Three Case Studies of Commercial Deployment

advertisement

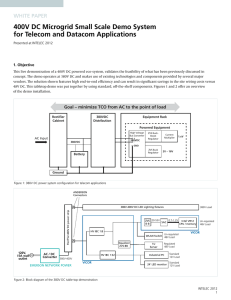

Three Case Studies of Commercial Deployment of 400V DC Data and Telecom Centers in the EMEA Region Sara Maly Lisy Mirna Smrekar Emerson Network Power Warrenville, USA Sara.Lisy@Emerson.com Emerson Network Power Zagreb, Croatia Mirna.Smrekar@Emerson.com copper cabling and installation costs of power distribution infrastructure. Abstract— Interest and adoption of 400V DC power has been growing over the past decade. After many years of studies and trials, commercial implementation of 400V DC power in production telecommunications and data center sites is becoming a reality. This adoption is driven by multiple motivators, depending on the site-specific application and layout. Because there is limited availability of 400VDC-powered telecom equipment today, an attractive distribution architecture is to distribute 400V DC power with long cable runs and convert 400V DC to -48V DC near the -48VDC-powered equipment loads. This allows users to achieve substantial cost savings on distributing 400V DC over long cable runs, while still feeding standard telecom equipment. This paper will present case studies of the implementation of 400V DC power at three sites in Europe and Africa. It will examine the decision making process behind 400V DC adoption from the end users’ points of view, and detail the deployment architectures. This paper will review case studies of two data center applications and one telecom application, detailing the different 400V DC adoption motivators and deployment architectures. The first case study shows deployment of a small scale 400VDC data center in 2N concept powered solely by 400VDC. 400VDC power is used not only for IT equipment, but also for cooling and lighting. Solar energy supplied from PV panels through solar MPPT units is connected directly to the 400VDC bus. II. CASE STUDY 1 A. Background Bachmann GmbH & Co. KG is a German-based manufacturer of electronic components and systems. The company has been focused on developing innovative power distribution equipment to enable data center and industrial sites to maximize energy efficiency. Bachmann was building a new data center for its internal operations and wanted to design it as a showcase of energy efficiency. 400V DC power was chosen as the main power distribution architecture in order to minimize the number of conversions between AC and DC power and to enable the integration of renewable energy sources that generate DC power. The second case study describes the deployment of a traditional data center with 2N concept. Both AC and 400VDC architectures were built in parallel to allow for future modular extension of either AC or 400VDC powered equipment depending on future needs. The third case study demonstrates how an existing -48VDC large telecom site is powered by 400VDC distribution. 400V DC power cabinets distribute power over long cables to 400VDC/48VDC conversion cabinets that are located near the -48VDC loads. B. Solution To ensure maximum availability, the data center was designed with a 2N configuration, with dual paths for power conversion, distribution, and cooling, Fig. 1. At the site entrance, an automatic transfer switch (ATS) connects both utility grid power and a back-up generator. The output of the ATS provides the 400VAC input to the two 400V DC power systems. A 230VAC feed from the ATS also supplies power to auxiliary AC powered loads, such as the security system and electrical sockets. I. INTRODUCTION In data centers, the primary drivers for 400V DC power are the simplicity of the power chain in comparison to AC power and the ability to provide redundancy and scalability in a very modular approach. By eliminating conversions back and forth between AC and DC power, 400V DC has the potential to decrease capital cost and footprint while increasing efficiency and availability. In addition, the use of DC power simplifies the integration of renewable energy sources. Compared to -48VDC power architectures traditionally used at telecom sites, 400V DC can significantly reduce the 978-1-4799-6582-3/15/$31.00 ©2015 IEEE 6 Fig. 1. Electrical drawing of Bachmann site. Integration of renewable energy was a major driver of the power architecture at this site. Bachmann engaged with the European Union DC Components + Grid (DCC+G) microgrid demonstration project to serve as a demonstration site for a version of a 400V DC power system that was developed for DCC+G [1]. Fig. 2 shows a system diagram. Fig. 2. - Schematic of 400V DC power system with integrated rectifiers, solar MPPT, and batteries. This 400V DC power system contains both rectifiers that convert utility AC power to 400V DC power, as well as solar MPPTs that convert variable DC power from solar PV panels to regulated 400V DC power. Both the rectifiers and solar MPPTs are hot-swappable modules that can be integrated into the same power system. The peak efficiency of the rectifiers is 97% and the peak efficiency of the solar MPPTs is 98%. Bachmann utilizes two 400V DC power systems, one for each side of the power distribution path, that are each populated with one 15kW rectifier and one 15kW solar MPTT. The power system cabinets also include two integrated battery racks each, to provide approximately 10 minutes of battery backup. These systems can be expanded with the installation of additional rectifiers, MPPTs, and battery trays. Solar panels are installed on the roof of the newly constructed building, which was designed to optimize the position of the solar panels relative to the sun, shown in Fig. 3. There are two arrays containing 21 panels, capable of producing up to 5250W. Each 400V DC power system is fed by one solar panel array and by the output of the ATS. Fig. 3. Solar panels on the roof of newly constructed Bachmann building. The output of each 400V DC power system is connected to a power distribution cabinet. These cabinets feed the circuits for facility loads and connect to 400V DC power distribution unit (PDU) power strips that were installed in IT racks. Bachmann designed and manufactured the 400V DC PDUs, shown in Fig. 4, which include connectors for power cables to servers protected by ABB 400VDC-rated circuit breakers. The PDUs power 400V DC servers, manufactured by HP, in IT racks in the data center. To show versatility of 400V DC as a main distribution voltage, some racks of AC-input servers are also included in the site. These are powered by in-rack 400VDC-to-AC inverters from local manufacturer, Schaefer. Fig. 4. 400V DC power distribution unit. ETSI EN 301 605 recommends two potential grounding schemes for 400V DC applications: TN-S and IT earthing topologies [2]. The Bachmann installation utilizes TN-S grounding, also referred to as negative pole grounding (NPG), for the 400V DC power distribution. The Bachmann site includes both 400V DC powering of data center and adjacent office building equipment, and TN-S grounding is commonly 7 adopted by building installations because it can be less complex than implementing IT grounding. The data center is cooled by two redundant 16kW 400VDC-powered CRAC units from local supplier, Weiss Klimatechnik. High efficiency LED lighting from Philips is powered by 400V DC and installed in both the data center and adjacent office building. Because LEDs are inherently powered by direct current, the use of 400V DC for powering eliminated a power conversion in the lighting ballast and significantly reduced the size and complexity of components in the ballast. The complete data center is shown in Fig. 5. C. Results The 400V DC data center and office microgrid have been operational since March 2015, with reported uninterrupted operation. The installation continues to serve the dual purposes of supporting Bachmann’s operations and demonstrating a complete miniaturized data center implementing the latest innovative and energy efficient technologies. The German Data Center Award gave Bachmann 3rd place prize for energy efficiency at the Future-Thinking Data Center Conference in Darmstadt in April 2015 [3]. Fig. 5. Bachmann data center. Left to right: 2 racks of AC servers with inverters in bottom; rack of 400VDC-powered servers; IT cross connection cabinet; 2 400V DC power systems. Overhead: 400VDC-powered LED lights. Each side of the AC power distribution is protected by a 250kVA UPS system. Each side of the DC power distribution includes a 120kW capacity 400V DC power system, also known as a DC UPS, which converts AC power to 400V DC power and provides backup via batteries, shown in Fig. 6 and Fig. 7. The 400V DC power systems were initially populated with three 15kW high efficiency rectifier modules each, and can be expanded with up to eight rectifier modules per bay as well as additional power bays for more capacity. III. CASE STUDY 2 A. Background Coromatic AB, a leading data center integration firm, was contracted by a Scandinavian company to build a new data center to consolidate its data center operations that had previously been distributed across a number of international sites. The company placed a high priority on energy efficiency and asked Coromatic to design a cutting-edge, high efficiency data center with high availability. The company was inspired by the Green.ch data center in Zurich, Switzerland, which implemented both AC power and 400V DC power in different sections of the data center. Installed in 2012, that project demonstrated capital and energy savings of 400V DC power distribution in a direct comparison to the AC section [4]. The Scandinavian company decided on a similar concept, with parallel AC and 400V DC infrastructures within its data center. It views 400V DC power as a green technology to enable energy efficiency via fewer conversions between AC and DC power and ease of potential future integration of renewable energy sources. Fig. 6. 400V DC power system diagram. B. Solution Coromatic designed the site architecture with separate AC and 400V DC architecture powering separate IT equipment loads. Both the AC and 400V DC power paths were designed with 2N redundancy. The site contains primary and secondary switchgear. The primary switchgear accepts 400VAC input from both the utility and backup generators, and feeds the 400V DC power systems, the secondary switchgear, and auxiliary AC-powered equipment. The secondary switchgear powers the site’s AC UPS systems and provides a maintenance bypass path for the UPS. Fig. 7. One of two 400V DC power systems initially installed in data center. 8 The 400V DC power systems are connected to strings of (28) 12V batteries, for 336V nominal and 378V float bus voltage. Remote distribution cabinets provide power distribution to circuits for both the AC and 400V DC power integrated side by side. AC and 400V DC power are distributed to IT racks, shown in Fig. 8., that contain an AC power strip on one side and a 400V DC power strip on the other. Both AC-input and 400VDC-input IT equipment may be used in the same rack, although individual servers accept either AC or 400V DC input, not both. The 400V DC equipment loads include servers from both HP and Cisco, as seen in Fig. 9. The cooling, lighting, and other auxiliary loads are powered off of the AC infrastructure. Fig. 9. Cisco 400VDC-powered server. For the 400V DC distribution, the site implemented an IT earthing topology, also referred to as high resistance mid-point grounding (HRMG). This grounding scheme, which inserts high impedance resistors between each pole and ground, is recommended for data center applications to enhance continuity of service [5]. In this approach, a single line-toground fault does not result in disruption of service and allows equipment to continue operating while the fault is identified. IV. CASE STUDY 3 A. Background An African telecommunications provider has a large network of telecom central offices which use primarily -48VDC-powered equipment. As the telecom operator continues to expand its operations, however, the distribution cabling and support infrastructure for -48V DC power has proved problematic at times. C. Results Initial equipment loads include approximately 80kW of AC power load and 30kW of 400VDC-powered loads. The AC and 400V DC power paths are being monitored to assess their respective power consumption, energy efficiency, and performance. Near future expansion plans call for 120-240kW of 400V DC powered loads and 300kW of AC-powered loads. The data center plans for an eventual total capacity of 1.5MW. The 400V DC power systems were chosen in part for their ability to expand in increments from small sub-100kW loads to much larger capacity. The company also plans to install up to 200kW of solar PV power at the data center site in the future. The telecom operator wanted to replace aging, inefficient -48V DC power systems and needed to expand the equipment in one of its central offices in South Africa. The building was set up with a power room with -48V DC power systems and batteries on the ground floor and -48V DC networking equipment on the floors above. Because of space constraints, many of the -48V DC distribution cables from the power plants to the remote distribution cabinets (RDCs) were run outside of the building. Expanding the -48V DC distribution would have been expensive and posed additional cable routing and support infrastructure challenges. The operator wanted to use a centralized power plant and batteries for ease of maintenance and separation of batteries from critical networking equipment. In order to upgrade this existing site, the telecom operator made the decision to replace the -48V DC power systems with a centralized 400V DC power system, and convert 400V DC to -48V DC near the equipment loads. This would alleviate the significant cable management issues existing in the -48V DC distribution, reduce expansion costs, and allow the use of existing equipment in their -48V DC core site. B. Solution The goal of this site was to minimize the copper required for long cable runs between the power room and equipment floors, while enabling the use of existing -48V DC powered equipment and RDCs. An additional benefit is to future proof for potential transition to 400VDC- powered loads. The site currently supports approximately 80kW of load, with 2N power distribution. Initially, two 120kW 400V DC power systems will be installed in an A + B configuration to support up to 2000A of -48V DC end loads. Each power system is comprised of eight 15kW modular rectifiers. The systems could be expanded further in the future with additional Fig. 8. IT rack with AC power strip on one side and 400V DC power strip on the other side. 9 power bays. Four 336V battery strings each made up of 28 12V cells will be connected to each power system to provide up to four hours of back up time in the event of AC grid failure. Both the 400V DC power systems and batteries will be located on the second floor in the power room, shown in Fig. 10. Each 400V DC power system contains a distribution section with 400VDC-rated circuit breakers. The distribution breakers will be connected to cabling that runs to 400VDC/-48VDC conversion systems located on the first floor of the building. These distribution cable lengths vary up to 77 meters. The 400VDC/-48VDC conversion systems will be located on the same floor as the -48V DC equipment loads. This enables the distribution of 400V DC power over long cable runs while allowing the use of existing -48VDC-powered equipment. The converter systems utilize 3.5kW converter modules, with peak efficiency of 97%. Each converter system has a maximum capacity of 105kW of -48V DC output per bay. In the initial site design, two converter systems will be populated with conversion capacity of 91kW and 56kW, respectively. Although typically mounted in an open relay rack, the 400VDC/-48VDC converter systems will be integrated into data center racks in accordance with the user’s preference, as shown in Fig. 11. -48V DC power will be distributed from the conversion systems via bulk 600A outputs that connect to -48V DC RDCs. These RDCs will distribute 48V DC to the -48V DC equipment loads via cabling. Fig. 10. Telecom power room with A+B layout. Initial 400V DC power systems in light blue; future expansion 400V DC power systems in pink; battery strings in blue. C. Results As of this writing, the installation on site is pending. Prior to making a decision, a comparison was performed to assess the cost of equipment and installation of -48V DC power distribution versus 400V DC distribution with 400VDC/-48VDC conversion. Previous studies have shown the potential to decrease capital costs by 25% or more using 400V DC distribution to 400VDC/-48VDC conversion, but the exact savings are highly dependent on site layout [6]. The telecom operator made calculations based on preliminary estimates of a typical layout and included the cost of power systems, batteries, conversion systems, cabling, and installation. This assessment found an estimated 25% savings, at which point the operator decided to move forward with designing the site implementation. Once the specific site layout was finalized, calculations showed that the 400V DC solution reduced the required cabling from battery plants and power systems to the RDCs to approximately 3,500 meters from the 10,500 meters required for -48V DC power distribution. Fig. 11. 400VDC/-48VDC converter system mounted in data center rack, preparing for installation. The results of these commercial deployments demonstrate a number of key aspects of 400V DC power. Installations were completed with full safety certifications in Europe. No safety issues were experienced in the deployment or operation of the sites. The 400V DC infrastructure throughout the power chain was assembled from commercially available 400V DC equipment. The power distribution systems have demonstrated stability, without typical AC power issues of harmonics or phase/voltage balancing. All three sites have planned for potential future expansion of the 400V DC power through the use of modular, scalable 400V DC power systems. The first case study demonstrated straightforward integration of solar energy that was simpler than the use of an inverter with an AC power distribution topology. V. SUMMARY The above case studies reviewed 400V DC power implementation at three separate sites. Each case represented a unique combination of adoption drivers and installation architecture. Table 1 summarizes the different scenarios. 10 TABLE 1. SUMMARY OF CASE STUDY APPLICATIONS End User Typical Power Type Application Primary 400VDC Driver Power Distribution Grounding Bachmann Data center AC Power Elimination of conversion stages; integration of solar power 400V DC distribution to 400V DC loads; AC loads powered via inverters TN-S (negative pole ground) Scandinavian company Data Center AC Power Elimination of conversion stages Parallel power paths distributing both 400V DC and AC power IT (high resistance midpoint grounding) African telecom Telecom -48V DC Cable reduction: cost and cable management 400V DC distribution to 48VDC conversion and loads IT (high resistance midpoint grounding) REFERENCES VI. CONCLUSION This paper has detailed case studies of 400V DC power in a variety of applications covering both data center and telecom sites. In each application, 400V DC power delivers benefits compared to traditional power architectures, with different motivations for each site [7]. After years of trials, these commercial deployments in Europe and Africa demonstrate increasing maturity and acceptance of 400V DC power. As 400V DC compatible equipment availability continues to expand, the pace of commercial deployments is expected to accelerate [8]. ACKNOWLEDGMENT The authors would like to thank their former colleague, Marek Szpek, for his diligent work on all three 400V DC implementations in this paper and for his years of dedication to the study and advancement of 400V DC power. 11 [1] B. Wunder, L. Ott, M. Szpek, U. Boeke, R. Weis, “Energy efficient DCgrids for commercial buildings,” IEEE/Intelec Vancouver 2014. [2] ETSI EN 301 605 – Environmental Engineering (EE); Earthing and bonding of 400 VDC data and telecom (ICT) equipment. [3] http://www.future-thinking.de/startseite-drzp/preistraeger/ [4] G. Ailee, W. Tschudi, “Edison Redux: 380 Vdc brings reliability and efficiency to sustainable data centers”, IEEE Power and Energy Magazine, 2012, Volume 10, Issue 6. [5] K. Hirose, T. Tanaka, T. Babasaki, S. Person, O. Foucault, B. Sonnenberg, M. Szpek, “Grounding concept considerations and recommendations for 400VDC distribution system,” IEEE/Intelec 2011. [6] S. M. Lisy, B.J. Sonnenberg, J. Dolan, “Case study of deployment of 400V DC power with 400V/-48VDC conversion,” IEEE/Intelec Vancouver 2014. [7] M. Szpek, B.J. Sonnenberg, S. M. Lisy, “400VDC distribution architectures for central offices and data centers,” IEEE/Intelec Vancouver 2014. [8] D. Geary, D. Mohr, D. Owen, M. Salato, B.J. Sonnenber, “380V DC eco-system development present status and future challenges,” IEEE/Intelec Hamburg 2013.