Superline

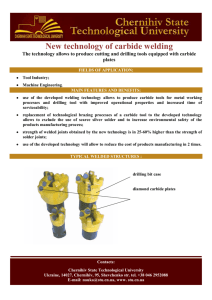

advertisement