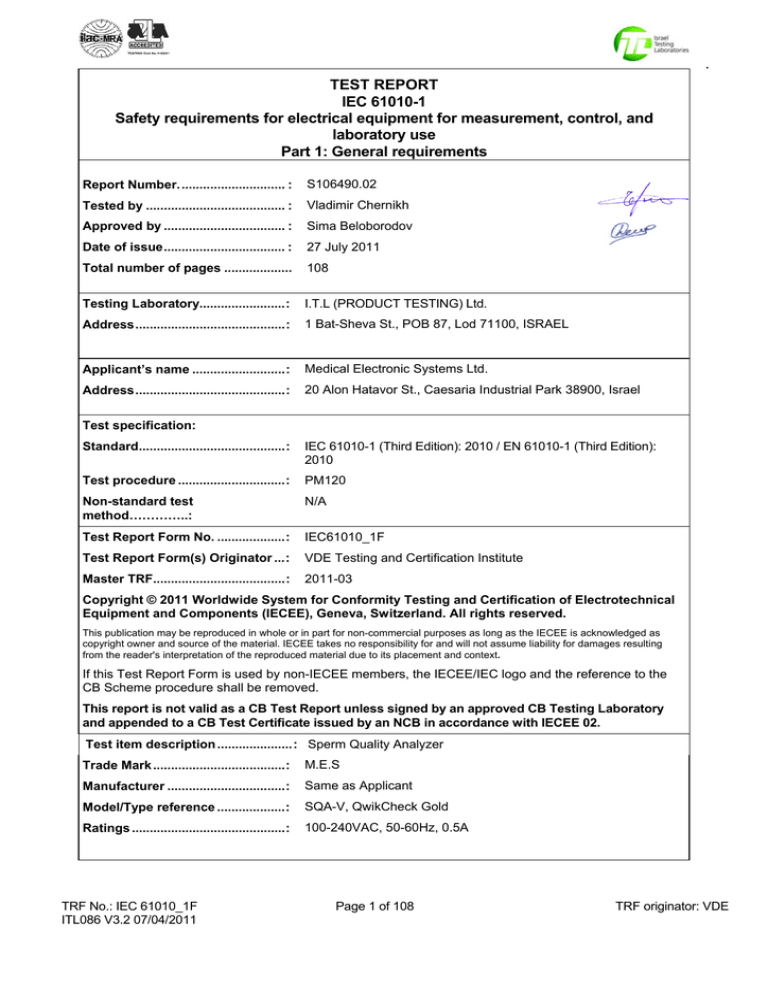

TEST REPORT

IEC 61010-1

Safety requirements for electrical equipment for measurement, control, and

laboratory use

Part 1: General requirements

Report Number. ............................. :

S106490.02

Tested by ....................................... :

Vladimir Chernikh

Approved by .................................. :

Sima Beloborodov

Date of issue.................................. :

27 July 2011

Total number of pages ...................

108

Testing Laboratory........................:

I.T.L (PRODUCT TESTING) Ltd.

Address..........................................:

1 Bat-Sheva St., POB 87, Lod 71100, ISRAEL

Applicant’s name ..........................:

Medical Electronic Systems Ltd.

Address..........................................:

20 Alon Hatavor St., Caesaria Industrial Park 38900, Israel

Test specification:

Standard.........................................:

IEC 61010-1 (Third Edition): 2010 / EN 61010-1 (Third Edition):

2010

Test procedure ..............................:

PM120

Non-standard test

method…………..:

N/A

Test Report Form No. ...................:

IEC61010_1F

Test Report Form(s) Originator ...:

VDE Testing and Certification Institute

Master TRF.....................................:

2011-03

Copyright © 2011 Worldwide System for Conformity Testing and Certification of Electrotechnical

Equipment and Components (IECEE), Geneva, Switzerland. All rights reserved.

This publication may be reproduced in whole or in part for non-commercial purposes as long as the IECEE is acknowledged as

copyright owner and source of the material. IECEE takes no responsibility for and will not assume liability for damages resulting

from the reader's interpretation of the reproduced material due to its placement and context.

If this Test Report Form is used by non-IECEE members, the IECEE/IEC logo and the reference to the

CB Scheme procedure shall be removed.

This report is not valid as a CB Test Report unless signed by an approved CB Testing Laboratory

and appended to a CB Test Certificate issued by an NCB in accordance with IECEE 02.

Test item description .....................: Sperm Quality Analyzer

Trade Mark .....................................:

M.E.S

Manufacturer .................................:

Same as Applicant

Model/Type reference ...................:

SQA-V, QwikCheck Gold

Ratings ...........................................:

100-240VAC, 50-60Hz, 0.5A

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 1 of 108

TRF originator: VDE

Report No. S106490.02

List of Attachments (including a total number of pages in each attachment - Table 1):

Document

No.

1

Documents included / attached to this report (description)

Page

Numbers

S106491.02 - IEC/EN 61010-2-101 test report

17

Test Report History:

This report may consist of more than one report and is valid only with additional or previous issued

reports:

Ref. No.

S106490.01, S106491.01

Original Report

S106490.02, S106491.02

Update report, adding model QwikCheck Gold

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Item

Page 2 of 108

TRF originator: VDE

Report No. S106490.02

Tests performed (name of test and test

clause):

Testing location:

ITL (Product Testing) Ltd.

1 Bat-Sheva St., POB 87, Lod 71100, ISRAEL

SQA-V:

4.4.2.3 Protective Conductor Abnormal

4.4.2.5 Motor Abnormal

4.4.2.10 Cooling Abnormal

5.1.3 Input Test

5.3 Marking Durability Test

6.3 Permissible Limits For Accessible Parts Test

6.5.2.4 Grounding Continuity Test

6.7.2.1 Clearances and Creepage Distances

6.8.3 Dielectric Strength Test

6.10.3 Capacitance Discharge Test

7.4 Stability Test

8.2.1, 8.2.2 Rigidity Test

9.4 Limited Energy Test

10.1-10.3 Temperature Test

10.5.2 Resistance To Heat Of Non-Metallic

Enclosure

QwikCheck Gold:

4.4.2.10 Cooling Abnormal

6.8.3 Dielectric Strength Test

7.4 Stability Test

8.2.1, 8.2.2 Rigidity Test

10.1-10.3 Temperature Test

10.5.2 Resistance To Heat Of Non-Metallic

Enclosure

Summary of compliance with National Differences

List of countries addressed: CH, DK, SE

Explanation of Codes:

CH=Switzerland, DK=Denmark, SE=Sweden

The product fulfils the requirements of _IEC/EN 61010-1:2010________

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 3 of 108

TRF originator: VDE

Report No. S106490.02

Copy of marking plate

The artwork below may be only a draft. The use of certification marks on a product must be

authorized by the respective NCBs that own these marks.

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 4 of 108

TRF originator: VDE

Report No. S106490.02

Test item particulars:

Type of item ................................................................. : Laboratory

Description of equipment function ............................... : Sperm Quality Analyzer

Connection to MAINS supply......................................... : Detachable cord set

Installation category ..................................................... : II

POLLUTION DEGREE ....................................................... : II

Protection class............................................................ : I

Environmental rating .................................................... : Standard

Equipment mobility....................................................... : Movable

Operating conditions.................................................... : Continuous

Overall size of equipment (W x D x H) ........................ : SQA-V: 32 x 30 x 24 cm

QwikCheck Gold: 32 x 24 x 20 cm

Mass of equipment (kg) ............................................... : SQA-V: 7kg

QwikCheck Gold: 4kg

Marked degree of protection to IEC 60529 ................. : IPX0

Possible test case verdicts:

- Test case does not apply to the test object ............... : N/A

- Test object does meet the requirement ..................... : P (Pass)

- Test object does not meet the requirement ............... : F (Fail)

Testing:

Date of receipt of test item............................................ : SQA-V: 04/04/2011

QwikCheck Gold: 21/07/2011

Date (s) of performance of tests................................... : SQA-V: 07/04/2011 to 29/06/2011

QwikCheck Gold: 25/07/2011 to 26/07/2011

General remarks:

The test results presented in this report relate only to the object tested.

This report shall not be reproduced, except in full, without the written approval of the Issuing testing

laboratory.

"(see ENCLOSURE #)" refers to additional information appended to the report.

"(see Form A.xx)" refers to a table appended to the report.

Throughout this report a

comma /

point is used as the decimal separator.

General product information:

The EUT is a mains powered sperm quality analyzer unit for laboratory use.

SQA-V mainly includes metal enclosure with front plastic panel, a power entry module with IEC 60320

type appliance inlet, integral line filter, 2-Pole switch and 2-Pole fuseholder, a certified power supply, a

certified printer, a SELV motherboard with lithium battery, a high voltage limited current DC/AC inverter for

the backlight, a camera, SELV PCBs, a DC Zoom motor in SELV, a DC fan.

Unit employs SELV Limited Energy RS-232 and video connections.

QwikCheck Gold is a partial version of SQA-V. QwikCheck Gold does not incorporate printer and DC

Zoom motor. QwikCheck Gold incorporates different enclosure, different type of DC fan and different

plastic of enclosure. Unless specified otherwise testing on model SQA-V represented testing on model

QwikCheck Gold.

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 5 of 108

TRF originator: VDE

Report No. S106490.02

Table 1: List of Test equipment

ITL

Instrument

1040 DVM

1147 Digital Oscilloscope

1026 Climatic Chamber

1217 Hipot

1010 Force Gauge

1302 Digital Thermometer

Leakage Current –

1135 EN60950

1335 Caliper Dial 0-150mm

1015 Ball for Impact Test

1215 Digital Power Analyzer

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Manufacturer

Fluke

Tektronix

Russels

Hipotronics

Chatillon

Fluke

Model

87

TDS3012

RD-16-1

HD-100

DPP 25

Hydra2635A

Serial

60370049

B015205

10921274

380301

17706

7702039

Custom

Motitoyo

Ergonomics

Valhalla Scientific

Custom

505-646-50

ITB15

2110A

1085

01-051

Page 6 of 108

33-407

CalDue

28/02/2012

24/02/2012

NCR

07/12/2011

26/04/2012

22/02/2012

23/02/2012

20/03/2012

20/03/2012

23/02/2012

TRF originator: VDE

Report No. S106490.02

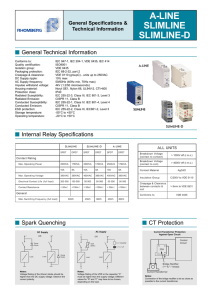

Table 3. List of Critical Components.

manufacturer/

type/model

technical data

trademark

Power Entry

Schurter or

CD24.1101.151 Rated: 110/250VAC, 50Module w/Integral equivalent

(former FKSP2- 60Hz, 2A

Appliance Inlet,

55-2/I)

Cx: 1x68nF X2

Line Filter, Double

Cy: 2x2.2nF

Pole Switch,

Double Pole

Fuseholder

object/part no.

FSF Series

Rated: 250V, 1A

EN133200

mark(s) of

conformity

VDE

UL1283

UR (E72928)

standard

CSA C22.2

No. 8

Fuse in PEM

above (2

Provided, In Line

and Neutral)

Schurter or

equivalent

Mains Wiring

Any

Any

Rated: 300V, VW-1,

105°C

UL758

UR

Switching Power

Supply

Mean Well

RPT-60B

Rated Input: 100240VAC, 50/60Hz, 1.40.9A

IEC606011+A1+A2

TUV

P/N 0034.1516

IEC/EN60127- SEV, VDE

1, -2

UL248-14

UR (E41599)

CSA C22.2

No. 248.14

Rated Output:

+5VDC/4A,

+12VDC/2A,

EN606011+A1+A2+A13

UL/CSA

60950-1

UR (E227340)

UL746C

UR (E121855)

EN60950:200

6+A11:2009

TUV SUD

UL/CSA60950

-1

UR

-12VDC/0.5A

Max. ambient 50°C

Isolating Sheet

below power

supply

Formex or

equivalent

Formex GK-17

Min. thickness: 0.4mm

Rated: VTM-0

Printer in SELV,

Citizen

employed only in

model SQA-V, not

employed in

QwikCheck Gold

CBM-920II-40

Lithium Battery on Panasonic or

Motherboard

equivalent

CR-2032

Rated: 5VDC, 2.5A

Rated: 3VDC

UL1642

UR (MH12210)

UL60950

UR (E99151)

Max. abnormal charging

current 10mA

Protection Circuit: IC U10

(DS1307)

Battery Protective Dallas or

Device U10

equivalent

(Protection

against reverse

charging current)

DS1307

Provides protection

against reverse charging

current

DC motor in

Hsiang Neng

SELV (Zoom),

employed only in

model SQA-V, not

employed in

QwikCheck Gold

HN-GH121045Y

Rated: 12VDC, 0.26A

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 7 of 108

Evaluated in

appliance

TRF originator: VDE

Report No. S106490.02

manufacturer/

object/part no.

type/model

trademark

PCB

Any

Any

Rated: V-0, min. 105°C

Wiring

Rated: VW-1, min. 60°C

Any

Any

technical data

mark(s) of

conformity

UR

standard

UL758

UR

PVC, TFE, PTFE,

Neoprene or Polyamide

Plastic of

Polyram

Enclosure,

employed only in

model SQA-V, not

employed in

QwikCheck Gold

PBB503

Plastic of

Elastogran

Enclosure,

employed only in

model QwikCheck

Gold, not

employed in

SQA-V

Elastolit K

4900/LT/FR

Inverter for

Backlight

CXA-L10L

TDK-Lambda

Evaluated in

appliance

Rated: V-0 for min.

thickness 3.0mm

Thickness in the

appliance 3.4mm

Rated: 5VA for min.

thickness 4.0mm

UL94, UL796

UR (E123445)

Thickness in the

appliance 3.4mm

Evaluated in

appliance

Rated Input: 12VDC

Rated Output: 300Vrms

DC Fan,

Sunonwealth or KDE1209PTV3

employed only in equivalent

model SQA-V, not

employed in

QwikCheck Gold

Rated: 12VDC, 1.3W,

min. 39 CFM

UL507

UR (E77551)

EN60950-1

TUV

DC Fan,

Sunonwealth or KDE1209PTV3

employed only in equivalent

model QwikCheck

Gold, not

employed in

SQA-V

Rated: 12VDC, 1.3W,

min. 39 CFM

UL507

UR (E77551)

EN60950-1

TUV

Alternate DC Fan, Sunonwealth or ME92251V3

employed only in equivalent

model QwikCheck

Gold, not

employed in

SQA-V

Rated: 12VDC, 1.3W,

min. 39.5 CFM

UL507

UR (E77551)

EN60950-1

TUV

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 8 of 108

TRF originator: VDE

Report No. S106490.02

4.4

Testing in SINGLE FAULT CONDITIONS

4.4.1

Fault tests

4.4.2

Application of SINGLE FAULT CONDITIONS

4.4.2.1

SINGLE FAULT CONDITIONS not

P

(see Form A.1 and A.2)

covered by 4.4.2.1 to

P

P

(see Form A.1 and A.2)

—

4.4.2.14

4.4.2.2

PROTECTIVE IMPEDANCE

No protective impedance

N/A

4.4.2.3

PROTECTIVE CONDUCTOR

Protective conductor was

disconnected. Voltage limits

exceeded permissible limits,

current limits did not exceed

permissible limits for accessible

parts (see Form A.1 and A.2)

4.4.2.4

Equipment or parts for short-term or intermittent

operation

No such unit

4.4.2.5

Motors

DC motor was locked, see

Form A.1 and A.2

4.4.2.6

Capacitors

No such parts

N/A

4.4.2.7

MAINS transformers

Part of certified power supply

N/A

4.4.2.7.2

Short circuit

Part of certified power supply

N/A

4.4.2.7.3

Overload

Part of certified power supply

N/A

4.4.2.8

Outputs

Only inherently Limited Energy

signal/data ports provided (RS232 and video), test waived

N/A

4.4.2.9

Equipment for more than one supply

One supply

N/A

4.4.2.10

Cooling

Blocked vents, disconnected

fan tests performed (see Form

A.1 and A.2)

4.4.2.11

Heating devices

N/A

4.4.2.12

Insulation between circuits and parts

N/A

4.4.2.13

Interlocks

N/A

4.4.2.14

Voltage selectors

N/A

4.4.3

Duration of tests

(see Form A.1 and A.2)

P

4.4.4

Conformity after application of fault conditions

Permissible limits, hi-pot pass

(see Form A.1; A.2; A.8, A.14)

P

5

MARKING AND DOCUMENTATION

P

5.1.1

General

P

Required equipment markings are:

—

visible:

P

From the exterior; or

P

P

N/A

P

P

After removing a cover; or

No such covers

N/A

Opening a door

No such doors

N/A

After removal from a rack or panel

No rack mounted unit

N/A

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 9 of 108

TRF originator: VDE

Report No. S106490.02

5.1.2

5.1.3

Not put on parts which can be removed by an

operator

Not put on parts which can be

removed by an operator

P

Letter symbols (IEC 60027) used

V, A, Hz

P

Graphic symbols (IEC 61010-1: Table 1) used

Not used

N/A

Identification

—

Equipment is identified by:

P

a) Manufacturer’s or supplier’s name or

trademark

Trademark and manufacturer

name marked

P

b) Model number, name or other means

Model name marked

P

Manufacturing location identified

Not required: unit is

manufactured at one location

MAINS supply

P

Equipment is marked as follows:

P

Marked VAC

a) Nature of supply:

—

Marked 50-60Hz

1) a.c. RATED MAINS frequency or range

of

frequencies.................................................. :

P

N/A

2) d.c. with symbol 1

b)

RATED supply

voltage(s) or range..................... : Marked 100-240VAC

P

c) Max. RATED power (W or VA) or input current ... : Marked 0.5A

The marked value not less than 90 % of the

maximum value

P

(see Form A.3)

P

If more than one voltage range:

—

One range

Separate values marked; or

N/A

Values differ by less than 20 %

d)

OPERATOR-set

for different RATED supply

voltages:

N/A

No operator set, voltage is

automatically selectable

—

Indicates the equipment set voltage

N/A

Portable equipment indication is visible from the

exterior

N/A

Changing the setting changes the indication

N/A

No mains socket outlets

N/A

With the voltage if it is different from the MAINS

supply voltage ................................................... :

No mains socket outlets

N/A

For use only with specific equipment

No mains socket outlets

N/A

If not marked for specific equipment it is marked

with:

No mains socket outlets

N/A

The maximum rated current or power; or

No mains socket outlets

N/A

Symbol 14 with full details in the documentation

No mains socket outlets

N/A

e) Accessory MAINS socket-outlets accepting

standard MAINS plugs are marked:

5.1.4

N/A

Fuses

P

Operator replaceable fuse marking

(see also 5.4.5) ........................................................ :

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 10 of 108

Fuseholder is marked with the

fuse rating 1A 250V

P

TRF originator: VDE

Report No. S106490.02

5.1.5

TERMINALS, connections and operating devices

No such devices affecting

safety

N/A

5.1.5.1

General

N/A

Where necessary for safety, indication of purpose

of TERMINALS, connectors, controls and indicators

marked

N/A

If insufficient space, symbol 14 used

N/A

Push-buttons and actuators of emergency stop

devices and indicators:

—

used only to indicate a warning of danger or

N/A

the need for urgent action

N/A

coloured red

N/A

coded as specified in IEC 60073

N/A

Supplementary means of coding provided, if

meaning of colour relates (see IEC 60073):

5.1.5.2

N/A

to safety of persons; or

N/A

safety of the environment

N/A

No terminals, appliance inlet

used

TERMINALS

P

MAINS supply TERMINAL identified

N/A

Other TERMINAL marking:

N/A

a)

FUNCTIONAL EARTH TERMINALS

N/A

(symbol 5

used)

b)

PROTECTIVE CONDUCTOR TERMINALS:

N/A

Symbol 6 is placed close to or on the TERMINAL;

or

N/A

Part of appliance inlet

c)

TERMINALS

No symbol required, appliance

inlet used

P

N/A

of control circuits (symbol 7

used)

N/A

d) HAZARDOUS LIVE TERMINALS supplied from

the interior

5.1.6

Standard MAINS socket outlet; or

N/A

RATINGS marked; or

N/A

Symbol 14 used

N/A

Switches and circuit breakers

P

If disconnecting device, off position clearly marked

Although mains switch not

regarded disconnect device, it

is marked with OFF and ON

position

If push-button used as power supply switch:

No such switch

P

N/A

Symbol 9 and 15 used for on-position

N/A

Symbol 10 and 16 used for off-position

N/A

Pair of symbols 9, 15 and 10, 16 close together

N/A

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 11 of 108

TRF originator: VDE

Report No. S106490.02

5.1.7

Equipment protected by DOUBLE INSULATION or

N/A

REINFORCED INSULATION

Protected throughout (symbol 11 used)

5.1.8

5.2

5.3

N/A

Only partially protected (symbol 11 not used)

Only partially protected

(symbol 11 not used)

N/A

Field-wiring TERMINAL boxes

No such parts

N/A

If TERMINAL or ENCLOSURE exceeds 60 °C:

N/A

Cable temperature RATING marked ....................... :

N/A

Marking visible before and during connection or

beside TERMINAL

N/A

No warning markings provided

or required

Warning markings

N/A

Visible when ready for NORMAL USE

N/A

Are near or on applicable parts

N/A

Symbols and text correct dimensions and colour:

—

a) symbols min 2,75 mm and text 1,5 mm high

and contrasting in colour with background

N/A

b) symbols and text moulded, stamped or

engraved in material min. 2,0 mm high and

N/A

0.5 mm depth or raised if not contrasting in

colour

N/A

If necessary marked with symbol 14

N/A

Statement to isolate or disconnect if access by

using a tool to HAZARDOUS LIVE parts is permitted

N/A

Durability of markings

Markings are durable and

legible

P

The required markings remain clear and legible in

(see Form A.4)

P

NORMAL USE

5.4

Documentation

P

5.4.1

General

P

Equipment is accompanied by documentation for

safety purposes for OPERATOR or RESPONSIBLE BODY

P

Safety documentation for service personnel

authorized by the manufacturer

Not intended for special

servicing

N/A

Documentation necessary for safe operation is

provided in printed media or

Printed media provided

P

in electronic media if available at any time

Per request

P

Documentation includes:

—

a) intended use

P

b) technical specification

P

c) name and address of manufacturer or

supplier

P

d) Information specified in 5.4.2 to 5.4.6

P

e) information to mitigate residual RISK

(see also subclause 17)

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 12 of 108

No residual risks

P

TRF originator: VDE

Report No. S106490.02

No such accessories

N/A

g) guidance provided to check correct function

of the equipment, if incorrect reading may

cause a HAZARD from harmful or corrosive

substances of HAZARDOUS live parts

No such hazard

N/A

h) instructions for lifting and carrying

Deemed not required

N/A

Warning statements and a clear explanation of

warning symbols:

No warning symbols

—

f)

5.4.2

accessories for safe operation of the

equipment specified

Provided in the documentation; or

N/A

Information is marked on the equipment

N/A

Equipment ratings

P

Documentation includes:

—

a) Supply voltage or voltage range .......................: Provided

P

Frequency or frequency range....................... :

Provided

P

Power or current rating .................................. :

Provided

P

b) Description of all input and output

connections in accordance to 6.6.1 a)

Provided

P

c)

Deemed not required: external

circuits are SELV

RATING of insulation of external circuits in

accordance to 6.6.1 b)

d) Degree of protection (IEC 60529)

Provided: Unit is intended for

indoor use, maximum

recommended operating

ambient 38degC, max. altitude

2000m, max. RH 80% for

temperatures of up to 31degC

decreasing linearly to 50% at

40degC, mains supply

fluctuations ±10%,

Overvoltage Category II,

Pollution Degree II

IPX0

N/A

e) if impact rating less than 5 J:

No impact rating less than 5 J

N/A

a) Statement of the range of environmental

conditions (see 1.4)

IK code in accordance to IEC 62262 marked or

N/A

symbol 14 of table 1 marked, with

N/A

RATED

5.4.3

N/A

energy level and test method stated

Equipment installation

N/A

No special installation

instructions deemed required

N/A

Documentation includes instructions for:

N/A

a) assembly, location and mounting

requirements

N/A

b) protective earthing

N/A

c) connections to supply

N/A

d) permanently connected equipment:

N/A

1) Supply wiring requirements

N/A

2) If external switch or circuit-breaker,

requirements and location recommendation

N/A

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 13 of 108

TRF originator: VDE

Report No. S106490.02

e) ventilation requirements

No special requirements

N/A

f)

No special requirements

N/A

Unit does not produce sound

N/A

special services (e. g. air, cooling liquid)

g) Instructions relating to sound level

5.4.4

Equipment operation

P

Instructions for use include:

P

a) identification and description of operating

controls

P

b) positioning for disconnection

Positioning for disconnection

is self-evident

P

c) instructions for interconnection

N/A

d) specification of intermittent operation limits

5.4.5

e) explanation of symbols used

No symbols

f)

Instructions regarding

replacement of the printer

paper and toner provided

P

g) cleaning and decontamination

Cleaning instructions provided

(not affecting safety)

P

h) Listing of any poisonous or injurious gases

and quantities

No such gases

N/A

i)

RISK

reduction procedures relating to

flammable liquids (see 9.5)

No flammable liquids

N/A

j)

RISK

reduction procedures relating burn from

surfaces permitted to exceed limits of 10.1

No heated surfaces

N/A

Additional precautions for IEC 60950 conforming

equipment in regard to moistures and liquids

No hazard related to moistures

and liquids

N/A

A statement about protection impairment if used in

a manner not specified by the manufacturer

Provided

replacement of consumable materials

N/A

P

Equipment maintenance

P

Instructions for RESPONSIBLE BODY include:

—

Instructions sufficient in detail permitting safe

maintenance and inspection and continued safety:

P

Instruction against the use of detachable MAINS

supply cord with inadequate rating

Cord is not part of investigation

Specific battery type of user replaceable batteries

Provided

Rating and characteristics of fuses

N/A

P

Any manufacturer specified parts

5.4.6

P

P

Rating of mains fuse provided

P

Instructions include following subjects permitting safe No such risks

servicing and continued safety:

N/A

a) product specific RISKS may affect service

personnel

N/A

b) protective measures for these RISKS

N/A

c) verification of the safe state after repair

N/A

Integration into systems or effects resulting from

special conditions

Aspects described in documentation

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 14 of 108

No such hazards

N/A

N/A

TRF originator: VDE

Report No. S106490.02

6

PROTECTION AGAINST ELECTRIC SHOCK

P

6.1

General

6.1.1

Requirements

—

Protection against electric shock maintained in

and SINGLE FAULT CONDITION

P

(see Form A.5)

P

NORMAL CONDITION

ACCESSIBLE

parts not HAZARDOUS LIVE

P

Voltage, current, charge or energy below the limits in

and in SINGLE FAULT CONDITION

between:

—

NORMAL CONDITION

ACCESSIBLE

6.1.2

parts and earth

P

two ACCESSIBLE parts on same piece of the

equipment within a distance of 1,8 m

P

Conformity is checked by the determination of 6.2

and 6.3 followed by the tests of 6.4 to 6.11

P

Exceptions

No exceptions

N/A

Following HAZARDOUS LIVE parts may be accessible to No exceptions

an OPERATOR:

N/A

a) parts of lamps and lamp sockets after lamp

removal

No exceptions

N/A

b) parts to be replaced by operator only by the

use of tool and warning marking

No exceptions

N/A

Those parts not HAZARDOUS LIVE 10 s after

interruption of supply

No exceptions

N/A

Capacitance test if charge is received from internal

capacitor

N/A

6.2

Determination of accessible parts

(see Form A.6)

P

6.2.1

General

Only plastic parts of enclosure,

earthed metal enclosure and

SELV circuits are operator

accessible

P

Unless obviously determination of accessible parts

as specified in 6.2.2 to 6.2.4

Determination is obvious

N/A

Examination

Determination is obvious

N/A

- with jointed test finger (as specified B.2)

Determination is obvious

N/A

- with rigid test finger (as specified B.1) and a force of Determination is obvious

10 N

N/A

Openings above parts that are HAZARDOUS LIVE

N/A

6.2.2

6.2.4

No such openings

- test pin with length of 100 mm and 4 mm in

diameter applied

6.2.4

N/A

Openings for pre-set controls

No such openings

N/A

- test pin with length of 100 mm and 4 mm in

diameter applied

No such openings

N/A

6.3

Limit values for ACCESSIBLE parts

6.3.1

Levels in NORMAL CONDITION

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

P

(see Form A.7)

Page 15 of 108

P

TRF originator: VDE

Report No. S106490.02

a) Voltage limits less than 33 V r.m.s. and 46,7

V peak or 70 V d.c.

Accessible enclosure voltage

limits less than 33 V r.m.s. and

46,7 V peak or 70 V d.c.

Inverter output voltage

exceeds 33 V r.m.s. and 46,7

V peak, see Form A.6

N/A

for wet locations voltage limits less than 16 V

r.m.s. and 22,6 V peak or 35 V d.c.

Voltages are not HAZARDOUS LIVE the levels of:

b) Current less than 0,5 mA r.m.s. for

sinusoidal, 0,7 mA peak non sinusoidal or

mixed frequencies or 2 mA d.c. when

measured with measuring circuit A.1 or A.2 if

less than 100 Hz

—

Inverter output current is less

than 0,5 mA r.m.s. for

sinusoidal, 0,7 mA peak non

sinusoidal or mixed

frequencies or 2 mA d.c. when

measured with measuring

circuit A.1, see Form A.6

P

N/A

for wet locations measuring circuit A.4 used

6.3.2

P

or

N/A

c) Levels of capacitive charge or energy less:

N/A

1) 45 µC for voltages up to 15 kV peak or d.c. or

line A of Figure 3

N/A

2) 350 mJ stored energy for voltages above 15

kV peak or d.c.

N/A

Levels in SINGLE FAULT CONDITION

(see Form A.7)

P

a) Voltage limits less than 33 V r.m.s. and 46,7

V peak or 70 V d.c.

Enclosure voltages exceed 33

V r.m.s. and 46,7 V peak when

PE conductor is disconnected

N/A

for wet locations voltage limits less than 16 V

r.m.s. and 22,6 V peak or 35 V d.c.

Voltages are not HAZARDOUS LIVE the levels of:

b) Current less than 0,5 mA r.m.s. for

sinusoidal, 0,7 mA peak non sinusoidal or

mixed frequencies or 2 mA d.c. when

measured with measuring circuit A.1 or A.2 if

less than 100 Hz

N/A

—

Enclosure (earth) leakage

current does not exceed 0,5

mA r.m.s. for sinusoidal, 0,7

mA peak non sinusoidal or

mixed frequencies or 2 mA d.c.

when measured with

measuring circuit A.1

P

N/A

for wet locations measuring circuit A.4 used

N/A

or

c) Levels of capacitive charge or energy less:

No stored capacitance

N/A

1) 45 µC for voltages up to 15 kV peak or d.c. or

line A of Figure 3

N/A

2) 350 mJ stored energy for voltages above 15

kV peak or d.c.

N/A

6.4

Primary means of protection

P

6.4.1

ACCESSIBLE parts prevented from being HAZARDOUS

LIVE by one or more of following means:

P

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 16 of 108

TRF originator: VDE

Report No. S106490.02

a)

ENCLOSURES or PROTECTIVE BARRIERS

(see

6.4.2)

b)

6.4.2

BASIC INSULATION

(see 6.4.3)

P

Basic insulation is provided

between primary and metal

enclosure

P

c) Impedance (see 6.4.4)

Not used

ENCLOSURES or PROTECTIVE BARRIERS

Plastic enclosure (barrier)

prevents access to hazardous

parts

N/A

P

- meet requirements for BASIC INSULATION, if

protection is provided by insulation

P

by

limited access

BASIC INSULATION

Plastic enclosure (barrier)

prevents access to hazardous

parts. Clearances between

primary and external / internal

(coated by conductive material)

surfaces comply with the

requirements for clearances

and creepage distances for

Reinforced Insulation for mains

circuit

P

Provided between mains and

metal safety earthed enclosure

(see Form A.13)

P

- meet CLEARANCE, CREEPAGE DISTANCE and solid

insulation requirements of 6.7

6.4.4

P

- meet rigidity requirements of 8.1

- meet requirements of 6.7 for CREEPAGE and

CLEARANCES between ACCESSIBLE parts and

HAZARDOUS live parts, if protection is provided

6.4.3

Plastic enclosure (barrier)

prevents access to hazardous

parts

Impedance

P

Not employed

N/A

Impedance used as primary means of protection

meets all of following requirements:

—

a) limits current or voltage to level of 6.3.2

N/A

b)

RATED for maximum WORKING VOLTAGE and

the amount of power it will dissipate

N/A

c)

CLEARANCE, CREEPAGE DISTANCE between

terminations of the impedance meet

requirements of BASIC INSULATION of 6.7

N/A

6.5

Additional means of protection in case of SINGLE FAULT CONDITION

P

6.5.1

ACCESSIBLE parts are prevented from becoming

HAZARDOUS live by the primary means of protection

P

and supplemented by one of:

a)

PROTECTIVE BONDING

b)

SUPPLEMENTARY INSULATION

(see 6.5.2)

(see 6.5.3)

c) automatic disconnection of the supply (see

6.5.5)

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 17 of 108

Metal parts of enclosure are

separated from primary by

Basic insulation and bonded to

PE terminal

P

Part of certified power supply

(Double or Reinforced

insulation is provided between

primary and SELV)

P

Not used

N/A

TRF originator: VDE

Report No. S106490.02

d) current- or voltage-limiting device (see 6.5.6)

Not used

N/A

Alternatively one of the single means of protection is

used:

Not used

N/A

e)

REINFORCED INSULATION

(see 6.5.3)

Part of certified power supply

(Double or Reinforced

insulation is provided between

primary and SELV). In addition,

Clearances between primary

and external / internal (coated

by conductive material)

surfaces comply with the

requirements for clearances

and creepage distances for

Reinforced Insulation for mains

circuit

f)

PROTECTIVE IMPEDANCE

(see 6.5.4)

P

N/A

6.5.2

PROTECTIVE BONDING

(see Form A.9, A.10 and A.11)

P

6.5.2.1

ACCESSIBLE conductive parts, may become

HARZARDOUS LIVE in SINGLE FAULT CONDITION:

P

Bonded to the PROTECTIVE CONDUCTOR TERMINAL; or

P

Separated by conductive screen or barrier bonded to

N/A

PROTECTIVE CONDUCTOR TERMINAL

6.5.2.2

Integrity of PROTECTIVE BONDING

P

a)

P

PROTECTIVE BONDING consists of directly

connected structural parts or discrete

conductors or both; and withstands thermal

and dynamic stresses

No soldered connections used

for bonding

b) Soldered connections:

N/A

Independently secured against loosening

N/A

Not used for other purposes

N/A

c) Screw connections are secured

d)

PROTECTIVE BONDING not

Screw (nut) connections are

secured by washers

P

P

interrupted; or

P

exempted as removable part carries MAINS SUPPLY

INPUT connection

e) Any moveable PROTECTIVE BONDING

connection specifically designed, and meets

6.5.2.4

No moveable connection

N/A

f)

No external metal braid of

cables used

P

No external metal braid of cables used

(not regarded as PROTECTIVE BONDING)

g) IF MAINS SUPPLY PASSES THROUGH:

Mains does not pass through

N/A

Means provided for passing protective conductor;

N/A

Impedance meets 6.5.2.4

N/A

h) Protective conductors bare or insulated,

if insulated, green/yellow

Exceptions:

Not applied

1) earthing braids;

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Green yellow color is used for

protective bonding

P

N/A

N/A

Page 18 of 108

TRF originator: VDE

Report No. S106490.02

2) internal protective conductors etc.;

Green/yellow not used for other purposes

TERMINAL suitable for connection

CONDUCTOR, and meets 6.5.2.3

6.5.2.3

of a PROTECTIVE

PROTECTIVE CONDUCTOR TERMINAL

N/A

Green/yellow not used for other

purposes

P

Appliance inlet used

P

Earthing pin of IEC 60320 type

appliance inlet (part of certified

power entry module) used

P

a) Contact surfaces are metal

P

b) Appliance inlet used

P

N/A

c) For rewirable cords and PERMANENTLY

CONNECTED EQUIPMENT, PROTECTIVE

CONDUCTOR TERMINAL is close to MAINS

supply TERMINALS

d) If no MAINS supply is required, any

PROTECTIVE CONDUCTOR TERMINAL:

Mains powered

N/A

Is near terminals of circuit for which protective

earthing is necessary

N/A

External if other terminals external

N/A

e) Equivalent current-carrying capacity to

MAINS supply TERMINALS

P

If plug-in, makes first and breaks last

Provided by IEC 60320 type

appliance inlet

P

g) If also used for other bonding purposes,

protective conductor:

Not used for other bonding

purposes

N/A

f)

Applied first;

N/A

Secured independently;

N/A

Unlikely to be removed by servicing

N/A

h) PROTECTIVE CONDUCTOR of measuring

circuit:

No measuring circuit

N/A

1) Current RATING equivalent to

measuring circuit TERMINAL;

N/A

2)

N/A

PROTECTIVE BONDING:

Not interrupted; or

i)

N/A

FUNCTIONAL EARTH TERMINALS allow

No functional earth terminals

N/A

Not used

N/A

independent connection

j)

If a binding screw used for PROTECTIVE

CONDUCTOR TERMINAL:

Suitable size for bond wire

N/A

Not smaller than M 4 (No. 6)

N/A

At least 3 turns of screw engaged

N/A

Passes tightening torque test

N/A

k) Contact pressure not capable being reduced

by deformation of materials

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 19 of 108

Contact pressure not capable

being reduced by deformation

of materials

P

TRF originator: VDE

Report No. S106490.02

6.5.2.4

Impedance of PROTECTIVE BONDING of plugconnected equipment

Impedance of PROTECTIVE

does not exceed 0.1

Ohm when tested at 25A

applied for 1min. (see Form

A.10)

Impedance between PROTECTIVE CONDUCTOR

TERMINAL and each ACCESSIBLE part where

PROTECTIVE BONDING is specified, is:

—

less than 0,1 Ohm; or

P

less than 0,2 Ohm if equipment is provided with

non detachable cord

6.5.2.5

P

BONDING

Detachable cord

N/A

Bonding impedance of PERMANENTLY CONNECTED

N/A

EQUIPMENT

6.5.2.6

6.5.3

Transformer PROTECTIVE BONDING screen

N/A

Transformer provided with screen for protective

bonding:

N/A

screen bonding consists of directly connected

structural parts or discrete conductors or both;

and withstands thermal and dynamic stresses

(see 6.5.2.2 a )

N/A

screen bonding with soldered connection (see

6.5.2.2 b ) is:

N/A

- Independently secured against loosening

N/A

- Not used for other purposes

N/A

SUPPLEMENTARY and REINFORCED INSULATION

SELV and plastic enclosure

with internal conductive coating

are separated from primary by

Reinforced insulation

(additionally evaluated as part

of certified power supply)

- meet CLEARANCE, CREEPAGE DISTANCE and solid

insulation requirements of 6.7

6.5.4

PROTECTIVE IMPEDANCE

P

P

Not used

N/A

Limits current or voltage to level of 6.3.1 in NORMAL

and to level of 6.3.2 in SINGLE FAULT CONDITION

N/A

CLEARANCE, CREEPAGE DISTANCE

between

terminations of the impedance meet requirements of

DOUBLE or REINFORCED INSULATION of 6.7

N/A

The protective impedance consists of one or more of

the following:

—

a) appropriate single component suitable for

safety and reliability for protection, it is:

N/A

1) RATED twice the maximum WORKING VOLTAGE

N/A

2) resistor RATED for twice the power dissipation

for maximum WORKING VOLTAGE

N/A

b) combination of components

N/A

Single electronic device not used as PROTECTIVE

N/A

IMPEDANCE

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 20 of 108

TRF originator: VDE

Report No. S106490.02

6.5.5

6.5.6

Automatic disconnection of the supply

Not used

N/A

a)

RATED to disconnect the load within time

specified in Figure 2

N/A

b)

RATED for the maximum load conditions of

the equipment

N/A

Current- or voltage limiting devices

Not used

N/A

Device complies with all of:

N/A

a)

RATED to limit the current or voltage to the

level of 6.3.2

N/A

b)

RATED

c)

N/A

for the maximum working voltage; and

RATED

for the maximum operational current if

applicable

N/A

CLEARANCE, CREEPAGE DISTANCE between

terminations of the impedance meet

requirements of SUPPLEMENTARY INSULATION

of 6.7

N/A

6.6

Connections to external circuits

RS-232 and video (both SELV,

limited energy) ports provided

P

6.6.1

Connections do not cause ACCESSIBLE parts of the

following to become HAZARDOUS LIVE in NORMAL

CONDITION or SINGLE FAULT CONDITION:

Unit employs RS-232 and

video (both SELV, limited

energy) ports, originated from

SELV outputs of the certified

power supply, intended for

interconnection with external

SELV circuits. No electrical

shock hazard can arise

P

- the external circuits

As above

P

- the equipment

As above

P

As above

P

short circuit of separation does not cause a HAZARD As above

P

Protection achieved by separation of circuits; or

Instructions or markings for each terminal include:

As above

N/A

a)

As above

N/A

As above

N/A

RATED conditions

for TERMINAL

b) Required RATING of external circuit

INSULATION

6.6.2

6.6.3

6.6.4

TERMINALS for external circuits

N/A

TERMINALS which receive a charge from an internal

capacitor are not HAZARDOUS LIVE after 10 s of

interrupting supply connection

No such terminals

N/A

Circuits with terminals which are HAZARDOUS LIVE

No such external circuits

N/A

These circuits are:

N/A

Not connected to ACCESSIBLE conductive parts; or

N/A

Connected to ACCESSIBLE conductive parts, but are

not MAINS circuits and have one TERMINAL contact at

earth potential

N/A

No ACCESSIBLE conductive parts are HAZARDOUS LIVE

N/A

ACCESSIBLE terminals for stranded conductors

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 21 of 108

No such terminals

N/A

TRF originator: VDE

Report No. S106490.02

No RISK of accidental contact because:

N/A

Located or shielded

N/A

Self-evident or marked whether or not connected

to ACCESSIBLE conductive parts

N/A

ACCESSIBLE TERMINALS will not work loose

6.7

Insulation requirements

6.7.1

The nature of insulation

6.7.1.1

Insulation between ACCESSIBLE parts or between

separate circuits consist of CLEARANCES, CREEPAGE

DISTANCES and solid insulation if provided as

protection against a HAZARD

6.7.1.2

CLEARANCES

6.7.1.3

N/A

(see Form A.5)

P

P

Level of insulation, working

voltage, transient overvoltage,

pollution degree considered

P

Required CLEARANCES reflecting factors of 6.7.1.1

6.7.1.1 a) to d) and rated

altitude considered.

Multiplication factor considered

1.00 for altitude up to 2000m

Equipment rated for operating altitude greater than

2000 m correction factor of Table 3 of 61010-1

applied

No such case

6.7.1.5

P

CREEPAGE DISTANCES

6.7.1.1 a) to d) and CTI of the

insulating material considered

P

Required CLEARANCES reflecting factors of 6.7.1.1

(see Form A.5)

P

N/A

CTI material group reflected by requirements

6.7.1.4

P

P

CTI test performed

Material group IIIa assumed for

PCB and IIIb for other materials

Solid insulation

6.7.1.1 a) to d) considered

P

Required CLEARANCES reflecting factors of 6.7.1.1

(see Form A.5)

P

Requirements for insulation according to type of

circuit

(see Form A.5)

P

a) 6.7.2 MAINS circuits of OVERVOLTAGE

CATEGORY II up to nominal supply voltage of

300 V

Applied

P

b) 6.7.3 Secondary circuits separated from

circuits defined in a) by transformer

No such case

N/A

c) K.1 MAINS circuits of OVERVOLTAGE CATEGORY

III and IV or OVERVOLTAGE CATEGORY II over

300 V

No such case

N/A

d) K.2 Secondary circuits separated from

circuits defined in a) by transformer

No such case

N/A

e) K.3 Circuits having one or more of:

No such case

N/A

1) maximum TRANSIENT OVERVOLTAGE is limited to No such case

known level below the level of MAINS CIRCUIT

N/A

2) maximum TRANSIENT OVERVOLTAGE above the

level of MAINS CIRCUIT

No such case

N/A

3) WORKING VOLTAGE is the sum of more than one No such case

circuit or a mixed voltage

N/A

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 22 of 108

N/A

TRF originator: VDE

Report No. S106490.02

6.7.2

4) WORKING VOLTAGE includes recurring peak

voltage, may include non-sinusoidal or nonperiodic waveform

Part of certified power supply

N/A

5) WORKING VOLTAGE with a frequency above

30 kHz

No such case

N/A

Insulation for MAINS CIRCUITS of OVERVOLTAGE

II with a nominal supply voltage up to

300 V

P

CATEGORY

6.7.2.1

CLEARANCES and CREEPAGE DISTANCES

Clearance between primary

and ground, enclosure

considered, Table 4 was used

(see Form A.13)

Values for MAINS CIRCUITS of table 4 are met

P

P

Coatings to achieve reduction to POLLUTION DEGREE I No coatings

comply with requirements of Annex H

N/A

6.7.2.2

Solid insulation

P

6.7.2.2.1

Withstands electrical and mechanical stresses in

normal use and all RATED environmental conditions of

1.4

P

Equipment passed voltage tests of 6.8.3 with values

of Table 5

(see Form A.14)

P

Complies as applicable:

a)

6.7.2.2.2

6.7.2.2.3

P

ENCLOSURE or PROTECTIVE BARRIER Clause 8

Plastic of enclosure complies

with the rigidity requirements of

Clause 8

P

b) moulded and potted parts requirements of

6.7.2.2.2

Part of certified power supply

N/A

c) inner layers of printed wiring boards

requirements of 6.7.2.2.3

Part of certified power supply

N/A

d) thin-film insulation requirements of 6.7.2.2.4

Part of certified power supply

N/A

Moulded and potted parts

Part of certified power supply

N/A

Conductors between same two layers are separated

by at least 0,4 mm after moulding is completed

Part of certified power supply

N/A

Inner insulation layers of printed wiring boards

Part of certified power supply

N/A

Separated by at least 0,4 mm between same two

layers

Part of certified power supply

N/A

REINFORCED INSULATION have adequate electric

strength; one of following methods used:

Part of certified power supply

N/A

a) thickness at least 0,4 mm

Part of certified power supply

N/A

b) insulation is assembled of minimum two

separate layers, each RATED for test voltage

of Table 5 for BASIC INSULATION

Part of certified power supply

N/A

c) insulation is assembled of minimum two

separate layers, where the combination is

rated for test voltage of Table 5 for

Part of certified power supply

N/A

Part of certified power supply

N/A

REINFORCED INSULATION

6.7.2.2.4

Thin-film insulation

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 23 of 108

TRF originator: VDE

Report No. S106490.02

Conductors between same two layers are separated

by applicable CLEARANCES and CREEPAGE DISTANCES

Part of certified power supply

N/A

REINFORCED INSULATION have adequate electric

strength; one of following methods used:

Part of certified power supply

N/A

a) thickness at least 0,4 mm

Part of certified power supply

N/A

b) insulation is assembled of min two separate

layers, each RATED for test voltage of Table 5

for BASIC INSULATION

Part of certified power supply

N/A

c) insulation is assembled of min three

separate layers, where the combination of

two layers passed voltage tests of 6.8.3 with

values of Table 5 for REINFORCED INSULATION

Part of certified power supply

N/A

6.7.3

Insulation for secondary circuits derived from MAINS

of OVERVOLTAGE CATEGORY II up to 300 V

No such insulation relied upon

N/A

6.7.3.1

Secondary circuits where separation from MAINS

CIRCUITS is achieved by a transformer providing:

—

- REINFORCED INSULATION

No such insulation relied upon

N/A

- DOUBLE INSULATION

No such insulation relied upon

N/A

- screen connected to the PROTECTIVE CONDUCTOR

No such insulation relied upon

N/A

CLEARANCES

No such insulation relied upon

N/A

a) meet the values of Table 6 for BASIC

INSULATION and SUPPLEMENTARY INSULATION;

or

No such insulation relied upon

N/A

No such insulation relied upon

N/A

or

No such insulation relied upon

N/A

b) pass the voltage tests of 6.8 with values of

Table 6; with following adjustments:

No such insulation relied upon

N/A

1) values for REINFORCED INSULATION are 1,6

times the values for BASIC INSULATION

No such insulation relied upon

N/A

2) if operating altitude is greater than 2000 m

values of CLEARANCES multiplied with factor of

Table 3

No such insulation relied upon

N/A

3) minimum CLEARANCE is 0,2 mm for POLLUTION

2 and 0,8 mm for POLLUTION DEGREE 3

No such insulation relied upon

N/A

CREEPAGE DISTANCES

No such insulation relied upon

N/A

Based on WORKING VOLTAGE meets the values of

Table 7 for BASIC and SUPPLEMENTARY INSULATION

No such insulation relied upon

N/A

Values for REINFORCED INSULATION are twice the

values of BASIC INSULATION

No such insulation relied upon

N/A

Coatings to achieve reduction to POLLUTION DEGREE I No such insulation relied upon

comply with requirements of Annex H

N/A

6.7.3.4

Solid insulation

No such insulation relied upon

N/A

6.7.3.4.1

Withstands electrical and mechanical stresses in

No such insulation relied upon

normal use and all RATED environmental conditions of

1.4

N/A

TERMINAL

6.7.3.2

twice the values of Table 6 for REINFORCED

INSULATION

DEGREE

6.7.3.3

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 24 of 108

TRF originator: VDE

Report No. S106490.02

No such insulation relied upon

N/A

No such insulation relied upon

N/A

No such insulation relied upon

N/A

No such insulation relied upon

N/A

Complies as applicable:

No such insulation relied upon

N/A

1) ENCLOSURE or protective barrier Clause 8

No such insulation relied upon

N/A

2) moulded and potted parts requirements of

6.7.3.4.2

No such insulation relied upon

N/A

3) inner layers of printed wiring boards

requirements of 6.7.3.4.3

No such insulation relied upon

N/A

4) thin-film insulation requirements of 6.7.3.4.4

No such insulation relied upon

N/A

Moulded and potted parts

No such insulation relied upon

N/A

Conductors between same two layers are separated

by applicable distances of Table 8

No such insulation relied upon

N/A

Inner insulation layers of printed wiring boards

No such insulation relied upon

N/A

Separated by at least by applicable distances of

Table 8 between same two layers

No such insulation relied upon

N/A

REINFORCED INSULATION have adequate electric

strength; one of following methods used:

No such insulation relied upon

N/A

a) thickness at least applicable distance of

Table 8

No such insulation relied upon

N/A

b) insulation is assembled of minimum two

separate layers, each RATED for test voltage

of Table 6 for BASIC INSULATION

No such insulation relied upon

N/A

c) insulation is assembled of min two separate

layers, where the combination is rated for 1,6

times the test voltage of Table 6

No such insulation relied upon

N/A

Thin-film insulation

No such insulation relied upon

N/A

Conductors between same two layers are separated

by applicable CLEARANCES and CREEPAGE DISTANCES

No such insulation relied upon

N/A

REINFORCED INSULATION have adequate electric

strength; one of following methods used:

No such insulation relied upon

N/A

a) thickness at least applicable distance of

Table 8

No such insulation relied upon

N/A

b) insulation is assembled of min two separate

layers, each RATED for test voltage of Table 6

for BASIC INSULATION

No such insulation relied upon

N/A

a) Equipment passed voltage test of 6.8.3.1 for

5 s with VALUES of Table 6 for BASIC and

SUPPLEMENTARY INSULATION

values for REINFORCED INSULATION are 1,6 times

the values of BASIC INSULATION

b) if WORKING VOLTAGE exceeds 300 V,

equipment passed voltage test of 6.8.3.1 for

1 min with a test voltage of 1,5 times working

voltage for BASIC or SUPPLEMENTARY

INSULATION

value for REINFORCED INSULATION

WORKING VOLTAGE

6.7.3.4.2

6.7.3.4.3

6.7.3.4.4

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

are twice the

Page 25 of 108

TRF originator: VDE

Report No. S106490.02

No such insulation relied upon

N/A

a.c. test of 6.8.3.1; or

No such insulation relied upon

N/A

d.c. test of 6.8.3.2 for circuits stressed only by

d.c. voltages

No such insulation relied upon

N/A

c) insulation is assembled of min three

separate layers, where the combination of

two layers passed voltage tests with 1,6 time

values of Table 6:

6.8

Procedure for dielectric strength tests

6.9

Constructional requirements for protection against

electric shock

P

6.9.1

If a failure could cause a HAZARD:

P

a) Security of wiring connections

P

b) Screws securing removable covers

6.9.2

6.9.3

(see Form A.5 and A.14)

P

No such screws

N/A

c) Accidental loosening

P

d) CREEPAGE and CLEARANCES not reduced

below the values of basic insulation by

loosening

P

Material not to be used for safety relevant insulation:

P

Easily damaged materials not used

Certified insulating materials

used

P

Non-impregnated hydroscopic materials not used

Non-impregnated hydroscopic

materials not used

P

Colour coding

P

Green-and-yellow insulation shall not be used

except:

P

Cord is not part of investigation

a) protective earth conductors;

N/A

P

b) protective bonding conductors;

c) potential equilization conductors;

No such conductors

N/A

d) functional earth conductors

No such conductors

N/A

6.10

Connection to MAINS supply source and connections

between parts of equipment

6.10.1

MAINS supply cords

RATED for

P

Cord is not part of investigation

maximum equipment current (see 5.1.3c)

N/A

N/A

Cable complies with IEC 60227 or IEC 60245

N/A

Heat-resistant if likely to contact hot parts

N/A

Temperature RATING (cord and inlet)....................... :

N/A

Green/yellow used only for connection to PROTECTIVE

N/A

CONDUCTOR TERMINALS

Detachable cords with IEC 60320 MAINS connectors:

—

Conform to IEC 60799; or

N/A

Have the current RATING of the MAINS connector

N/A

6.10.2

Fitting of non-detachable MAINS supply cords

6.10.2.1

Cord entry

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

No non-detachable cords

N/A

N/A

Page 26 of 108

TRF originator: VDE

Report No. S106490.02

6.10.2.2

Inlet or bushing smoothly rounded; or

N/A

Insulated cord guard protruding >5D

N/A

Cord anchorage

N/A

Protective earth conductor is the last to take the

strain

N/A

a) Cord is not clamped by direct pressure from

a screw

N/A

b) Knots are not used

N/A

c) Cannot push the cord into the equipment to

cause a HAZARD

N/A

d) No failure of cord insulation in anchorage

with metal parts

N/A

e) Not to be loosened without a tool

N/A

f)

N/A

Cord replacement does not cause a HAZARD

and method of strain relief is clear

Push-pull and or torque test

6.10.3

N/A

Plugs and connectors

P

MAINS supply plugs, connectors etc., conform with

relevant specifications

Certified IEC 60320 type

appliance inlet employed (part

of certified power entry module)

If equipment supplied at voltages below 6.3.2.a) or

from a sole source:

6.11

P

—

Plugs of supply cords do not fit MAINS sockets above

rated SUPPLY voltage

No cords

MAINS type plugs used only for connection to MAINS

supply

Certified IEC 60320 type

appliance inlet employed for

connection to mains (part of

certified power entry module)

P

Plug pins which receive a charge from an internal

capacitor

Voltage between L and N

connections of the inlet

decayed to 0V within 5s after

supply disconnection with

mains switch in ON position.

No test required with mains

switch in OFF position as

capacitance stored in Cx

capacitor of power entry

module is 68nF (mains switch

is located behind X2 capacitor)

(see Form A.7)

P

Accessory MAINS socket outlets:

No such parts

—

N/A

a) Marking if accepts a standard MAINS plug

(see 5.1.3e)

N/A

b) Input has a protective earth conductor if

outlet has EARTH TERMINAL CONTACT

N/A

Disconnection from supply source

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 27 of 108

P

TRF originator: VDE

Report No. S106490.02

6.11.1

Disconnects all current carrying conductors

IEC60320 type appliance

coupler employed for

disconnection from mains.

Appliance coupler disconnects

both L and N

6.11.2

Exceptions

No exceptions

6.11.3

Requirements according to type of equipment

6.11.3.1

PERMANENTLY CONNECTED EQUIPMENT and multiphase equipment:

N/A

N/A

No such equipment

N/A

Employs switch or circuit-breaker

N/A

If switch or circuit-breaker is not part of the

equipment, documentation requires:

6.11.3.2

6.11.4

—

a) Switch or circuit-breaker to be included in

building installation

N/A

b) Suitable location easily reached

N/A

c) Marking as disconnecting for the equipment

N/A

Single-phase cord-connected equipment

P

Equipment is provided with one of the following:

P

a) Switch or circuit-breaker

Although provided, not

regarded disconnect device

N/A

b) Appliance coupler (disconnectable without

tool)

IEC 60320 type appliance

coupler regarded disconnect

device

P

c) Separable plug (without locking device)

Not regarded disconnect

device

Disconnecting devices

IEC 60320 type appliance

coupler regarded disconnect

device

N/A

P

Electrically close to the SUPPLY

6.11.4.1

6.11.4.2

P

P

Switches and circuit-breakers

Although provided, not

regarded disconnect device

N/A

When used as disconnection device:

—

Meets IEC 60947-1 and IEC 60947-3

N/A

Marked to indicate function ..................................... :

N/A

Not incorporated in MAINS cord

N/A

Does not interrupt PROTECTIVE EARTH CONDUCTOR

N/A

Appliance couplers and plugs

P

Where an appliance coupler or separable plug is

used as the disconnecting device (see 6.11.3.2):

IEC 60320 type appliance

coupler regarded disconnect

device

P

Readily identifiable and easily reached by the

operator

P

Single-phase portable equipment cord length not

more than 3 m

Cord is not part of investigation

PROTECTIVE EARTH CONDUCTOR connected first and

disconnected last

Provided by IEC 60320 type

appliance coupler

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 28 of 108

N/A

P

TRF originator: VDE

Report No. S106490.02

7

PROTECTION AGAINST MECHANICAL

HAZARDS

P

7.1

Equipment does not cause a mechanical HAZARD in

NORMAL nor in SINGLE FAULT CONDITION

P

Conformity is checked by 7.2 to 7.7

P

Sharp edges

P

Easily touched parts are smooth and rounded

P

Do not cause injury during NORMAL USE and

P

Do not cause injury during SINGLE FAULT CONDITION

P

7.2

7.3

Moving parts

Moving parts (fan and zoom

motor) are suitably guarded

within enclosure and are not

operator accessible

P

7.3.1

HAZARDS from moving parts limited to a tolerable

level with the conditions specified in 7.3.2 and 7.3.5

No such hazards

N/A

Exceptions

No such hazards

N/A

Access to HAZARDOUS moving parts permitted under

following circumstances:

No access permitted

N/A

RISK assessment in accordance with 7.3.3 carried

out

7.3.2

N/A

a) obviously intended to operate on parts or

materials outside of the equipment

inadvertent touching of moving parts minimized

by equipment design (e .g. guards or handles)

N/A

N/A

b) If operator access is unavoidable outside

normal use following precautions have been

taken:

7.3.3

1) Access requires TOOL

N/A

2 ) Statement about training in the instructions

N/A

3 ) Warning markings on covers prohibiting

access by untrained operators

N/A

or symbol 14 with full details in documentation

N/A

RISK assessment for mechanical HAZARDS to body

parts

No such hazards

RISK is reduced to a tolerable level by protective

measures as specified in Table 12

N/A

Minimum protective measures:

7.3.4

N/A

—

A. Low level measures

N/A

B. Moderate measures

N/A

C. Stringent measures

N/A

Limitation of force and pressure

No such hazards

Following levels are met in normal and single fault

condition:

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 29 of 108

N/A

N/A

TRF originator: VDE

Report No. S106490.02

Continuous contact pressure below 50 N / cm² with

force below 150 N

N/A

Temporary force below 250 N for an area at least of

3 cm² for a maximum duration of 0,75 s

N/A

7.3.5

Gap limitations between moving parts

7.3.5.1

Access normally allowed

N/A

If levels of 7.3.4 exceeded and body part may be

inserted minimum gap as specified in Table 13

assured in NORMAL and in SINGLE FAULT CONDITION

N/A

Access normally prevented

N/A

Maximum gap as specified in Table 14 assured in

and in SINGLE FAULT CONDITION

N/A

7.3.5.2

No such hazards

N/A

NORMAL

7.4

Stability

P

Equipment not secured to building structure is

physical stable

Equipment is stable by design

Stability maintained after opening of drawers etc. by

automatic means, or

No such parts

N/A

warning marking requires the application of means

N/A

Compliance checked by following tests as applicable:

—

a) 10° tilt test for other than handheld

equipment

No overbalance as a result of

10° tilt test

b) multi-directional force test for equipment

exceeds height of 1 m and mass of 25 kg

No such case

N/A

c) downward force test for floor-standing

equipment

No such case

N/A

d) overload test with 4 times maximum load for

castor or support that supports greatest load

No such case

N/A

e) castor or support that supports greatest load

removed from equipment

No such case

N/A

7.5

Provisions for lifting and carrying

7.5.1

Equipment more than 18 kg :

—

Less than 18kg

Directions in documentation

7.6

Handles or grips

No such parts

Lifting devices and supporting parts

N/A

N/A

No such parts

N/A

Rated for maximum load; or

N/A

tested with four times maximum static load

N/A

Wall mounting

No such equipment

Mounting brackets withstand four times weight

7.7

N/A

N/A

Handles or grips withstand four times weight

7.5.3

P

N/A

Has means for lifting or carrying; or

7.5.2

P

Expelled parts

N/A

N/A

No such parts

N/A

Equipment contains or limits the energy

N/A

Protection not removable without the aid of a tool

N/A

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 30 of 108

TRF originator: VDE

Report No. S106490.02

8

RESISTANCE TO MECHANICAL STRESSES

P

8.1

Equipment does not cause a HAZARD when subjected

to mechanical stresses in NORMAL USE

P

Normal protection level is 5 J

Considered 5J

P

Levels below 5 J but not less than 1 J are acceptable Not for levels below 5J

if all of following criteria are met:

N/A

a) lower level justified by RISK assessment of

manufacturer

N/A

b) equipment installed in its intended

application is not easily touched

N/A

c) only occasional access during NORMAL USE

N/A

d) IK code in accordance to IEC 62262 marked

or symbol 14 used with full information in the

documentation

N/A

For non-metallic ENCLOSURES rated below 2 °C

ambient temperature value chosen for minimum

rated temperature

N/A

Impact energies between IK values, the IK code

marked for nearest lower value

N/A

Conformity is checked by performing following tests:

—

1) static test of 8.2.1

Performed, no hazard

P

2) impact test of 8.2.2 with 5 J except for HAND-

Performed, no hazard

P

HELD EQUIPMENT

if impact energy not selected to 5 J alternate

method of IEC 62262 used

3) drop test of 8.3.1 or 8.3.2 except for FIXED

and EQUIPMENT with mass over 100 kg

Equipment rated with an impact rating of IK 08 that

obviously meets the criteria

N/A

Drop tests waived based on

engineering judgment: unit

obviously cannot be affected by

this test

N/A

N/A

After the tests inspection with following results:

—

- HAZARDOUS LIVE

ACCESSIBLE

P

parts above the limits of 6.3.2 not

- insulation pass the voltage tests of 6.8

P

i)

no leaks of corrosive and harmful

substances

P

ii)

ENCLOSURE shows

HAZARD

P

iii)

CLEARANCES

no cracks resulting in a

not less than their permitted

P

values

iv) insulation of internal wiring remains

undamaged

P

v)

P

PROTECTIVE BARRIERS

not damaged or

loosened

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 31 of 108

TRF originator: VDE

Report No. S106490.02

vi) No moving parts exposed, except permitted

by 7.3

P

vii) no damage which could cause spread of fire

P

8.2

ENCLOSURE rigidity test

P

8.2.1

Static test

P

- 30 N with 12 mm rod to each part of ENCLOSURE

Applied to enclosure with

acceptable results

- in case of doubt test conducted at maximum RATED

ambient temperature

No such doubt

Impact test

Applied to enclosure with

acceptable results

P

Impact applied to any part of ENCLOSURE causing a

if damaged

Applied to metal and plastic

enclosure

P

HAZARD

Impact energy level and corresponding IK code .... :

5J impact applied

P

Non-metallic ENCLOSURES cooled to minimum RATED

ambient temperature if below 2 °C

Not intended for ambient below

2 °C

N/A

8.3

Drop test

Drop tests waived based on

engineering judgment: unit

obviously cannot be affected by

this test

N/A

8.3.1

Other than HAND-HELD and DIRECT-PLUG-IN EQUIPMENT

N/A

Tests conducted with a drop height or angle of...... :

N/A

HAND-HELD and DIRECT-PLUG-IN EQUIPMENT

N/A

Non-metallic ENCLOSURES cooled to minimum RATED

ambient temperature if below 2 °C

N/A

Drop test conducted with an height of 1 m

N/A

8.2.2

8.3.2

P

N/A

9

PROTECTION AGAINST THE SPREAD OF FIRE

P

9.1

No spread of fire in NORMAL and SINGLE FAULT

P

CONDITION

9.2

MAINS supplied equipment meets requirements of 9.6 Overcurrent protection per

additionally

clause 9.6 provided

P

Conformity is checked by minimum one or a

combination of the following (see Figure 11):

(see Form A.17)

P

a) Fault test of 4.4; or

Not relied upon

N/A

b) Application of 9.2 (eliminating or reducing the

sources of ignition); or

Not relied upon

N/A

c) Application of 9.2 (containment of fire within

the equipment)

This method is used

Eliminating or reducing the sources of ignition within

the equipment

Not relied upon

N/A

a) 1) Limited-energy circuit (see 9.4); or

Not relied upon

N/A

Not relied upon

N/A

Not relied upon

N/A

2) BASIC INSULATION provided for parts of

different potential; or

Bridging the insulation does not cause ignition

TRF No.: IEC 61010_1F

ITL086 V3.2 07/04/2011

Page 32 of 108

P

TRF originator: VDE

Report No. S106490.02

9.3

9.3.1

b) Surface temperature of liquids and parts

(see 9.5)

Not relied upon

N/A

c) No ignition in circuits designed to produce

heat

Not relied upon

N/A

Containment of the fire within the equipment, should

it occur

P

a) Energizing of the equipment is controlled by

an operator held switch

Not used

N/A

b) ENCLOSURE is conform with constructional

requirements of 9.3.1; and

ENCLOSURE is conform with

constructional requirements of

9.3.1

Requirements of 9.5 are met