unwind tester model ut-60 operating instructions

advertisement

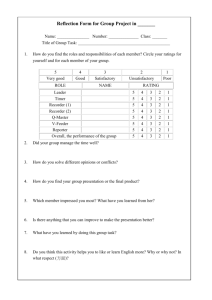

UNWIND TESTER MODEL UT-60 OPERATING INSTRUCTIONS KERSHAW I N S T R U M E N T A T I O N I N C . 51 7 A u b u r n Ave . Swedesboro, New Jersey, U.S.A. 08085 Phone: 856-467-5482 Fax: 856-467-2341 Operating Instructions Tape Unwind Tester Model UT-60 01. Description of Operation This tester features a variable speed DC drive, a load cell to measure the unwind tension, a digital meter to display the tension, and an analog output for an optional strip chart recorder. A slip clutch is coupled to the windup shaft to provide an over-running windup to take up slack as the material leaves the drive rolls. The web speed is adjustable and the speed is indicated by the speed meter. The wind-up torque is adjustable for the strength of the tape being tested. This torque is indicated by the clutch torque meter in percent. The small digital counter displays total tape travel in tenths of inches. This counter is activated by a pulse generator driven by the drive shaft. 02. Motor Controls The Start push button will start the motor and the stop push button will stop the motor. The speed of the motor is adjusted by turning the speed potentiometer on the console, and the speed is indicated on the digital display in feet per minute. 03. Clutch Controls The wind-up torque is adjusted by turning the clutch-torque potentiometer on the console. This torque is indicated on the digital display in percent. 04. Length Measurement The length of tape is indicated in tenths of inches and can be reset to zero by pressing the reset button. 05. Load Cell Controls A zero adjustment is provided to tare out any error at the beginning of the test. This zero adjustment will zero both the digital display and the (optional) strip chart recorder. A selector switch is provided to set the tape width to be tested. This selector switch will calibrate the digital display as if the tape were 1 inch wide. The machine is currently calibrated as follows: Switch Position A B C D E F Width 1/2" 3/4" 1" 1 1/2" 2" 3" Digital Display with 80 oz Test Weight 160 107 80 53 40 27 FIGURE 1 Strip Chart Recorder Output The analog output for the optional strip chart recorder is directly connected to the digital display and is also scaled with the tape width selector switch. The recorder chart can be scaled by adjusting the range selector switch on the front of the recorder as follows: Range Selection 100 mV 200 mV 500 mV Digital Display 100 ozs. 100 ozs. 100 ozs. Recorder Pen 100% 50% 20% FIGURE 2 The other features of the optional strip chart recorder are described in the recorder manual. Calibration Instructions Tape Unwind Tester Model UT-60 CI. C2. C3. Preparation a. Move the instrument console to a location where the operator has access to both the front and rear of the instrument console. b. Remove the rear cover plate from the console. Clutch Calibration a. Adjust the clutch-torque potentiometer on the front of the console to its maximum. b. Adjust the clutch-torque span potentiometer located inside the cabinet on the rear of the digital torque display until the digital display reads 100%. Speed Calibration a. Press the "Start" button to start the drive. b. Adjust the speed of the machine to an approx. operating speed. c. Use a hand tach. on the main drive rolls of the machine and note the speed in R.P.M. Note: The main drive rolls are 1 foot in circumference so 100 RPM equals 100 feet/minute. d. Adjust the speed span potentiometer in the front of the console until the digital display matches the tachometer reading. Tension Calibration a. Remove the left hand drive roll from the drive shaft by loosening the 2 set screws and pulling the knurled roll off. b. Slide the 1 1/2" calibration bearing onto the drive shaft. c. Thread the calibration string (provided) along the webpath, over the unwind sensing roll as shown in Diagram 1. d. Adjust the zero potentiometer until the digital display reads zero. e. Turn the drive on and adjust the speed to a crawl to break the static friction in the machine. f. Hang a dead weight (5 lbs. = 80 ozs.) from the string as shown in Diagram 1. g. Refer to Figure 1 from the Operating Instructions. h. Move the selector switch to position "A" and adjust the potentiometer located inside the cabinet on the right hand side until the display reads the correct reading, [see figure 1]. i. Repeat this procedure for the other selector switch position using the values in figure 1. j. The tester is now ready for operation. UNWIND TESTER MODEL UT-60 CALIBRATION BEARING — NOTE KNURLED DRIVE ROLL HAS BEEN REMOVED DRIVE ROLL CALIBRATION STRIN6 SUPPLY ROLL TAKE UP ROLL CALIBRATION WEIGHT LOAD CELL ASSEMBLY DIAGRAM 1. CALIBRATION STRING WEB PATH UT-60 UNWIND TESTER MODEL UT-60 DRIVE ROLLS SUPPLY ROLL TAKE UP ROLL LOAD CELL ASSEMBLY DIAGRAM 2, TAPE PATH VT-60