Data Sheets - RectorSeal

advertisement

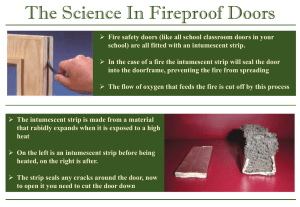

Firestopping http://flamesafe.rectorseal.com P R O D U C T I N F O R M A T I O N FlameSafe Intumescent Wrap Strips and Devices ® Resilient Strip to Firestop Combustible Penetrants Benefits • Underwriters Laboratories classified • L isted in systems with up to 3 hour fire rating • T ested to UL 1479 (ASTM E814) • Highly flexible and resilient • 1 in. (25.4 mm) and 1.5 in. (38 mm) widths • Easy to use, cut and fabricate • Rapid expansion • W ater resistant • 12 ft (3.65 m) rolls Description The FlameSafe®Intumescent Wrap Strip (FSWS) is a highly flexible, resilient strip designed to firestop combustible penetrants in fire-rated walls and floors. Highly intumescent, the FSWS rapidly expands to form a dense char to prevent the spread of fire, FlameSafe Intumescent Wrap Strip smoke and toxic gasses when exposed to temperatures in excess of 250°F (121°C). The FSWS continues to expand up to 1000°F (538°C). Available in 12 ft (3.65 m) rolls, the FSWS is easy to cut and fabricate to match the circumference of the penetrant. Physical Properties FSW S 100 FSW S 150 Weight 1.4 lbs (0.64 kg) 12 ft (3.65 m) roll 2.9 lbs (1.3 kg) 12 ft (3.65 m) roll Dimensions 12 ft x 1 in. x 0.25 in. (3.65 m x 25.4 mm x 6 mm) 12 ft x 1.5 in. x 0.25 in. (3.65 m x 38 mm x 6 mm) Application The FlameSafe Intumescent Wrap Strip is used in conjunction with sealant as a “tuck-in” system or a restraining collar to firestop combustible penetrants such as PVC, cc-PVC, CPVC, FRPP, cc-ABS and ABS pipe, as well as insulated pipe. It has been tested and approved for use in concrete floor/wall, gypsum wall, as well as wood joist and wood chase wall floor/ceiling assemblies. Applications where annular space is restricted may require the use of the FlameSafe Restraining Collar with the wrap strip. Application Guide Penetrations Metallic Non-metallic Installation Installation temperature should be between 40°F to 90°F (4°C to 32°C). Wrap a layer of the FSWS, cut to size around the penetrant and hold in place with masking tape. Refer to the appropriate UL approved system for specific application requirements. Once the wrap strip is in place, the system may require caulk, such as FlameSafe FS 1900 Sealant, to ensure a tight smoke seal. The FSWS is available in two sizes: If system requires multiple wrap 12 ft x 1 in. x 0.25 in. (3.65 m x strips, overlay layers of wrap 25.4 mm x 6 mm) and 12 ft x strip on top of each other. 1.5 in. x .25 in. (3.65 m x 38 mm If system requires a FlameSafe x 6 mm). The FlameSafe Restraining Collar (minimum 28 gauge) measure and calculate Restraining Collar is available in the required length of restraining 25 ft (7.6 m) rolls in 1 in. or 1.5 in. (25.4 mm or 38 mm) widths. collar to completely cover the outer diameter of the wrap strip installed, plus an additional 1 in. Pre-Assembled Devices (25.4 mm) overlap. Place collar The Wrap Strip Device (FSWSD) around the wrap strip and secure is a pre-assembled wrap strip and with the appropriate steel restraining collar which is used to anchors, toggle bolts or screws. firestop combustible penetrants X Cables B Cable trays Insulated A. FlameSafe Restraining Collar B. Max. 5 in. (127 mm) or smaller non-metallic pipe C. FSWS Wrap Strip X Misc. electrical HVAC Mixed X A Joints C Perimeter Barrier (Curtain Wall) Application Standards The FlameSafe FSWS is classified by Underwriters Laboratories Inc. and Underwriters’ Laboratories of Canada for 1, 2 and 3 hour rated systems in accordance with ASTM E814 (UL 1479/CAN4S115M), “Fire Tests of ThroughPenetration Firestops.” It is Factory Mutual approved and accepted by the City of New York (MEA 189-99-M Vol. II). *See note A B C D *See note A. FlameSafe FS 1900 Sealant applied in a 0.25 in. (6 mm) bead at floor surface or both wall surfaces B. Min. 4.5 in. (114 mm) concrete floor/wall or block wall C. FlameSafe FSWS 150 Wrap Strip and Restraining Collar installed securely to ceiling or both wall surfaces with steel anchors D. Max. 5 in. (127 mm) or smaller rigid non-metallic conduit, PVC or ABS piping as an open (vented) or closed system Concrete Floor/Wall – 3 Hour (UL C-AJ-2212) *Refer to UL designs for full system description. Firestops.” It has been tested and approved for use in concrete floor/wall, concrete block/CMU wall, gypsum wallboard and wood joist and wood chase floor/ceiling assemblies. It is available for pipe sizes 1.5 in. to 6 in. (38 mm to 152.4 mm) and in both 1 in. and 1.5 in. (25.4 mm and 38 mm) widths. FlameSafe Wrap Strip (FSWS), Restraining Collars (FSRC) and Devices (FSWSD) such as PVC, cc-PVC, CPVC, FRPP, ABS and cc-ABS pipe. It is especially useful for applications where annular space is restricted. The collar device is highly intumescent and rapidly forms a dense char to prevent the spread A B C D * Se e n o t e of fire, smoke and toxic gasses when exposed to temperatures in excess of 250°F (121ºC). The FSWSD is listed by Underwriters Laboratories Inc. in accordance with ASTM E814 (UL 1479), “Fire Tests of Through-Penetration A. One or two layers of Type X gypsum wallboard for a 1 or 2 hr rating respectively B. Install one layer of FlameSafe FSWS 150 Wrap Strip around penetrant C. Max. 3 in. (76 mm) or smaller rigid non-metallic conduit, PVC, cc-PVC, CPVC, piping as an open (vented) or closed system D. FlameSafe FS 1900 Sealant applied into annular space 0.625 in. (16 mm) deep Gypsum Wallboard – 1 and 2 Hour (W-L-2168) A Maintenance Applications using FlameSafe Intumescent Wrap Strip and the FlameSafe Restraining Collar are maintenance free, however, installations should be inspected periodically for accidental damage and repaired as per the original approved design. Recommended storage temperatures for the FSWS should be between 40°F to 90°F (4°C to 32°C). B C D * Se e n o t e A. Min. 4.5 in. (114 mm) concrete floor or wall B. FlameSafe FS 1900 Sealant applied into annular space 0.75 in. (19 mm) deep with a 0.25 in. (6 mm) crown C. FlameSafe FSWS 150 Wrap Strip installed in two layers around penetrant D. Max. 3 in. (76 mm) or smaller rigid non-metallic conduit, PVC, CPVC, or ABS piping as an open (vented) or closed system Concrete Floor or Block Wall – 3 Hour (UL C-AJ-2201) A B C D E F G A. Max. 2 in. (50.8 mm) dia. or smaller rigid non-metallic conduit, ABS, PVC, or CPVC pipe as a closed or open (vented) system B. Min. 0.75 in. (19 mm) lumber or plywood subfloor Max. 3 in. (76 mm) opening C. FlameSafe FS 1900 Sealant Fill annular space and add 0.375 in. (10 mm) crown D. Nominal 2 in. x 10 in. (50.8 mm x 254 mm) lumber joists *See note Wood Joist Floor – 2 Hour (UL F-C-2084) *Refer to UL designs for full system description. E. FlameSafe Wrap Strip 1 layer 1 in. (25.4 mm) wide wrapped around penetrant and protruding 0.25 in. (6 mm) below ceiling surface F. One layer of Type X gypsum wallboard capable of providing a 1 hr rating or two layers capable of providing a 2 hr rating G. FlameSafe FS 1900 Sealant applied 0.625 in. (16 mm) into annular space with 0.375 in. (10 mm) crown at ceiling surface Availability FlameSafe Intumescent Wrap Strip and FlameSafe Restraining Collars are available through authorized RectorSeal distributors in the following quantities: De sc rip tio n Pa rt N o . Std . Pa c k We ig ht FSWS 100 Wrap Strip 12 ft x 1 in. x .25 in. (305 m x 25.4 mm x 6 mm) 66911 1 2.0 lbs (0.90 kg) FSWS 150 Wrap Strip 12 ft x 1.5 in. x .25 in. (305 m x 38 mm x 6 mm) 66912 1 2.4 lbs (1.1 kg) FSRC 100 Restraining Collar 25 ft x 1 in. (7.6 m x 25.4 mm) 66914 1 3.5 lbs (1.6 kg) FSRC 150 Restraining Collar 25 ft x 1.5 in. (7.6 m x 38 mm) 66915 1 4.0 lbs (1.8 kg) FSWSD 1-150 Device 1 in. x 1.5 in. (25.4 mm x 38 mm) 66941 1 .35 lb (0.16 kg) FSWSD 1-200 Device 1 in. x 2 in. (25.4 mm x 50.8 mm) 66942 1 .40 lb (0.18 kg) FSWSD 1-300 Device 1 in. x 3 in. (25.4 mm x 76 mm) 66943 1 .75 lb (0.34 kg) FSWSD 1-400 Device 1 in. x 4 in. (25.4 mm x 102 mm) 66944 1 1.2 lbs (0.54 kg) FSWSD 1.5-150 Device 1.5 in. x 1.5 in. (38 mm x 38 mm) 66951 1 .40 lb (0.18 kg) FSWSD 1.5-200 Device 1.5 in. x 2 in. (38 mm x 50.8 mm) 66952 1 .50 lb (0.23 kg) FSWSD 1.5-300 Device 1.5 in. x 3 in. (38 mm x 76 mm) 66953 1 .90 lb (0.41 kg) FSWSD 1.5-400 Device 1.5 in. x 4 in. (38 mm x 102 mm) 66954 1 1.4 lbs (0.64 kg) Warranty All statements, technical information and recommendations contained herein are based on tests we believe to be reliable. However, since the conditions of use and application are beyond our control, RectorSeal shall not be liable for any damage, direct or consequential, resulting from the use of this material or design. RectorSeal’s only warranty shall be to replace any of its products found to be defective. Technical Support RectorSeal provides technical support for all its products, including FlameSafe Intumescent Wrap Strip and the FlameSafe Restraining Collar. Call toll free at 800-231-3345 for assistance in product selection and for detailed specifications and approvals. We provide engineering analysis for unique firestopping applications, including system design drawings suitable for submittals. Material Safety Data Sheets are also available. More information is available at our web site, http://flamesafe.rectorseal.com. For Technical Assistance call toll free at 800-231-3345. Visit our web site at http://flamesafe.rectorseal.com RectorSeal 2601 Spenwick Dr Houston, Texas 77055 FlameSafe is a registered trademark of RectorSeal RectorSeal makes the Limited Express Warranty that when the instructions for storage and handling of our products are followed we warrant our products to be free from defects. THIS LIMITED EXPRESS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER EXPRESS OR IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, AND OF ANY OTHER OBLIGATION ON THE PART OF RECTORSEAL. The sole remedy for breach of the Limited Express Warranty shall be the refund of the purchase price. All other liability in negated and disclaimed, and RectorSeal shall not be liable for incidental or consequential damages. Suggestions and recommendations covering the use of our products are based on our past experience and laboratory findings. However, as we have no control as to the methods and conditions of application, we only assume responsibility for the uniformity of our products within manufacturing tolerances. These products may be covered by patents or patents pending. FS-220D Printed in USA Copyright 2009 RectorSeal 9/09 RECTORSEAL 2601 Spenwick Drive, Houston, Texas 77055 wwww.rectorseal.com