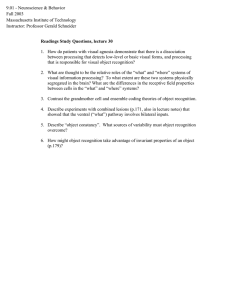

The Schneider Electric Gulf Customer Newsletter

September 2009 - Issue No.11

We enhance automation

and connectivity everywhere by

making it simpler for you to run

many aspects of your business

2

Editor's note

Dear Customer,

A very challenging first half of 2009 quickly passed. Schneider Electric

continues to move from selling products to providing products, solutions and

services.

Today, the energy management market is growing rapidly. Our customers need

safe, reliable, efficient, productive and green energy. They also expect increasingly

appropriate responses to the issues in their business sectors. Our offers and our

references show that we can meet these needs with solutions that can fit in at all

levels of the energy value chain in buildings, infrastructure, manufacturing operations,

data centers and residential.

Our team of business experts presented new and innovative solutions to help

customers involved in Oil & Gas to meet challenges, increase productivity and

reduce operating costs without compromising environmental concerns or safety in

the Gastech 2009 exhibition in Abu Dhabi, U.A.E. Despite an unfavorable business

environment that is not sparing the Oil & Gas market, Gastech organizations

communicated on the success of the event – 10,215 people from 84 countries

attended the event – an attendance up by almost 78% from Gastech 2006.

In this issue we are putting in a nutshell of what has been presented during Gastech

2009 such as optimizing energy efficiency for large Oil & Gas sites through new

energy management solutions, maximizing safety in Oil & Gas process plants in

which Schneider Electric develops a unique solution based on the Quantum Safety

PLC; our intelligent Power & Motor Control Centre (iPMCC) solution – the keystone

for energy and process automation management in large sites, Schneider Electric

and Krohne’s collaboration on new pipeline management solutions… and a lot more!

Director: Georges Barbarin

Editor: Stephanie Alviso

Designer: Dax Gaudiel

All rights reserved. No part of this magazine

may be reproduced or transmitted in any form

or by any means, electronic or mechanical,

including photocopying or by any information

storage and retrieval system, without prior

permission in writing from the copyright

owners.

Switched ON is published quarterly by

Schneider Electric FZE, E Wing, Level 4,

Dubai Silicon Oasis, Emirates Road & Dubai-Al

Ain Road Intersection,

P.O. Box 341057, Dubai, UAE

Tel: +971 4 709 9100 Fax: +971 4 709 9101

E-mail: ae-ccc-gulf@ae.schneider-electric.com

Website: www.schneider-electric.com

www.schneider-electric.ae

Issue No. 11 – September 2009

In continuous effort of Schneider Electric to provide our customers a single and

strong brand, giving you wider offer, complete solutions and services, all Merlin

Gerin and Telemecanique products are now becoming Schneider Electric. The new

Schneider Electric brand will be used progressively for all our product ranges. The

family and range names will be highlighted to make them easy to identify. Apart from

these changes in branding, all other specifications remain unchanged: box sizes,

batch sizes, weights, commercial references and other information shown on the

packs.

Schneider Electric team hopes you enjoy reading this issue packed with promotions,

events and technical features; once again your feedback is highly encouraged and

appreciated.

Warm wishes to you and your family for a blessed Ramadan and a joyous Eid Al Fitr

from Schneider Electric and Switched ON Team.

Make the most of your energy!

Georges Barbarin

Marketing Director

Schneider Electric Gulf Countries

Contents

In the news

5 Schneider Electric unveils latest innovative solutions for the

7

8

Oil&Gas Industry at Gastech 2009

Schneider Electric Water & Waste Water Solutions

Distribution Substation Solution: Seminars in Abu Dhabi,

Dubai & Qatar

10 Ringmaster & Easergy T200: Seminar for Dubai Electricity

& Water Authority (DEWA)

13 Ringmaster for Sharjah Electricity & Water Authority

(SEWA)

14 Schneider Electric & Al Mulla Engineering Group conduct

seminar on Smart Building Technologies

16 The IT Challenge of the Future: Energy & Cooling and

Environmental Responsibility

What's on

19 Optimising energy efficiency for large Oil & Gas sites

20

through new energy management solutions

Schneider Electric and KROHNE present New Pipeline

Management Solutions at Gastech 2009

Guided tour

22 Maximising safety in Oil & Gas process plants

On the product front

24 TeSys D: the most innovative and consistent motor starter

solution in the market for Size 3

Tech talk

26 Schneider Electric presents its intelligent Power & Motor

Control Centre (iPMCC) Solution, the keystone for energy

and process automation management in large sites

Issue No. 11 – September 2009

3

Schneider Electric in Gastech 2009

held in ADNEC Exhibition Center, Abu Dhabi

May 25 - 28, 2009

In the news

Schneider Electric unveils latest

innovative solutions for the Oil&Gas

Industry at Gastech 2009

Schneider Electric demonstrated new and innovative solutions to help

customers involved in Oil & Gas meet the challenges to increase productivity

and reduce operating costs without compromising environmental concerns

or safety at Gastech 2009, the 24th International Conference and Exhibition

held in Abu Dhabi from 25 to 28 May 2009 and hosted by ADNOC and its

Group of Companies.

His Highness General Sheikh Mohammed bin Zayed Al Nahyan, Crown Prince of Abu Dhabi

and Deputy Supreme Commander of the UAE Armed Forces toured the exhibition and

visited Schneider Electric booth. John Griffiths, Managing Director of Schneider Electric Gulf

Countries and Remy Valerino, Marketing Campaign Vice-President of Schneider Electric had

more than 12 minutes conversation with the Crown Prince.

In this vital global competitive market, our

customers want to manage hazardous operations,

reduce their energy costs, mitigate external risks and

maintain uptime,” says Patrick Albos, Vice President Oil

& Gas Solutions, Schneider Electric. “We are a leading

solution provider for this industry with recognised

credentials in all major production locations in the

Middle East, North America, Europe, Russia, Africa and

Latin America. Schneider Electric is able to leverage its

expertise in the upstream, midstream and downstream

processes to build efficient, tested, integrated and

both standard and customised solutions. We have the

ability to manage complex projects, in multicultural

environments, with a very specific methodology for doing

business which our customers appreciate.

Issue No. 11 – September 2009

5

6

In the news

Gastech 2009 is the year’s largest international conference and

exhibition for the LNG, LPG and natural gas industries. All the major

players from the gas supply chain gathered and discussed the main

challenges affecting business in this sector, as well as the latest

trends and developments. Despite the harsh economic environment,

Schneider Electric wants to stay close to its customers, and make

the most of all opportunities to work alongside them, such as

international fairs.

Gastech 2009 proved to be a true milestone event, with total unique

attendance over the four days of 10,215 from 84 countries – the

largest number of countries ever represented at Gastech throughout

its 37-year history.

Gastech’s attendance was up by almost 78% from 2006 (also held

in Abu Dhabi and attended by 5,752). The Gastech exhibition was

the largest-ever, featuring 387 exhibitors from 37 countries and

spanning over 13,000m2 (net space).

On this occasion, Schneider Electric featured its new

Oil & gas solutions, emphasizing 5 main areas:

; Energy management solution for large sites

; Integral safety solution for offshore platforms

; Pipeline management solution for process optimisation and pipe

integrity

; Critical power solution

; Integral security solution

More than merely an equipment provider, Schneider Electric leverages

its expertise in the Oil & Gas process to build efficient and both

customized and standardized solutions and deliver them as a

one-stop partner to our customers.

Schneider Electric also conducted private conferences

with customers on critical subjects in the Oil & Gas

market:

; Enterprise Energy management

; Integral Safety solution

; Pipeline management at the minimum cost

; Secure power for critical applications

Issue No. 11 – September 2009

In the news

Schneider Electric Water &

Waste Water Solutions

“Increase availability and performance levels of your plant”

“I need to distribute water 24/7”

“I’m looking for an integrated power and control solution”

“I need End to end lifecycle services”

Schneider Electric offers innovative solutions to the water industry including advanced

energy solutions for remote pumping stations with remote monitoring, control including

access control and security solutions.

Schneider Electric is providing solutions on how to optimize CAPEX and OPEX, total

process control and energy management for treatment plants and desalination plants with

integrated power and control systems, tools to maximize efficiency and reduced operating

costs. Its energy management solutions also cover plant survey and analysis. Offering the

right solutions to improve the power quality and reduce energy losses.

Schneider Electric Solutions project management team leads and offers the right solutions,

solving customer needs and offers simple, flexible, integrated power and control solutions

with advance real time process management and control systems and complete field level

to enterprise solutions.

Desalination

plant

Storage or

overpressure station

Consumption

Treatment

plant

Wastewater

lift station

Pumping station and

containment reservoir

Discharge into

the natural

environment

Wastewater

treatment

Schneider Electric conducts End User

Seminar on Water & Waste Water

Solutions

The seminar focused on the issues and

problems faced by the customers in their

previous projects; emphasis was given on

providing the right solutions to solve the

issues

During the seminar a demonstration was

done on typical applications like….

a) Remote pump management on GSM

b) High available system including Disaster

recovery system, online modifications

c) Intelligent Motor Control and Energy

Management Solutions

Issue No. 11 – September 2009

7

8

In the news

Distribution Substation Solution

Seminars in Abu Dhabi, Dubai & Qatar

Schneider Electric, a leader in the Medium Voltage secondary

distribution, has been providing compact MV panels, ringmain

units, protection relays and a lot more for many years is now

offering a total solution for distribution substations.

In any distribution substation, the four important products are, MV switchgear panel,

protection relay, transformer and now-a-days the Remote Terminal Unit for telecontrol. When

Schneider Electric combines GenieEvo, Sepam, Trihal and Easergy T200 products, they

become a perfect solution for 11/0.415kV distribution substations.

Schneider Electric organized seminars in Abu Dhabi, Dubai and Doha on 16, 17 and 18

March 2009 respectively with an overwhelming response of 375 total customers attended in

all 3 locations.

Speakers were Mike Adams, Technical Manager from Schneider Electric UK; Laurent

Bucchi, Business Development Manager, Schneider Electric Telecontrol, France; Ravi

Rangasamy, Senior Marketing Manager on MV Solutions, Gulf Countries and Cedric Bayle,

Business Development Manager, Schneider Electric Protection, France.

Issue No. 11 – September 2009

In the news

GenieEvo

GenieEvo is an environmentally insensitive partition metal switchgear medium voltage

range. With fast delivery, advanced safety features and compliance with the most stringent

standards, GenieEvo offers you an innovative, simple and highly reliable solution to your

primary distribution needs.

GenieEvo not only brings the latest vacuum circuit breaker technology, but also insulation

systems to ensure compact dimensions when compared with conventional air insulated

equipment. Compact modular circuit breakers, combined with a wide range of protection

modules offer simple and highly reliable solutions for virtually any application.

Easergy T200I

Thanks to the simplicity of implementation and operation, combined to the flexibility of a

product opened to a wide variety of SCADA systems and to all communication medium

types, Easergy T200I is the solution to optimise your MV underground network operation.

Easergy T200I integrates within a single unit, all functions to remote control an MV

substation. It is used for applications in MV substations and underground networks.

Sepam

Sepam Digital protection relays for current and voltage protection, for any distribution

system protect your power system with full peace of mind. With 20 years of experience in

digital relays, it is a consistent range of relays organized according to applications.

Trihal

Trihal cast resin distribution transformer from 160kVA to 15 MVA up to 36kV offers you a

total safety even with regard to the most severe conditions. It guarantees reliability and

respect of environment thanks to its self-extinguishing property, it is 100% recycable and it

presents no risk of pollution. Trihal is used for MV and LV application in Buildings, Industry

and Energy and infrastuctures. Trihal is 5 years guaranteed: more than a guarantee, a

commitment on quality.

Issue No. 11 – September 2009

9

10

In the news

Ringmaster & Easergy T200

Seminar for Dubai Electricity &

Water Authority (DEWA)

A number of DEWA Engineers actively participated in a dedicated

seminar that Schneider Electric organized for Dubai Electricity &

Water Authority (DEWA) on Ringmaster, the hi-reliable Gas Insulated

ring main units for underground secondary distribution and Easergy

T200 MV substation control unit, on 19th March 2009 in DEWA

Auditorium, Dubai, UAE.

Speakers were Mike Adams, Technical

Manager, Schneider Electric UK for

Ringmaster; Laurent Bucchi, Business

Development Manager, Schneider Electric

Telecontrol, France for Easergy T200 with

the support of Ravi Rangasamy, Senior

Marketing Manager - Medium Voltage

Solutions, Schneider Electric Gulf Countries.

Together, they explained the adaptability of

T200 RTU with Ringmaster and distribution

SCADA.

Ringmaster has both extensible and

non-extensible MV functional units: circuit

breaker, switch, feeder metering units:

@ rated current up to 630 A

@ short circuit current up to 21 kA / 3 sec

@ indoor and outdoor IP54 design

@ internal arc proof

@ gas pressure indicator

Self powered protection and monitoring

control devices allowing the security of your

installation

Issue No. 11 – September 2009

@ Time Limit Fuses (TLF)

@ VIP protection relays

@ Easergy T200E telecontrol

Easergy T200I integrates within a single

unit, all functions to remote control an MV

ring main unit or a substation:

@ Management of 1 to 16 switchgear/circuit

breaker

@ Uninterruptible power supply 24 or 48 Vcc

@ Fault passage indicator

@ Current measurements

@ MV network reconfiguration automation

functions

@ Local display and control

@ Large catalogue of protocols: IEC 870-5101 and 104, DNP3, Modbus and various

customer owned protocols

@ Various transmission systems: Ethernet,

RS232, Radio, PSTN, GSM, GPRS,

private line...

!

w

e

N

Altivar 312

Schneider Electric has launched a

new range of variable speed drives

for industrial machines 0.18 to 15kW up to 600V

F

Features

@ Enhanced communication: Integrated Modbus &

CANopen

@ CANopen daisy chain, DeviceNet, ProfibusDP option

@ Simplified user interface, setup via Bluetooth® mobile

phone

@ Graphic, multi-line, multi-language keypad IP54/IP65

option

@ Ergonomically designed local control on front facia for

start/stop, speed variation & programming...

@ Numerous application-specific functions

@ Auto-tuning for optimum performance

@ Integrated EMC filter

@ Operation up to 50ºC without derating

Register and download the Altivar 312 catalogue

and get a chance to win a nice wooden pen case.

Hurry! Limited offer only!

Go to www.sereply.com

Enter your keycode Keycode 72222T

Click on “FREE wooden pen case to 10 downloaders”

In the news

13

Ringmaster

Seminar for Sharjah Electricity &

Water Authority (SEWA)

Schneider Electric organized a dedicated seminar for Sharjah Electricity

& Water Authority (SEWA) on Ringmaster, the hi-reliable Gas Insulated ring

main unit for underground secondary distribution, last 16 March 2009 in

SEWA premises.

Ravi Rangasamy, Senior Marketing Manager - Medium

Voltage Solutions, Schneider Electric Gulf Countries presented

updates about Schneider Electric and its products and solutions

offers. Mike Adams, Technical Manager, Schneider Electric UK

discussed the innovations on the design of Ringmaster and

explained the suitability of the product to the harsh climatic

conditions.

Ringmaster is a compact highly reliable solution for both indoor

and outdoor applications of MV distribution networks up to

13.8kV. Ringmaster’s benefits are modularity, simplicity and

insensitivity to the environment. It offers multiple configurations

and meets all the MV applications requirements from simple

transformer protection to sectionalising with remote control.

Extensible RMU combining all MV functional units: circuit breaker,

switch, feeder metering units

@ rated current up to 630 A

@ short circuit current up to 21 kA

@ indoor outdoor IP54 design

@ internal arc proof

@ gas pressure indicator

Self powered protection and monitoring control devices allowing the

security of your installation

@ Time Limit Fuses (TLF)

@ VIP protection relays

@ Easergy T200E telecontrol

Issue No. 11 – September 2009

14

In the news

Schneider Electric & Al Mulla

Group conduct seminar on

Smart Building Technologies

Schneider Electric in partnership with Al Mulla Engineering Group conducted

a seminar on Building Technologies held last 15th June 2009 at the

Madisson SAS Hotel, Kuwait.

Modern buildings today are increasing complex, whereas historically

building systems have operated in isolation. As buildings migrate

from a collection of disparate systems operating in silos into a

truly unified system, the challenge is to provide a building where

the underlying systems are truly integrated in a single system: a

one-stop resource for controlling multiple building systems – and

lowering energy costs via a single interface. A truly Smart Building.

The problems that arise from installing and managing isolated

building systems are endless. Even worse, the higher energy costs

that result from such inefficiencies continue to drain – and waste

– your energy dollars needlessly. The Schneider Electric Smart

Building Solution overcomes these problems. Our fully integrated,

centralized approach eliminates:

; Inconsistent communication and coordination between standalone systems

; Connectivity and operational problems caused by non-

compatible interfaces and gateways from multiple vendors, such

as:

@ Higher engineering and customization costs

@ Incompatibility issues and the corresponding costs of new

versions and product enhancements

@ “Finger-pointing” between vendors when things go wrong

Issue No. 11 – September 2009

In the news

15

; The difficulty of learning, monitoring and

servicing disparate technologies

; The extra management resources needed

to maintain numerous isolated systems

With Schneider Electric Smart Building

Solutions, you replace complex problems

with an energy-saving option that increases

your efficiency and minimizes your energy

costs.

The event was attended by local consultants

and property owner representatives. Endusers such as KNPC, KOC, KISR and Kuwait

University also attended the event.

The event helped the

attendees understand

that Schneider Electric,

through the Al Mulla group,

today offers complete

range of integrated energy

management technology

The seminar and live demos helped the

attendees understand how Schneider

Electric today in partnership with the Al Mulla

Group in Kuwait offers a complete range of

integrated energy management solutions to

make your building truly “smart”.

Elevator

Control

Energy

Management

A Complete Building Solution

seamlessly manages all of your

building’s critical systems from a single

source.

Security &

Access

Automated

Parking

Fire Alarm

Monitoring

Variable

Frequency

Drives

Building

Automation

HVAC

Monitoring

Control

Digital Video

Management

Drives

Lighting

Monitoring

& Control

Power

Management

& Monitoring

Power Quality

Correction &

Availability

Electrical

Distribution

Monitoring &

Control

Issue No. 11 – September 2009

16

In the news

The IT Challenge of the Future:

Energy & Cooling and Environmental Responsibility

Dubai, 1st April 2009 –– Information technology systems are an essential

and strategic component of every enterprise and every building. For those

who design and manage Enterprise Information and Communication

Technology systems, the guiding principle has always been - Better, Faster,

Cheaper. Give clients better performing systems to achieve results faster

and reduce costs. Today a new element has to be added to that mandate environmental responsibility.

According to IDC, energy and cooling

expenses will grow eight times faster than

the amount of money spent on purchasing

new servers through 2010, warns APC

by Schneider Electric, a global leader in

power, cooling, and management solutions.

Predictions show that changes in power

supply and cooling in data centers will have

a serious impact on users, suppliers of data

center solutions and energy sources. In fast

growing regions such as the GCC, power

is in short supply. This calls for technology

solutions that address this challenge fast.

Information systems provide an increasingly

ubiquitous network within the companies

and offer services in new fields. Using this

network, companies can provide faster and

better services to their customers, including

RFID and VoIP solutions. The emerging and

broadening information services also induce

changes in data centers; they require more

servers and processors, higher network and

storage capacity. Due to these changes, IT

professionals face the following challenges:

The majority of existing data centers (and

some of the new ones being implemented

now) are not suitable for operating highdensity systems. Data center suppliers and

operators must change their approach to

apply the new technologies. “The presence

of higher power in data centers will directly

affect all users. IDC predicts that in 2010

the amount spent on cooling and powering

the existing installed base of servers will be

over 70% of what is spent on purchasing

new servers,” warns Christian Bertrand,

ME & Turkey Director at APC by Schneider

Electric. “Building completely new data

centers might be cheaper than reorganizing

conventionally-built ones, even in the

medium-term. We could say that the data

center design methodology of yesterday,

the conventional server technologies and

today's requirements together will form the

greatest IT challenge of tomorrow”, added

Christian.

Speed and Agility: The world of business

that requires increasingly faster response

relies more and more on information

systems. The imperfection of an information

system must not hold back the launch of a

new service or project. In addition, this must

be provided in a solution where investment

grows with revenue: “Pay as You Grow”.

Impact on the infrastructure: modular and

scalable solutions are needed for power

supply and cooling.

Issue No. 11 – September 2009

In the news

17

an unplanned downtime is becoming an

even more important factor not only for

information systems, but also for server

infrastructure: instead of MTBF , MTTR is

becoming the first priority. In case of IT

devices, this change drives the emergence

of modular systems and virtualization.

Impact on the infrastructure: emergence

of easily reparable modular solutions,

increased demand for comprehensively

manageable equipment.

Footprint, rental costs, and expansion

possibilities: Placing more equipment

requires more floor space, requiring

constant expansion of data centers. The

costs associated with occupied areas

(for example rental costs) limit expansion

possibilities, particularly in downtowns and

in several cases server rooms cannot be

enlarged due to the lack of free space in

the building. Area limitations motivate IT

professionals for dynamic growth, namely

they have to provide higher performance

by server consolidation and high-density

applications using the same floor space.

This solution can be implemented by using

1U and blade servers, or virtualization

technologies. Impact on the infrastructure:

higher power consumption, higher power

density, and overheating problems when

using conventional cooling methods.

Security requirements, availability:

The increasing amount of stored data,

threats entering through e-mails, fear from

terrorism and higher availability requirements

demand more secure systems with higher

availability. This trend is also fuelled by

different requirements, regulations and

internal policies (Basel 2, SOX, BCP , DRP

, etc.) The fastest possible restoration after

Cost reduction: This is a general and

ever-increasing requirement in all fields.

Companies try to reduce their costs by

cutting back on the expenditure related to

employment (reducing maintenance and

operating requirements) and electricity, and

reducing floor space and amount of physical

hardware devices. The energy costs can

be significantly decreased by applying

virtualization technologies on several fields

(for example, remotely accessible monitoring

and management systems, server

consolidation, cooling power). Impact on the

infrastructure: High-density devices require

unconventional cooling, and infrastructure

devices have to be well manageable.

Infrastructure challenges: High-density

servers can generate high heat load

on a much smaller place, compared to

equipment manufactured a few years ago. In

addition, virtualization technologies increase

the average capacity utilization 5 or 6-fold.

In an environment like this, cooling problems

arise much earlier than power supply

problems. The challenges of high-density

cooling include separation of cool and warm

air, increasing the efficiency of cooling,

ensuring heat removal and possibilities for

comprehensive manageability and predictive

troubleshooting.

Legacy systems work fine for brute-force cooling the entire room, but skyrocketing

energy costs make them fiscally irresponsible and their fundamentally oversized

design makes them incapable of meeting today’s high-density challenges. Even worse,

power and cooling waste may actually prevent you from purchasing much-needed

new IT equipment. Simple problem - simple solution: Cut your power and cooling

costs and use the savings to buy the IT equipment you need – concludes Christian.

Issue No. 11 – September 2009

Intelligent outlook

Compact NSX

100-630A

Next-generation circuit breakers

for direct access to energy efficiency

Discover the first step towards

Energy Efficiency

With Schneider Electric Solutions it has been

always simple! Find out how our Power

Distribution products help you to achieve

Energy Efficiency.

Register and get a chance to be

the lucky winner of Schneider

Electric Backpack.

Hurry! Limited offer only!

Go to www.sereply.com

Enter your keycode Keycode 72222T

Click on “Energy Measurement and Communication:

The first step towards Energy Efficiency”

What's On

19

Optimising energy efficiency

for large Oil & Gas sites through new energy

management solutions

Schneider Electric announced new and innovative solutions to help customers involved in

the Oil&Gas industry to meet demand for increased energy efficiency throughout operations.

The new solutions also increase energy reliability and availability, reducing operating

costs without compromising environmental concerns or safety. Schneider Electric has

an established track record helping customers to optimise energy use and performance

through combined energy management, security and safety.

be ineffective, or may become

ineffective over time. Significant

errors in utility bills can be

overlooked. Without clear data,

accountability for energy use tends

to be poor, and behaviour may

run counter to the organization's

interests.”

With extensive and long-term

experience and expertise in energy

management for the Oil and Gas

industry, Schneider Electric provides

solutions from design to installation,

including electrical houses and arc

resistant equipment, integrated with

its energy management system

to ensure reliability and safety.

The company provides purposedesigned solutions which avoid

downtime, reduce time to repair, cut

time between failures and maintain

high levels of productivity, increasing

the useful life of equipment. For the

customer this means a reduction in

both capital spending and operating

costs together with increased

reliability of energy supply and

control, even in hazardous areas.

“Measurement and analysis of

energy usage data provides

customers with the means

to understand their energy

consumption,” said Luis Felipe

Kessler. “Without access to this

type of analysis, it is possible

to miss the most obvious and

relevant areas for improving

energy efficiency. Therefore energy

measures that are taken may

With an Enterprise Energy

Manager, Schneider Electric is able

to integrate existing databases

(energy management and process

data) and automatically update

performance summaries, providing

up-to-date views of analysed data

and making the effectiveness of

energy efficiency measures more

transparent to the user.

Schneider Electric experts are

trained to improve Energy Efficiency

in large sites and conduct energy

quality studies, electrical system

optimization and solutions to help

extend the useful life and reliability

of equipment and assets, to reduce

commissioning time and downtime

and commissioning, and to provide

load flow and voltage profile

studies, short circuit calculations

and protection analysis.

“We can thus offer increased

production with less energy,

together with a clear view of the

energy expenses associated with

production and other systems,”

concludes Luis Felipe.

The new Schneider Electric solution

meets customer requirements for an

open, scalable and extendable Energy

Management and Control Solution which is

characterised by ease of use. Fully compliant

with IEC61850, it is supported by end to

end engineering from initial pilot studies to

customer autonomy. It provides safe electrical

evolution and maintenance with advanced

electrical network modelling, high levels of

reliability and fast recovery with integrated

fast load shedding features, secure and fast

decision–making through online simulation

and built-in training,

– said Luis Felipe Kessler, Downstream

Solution Director

Issue No. 11 – September 2009

20

What's On

Schneider Electric and KROHNE

present New Pipeline Management

Solutions at Gastech 2009

Schneider Electric, the global specialist in

energy management, unveiled new and

innovative pipeline management solutions

at Gastech 2009 in Abu Dhabi, the 24th

international conference and exhibition for

the LNG, LPG and natural gas industries,

last 25 to 28 May 2009.

These offerings were presented in

collaboration with KROHNE, the

measurement technology specialist and

will help customers involved in Oil and

Gas meet challenges to enhance pipeline

performance and safety through energy

management, integral security, advanced

process automation and a complete pipeline

instrumentation package.

The combined solution consists in

a collaborative, open and scalable

architecture platform that allows monitoring

and managing pipeline operations with

increased security and safety levels. It also

includes both leaders’ track record project

execution capabilities and local services.

Real-time monitoring & automation is

achieved through the Schneider Electric’s

SCADA System, Safety PLC & RTU’s while

protecting assets with:

@ Cathodic protection monitoring,

@ Integral security systems, such as CCTV

and access control,

@ Secure power,

Issue No. 11 – September 2009

@ Reliable electrical distribution

@ Advanced energy management to

optimize energy consumption and

improve performance.

KROHNE will provide pipeline

instrumentation including highly accurate

custody transfer flow measurement

products together with its most reliable

pipeline leakage detection system,

translating in improved business

performance.

“This partnership is a great opportunity for

our customers who require solutions for

pipeline process optimisation and enhanced

pipeline integrity. With the recognised

expertise of Schneider Electric in energy

management and security, KROHNE

will add its know-how in model-based

leak detection combined with its best-inclass flow meters,” comments Stephan

Neuburger, Krohne Managing Director.

“As a leading solutions provider for the

Oil & Gas industry, this partnership is the

answer to the midstream process to build

efficient and tested solutions,” adds Patrick

Albos, Vice-President Oil & Gas Solutions,

Schneider Electric.

What's On

21

About KROHNE

Established in 1921, KROHNE

is a family-owned business employing

2,510 people around the world with

representatives on all continents. The

company has its headquarters in Duisburg,

Germany and develops, manufactures and

sells products in the field of measuring

technology, standing for innovation and

superior product quality. KROHNE is one

of the market leaders in industrial process

measuring technology.

About Schneider Electric

As a global specialist in energy management

with operations in more than 100 countries,

Schneider Electric offers integrated

solutions across multiple market segments,

including leadership positions in energy and

infrastructure, industrial processes, building

automation, and data centres/networks,

as well as a broad presence in residential

applications. Focused on making energy

safe, reliable, and efficient, the company's

114,000 employees achieved sales of more

than 18.3 billion euros in 2008, through

an active commitment to help individuals

and organisations “Make the most of their

energy™”.

www.schneider-electric.com

Editors Note: About

Schneider Electric at

Gastech 2009

From 25-28 May 2009, Gastech,

the largest international conference

and exhibition for the LNG, LPG and

natural gas industries gathered in

Abu Dhabi (United Arab Emirates)

all major players from gas supply

chain. More than 10,000 customers,

from all over the world, discussed

the main challenges affecting the

business within this sector as well as

latest trends and developments.

As a leading

solutions provider

for the Oil & Gas

industry, this

partnership is

the answer to the

midstream process

to build efficient and

tested solutions.

Issue No. 11 – September 2009

22

Guided tour

Maximising safety in Oil & Gas

process plants

In the last few years, safety has become a major concern in most industries,

in particular Oil&Gas, driving our efforts and developments to provide our

customers with solutions that maximise safety in Oil&Gas process plants.

between failures (MTBF). Safety PLC using

microprocessor diversity and Hot/Standby

features, makes it inherently secure by

avoiding common mode failures. It makes

migration from control system to safety

loops very cost-effective, with friendly tools

designed to easily mix safety modules with

non-interfering control modules, even in the

same racks.

In Oil & Gas installations, a failure can

have dramatic consequences on people,

processes and the environment. Reliance

on safety PLCs is the only way to effectively

and efficiently monitor and supervise

process status and react appropriately in

case of unforeseen events.

Despite the fact that safety systems are

“dormant”, i.e. seldom operate, they are

embedded with powerful diagnostics that

perform automatic auto-tests to make

sure they will respond in emergency

situations. To meet the demanding needs

of critical sites, and provide availability and

safety of both personnel and machines,

Schneider Electric has developed integrated

architectures to cover various applications

such as emergency shutdown systems

(ESD), fire and gas systems (F&G), burner

management systems (BMS) and boiler

protection.

The Quantum Safety PLC ensures a

high level of both safety and availability:

its Hot Stand-By architecture increases

system dependability, extended mean time

Issue No. 11 – September 2009

Schneider Electric is developing a unique

solution based on the QUANTUM Safety

PLC for the Offshore Industry. This solution,

aimed at medium-sized drilling or production

platforms, consists of an integrated and

embedded ESD process, F&G systems

and building fire systems to monitor and

automatically initiate the appropriate action

in case of any fire and gas hazards on the

platform. Any such incident or unexpected

event is stored in a sequence of events

file, reported to the security and control

room and dynamically displayed on a

CITECT HMI (Human Machine Interface)

device. Secure power is supplied via a

GUTOR hardened and redundant UPS,

and some of the instrumentation is taken

from the TAC/PELCO line of products.

With wide-ranging expertise in PLCs as

well as safety, Schneider Electric is able to

manage complex turnkey projects, helping

our customers to make the most of their

energies. We master the entire process,

from hazards and operability (Hazop)

studies by our Projects and Engineering

Centre (PEC), the design and engineering

of complex solutions, all the way to the

commissioning and maintenance of friendly

architecture for safety-integrated systems.

Customer benefits:

> Best-in-class solutions

to provide reduced

maintenance and high

availability.

> Optimized personnel

and machine safety

> Improved environmentfriendliness with

relevant maintenance,

retrofit and upgrading.

> Increased energy

efficiency to reduce

energy cost.

> Safe and secure assets

with CCTV

Looking for economical

solution for iMCC?

Lead your efficiency,

cost management and profitability.

TeSys U

One Product. Complete Starter.

Power Base

Control Unit

STB Module

LOAD

Disconnecting

Beckhoff

Standard

Multi-functional

Switching

Protecting against

short-circuits

Protecting against

overload

Control

Motor management

Features and advantages:

Simple design one size up to 32A and time saving in

implementation.

Compact space saving up to 40% and less wiring, so

reduced material cost.

Modularity last minute modification, so very flexible design.

Continuity of service total coordination, so no down time.

Easy maintenace save history of last 5 faults.

Green Solution low energy consumption.

Register & download the catalogue to get

a chance of winning Digital Calculator.

Hurry! Limited offer only!

Go to www.sereply.com

Enter your keycode Keycode 72222T

Click on “TeSys U Starter-controllers: Lead your

efficiency, cost management and profitability.”

Communication

Module

Advanced

24

On the product front

TeSys D: the most innovative and

consistent motor starter solution in

the market for Size 3

As a world leader for a motor starter solution, we are glad to inform you that

we have renewed our offer for Contactors & O/L relays for 40 A to 65A

range in April 2009.

We already renewed our offer for GV3 Motor circuit breaker for 40 A to

65A range in Oct 2007. Thus, we completed a full renewal of offer for Size 3

starter.

@ Our new offer provides a complete and innovative installation system that makes

our motor starter solution easy

to mount and easy to install.

@ The innovative EverLink power connection ensures more safety and long term tightening

quality.

@ Our competitors have now ageing motor starter offers and we are coming up to the

market with decisive advantages over the competition.

Complete and smart installation system

that makes the difference against competitors

Vertical motor

starter combination

Horizontal motor

starter combination

The EverLink®, terminal has been

designed to build easy, quick and

safe motor starter combination

Issue No. 11 – September 2009

S Busbar

The S Busbar

provides easy,

quick and

compact size

motor starter

combination

On the product front

The EverLink® technology ensures

high quality power connection

EverLink®, the new patented terminal

technology, ensures permanent tightening

quality of the cable conductors

• Reduced maintenance time

25

Stronger,

safer and long

lasting power

connection

• Safety of the connections

• IP20 protection against direct contact

Other advantages:

@ Safety cover in front of coil: High standard of safety to avoid accidental close.

@ 2 Built in NO + NC contacts.

@ Clear segregation between control terminals (on white background) and power terminals

on (black background.), eliminate risk of error.

@ Aesthetic cabling and savings in space using the cable guide for control connections.

Click here for more information about the product

www.schneider-electric.ae

Issue No. 11 – September 2009

26

Tech talk

Schneider Electric presents its intelligent

Power & Motor Control Centre (iPMCC)

solution, the keystone for energy and process

automation management in large sites

Schneider Electric presented its new and innovative solutions to help

customers involved in the Oil & Gas industry to meet challenges of energy

reliability and availability, ensuring overall process performance and reducing

operating costs while respecting environmental concerns and safety

requirements. Schneider Electric has an established track record helping

customers to get the most from their energies and optimise performance

through combined energy management, integral security and safety.

Companies in the Oil & Gas and petrochemical industry operate in a highly competitive economic climate

and the search for increased productivity has become more and more critical. Schneider Electric’s

MotorSysTM iPMCC solutions, which can significantly improve the energy efficiency of customer assets, have

helped some of our clients increase productivity by as much as 15%. In specific terms, we are committed to

ensuring that our solutions have an immediate impact on production times while respecting environmental and

safety requirements as well as reducing costs throughout the entire lifecycle of the site. Our main goal is to give

customers the means to reduce their electrical energy consumption as well as allocate the costs for each motor

application,

says Didier Rochas, Oil & Gas Solution Leader – Power Business Unit.

With 25% of the electrical energy

consumed in the industry worldwide, Oil &

Gas is the most energy intensive industry.

Because electric motors account for up to

70% of this energy consumption, reducing

power cuts and downtimes for repairs and

failures, as well as better asset and energy

management are key challenges to succeed

in increasing productivity.

The intelligent MotorSysTM iPMCC

solutions developed by Schneider Electric

provide dependable, high quality

energy (intelligent Power Control Centre)

and optimise the operational performance

of LV motors through a complete range

of protection and intelligent functions

(intelligent Motor Control Centre).

These solutions harness Schneider Electric’s

specific expertise in energy management

and industrial process automation.

Issue No. 11 – September 2009

Built on tested and validated

architectures, they are installed at the centre

of each site to form the keystone of the

energy management of your production

workshops.

And because they are compatible with all

the communication protocols used in the

process industry, including Ethernet TCP/IP,

Profibus-DP, DeviceNet and Modbus, they

integrate effortlessly into the infrastructure of

your sites’ local industrial network (LAN) as

well as in all control and monitoring systems

for process automation (DCS…) and energy

management (EMCS…).

Moreover, these fully customisable solutions

can be tailored to meet all the requirements

of continuous and critical processes.

Customer Voice

A look at our

customer feedback

At Schneider Electric, we strongly believe in listening to our customers because customers

are too important to ignore! Whether is it a suggestion for improvement or a

compliment of our service, we value it and take it seriously.

We look forward to more comments from you in the future.

Your feedback is important to us...

Register and get a chance to win 2GB USB memory stick!

3 Lucky respondents for each issue.

Go to www.sereply.com

Enter your keycode Keycode 72222T

Click on “Customer Voice”

TeSys U

One Product. Complete Starter.

New!

Intelligent outlook

Compact NSX

100-630A

Next-generation circuit breakers

for direct access to energy efficiency

Register & download the

catalogue to get a chance of

winning Digital Calculator.

Register and get a chance to

be the lucky winner of

Schneider Electric Backpack.

Hurry! Limited offer only!

See details on page 23

See details on page 18

Altivar 312

New range of variable speed drives for

industrial machines - 0.18 to 15kW

up to 600V

R

Register

and download the

Altivar 312 catalogue and get a chance

A

to win a nice wooden pen case.

Hurry! Limited offer only!

H

Winners from March 2009 issue:

> David Binley

CH2MHILL, Dubai

> Simionides Elie

Debbas Qatar LLC, Qatar

> Salile Sh. Rao

Sharikat Fanniya Omaniya LLC, Oman

See details on page 11

Check this out!

Schneider Electric Solutions brochures

Water Solutions Brochure

Hotel Solutions Brochure

Collection of Building Management Solutions Brochures

Grab a copy now and

make the most of your energy!

Pump Control System Brochure