Assessment Procedure and Criteria for Determining Suitability of

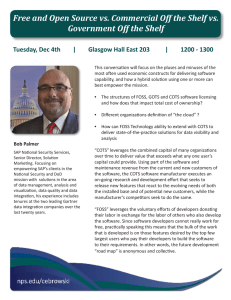

advertisement