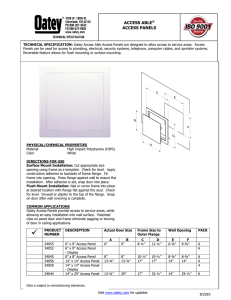

American Panel

advertisement