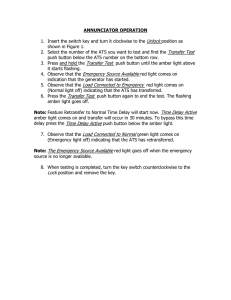

ATS with Power Distribution

advertisement