Continental™ High Temp Catalog

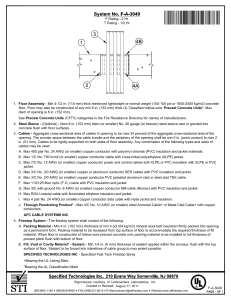

advertisement