Phy5620 Lab1

advertisement

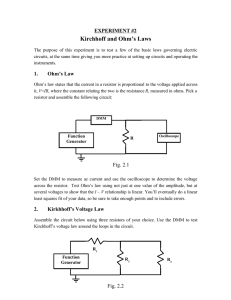

1 Physics 5620 Laboratory 1 Laboratory Equipment and DC Circuits Objective: In this laboratory session, you are to become familiar with the electronic equipment in the laboratory, to learn proper operational procedures, and to know the capabilities and limitations of the equipment. Most importantly, you are to learn how to take good care of the equipment. You will need to consult with the instructor for an explanation of details about the equipment and its operation. Introduction: The laboratory workstations are based on the National Instruments program NI ELVIS (Educational Laboratory Virtual Instrumentation Suite) which runs on top of NI LabView. The workstations include software based test instruments and a breadboard on which you will construct your circuits. The breadboard permits you to assemble circuits using 22 gauge jumper wires without the need to solder components together. This allows rapid prototyping of many circuits during the lab period. Some of the more useful software based instruments you will encounter are: Function Generator This instrument provides you with choices for the type of output waveform (sine, square, or triangle), amplitude selection, and frequency settings. In addition, the instrument offers DC offset setting, frequency sweep capabilities, and amplitude and frequency modulation. Oscilloscope This instrument provides the functionality of the standard desktop oscilloscope found in typical undergraduate laboratories. The NI ELVIS - Scope has two channels and provides scaling and position adjustment knobs along with a modifiable timebase. You can also choose trigger source and mode settings. The autoscale feature allows you to adjust the voltage display scale based on the peakto-peak voltage of the AC signal for the best display of the signal. Depending on the DAQ device cabled to the NI ELVIS hardware, you can choose between digital or analog hardware triggering. You can connect to the NI ELVIS - Scope from the NI ELVIS Prototyping Board or from the BNC connectors on the front panel of the benchtop workstation. The FGEN or DMM signals can be internally routed to this instrument. In addition, this computer-based scope display has the ability to use cursors for accurate screen measurements. The sampling rate of the Oscilloscope is determined by the maximum sampling speed of the DAQ device installed in the computer attached to the NI ELVIS hardware. Digital Multi Meter (DMM) This commonly used instrument can perform the following types of measurements: • • • • DC voltage AC voltage Current (DC and AC) Resistance • • • • Capacitance Inductance Diode test Audible continuity You can connect to the DMM from the NI ELVIS Prototyping Board or from the banana-style connectors on the front panel of the benchtop workstation. 2 Breadboard The NI ELVIS Prototyping Board connects to the benchtop workstation. The prototyping board provides an area for building electronic circuitry and allows the connections necessary to access signals for common applications. You can use multiple prototyping boards interchangeably with the NI ELVIS Benchtop Workstation. Fig. 1. The NI ELVIS desktop system. Experiments: 1.1 DC Voltages Measured by the Oscilloscope and the DMM With the breadboard powered off, connect the +15 V supply to the DMM. You will need to make connections to both the +15 V and Ground connections. Question 1: Why do you need two connections to measure a voltage? Measurement 1: Turn on the power to the NI ELVIS breadboard and use the DMM to measure the DC voltage. Record the measurements in a table as shown below. Next start the oscilloscope soft panel and measure the +15 V supply with the oscilloscope set to DC coupling. Voltage with DMM Voltage with scope, DC coupled Voltage with scope, AC coupled Question 2: Notice that, with AC coupling to the oscilloscope, any DC voltage in the input signal is cutoff. Why? 3 1.2 AC Voltages Measured by the Oscilloscope and the DMM: Use the function generator to display a 1 kHz sine wave (with zero VDC offset) at 2.5 V peak-to-peak and display it on the oscilloscope. Measurement 2: Use the calibrated setting of the vertical amplifier input (DC coupled) of the scope to measure the peak-to-peak value of the signal. Then use the DMM to measure the rms (root-mean-square) value. Convert the peak-to-peak value to an rms value to see if the two measurements agree. Repeat the measurements for the frequencies and waveforms listed in the table below. Frequenc y 1 kHz 10 kHz 50 kHz 100 kHz 100 Hz 10 Hz 5 Hz 1 Hz 1 kHz 1 kHz Waveform Amplitude (Vpp) sine sine sine sine sine sine sine sine square triangle 2.5 V 2.5 V 2.5 V 2.5 V 2.5 V 2.5 V 2.5 V 2.5 V 2.5 V 2.5 V Calculated RMS DMM Reading Question 3: On the basis of your observations, is there a frequency range or cut-off frequency after which the DMM measurements of sinusoidal voltages becomes inaccurate? Question 4: Does the DMM measure a true RMS voltage value for non-sinusoidal waveforms? Question 5: Do you observe any distortion of the signals on the oscilloscope? 1.3 Resistance Measurements with the DMM: Even though the DMM is functioning as an ohmmeter, it is still using its digital voltmeter capabilities. However, in the Ω-function mode, the DMM supplies a current to the external load resistance when connected to its output terminals and measures the corresponding voltages at these terminals. Measurement 3: Set the DMM function to Ω, and measure ≥ 4 different carbon resistors (3 or 4 band resistors only). Compare the measured values to the nominal values as determined by the resistor color code. Question 6: Is the agreement within the indicated resistor tolerance (4th band)? 4 Color Code Nominal Resistance Measured Resistance % Error 1.4 Introduction to the Breadboard: The breadboard is a convenient, time-saving way to construct and test electrical circuits. The NI ELVIS breadboards have their own power supplies with a +5VDC terminal for TTL circuitry, ±15VDC terminals for CMOS and op-amp circuitry, and several GND (ground) connections. Measurement 4: Measure these voltages with respect to GND using the DMM in the DC (voltage) mode with an appropriate voltage scale setting (i.e. voltage to be measured ≤ voltage scale). Terminal (voltage source) +5VDC +15VDC -15VDC DMM Reading The breadboard consists of a series of metal clips that are interconnected in columns and row with a plastic housing on the top which permit connections by wire jumpers. Measurement 5: Using the DMM as an ohmmeter, determine with sockets (holes) are interconnected in columns and which ones in row. Sketch a diagram of the interconnections in Figure 2. 5 Fig. 2. Bread Board Grid 1.5 DC Circuits and Verification of Kirchoff’s Laws: Question 7: How would you express Kirchoff’s Laws in words? Using the values R1 = 1.0 kΩ, R2 = 2.2 kΩ, R3 = 4.7 kΩ, construct the circuit shown in Figure 3. Measurement 6: Measure the currents (I1,2,3 ) and voltages (VA,B,C ) using the DMM. Report the measured currents and voltages in a table. Calculate the quantities I1,2,3 and VA,B,C , list them in the same table, and compare them with your measured values. I1 R1 I3 B A 5V R2 R3 I2 C Fig. 3. Voltage Divider Circuit Question 8: Is the level of agreement consistent with the resistor tolerances and the accuracy of your measurements? 1.6 The Resistor Color Code: A discrete resistor typically is marked with a set of 3 or 4 colored bands which encodes its value. Table 1 below denotes the numerical values for the colors appearing in the first 3 colors in a color code: Color Black Brown Red Orange Yellow Green Blue Violet Gray White Value 0 1 2 3 4 5 6 7 8 9 Table 1. Resistor Color Code Values The bands in a color code define the value (in ohms) of the resistor and its tolerance. Figure 4 is a sketch of the bands on a resistor. The first band on the right is a digit in 6 the 10’s place, the second band is a digit in the 1’s place, and the third band is the power of ten to multiply the first two by. The fourth band denotes the tolerance or the expected uncertainty in the value given by the first 3 bands. Table 2 contains the tolerance values of the fourth band. Color of 4th Band Gold Silver Missing Tolerance ±5 % ±10 % ±20 % Table 2. Resistor Color Code Tolerances Fig. 4. The Resistor Color Code