QNET: Engineering Trainer

to Teach Controls

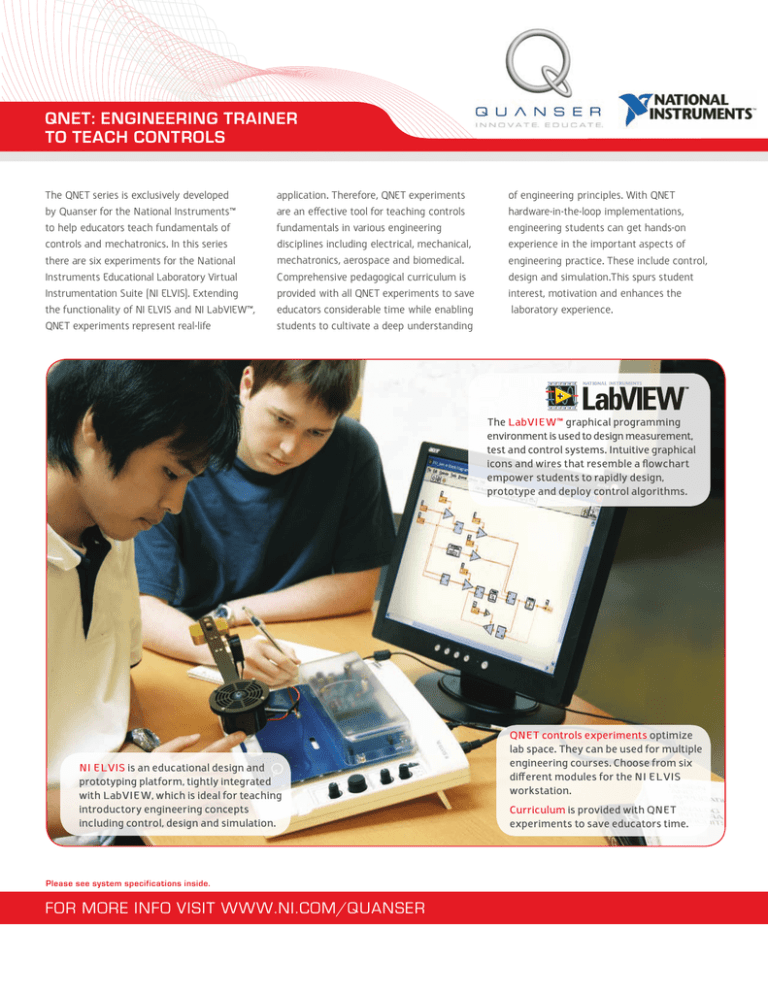

The QNET series is exclusively developed

by Quanser for the National Instruments™

to help educators teach fundamentals of

controls and mechatronics. In this series

there are six experiments for the National

Instruments Educational Laboratory Virtual

Instrumentation Suite (NI ELVIS). Extending

the functionality of NI ELVIS and NI LabVIEW™,

QNET experiments represent real-life

application. Therefore, QNET experiments

are an effective tool for teaching controls

fundamentals in various engineering

disciplines including electrical, mechanical,

mechatronics, aerospace and biomedical.

Comprehensive pedagogical curriculum is

provided with all QNET experiments to save

educators considerable time while enabling

students to cultivate a deep understanding

of engineering principles. With QNET

hardware-in-the-loop implementations,

engineering students can get hands-on

experience in the important aspects of

engineering practice. These include control,

design and simulation.This spurs student

interest, motivation and enhances the

laboratory experience.

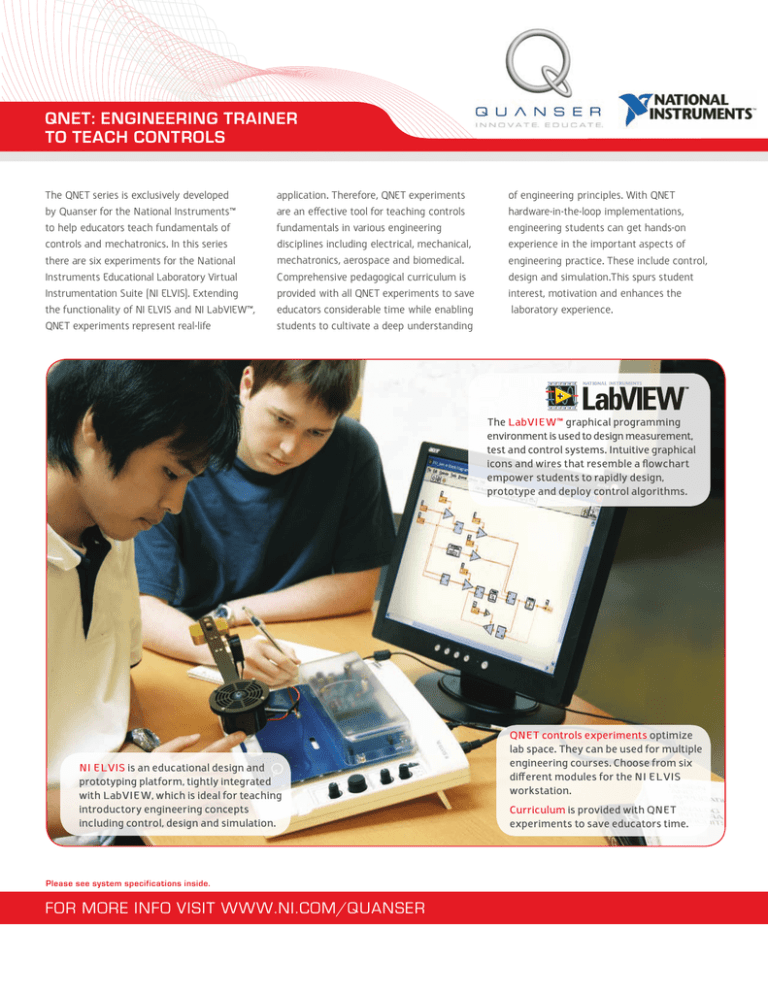

The LabVIEW™ graphical programming

environment is used to design measurement,

test and control systems. Intuitive graphical

icons and wires that resemble a flowchart

empower students to rapidly design,

prototype and deploy control algorithms.

NI ELVIS is an educational design and

prototyping platform, tightly integrated

with LabVIEW, which is ideal for teaching

introductory engineering concepts

including control, design and simulation.

Please see system specifications inside.

For more info visit www.NI.com/QUANSER

QNET controls experiments optimize

lab space. They can be used for multiple

engineering courses. Choose from six

different modules for the NI ELVIS

workstation.

Curriculum is provided with QNET

experiments to save educators time.

Applicable

Engineering

Discipline

Teaching Control with QNET and NI ELVIS: Six Experiments to Choose From

Choose from six QNET experiments to teach introductory controls to engineering students in electrical, mechanical, mechatronics, biomedical and

• Printers

• Cameras

• Robots

• CD players

• Vehicles

The Rotary Inverted Pendulum Trainer

offers students the opportunity to balance a

vertical rod at the tip of a rotating arm using

a DC motor. This is a classic pendulum control

experiment that can now be performed

more cost-effectively using the NI ELVIS

platform and LabVIEW™ software.

• Segway transporter

• Stabilization of rocket during take-off

• Human posturing system

• Traction control of vehicles

QNET HVAC Trainer

QNET Mechatronic

Sensors Trainer

QNET VTOL Trainer

Curriculum

Included

Technical Specifications

• Durable DC servo motor

• Built-in power amplifier

• High resolution optical encoder to sense position

• Plug-and-play design facilitates quick and easy

lab setup

• Compact and easy to store

• Protective cover to shield the circuitry

• System modeling

• Model validation

• Position and speed control

• System simulation

• Proportional–Integral–Derivative

(PID) Control design

• Tracking error

• Disturbance rejection

Motor

Torque constant

Terminal resistance Rotor inertia Max torque PWM Amplifier

Gain Max output voltage • Documented energy based-swing up control design

based on the pendulum link model

• Durable DC servo motor

• Precise and stiff machined components

• Built-in power amplifier

• High resolution optical encoders to sense positions

• Fully document system model and parameters

• Plug-and-play design facilitates quick and easy lab setup

• Compact and easy to store

• Protective cover to shield the circuitry

• System modeling

• Parameter estimation

• Balance control

• Linear-Quadratic Regulator (LQR) design

• Non-minimum phase

• Friction compensation

• Nonlinear swing-up control

• Energy-based design

• Hybrid balance / swing-up control

Motor

Torque constant

Terminal resistance Rotor inertia Max torque PWM Amplifier

Gain Max output voltage Max current Max output power Current Sensor

Sensitivity • Temperature control

• Relay / on-off control design

• System modeling

• Parameter identification

• roportional–Integral (PI) control design

Temperature Sensor

Calibration

Blower

Airflow

Chamber

Cross section area

Potentiometer

Mechanical angle range Independent linearity Infrared Sensor

Distance measuring range Pressure Sensor

Pressure range Sensitivity Quantization step Sonar

Object detection Sonar range 0.033 N.m/A

8.7 ohms

18 g.cm2

0.1 N.m

2.3 V/V

24 V

0.033 N.m/A

8.7 ohms

18 g.cm2

0.1 N.m

2.3 V/V

24 V

5A

120 W

1.0 A/V

The HVAC Trainer teaches students how

to design a control system that regulates

temperature in a chamber using the NI ELVIS

workstation and LabVIEW™ interface. It is

ideal for illustrating concepts covered in fluid

dynamics and thermodynamics control courses.

• Heating ventilation and air

conditioning system (e.g room

climate control)

• Incubators

• Aquarium

• Surge tank

• Bioreactors

• Transparent chamber

• Durable fan

• 12V halogen lamp as the heat source

• Integrated electronic temperature sensor

• Built-in power amplifier

• Plug-and-play design facilitates quick and easy lab setup

• Compact and easy to store

• Protective cover to shield the circuitry

The Mechatronic Sensors Trainer teaches

how to use various types of sensors and

demonstrates their advantages and

limitations. One of the most useful topics

in an introductory Mechatronics course

is the understanding and application of

sensors. This experiment introduces the

student to a wide variety of sensors that

are commonly used today.

• Magnetic field transducer for

throttle, pedal, suspension, and valve

position sensing

• Optical sensor for non-contact

position sensing and safety in an

assembly line

• Piezo film sensors to log vibration history

of package

• Various switches and LEDs are used in

electronic devices

• Sonar and infrared range sensors

often found in robots

Includes more than 10 different types of sensors/switches:

• Strain gage

• Piezo film sensor

• Rotary potentiometer

• Pressure sensor

• Thermistor sensor

• Sonar, infrared, optical, and magnetic field range

sensors

• Micro switch, push button, and optical switch

• Two digital output LEDs

• Encoder

• Plug-and-play design facilitates quick and easy lab setup

• Compact and easy to store

• Protective cover to shield the circuitry

• Benefits and drawbacks of certain

sensors

• Sensor behavior

• Calibration

• Using sensors to identify natural

frequency of material

• Need for debounce in switches

and buttons

• Understanding how encoders work

The Vertical Take-Off and Landing (VTOL)

module introduces students to the

fundamentals of aerospace engineering,

such as basic flight dynamics and control.

• Helicopters

• Rockets

• Balloons

• Harrier jets

• Tiltrotors

• High quality rugged propeller assembly

• Variable-speed fan with safety guard

• High resolution encoder

• Fully document system model and parameters

• Reliable QNET base and amplifier components

• Plug-and-play design facilitates quick and easy

lab setup

• Compact and easy to store

• Protective cover to shield the circuitry

• Flight dynamics, (e.g. modeling the

plant)

• Identifying parameters experimentally

• Model validation

• Proportional–Integral–Derivative (PID)

control

• Cascade control

• Dealing with actuator dynamics

Rotor

Power (at 1.5 A) Thrust (at 1.5 A) Efficiency (at 1.5 A) Encoder

Lines per revolution Resolution-quadrature Type Dimensions

Body length • Electromyograph with opto-isolated electrode and a

grounding strap

• Electromyograph runs on two AA batteries

• Pulse-width controlled metal gear servo

• QNET board includes signal conditioning circuit

and PWM

• Plug-and-play design facilitates quick and easy

lab setup

• Compact and easy to store

• Protective cover to shield the circuitry

• Analyzing the electromyogram signal

• Signal conditioning (e.g. ast Fourier

Transform (FFT) and filtering)

• Developing task-based servo

control from processed

electromyogram

EMG Sensor

Analog output Gain

Upper cut-off frequency

Lower cut-off frequency

Common mode rejection

ratio

Servo

Operating range Stall torque Dimensions Weight The Myoelectric trainer is an exciting way

to introduce students to biomedical

engineering. Students can learn how to

control a servo from the contraction of

muscles using the principles of

electromyography (EMG).

QNET MYOELECTRIC

Trainer

Key Attributes

• Myoelectric prosthetics

• Bioinstrumentation

• Clinical diagnostic tool: identifying

neuromuscular diseases

• Assisted control in aircrafts

• Unvoiced speech recognition

20 deg C/V

0.81 m3/min

15.9 cm2

300 deg

+/- 5 %

20 to 150 cm

0 - 207 kPa

0.0193 V/kPa

3 mV

Products and/or services pictured and referred to herein and their accompanying specifications may be subject to change without notice. Products and/or services

mentioned herein are trademarks or registered trademarks of Quanser Inc. and/or its affiliates. Other product and company names mentioned herein are trademarks or

registered trademarks of their respective owners. ©2010 Quanser Inc. All rights reserved.

Rev 2.0

Motor Encoder

Lines per revolution Resolution-quadrature Type Pendulum Encoder

Lines per revolution

Resolution- Quadrature

Type

Pendulum

Pendulum length Pendulum mass Coupling arm length 5A

120 W

1.0 A/V

360 lines

0.25 deg/count

TTL

360 lines

0.25 deg/count

TTL

1024 Lines

0.0879 deg/count

TTL

19.1 cm

27 g

8.26 cm

Pulse Width Modulation PWM Amplifier

Gain

2.3 V/V

Max output voltage

24 V

Max current

5A

Max output power

120 W

Current Sensor

Sensitivity

1.0 A/V

Resolution Reading frequency Piezo Film

Location of mass

from edge Sensitivity at resonance Resonant frequency

3dB frequency 2.54 cm

20 Hz

Fan chamber diameter Fan chamber height Counterweight mass Pitch range of motion

(from horizontal) PWM Amplifier

Gain Max output voltage Max current Max output power 6.8 cm

4.1 cm

270 g

1.40 cm

16.0 V/g

40.0 Hz

20.0 Hz

0 - 6.45 m

0.15 - 6.45 m

5.4 W

32 g

5.93 g/W

1024 lines

0.0879 deg/count

TTL

28.4 cm

+/-5 V

300 V/V

500 Hz

25 Hz

80 dB

4.8-6.0 V

0.294 N.m

2.9x1.3x3.0 cm

21.9 g

All QNET modules comply with the following international quality standards:

For more info visit www.NI.com/QUANSER

Max current Max output power Current Sensor

Sensitivity Encoder

Lines per revolution Resolution-quadrature

Type Isolation Amplifier

Input voltage

(accurate and linear)

Gain

Output low voltage

Output high voltage

Bandwidth

+/- 28 deg

2.3 V/V

24.0 V

5A

120 W

+/- 0.2 V

8 V/V

1.29 V

3.8 V

100 kHz

AEROSPACE

QNET DC Motor

CONTROL Trainer

The DC Motor Control Trainer illustrates

the fundamentals of DC motor control

using the NI ELVIS platform and LabVIEW™

software. It can quickly and easily be

configured to control motor position and

speed, as well as modeling experiments.

QNET Rotary

Inverted

Pendulum

Trainer

Real-life

Applications

BIOMEDICAL

Teaching Fundamentals

of Control

Mechanical

QNET MODULES

for NI ELVIS

To request a demonstration or quotation, please visit www.ni.com/quanser

ELECTRICAL

you will find a summary of key attributes, curriculum and technical specifications of each QNET module. Please note NI ELVIS is sold separately.

MECHATRONICS

aerospace. The table below provides an overview of how each QNET module can be used to demonstrate specific industrial applications. In addition,

BRING ADVANCED MECHATRONICS TO YOUR LAB

WITH LABVIEW™ AND QUANSER TECHNOLOGY

While the QNET series for the NI ELVIS provides a cost-effective solution

for teaching introductory control and mechatronics principals, you

can leverage the National Instruments™ educational platform for

advanced teaching and research. LabVIEW™ software and a wide

range of National Instruments™ hardware are fully compatible with

Quanser control experiments for intermediate and advanced level

teaching and research. The experiments cover topics applicable

to most engineering disciplines such as electrical, mechanical,

mechatronics, aerospace and civil. From rotary to linear and to

more advanced, Quanser experiments are distinctively modular. This

enables labs to maximize their investment in National Instruments™

technology and cost-effectively employ the same power plant and

data acquisition card to perform experiments of varying complexity.

tests, and final implementation. By combining these tools with the

LabVIEW™ Control Design and Simulation Module, students can take

advantage of custom algorithm development, analysis and visualization.

You can also integrate LabVIEW™ Real-Time and LabVIEW FPGA

software with NI hardware to quickly design, prototype, and deploy

your system using one single platform. National Instruments

multifunction data acquisition devices combine analog input, analog

output, digital I/O, and counter/timers on a single device. With new,

innovative analog and digital designs, M Series and X Series set a

new standard for performance, I/O capability, safety, and value.

NI R Series field programmable gate array (FPGA)-enabled I/O devices

offer the best combination of value and performance by integrating

FPGA technology with analog and digital I/O on a single device that

is available in standard PC form factors.

As illustrated below, easy integration with National Instruments™

hardware provides many options for prototyping, hardware-in-the-loop

Please visit www.quanser.com for a detailed list of National

Instruments™ cards that are compatible with Quanser experiments.

NI LabVIEW Control Design

and Simulation Module

Quanser AMPAQ

Quanser Active

Suspension

Unit

NI R Series

Multifunction

RIO Device

Quanser Comprehensive Curriculum

The Active Suspension is an example of a Quanser experiment that is suitable

for intermediate/advanced level teaching. The combination of LabVIEW™

software, National Instruments™ R Series multi-function devices and

Quanser experiment represents a self-contained control workstation. The

capabilities of this powerful yet adaptable bundle are extended further by

curriculum, complete with Instructor and student workbooks. The LabVIEWbased curriculum is developed by engineers for engineers to effectively teach

and demonstrate the mechatronic design approach practiced in industry. This

includes modeling, controller design, simulation and implementation.

See the full range of mechatronic controls experiments for LabVIEW™ and National Instruments

hardware at www.quanser.com/nimcc

About Quanser:

With 20 years in control design, Quanser is the world leader in education and research for real-time control design and implementation. We specialize in outfitting

engineering control laboratories to help universities captivate the brightest minds, motivate them to success and produce graduates with industry-relevant skills.

Universities worldwide implement Quanser’s open architecture control solutions, industry-relevant curriculum and cutting-edge workstations to teach introductory,

intermediate or advanced controls to students in Electrical, Mechanical, Mechatronics, Robotics, Aerospace, Civil, and various other engineering disciplines.

Quanser educational solutions are fully compatible with:

For more info visit www.NI.com/QUANSER