ATEX Explosion Protection

advertisement

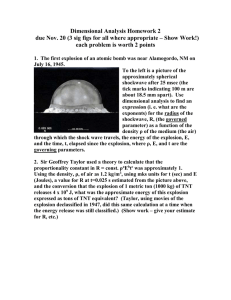

00_atex_U1_U4_200606_en.FH10 Tue Jul 11 13:27:40 2006 Seite 1 Overview July 2006 Explosion Protection (ATEX) Fundamentals low-voltage CONTROLS AND DISTRIBUTION The full range of Ex applications under control: ATEX (atmosphère explosive) Introduction In many industries, the manufacture, processing, transport, or storage of combustible materials results in the creation, or release into the surrounding environment, of gases, vapors, or mist. Other processes create combustible dust. An explosive atmosphere can form in conjunction with the oxygen in the air, resulting in an explosion if ignited. Particularly in areas such as the chemical and petrochemical industries, the transport of crude oil and natural gas, the mining industry, milling (e.g. grain and granular solids) and many other branches of industry, this can result in serious injury to personnel and damage to equipment. To guarantee the highest possible level of safety in these areas, the legislatures of most countries have developed appropriate obligations in the form of laws, regulations and standards. In the course of globalization, it has been possible to make significant progress towards harmonizing guidelines for explosion protection. With the Directive 94/9/EU the European Union creates the prerequisites for complete standardization because all new devices must be approved in accordance with this directive since July 1, 2003. The brochure "Explosion Protection Fundamentals" is designed to provide users and interested readers with an overview of explosion protection in conjunction with electrical equipment and systems. It also assists in decoding device labels. However, it does not replace intensive study of the relevant fundamentals and guidelines when planning and installing electrical systems. 2 Introduction Index Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Physical principles and parameters . . . . . . . . . . . . . 4 Classification of explosion-protected equipment . . . . . . . . . . . . . . . 8 Low-voltage product range for hazardous areas . 13 Further information . . . . . . . . . . . . . . . . . . . . . . . . . 20 Introduction 3 Physical fundamentals and parameters Explosion Primary and secondary explosion protection An explosion is the sudden chemical reaction of a combustible substance with oxygen, involving the release of high energy. Combustible substances can be present in the form of gases, mist, vapor, or dust. An explosion can only take place if the following three factors coincide: The principle of integrated explosion protection requires all explosion protection measures to be carried out in a defined order. A distinction is made here between primary and secondary protective measures. 1. Combustible substance (in the relevant distribution and concentration) Primary explosion protection covers all measures that prevent the formation of a potentially explosive atmosphere. 2. Oxygen (in the air) What protective measures can be taken to ensure that the risk of an explosion will be minimized? 3. Source of ignition (e.g. electrical spark) ■ Avoidance of combustible substances ■ Inerting (addition of nitrogen, carbon dioxide, etc.) ■ Limiting of the concentration ■ Improved ventilation Secondary explosion protection is required if the explosion hazard cannot be removed or can only be partially removed using primary explosion protection measures. Integrated explosion protection Oxygen EXPLOSION Combustible substances 4 Ignition source Physical fundamentals and parameters 1 Prevent the formation of potentially explosive atmospheres 2 Prevent the ignition of potentially explosive atmospheres 3 Restrict the effects of an explosion to a negligible level The consideration of technical safety parameters is necessary for the characterization of potential dangers: The explosion limits depend on the surrounding pressure and the proportion of oxygen in the air (see the table below). Flash point We refer to a deflagration, explosion, or detonation, depending on the speed of combustion. The flash point for flammable liquids specifies the lowest temperature at which a vapor-air mixture forms over the surface of the liquid that can be ignited by a separate source. If the flash point of such a flammable liquid is significantly above the maximum occurring temperatures, a potentially explosive atmosphere cannot form there. However, the flash point of a mixture of different liquids can also be lower than the flash point of the individual components. In technical regulations, flammable liquids are divided into four hazard classes: Hazard class Flash point AI < 21 °C AII 21 °C to 55 °C AIII > 55 °C to 100 °C B < 21 °C, soluble in water at 15 °C Explosion limits Combustible substances form a potentially explosive atmosphere when they are present within a certain range of concentration. If the concentration is too low (lean mixture) and if the concentration is too high (rich mixture) an explosion does not take place. Instead slow burning takes place, or no burning at all. Only in the area between the upper and the lower explosion limit does the mixture react explosively if ignited. A potentially explosive atmosphere is present if ignition represents a hazard for personnel or materials. A potentially explosive atmosphere, even one of low volume, can result in hazardous explosions in an enclosed space. Substance designation Lower explosion limit [Vol. %] Upper explosion limit [Vol. %] Acetylene 2.3 Ethylene Petrol Benzene Natural gas Heating oil/diesel Methane Propane Carbon bisulfide City gas Hydrogen 2.3 ~ 0.6 1.2 4.0 (7.0) ~ 0.6 4.4 1.7 0.6 4.0 (6.0) 4.0 78.0 (self-decomposing) 32.4 ~8 8 13.0 (17.0) ~ 6.5 16.5 10.9 60.0 30.0 (40.0) 77.0 Explosion limits of combustible substances 100 Vol.% Air concentration Mixture too lean: No combustion G Area subject to explosion 0 Vol.% Mixture too rich: Partial deflagration No explosion Explosion limit 0 Vol.% Concentration of combustible substance 100 Vol.% Physical fundamentals and parameters 5 Physical fundamentals and parameters Dust In industrial environments, e.g. in chemical factories or corn mills, solids are frequently encountered in fine form – e.g. as dust. Dust is defined in EN 50281-1-21) as "small solid particles in the atmosphere which are deposited because of their own weight, but which still remain in the atmosphere for a period of time as a dust/air mixture". Deposits of dust are comparable with a porous body, and have a hollow space of up to 90 %. If the temperature of dust deposits is increased, the result may be spontaneous ignition of the combustible dust. If dust deposits with a small grain size are whirled up, there is a danger of explosion. This increases as the size is reduced, since the surface area of the hollow space becomes larger. Dust explosions are frequently the result of whirled up glowing layers of dust which possess the basis for ignition. Explosions of gas or vapor mixtures with air can whirl up dust where the gas explosion then merges into a dust explosion. In collieries, explosions of methane gas frequently lead to explosions of coal dust whose effect was often greater than that of the gas explosion. 1) Parallel to DIN 50281 there is already EN 61241-1. 6 Physical fundamentals and parameters The danger of an explosion is prevented by using explosionproof devices according to their suitability. The identification of the device category reflects the efficiency of explosion protection, and thus the application in corresponding hazardous areas. The danger of explosive dust atmospheres and the selection of appropriate protective measures are assessed using safety parameters for the involved substances. Dusts are considered according to two substance-specific properties: ■ Conductivity Dusts are referred to as conductive if they have a specific electric resistance up to 103 Ohmmeter. ■ Combustibility Combustible dusts can burn or glow in air, and form explosive mixtures with air at atmospheric pressure and at temperatures from – 20 °C to + 60 °C. Safety parameters for whirled-up dusts are, for example, the minimum ignition energy and the ignition temperature, whereas for deposited dusts, the glow temperature is a characteristic property. Minimum ignition energy The application of a certain amount of energy is required to ignite a potentially explosive atmosphere. The minimum energy is taken to be the lowest possible converted energy, for example, the discharge of a capacitor, that will ignite the relevant flammable mixture. Minimum ignition energy (mJ) 1000 rare 100 The minimum energy lies between approximately 10-5 J for hydrogen, and several Joules for certain dusts. What can cause ignition? ■ Hot surfaces ■ Adiabatic compression ■ Ultrasound ■ Ionized radiation ■ Open flames ■ Chemical reaction ■ Optical radiation ■ Electromagnetic radiation ■ Electrostatic discharge ■ Sparks caused mechanically by friction or impact ■ Electrical sparks and arcs Welding sparks, sheaf of impact sparks in mills Sheaf of grinding sparks 10 1 rare rare electrostatic discharges, impact sparks 0.1 0.01 Gases Dusts Practice-oriented ignition source Physical fundamentals and parameters 7 Classification of explosion-proof equipment Identification The identification of electrical equipment for hazardous areas should permit recognition of: ■ The vendor of the equipment ■ A designation by which it can be identified ■ The area of use ■ - Below ground I - Other areas II Gases and vapors - G -, dusts - D - or mines - M -, ■ The categories which indicate whether the device can be used for particular zones, Example ■ The type(s) of protection with which the equipment complies, ■ The testing agency which provided the test certificate, the standard (or its release version) with which the equipment complies – including the testing agency’s registration number of the certificate and, if necessary, any special conditions which have to be observed. ■ In addition, the data should be provided which are usually required for such a device of industrial design. Meaning > 0032 II 2D IP65 T 80°C Temperature range Housing protection class Ex protection zone Named agency for certification of the QA system according to directive 94/9/EC Conformity symbol Example of identification according to directive 94/9/EC Example Meaning EXAMPLE COMPANY type 07-5103-.../... Identification of vendor and type Manufactured according to EN 61241-.-. Protected by enclosure, IP65 degree of protection Max. surface temperature + 80 °C Ex II 2D IP65 T 80°C IBExU 00 ATEX 1081 Consecutive number of testing agency ATEX generation Year of test Symbol of testing agency Example of a device identification 8 Classification of explosion-proof equipment Device groups/categories Zones Devices are classified into device groups: Areas subject to explosion hazard are divided into zones. Division into zones depends on the chronological and geographical probability of the presence of a hazardous, potentially explosive atmosphere. ■ Device group I - in underground operations - in mines as well as open-cast operations - and their surface installations ■ Information and specifications for zone subdivision can be found in EN/IEC 60079-10. Device group II - Devices for use in the other areas Each device group contains equipment that is in turn assigned to different categories (Directive 94/9/EC). The category specifies the zone in which the equipment may be used. Device group Device category Zone I Mining Mine gas and/or flammable dusts M = Mining M1 M2 --- II Other areas Potentially explosive atmosphere G = Gas 1G 2G 3G 0, 1, 2 1, 2 2 D = Dust 1D 2D 3D 20, 21, 22 21, 22 22 Explanation of the device categories: M 1, 1 G, 1D Extremely high level of safety = device safety must be guaranteed even in the case of rare device faults, e.g. simultaneous fault in two devices. M 2, 2 G, 2D High level of safety = device safety must be guaranteed in the case of frequent device faults, e.g. fault in one device. 3 G, 3D Normal level of safety = device safety must be guaranteed in the case of fault-free operation. Explanation of the zones: 0, 20 It is to be expected that a hazardous, potentially explosive atmosphere will occur continuously, often and over extended periods. 1, 21 It is to be expected that a hazardous, potentially explosive atmosphere will only occur occasionally. 2, 22 It is to be expected that a hazardous, potentially explosive atmosphere will occur only rarely and then only for a short period. Connection between device group, device category and zone Many low-voltage controlgear and switching devices, e.g. overload relays and motor starter protectors are intended for switching and controlling equipment in explosive atmospheres while being positioned outside. These devices are labeled with the category of the equipment to be protected. The category, however, is written in round brackets, e.g.: Ex II (2) GD Classification of explosion-proof equipment 9 Classification of explosion-protected equipment Types of protection The protection types are design measures and electrical measures carried out on the equipment to achieve explosion protection in the areas subject to explosion hazard. Protection types are secondary explosion protection measures. The scope of the secondary explosion protection measures depends on the probability of the occurrence of a hazardous, potentially explosive atmosphere. Electrical equipment for areas subject to explosion hazard must comply with the general requirements of EN 60079-0 and the specific requirements for the relevant type of protection in which the equipment is listed. However, the type of protection "Protection by housing" does not refer to EN 60079-0, but to EN 61241-0. The types of protection listed on the following pages are significant in accordance with EN 60079-0. All types of protection are based on different protection concepts. Gases – Types of protection Type of L = Label protection Schematic representation General requirements Increased safety Application in zone Basic principle Standard Examples 1 2 ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ General requirements for the type and EN 60079-0 testing of electrical equipment intended for the Ex area. Applies only to equipment, or its component parts, that normally does not create sparks or arcs, does not attain hazardous temperatures, and whose mains voltage does not exceed 1 kV. EN 60079-7 IEC 60079-7 FM 3600 UL 2279 REPG Terminals, connection boxes Flamed proof enclosure If an explosion occurs inside the enclosure, the housing will withstand the pressure and the explosion will not be propagated outside the enclosure. EN 60079-1 IEC 60079-1 FM 3600 UL 2279 REPG Switchgear, transformers Pressurp ized enclosure The ignition source is surrounded by a pressurized (minimum 0.5 mbar) protective gas – the surrounding atmosphere cannot enter. EN 60079-2 IEC 60079-2 FM 3620 NFPA 496 Control cabinets, switching cabinets Intrinsic safety By limiting the energy in the circuit, the for- EN 50020 mation of impermissibly high temperatures IEC 60079-11 sparks, or arcs is prevented. FM 3610 UL 2279 REPG Actuators, sensors, PROFIBUS DP RS 485-iS Oil o immersion Equipment or equipment parts are imEN 50015 mersed in oil and thus separated from the IEC 60079-6 Ex atmosphere. FM 3600 UL 2279 REPG Transformers, switchgear Sand filling q Ignition source is buried in sand. The Ex EN 50017 atmosphere surrounding the housing can- IEC 60079-5 not be ignited by an arc. FM 3600 UL 2279 REPG Heater strips, capacitors Molding m By embedding the ignition source in a molding, it cannot ignite the Ex atmosphere. Sensors, switchgear e i Protection n types 10 0 Zone 2: This protection type comprises several types of protection EN 60079-18 IEC 60079-18 FM 3600 UL 2279 REPG Slightly simplified application of the other EN 60079-15 Zone-2 protection types – "n" stands for IEC 60079-15 "non-igniting". Classification of explosion-proof equipment Programmable controllers ■ Dusts – Types of protection Application in zone Type of protection Label Basic principle Pressurized enclosure pD Molding mD Standard Examples 20 21 22 The penetration of a surrounding atmosphere into the en- EN 502811) closure of electrical equipment is prevented in that a pro- IEC 61241 tective gas (air, inert gas or other suitable gas) is kept within the enclosure at a pressure higher than the surrounding atmosphere. Equipment where sparks, arcs or hot components occur in normal operation ■ ■ ■ Parts which could ignite an explosive atmosphere through EN 502811) sparks or warming-up are potted in a casting compound IEC 61241 such that the explosive atmosphere cannot ignite. This is achieved by surrounding the components on all sides by a casting compound which is resistant to physical (in particular electrical, thermal and mechanical) and chemical influences. Large machines, slipring or collector motors, switchgear and control cabinets ■ ■ ■ Protection by enclosure tD The enclosure is sealed so tight that no combustible dust EN 502811) can penetrate into it. The surface temperature of the exter- IEC 61241 nal enclosure is limited. Measuring and monitoring systems ■ ■ ■ Intrinsic safety iaD, ibD Current and voltage are limited such that intrinsic safety is EN 502811) guaranteed. No sparks or thermal effects can ignite a IEC 61241 dust/air mixture. Sensors and actuators ■ ■ ■ Explosion groups Determination of explosion group In the explosion groups, a distinction is first made between equipment of Group I and of Group II: A gas is present both inside and outside a flame-proof enclosure. The gas inside the explosion chamber is ignited. Electrical equipment of Group I is used for mines subject to fire-damp. Result: If an ignition inside the explosion chamber is not transferred through the gap of defined width to the outside, the explosion group has been determined. A further division into explosion groups is made for the electrical equipment of Group II. The division depends on the spark ignition capability through a gap of defined width and length (according to EN 60079-14). Gap length Explosion chamber Electrical equipment with approval for explosion group IIC may also be used in explosion groups IIA and IIB. Explosion group Use Group I Electrical equipment for mines subject to fire-damp ==> fire-damp protection EEx...I Group II Electrical equipment for all other areas subject to explosion hazard ==> explosion protection EEx...II Gap width1) Potentially explosive atmosphere 1) 2) Explosion group Gap width limits for flameproof enclosure2) IIA > 0.9 mm IIB 0.5 mm to 0.9 mm IIC < 0.5 mm Degree of hazard Equipment requirements low Parallel to DIN 50281 there is already EN 61241-1. The gap width limit is the width between two 25-mm long, parallel flange surfaces of an explosion chamber. low high high Classification of explosion-proof equipment 11 Classification of explosion-protected equipment Temperature classes The ignition temperature of flammable gases or a flammable liquid is the lowest temperature of a heated surface at which the gas/air or vapor/air mixture ignites. Thus the highest surface temperature of any equipment must always be less than the ignition temperature of the surrounding atmosphere. Temperature classes T1 to T6 have been introduced for electrical equipment of Explosion Group II. Equipment is assigned to each temperature class according to its maximum surface temperature. Equipment that corresponds to a higher temperature class can also be used for applications with a lower temperature class. Explosion group Temperature classes I Methane II A T1 Flammable gases and vapors are assigned to the relevant temperature class according to ignition temperature. Temperature class Maximum upper surface temperature of the equipment Ignition temperatures of combustible substances T1 450 °C > 450 °C T2 300 °C > 300 °C T3 200 °C > 200 °C T4 135 °C > 135 °C T5 100 °C > 100 °C T6 85 °C > 85 °C T2 T3 T4 Acetone Ethane Ethylacetate Ammonia Benzene (pure) Ethanoic acid Carbon monoxide Carbon oxide Methane Methanol Propane Toluol Ethyl alcohol i-amyl acetate n-butane n-butylalcohol Petrol Diesel fuel Aircraft fuel Heating oils n-hexane Acetylaldehyde Ethylether II B City gas (illuminating gas) Ethylene II C Hydrogen Acetylene Classification of gases and vapors into explosion groups and temperature classes 12 Classification of explosion-proof equipment T5 T6 Carbon bisulfide Product range of Low-voltage controls and distribution for potentially explosive areas Systems AS-Interface – consistent system, superior strategy As a cost-effective and robust bus system at field level, AS-Interface connects – open and manufacturer-independent – actuators and sensors to control – for standard as well as safety applications. A serial field bus connects all automatization components easily, safely and consistently. The ATEX-certified K60 compact modules make the application of AS-Interface possible even in potentially explosive areas. Type Digital I/O modules IP67 – K60 Series Certificate number 3RK1 400-1DQ05-0AA3, K60 3RK1 200-0CQ05-0AA3 ATEX 2705 Certification based on Type of protection/ Identification EN 60947-5-2, Ex II (3) D X EN 50281-1-1 You can find further information on this product in Catalog LV 1 and in Catalog Technical Information LV 1 T in chapter 2. Low-voltage controls and distribution for potentially explosive areas 13 Product range of Low-voltage controls and distribution for potentially explosive areas Protecting1) SIRIUS motor starter protectors for motor protection 3RV motor starter protectors are compact, current limiting motor starter protectors. They guarantee safe disconnection in the event of a short circuit and protect consumers and plants from overload. Moreover, they are suitable for normal switching of loads with low switching frequency as well as for the safe disconnection of the plant from the mains during maintenance or changes. SIRIUS 3RV is the only universal product family on the market for motor starter protectors up to 100 A. Motor starter protectors for motor protection Type Size Certificate number Certification based on 3RV10 11 S00 3RV10 21 S0 DMT 02 ATEX F 001, IEC 60947-4-1, DMT 02 ATEX F 001 N1 EN 60079-14 3RV10 31 S2 3RV10 41 S3 3RV10 42 S3 Type of protection/ Identification Ex II (2) GD You can find further information on this product in Catalog LV 1 and in Catalog Technical Information LV 1 T in chapter 5. 1) Information for the implementation of current monitoring motor protection devices. Definition of the locked-rotor time tE: if the rotor of an explosion-protected three-phase AC motor of protection type "Increased Safety" EEx e stalls (locks) at operating temperature during runtime, the motor must be switched off, at the very latest, when either the rotor or the stator winding have reached their maximum temperature. The time that elapses until the rotor or stator winding has reached maximum temperature is called the locked-rotor time tE or tE time. The demands made on overload protective devices with regard to tE time: for tripping devices and relays with inverse time-delay operation, tripping characteristics must be available at the operating site. The characteristics should show the release time for 3-pole loading, assuming a cold state and a room temperature of 20 °C, depending on at least a 3 - 8-fold setting current. The protective devices must comply with the specified release times with a permissible deviation of ± 20 %. The tripping devices and relays for machines with cage rotors must be selected such that the release times for 3-pole loading do not exceed the lockedrotor time tE specified on the type plate. For information on the tripping characteristics of our circuit-breakers and overload relays, visit our web site at: www.siemens.com/lowvoltage/manuals 14 Low-voltage controls and distribution for potentially explosive areas Protecting1) (continued) SIRIUS 3RB2 and 3RU1 overload relays SIRIUS overload relays, which are available as solid-state (3RB2) and thermal (3RU1) versions, are designed for the inverse-time delayed protection from overload in the main circuit. This includes all electrical loads – as well as all other relevant switching and protection devices in the respective load feeder. The overload relays are certified according to ATEX and thus suitable for motors with "increased safety" type of protection EEx e. 3RB20, 3RB21 3RU11 Type Size Certificate number Certification based on Type of protection/ Identification for standard applications 3RB20, 3RB21 EN 60079-14, IEC 60947-4-1, IEC 61508 Ex II (2) GD 3RB22, 3RB29 S00 to S12 PTB 06 ATEX 3001 for High-Feature applications 3RU11 1 S00 3RU11 2 S0 DMT 98 ATEX G 001, IEC 60079-14, DMT 98 ATEX G 001 N1 EN 60079-14 3RU11 3 S2 3RU11 4 S3 3RB solid-state overload relays PTB 05 ATEX 3022 3RU1 thermal overload relays for standard applications Ex II (2) GD You can find further information on this product in Catalog LV 1 and in Catalog Technical Information LV 1 T in chapter 5. 1) Information for the implementation of current monitoring motor protection devices. Definition of the locked-rotor time tE: if the rotor of an explosion-protected three-phase AC motor of protection type "Increased Safety" EEx e stalls (locks) at operating temperature during runtime, the motor must be switched off, at the very latest, when either the rotor or the stator winding have reached their maximum temperature. The time that elapses until the rotor or stator winding has reached maximum temperature is called the locked-rotor time tE or tE time. The demands made on overload protective devices with regard to tE time: for tripping devices and relays with inverse time-delay operation, tripping characteristics must be available at the operating site. The characteristics should show the release time for 3-pole loading, assuming a cold state and a room temperature of 20 °C, depending on at least a 3 - 8-fold setting current. The protective devices must comply with the specified release times with a permissible deviation of ± 20 %. The tripping devices and relays for machines with cage rotors must be selected such that the release times for 3-pole loading do not exceed the lockedrotor time tE specified on the type plate. For information on the tripping characteristics of our circuit-breakers and overload relays, visit our web site at: www.siemens.com/lowvoltage/manuals Low-voltage controls and distribution for potentially explosive areas 15 Product range of Low-voltage controls and distribution for potentially explosive areas Starting SIRIUS 3RW soft starters Soft starters offer you a complete spectrum covering all standard and High-Feature applications of motor starting. Thus the advantages of soft starting and smooth ramp-down for simple and economical realization of optimal machine concepts are available today for the most diverse applications. Soft starters for standard applications Type Size Certificate number Certification based on Type of protection/ Identification 3RW40 S6, S10/ S12 BVS 05 ATEX F 002 EN 60079-14, IEC 60947-4-2, IEC 61508 Ex II (2) GD You can find further information on this product in Catalog LV 1 and in Catalog Technical Information LV 1 T in chapter 6. 16 Low-voltage controls and distribution for potentially explosive areas Monitoring and control1) SIMOCODE pro 3UF7 motor management system The communication-capable, modularly designed SIMOCODE pro motor management system (SIRIUS Motor management and Control Devices) quickly and reliably protects motors of types of protection EEx e and EEx d in potentially explosive areas. SIMOCODE pro is certified according to the latest ATEX standards. The use of SIMOCODE pro also means that no time is lost because of periodically necessary function tests of feeders in the Ex area. SIMOCODE pro motor management and control devices Type Size Certificate number 3UF7 S00 to BVS 06 ATEX F 001 S12 Certification based on Type of protect./ Identification EN 60079-14, IEC 60947-4-1, IEC 61508 Ex I (M2), Ex II (2) GD You can find further information on this product in Catalog LV 1 and in Catalog Technical Information LV 1 T in chapter 7. SIRIUS 3RN1 thermistor motor protection relays for PTC sensors 3RN1 thermistor motor protection relays are advantageous wherever current-dependent protection by means of motor starter protectors or overload relays are not the ideal means of monitoring. In certain situations an overheating can occur often due to external influences. This overheating cannot be detected by the thermal image in the motor starter protector/overload relay. SIRIUS thermistor motor protection relays are certified for gases and dust according to ATEX. Type Width Certificate number Certification based on Type of protect./ Identification EN 60079-14, IEC 60947-8 Ex II (2) G mm Thermistor motor protection 3RN10 relays for PTC sensors 3RN10 11-.B, (PTCs Type A) 3RN10 11-.G, 3RN10 12-.B, 3RN10 12-.G, 3RN10 13-…0 22.5; 45 PTB 01 ATEX 3218 Ex II (2) GD You can find further information on this product in Catalog LV 1 and in Catalog Technical Information LV 1 T in chapter 7. 1) Information for the implementation of current monitoring motor protection devices. Definition of the locked-rotor time tE: if the rotor of an explosion-protected three-phase AC motor of protection type "Increased Safety" EEx e stalls (locks) at operating temperature during runtime, the motor must be switched off, at the very latest, when either the rotor or the stator winding have reached their maximum temperature. The time that elapses until the rotor or stator winding has reached maximum temperature is called the locked-rotor time tE or tE time. The demands made on overload protective devices with regard to tE time: for tripping devices and relays with inverse time-delay operation, tripping characteristics must be available at the operating site. The characteristics should show the release time for 3-pole loading, assuming a cold state and a room temperature of 20 °C, depending on at least a 3 - 8-fold setting current. The protective devices must comply with the specified release times with a permissible deviation of ± 20 %. The tripping devices and relays for machines with cage rotors must be selected such that the release times for 3-pole loading do not exceed the lockedrotor time tE specified on the type plate. For information on the tripping characteristics of our circuit-breakers and overload relays, visit our web site at: www.siemens.com/lowvoltage/manuals Low-voltage controls and distribution for potentially explosive areas 17 Product range of Low-voltage controls and distribution for potentially explosive areas Detection 3SE2 position switches Position switches are used wherever movable parts in plants and on machines have to be positioned, controlled and monitored. Whether for monitoring protection equipment with hinges or for monitoring laterally movable protection equipment or for detecting dangerous movements of machine parts – our devices can meet practically all industrial requirements. Type Width Certificate number Certification based on Type of protection/ Identification mm Position switches 3SE2 100-.....-0AE0 56 3SE2 120-.....-0AE0 40 ATEX 2603a EN 50281-1, EN 50014 Ex II 3D You can find further information on this product in Catalog LV 1 and in Catalog Technical Information LV 1 T in chapter 8. 18 Low-voltage controls and distribution for potentially explosive areas Commanding and signaling 3SB3 commanding and signaling devices Commanding and signaling devices make sure that the conditions of machines and plants (e.g. sources of error or disturbances) are being signaled in time and reliably and that machines and plants are being controlled and brought to a safe condition in case of an emergency. Part of our extensive product range are actuators and switch blocks as well as lampholders with LED which are called simple electrical apparatus in compliance with ATEX directive 94/9/EG thus being suitable for application in intrinsic circuits. Type Version Certificate number Certification based on Type of protection Actuator 3SB30 .. 3SB35 .. Plastic or metal actuator Contact block 3SB34 .. ATEX 2690b Simple electrical apparatus in compliance Spring-loaded with EN 50020, terminals or screw IEC 60947-5-1 connection Application only in circuits of type of protection i (Intrinsic safety) acc. to EN 50020 Spring-loaded ATEX 2689b Simple electriterminals or screw cal apparatus in connection compliance with EN 50020, Rated voltage IEC 60947-5-1 24 V AC/DC, BA 9s base Application only in circuits of type of protection i (Intrinsic safety) acc. to EN 50020 Application up to a voltage of 26,4 V (LEDs) Actuating elements Components for actuating elements Lampholder 3SB34 ..-1A LED 3SB39 01-1.A You can find further information on this product in Catalog LV 1 and in Catalog Technical Information LV 1 T in chapter 9. Visit us on the Internet: www.siemens.com/lowvoltage/atex Test certificates can be found under www.siemens.com/automation/support Low-voltage controls and distribution for potentially explosive areas 19 00_atex_U1_U4_200606_en.FH10 Tue Jul 11 13:27:40 2006 Seite 2 Further information Literature European Parliament and Council Directive 94/9/EC of 23 March 1994 on the forthcoming legislation for Member States on protective devices and systems for use in potentially explosive atmospheres Official Journal of the European Communities, No. L 100/1 DIN VDE 0170/0171 Part 1 ff. Electrical apparatus for potentially explosive atmospheres DIN VDE 0470 Part 1 (EN 60529) IP degree of protection; protection of persons against access to hazardous parts and of electrical equipment against ingress of solid foreign objects and harmful quantities of water DIN VDE 0165/02.91 Installation of electrical apparatus in potentially explosive areas DIN EN 60079-14 VDE 0165 Part 1:2004-07 Electrical apparatus for potentially explosive gas atmospheres Electrical installations in hazardous areas (other than mines) VDE-Verlag GmbH, Berlin NFPA 70 - 1996 National Electrical Code, Ausgabe 1996 National Fire Protection Association, Quincy, MA, USA NFPA 70 - 1999 National Electrical Code, Ausgabe 1999 National Fire Protection Association, Quincy, MA, USA 1998 Canadian Electrical Code, 18. Ausgabe Canadian Standards Association, Etobicoke, ON, Canada 1996 National Electrical Code Review and Application Guide Killark Electric Manufacturing Company, St. Louis, MO, USA 1998 Canadian Electrical Code Review and Application Guide Hubbell Canada Inc. - Killark, Pickering, ON, Canada Publication Explosionsschutz - Grundlagen R. STAHL SCHALTGERÄTE GMBH, Waldenburg www.siemens.com/lowvoltage Siemens AG Automation and Drives Low-Voltage Controls and Distribution Postfach 48 48 90327 NÜRNBERG GERMANY w w w. si e m e n s .c o m/ a uto ma t i o n The information provided in this brochure contains descriptions or characteristics of performance which in case of actual use do not always apply as described or which may change as a result of further development of the products. An obligation to provide the respective characteristics shall only exist if expressly agreed in the terms of contract. Availability and technical specifications are subject to change without notice. All product designations may be trademarks or product names of Siemens AG or supplier companies whose use by third parties for their own purposes could violate the rights of the owners. Order No. E86060-T1811-A101-A1-7600 Token fee: 0,00 Subject to change without prior notice | Dispo 27602 | KB 0706 2. ROT 20 En / 603057 | Printed in Germany | © Siemens AG 2006 K. Nabert and G. Schön: Sicherheitstechnische Kennzahlen brennbarer Gase und Dämpfe (Safety characteristics of flammable gases and vapors) Deutscher Eichverlag, Braunschweig