Power system protection

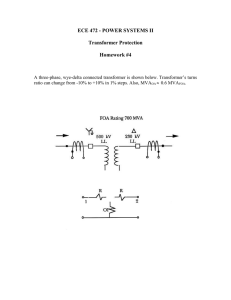

advertisement