • Electronic “transformer” = reverse phase cut dimmer or “CL” rated dimmer – Try swapping out low voltage dimming modules – Check 0-10 volt drive circuit voltage Final Comment - Flicker • PWM dimming causes flicker that can be detected by the naked eye • Most constant voltage and low voltage circuits flicker at 120 Hz • Flicker cannot be easily mitigated without higher frequency PWM • Flicker is least likely in constant current driver circuits When Dimming Goes Wrong • Line voltage solutions – Try a stabilizing load • Connect a 40 watt incandescent lamp across the dimmer output, check to see if it dims and if that makes the LED’s work better – Add an incandescent load permanently to stabilize the circuit – Add a resistor module to stabilize the circuit Electronic transformer and dimmer 0% 75% 25% 100% 50% No Dimmer 22 Saturday, October 12, 2013 Thank you for attending FINAL QUESTIONS Please remember to complete the course evaluations. Thank you. 23