Power adapter design for seamless interface of low voltage DC

advertisement

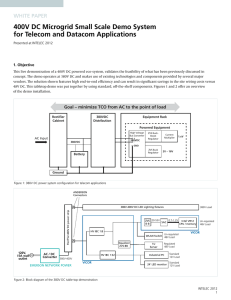

Power adapter design for seamless interface of low voltage DC equipment to 400V DC distribution Maurizio Salato, VICOR BJ Sonnenberg, Dustin J Becker, EMERSON Network Power David E. Geary, UNIVERSAL Electric Corporation / StarLine DC Solutions Table of content • • • • • Power Adapter Characteristics of Interest Telco site evolution options Existing sites transition to 400V DC Implications of power conversion location Power Components for 380V Adapter and the Equalizer concept • Architectural Matrixes • System safety and Harmonics considerations • Conclusions Power Adapter Characteristics of Interest • Location in the power stream: – – – – The power drop box (busway or cable) The rack power strip 1U space “power shelf” within the rack Plug‐in unit at “blade” level • Electrical function and power conversion topologies • Battery backup “equalization” • Safety and protections • Harmonics Telco site evolution options Today Next Step Facility AC Loads Utility Gen Critical AC Loads AC UPS Batt -48V DC Power System AC -48VDC Batt Facility AC Loads . DC Critical 48V DC Loads Facility DC Loads AC DC Many Transition Paths Possible Utility Gen ● 380V DC 400V DC Power System Batt Paths forward with 400V DC for larger core sites: 1. 2. 3. Greenfield with 400V loads (bulk or distributed 400V) Retrofit/expand -48V loads with 400V main plant (bulk) Greenfield with bulk 400V to distributed 400V/-48V Local Generation Source DC DC Critical AC Loads Critical 400V DC Loads Critical -48V DC Loads Existing sites transition to 400V DC 48V DC bulk equipment 380VDC cabling or bus way 48VDC cabling 380VDC System 380/48VDC Conversion + Secondary Distribution 48VDC Equipment Rack 380VDC Equipment Rack The main power distribution from a 400V DC system is built with 400V DC bus way or cabling, directly to 400V DC enabled loads. For loads requiring 48V DC inputs, a bulk 400V‐48V DC conversion replaces the “secondary distribution bay” and is located close to the loads to eliminate long 48V DC cable runs. Existing sites transition to 400V DC 48V DC rack mounted equipment The 400V DC distribution is extended close to the powered rack . The options for location of the 400V‐48V DC conversion depend on the type of feeder used (bus‐way or cabling) and distribution inside the rack. Due to the relatively low power density of 48V DC powered racks, the conversion section is compact and can be located in a bus way plug‐in box, a junction box on top of rack, inside the power strip itself or in a rack mounted shelf Implications of power conversion location 380V busway Adapter output supplies Rack units management System availability / redundancy Busway or wire drop‐box Entire rack Un‐qualified operator (SELV) Fair (rack to rack) Location Rack Rack power shelf Groups of units Un‐qualified operator (SELV) Medium (group to group) Individual unit adapter Single unit Qualified operator (AC, 400V DC) Maximum (unit to unit) Power Components for 380V Adapter I SAC V 32·I I V/32 SAC V 8·I V/8 K=1/32 K=1/8 BC K=1/32: high voltage bus converter, 260‐400V input, 32:1 ratio, 8‐12.5V output BC K=1/8: high voltage bus converter, 260‐400V input, 8:1 ratio, 32‐50V output ZVS BO ZVS BU ZVS BB ZVS BO: Zero Voltage Switching Boost regulator, 8V min. input, 55V max. output ZVS BU: Zero Voltage Switching Buck regulator, 55V max. input, 8V min. output ZVS BB: Zero Voltage Switching Buck‐Boost regulator, 32‐55V input, 20‐55V output The Equalizer Concept • Compliance to ETSI EN 300 132‐3‐1 • Regulate ONLY if voltage falls below normal operating range (365 V ± 15 V) • 96%98% efficiency under normal operating conditions • SELV Output 380V to 12V power components matrix Power distribution 12V Loads Source Load Range VIN VOUT [V] Regulated 384V ± 1% 380‐388 Semi‐regulated ETSI EN 300 132‐3‐1 EMERGE >3ms 380V ‐8% +3% 350‐390 380V nom 260‐400 12V Backplane 12V ± 2% 11.75‐12.25 HDD 12V ± 4% 11.5‐12.5 BC K=1/32 BC K=1/8 & BU regulator BC K=1/32 & BO equalizer VRMs 12V ± 35% 8‐16 380V to 48V power components matrix Power distribution 48V Loads Source Load Range VIN VOUT [V] Regulated 384V ± 1% 380‐388 48V Backplane 48V ± 2% 47‐49 ETSI 48V 48V nom 36‐60 BC K=1/8 BC K=1/8 & BO equalizer Semi‐regulated 380V ‐8% +3% 350‐390 BC K=1/8 & BB regulator ETSI EN 300 132‐3‐1 EMERGE >3ms 380V nom 260‐400 BC K=1/8 & BO equalizer FPA 45V nom 32‐60 Adapter power architecture, peak efficiency and density vs. Distribution Ratio (DR) Power component density (components only) [W/inch3 – (W/cm3)] Power conversion peak efficiency 2000 (122) 98% Non‐equalized output 97% 1200 (73) 96% Equalized output 95% Regulated output 94% 400 (25) Equalizer Bus Conv. Bus Conv. Bus Conv. Equalizer + Power components Regulator Bus Conv. + + OR Regulator 0.8 3 5 ܸಾಲ െ ܸಾಿ ܸಿೀಾ ܴܦൌ ܸௗಾಲ െ ܸௗಾಿ ܸௗಿೀಾ Safety and Operators protections The SAC converter galvanically isolates the 400V DC and the low voltage distribution systems Isolated, floating supply, 200V max with respect to hearth. Mid‐point resistive grounding early‐detection system for isolation faults. Safely sustains up to 500V operating input to output voltage differential. Low voltage secondary in UL/CSA 60950 qualified SELV range. Harmonics • AC distribution systems are affected by higher order harmonics generated by the interaction of AC‐DC converters. – the impact of high THD on AC distribution systems can affect up to 59% of the installed wiring capacity, leading to significant higher operating costs or even hazards. • Bulk power systems and DC‐DC converters generate harmonics that typically start at the switching frequency of the considered converter, therefore a much higher frequency than AC‐DC converters. – Passive filtering for this type of spectrum is usually effective, small and avoids low frequency beats that may result from the interaction of asynchronous DC‐DC converters. Moreover, filter size allows effective integration within the adapter enclosure. Conclusions • • • • 400V DC distribution systems offer quantifiable advantages not only for new telecom and/or datacenter facilities, but also for upgrades of existing ones. Power component‐based architectures for power adapters have been discussed and analyzed. The proposed locations leverage the space available within equipment racks or within racks’ rows, making maximum use of available space and enabling maximum racks density as far as equipment loads. Best location of power adapter for use with legacy loads depends on user preference based on the following criteria : – – – – – • Safety Availability Efficiency Ease of harmonics content elimination Cabling size For high density loads, the best system architecture from efficiency , reliability and space savings standpoint is a direct 380VDC connection to the motherboard with on‐ board 380VDC‐48VDC bus converter and direct 48V to processor/memory factorized power system.