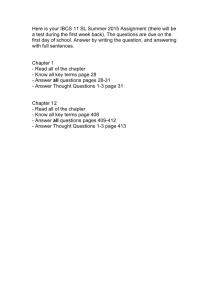

Phase II Final Report

advertisement