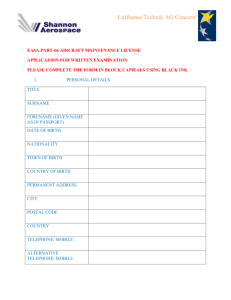

- Lufthansa Technik AG

advertisement