S7-300 Automation System Module Data

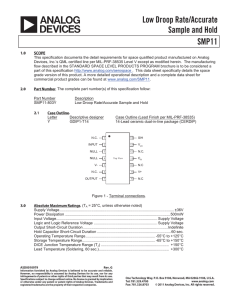

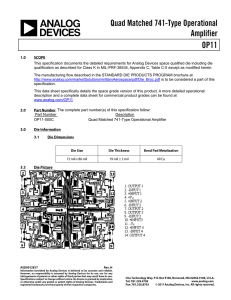

advertisement