HARDWARE CODE

SOFTWARE CODE

MAX ALLOWABLE AMBIENT TEMP: 70 C (158 F)

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES.

OPERATION IS SUBJECT TO THE FOLLOWING TWO CONDITIONS:

1) THIS DEVICE MAY NOT CAUSE HARMFUL INTERFERENCE

AND 2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE

RECEIVED, INCLUDING INTERFERENCE THAT MAY CAUSE

UNDESIRED OPERATION.

®

20M1

5705380-B

MODEL

B

C

D

LISTED ENERGY

MANAGEMENT

EQUIPMENT C ®

SUBASSEMBLY

20M1

NOVAR CONTROLS

CORPORATION

COPLEY, OH 44321

A

E

SERIAL

NUMBER

F

RELAY OUTPUT STATUS

MODULE ADDRESS

CUSTOM CONTROLLER

The LOGIC ONE Building Management System

Custom Controller

Installation Instructions

DOC. #560309000—A 7/30/04 PRINTED IN U.S.A.

Regulatory Compliance

Safety

This device has been tested and found to be in compliance with the requirements set forth in UL 916,

Energy Management Equipment, and is listed by Underwriters Laboratories, Inc., for installations in

the United States.

This device has been tested and found to be in compliance with the requirements set forth in C22.2,

No. 205-M1983, Signal Equipment, and is Certified by Underwriters Laboratories, Inc., for installations

in Canada.

Disclaimer

Logic One® is a registered trademark of Novar Controls Corporation.

The material in this manual is for information purposes only. The contents and the product it

describes are subject to change without notice. Novar Controls Corporation makes no

representations or warranties with respect to this manual.

In no event shall Novar Controls Corporation be liable for technical or editorial omissions or mistakes

in this manual, nor shall it be liable for any damages, direct or incidental, arising out of or related to

the use of this manual.

Copyright © 2004 by Novar Controls Corporation. All rights reserved.

No part of this manual may be reproduced in any form or by any means

without prior written permission from Novar Controls Corporation.

Novar Controls Corporation

6060 Rockside Woods Blvd., Cleveland, OH 44131

Tel: 800.348.1235

www.novarcontrols.com

Custom Controller Installation Instructions

Description

The Custom Controller (CC) is a dedicated, direct digital control module that

provides precise and integrated control of custom applications for rooftop and

air-handling units. This Logic One® module efficiently controls heating and

cooling stages, the fan, and damper operation to provide a fully integrated

temperature control system. The CC also incorporates an analog input to monitor

the outside air damper position.

This document provides instructions for mounting the CC, supplying it with

power, wiring the inputs and outputs, connecting it to network communications,

setting its address, and checking the installation.

Specifications

Agency Approvals

Listed device:

Standards used:

CUL/UL E90949

UL 916, Energy Management Equipment

CSA C22.2, No. 205-M1983, Signal Equipment

Power Requirements

Voltage:

Consumption:

24 VAC, Class 2

8 VA

Operating Environment

Temperature:

Humidity:

–40° to 158°F (–40° to 70°C)

0 to 99% Relative, noncondensing

Physical Dimensions

Height:

Width:

Depth:

Weight:

5.5 inches

8 inches

1.875 inches

1.75 lb

Precautions

Take the following precautions during installation:

Doc. #560309000—A 7/30/04

§

Observe national and local electrical codes.

§

Observe voltage and current limits marked on the module.

§

Do not connect 115 volts to any terminal of the CC. It is a Class 2 (low

voltage) control device.

1

Custom Controller Installation Instructions

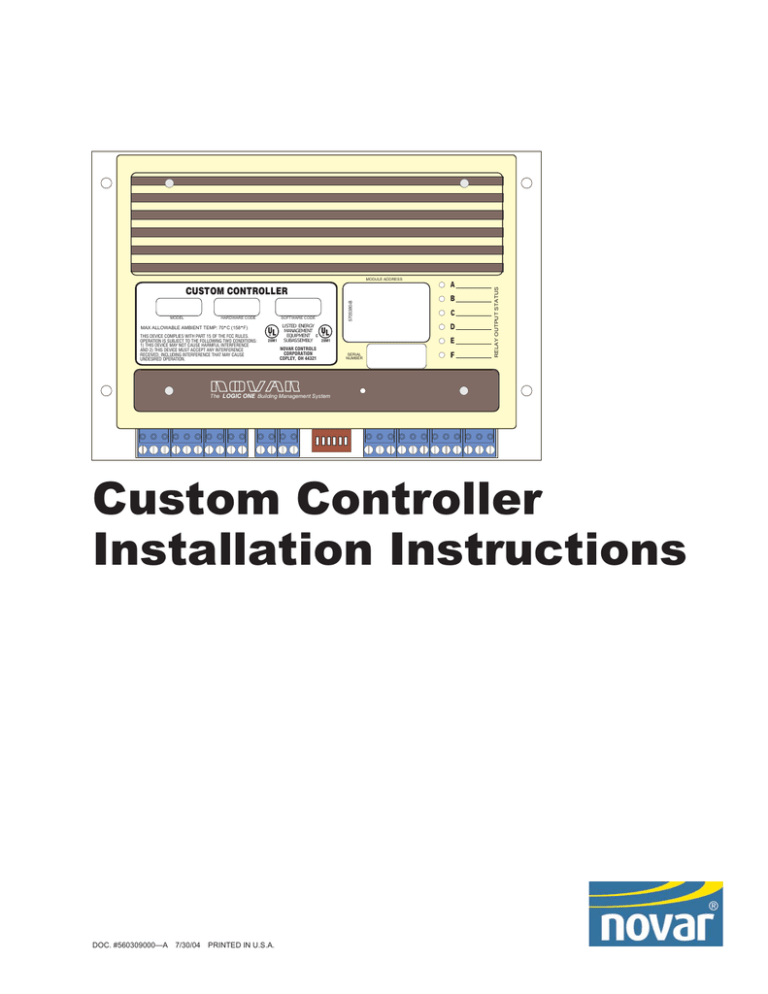

Mounting the Custom

Controller

The CC is designed to be mounted in the control compartment of the rooftop or

air-handling unit. It must be installed so that the unit and mounting hardware do

not interfere with proper operation of the rooftop or air-handling equipment.

Use the following procedure and refer to Figure 1, as necessary, to mount the CC.

Step

Procedure

1

Turn off all power to the rooftop or air-handling unit before

mounting the CC.

2

Position the CC against the mounting surface and mark the

surface to show the location of the four mounting holes.

3

Drill a hole at each of the places marked on the mounting

surface.

4

Insert metal screws (not included) through each of the four

mounting holes on the CC and into the holes in the mounting

surface, tightening each to secure the controller.

MODULE ADDRESS

5½"

CUSTOM CONTROLLER

MODEL

HARDWARE CODE

SOFTWARE CODE

MAX ALLOWABLE AMBIENT TEMP: 70 C (158 F)

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES.

OPERATION IS SUBJECT TO THE FOLLOWING TWO CONDITIONS:

1) THIS DEVICE MAY NOT CAUSE HARMFUL INTERFERENCE

AND 2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE

RECEIVED, INCLUDING INTERFERENCE THAT MAY CAUSE

UNDESIRED OPERATION.

®

20M1

5705380-B

Mounting

Holes

B

C

D

LISTED ENERGY

MANAGEMENT

EQUIPMENT C ®

SUBASSEMBLY

20M1

NOVAR CONTROLS

CORPORATION

COPLEY, OH 44321

A

E

SERIAL

NUMBER

F

RELAY OUTPUT STATUS

8"

Mounting

Holes

The LOGIC ONE Building Management System

Figure 1.

2

Mounting holes on the Custom Controller

Doc. #560309000—A 7/30/04

Custom Controller Installation Instructions

Supplying the Custom

Controller with Power

The CC is powered by 24-volts alternating current and rated 8 VA. Connect the 24

volts to Terminals 15 and 16, located under the Power VAC 8VA label (see

Figure 2).

NOTE! The 24-VAC power connection is isolated. One

transformer can be used to power multiple modules within

the restrictions of an 8-VA consumption.

Wiring the Inputs

The CC has a removable terminal strip that uses screw connections. The inputs

are Terminals 1 through 10, located on the left side of the strip (see Figure 2).

Terminals 13 and 14 under the Analog Outputs label are also used as inputs to

monitor feedback from an electric damper actuator.

Auxiliary Potentiometer

The following procedure should be used to connect an auxiliary potentiometer to

the CC.

Step

Procedure

1

Connect the wiper wire to Terminal 1 under the Aux Pot label.

2

Connect the clockwise wire to Terminal 2 under the Aux Pot

label.

3

Connect the counterclockwise wire to Terminal 4 at the Temp

Sensor Input label.

§

This connection makes it possible to adjust the zone setpoint.

The Novar Controls Futura Temperature Sensor (Model FTS-3A) can be used

with the CC to provide optional setpoint adjustment (potentiometers).

Installation instructions are supplied with the sensor.

Figure 2.

Custom Controller terminal strip

Doc. #560309000—A 7/30/04

3

Custom Controller Installation Instructions

Temperature Sensor

Each CC must use a Remote Temperature Sensor (RTS-UVC) for discharge air in

addition to one of the following:

§

§

UVC Wall-Mount Indoor Temperature Sensor (WTS-UVC)

Futura Temperature Sensor (FTS-3 or FTS-3A) with temperature setpoint

adjustment

The temperature sensor input terminals are located under the Temp Sensor Input

label on the terminal strip.

Use the following procedure to connect the temperature sensors.

Step

Procedure

1

Connect the Wall-Mount Temperature Sensor’s plus (+) wire to

Terminal 3.

2

Connect the Remote Temperature Sensor’s red wire to Terminal 5.

3

Connect the black (–) wire from both sensors to Terminal 4.

To wire the other sensors to the CC, refer to their specific installation

instructions.

NOTE! Maximum recommended sensor wire length for

connecting the temperature sensors to the CC is 100 feet,

using 22-gauge wire (Belden 8761, Novar Controls

WIR-1010, or equivalent).

Status Input

Terminals 6, 7, and 8, labeled Status Input, are for digital input connections.

Terminals 6 and 7 are for the fan status and Terminals 7 and 8 are for the dirty

filter status. These are dry contact closure, digital inputs and are connected as

normally open with the fan status closing when the fan is on and the filter status

closing when the filter is dirty.

Override Switch Input

A normally open momentary contact switch and a status light-emitting diode

(LED) can be connected to Terminals 9 and 10 under the Override Switch label.

The override’s effective time period is defined in the software.

The Novar Controls Futura Temperature Sensor provides an override switch and

status LED. Its installation instructions outline the proper connections.

4

Doc. #560309000—A 7/30/04

Custom Controller Installation Instructions

Damper Feedback Sensor

Terminals 13 and 14, under the Analog Outputs label, can be used as an analog

input (0 to 10 VDC) to monitor a feedback signal from an electric damper actuator.

This feedback signal measures actual damper motor feedback between 0 and 10

VDC, linear. Figure 3 provides a wiring diagram of this feedback signal.

AUX

POT

ADJ +5V

1

2

TEMP

SENSOR

INPUT

STATUS

INPUT

OVERRIDE

SWITCH

S1 COM S2 DI 1 RET DI 2 O/R RET

3

4

5

6

7

8

9

10

ANALOG

OUTPUTS

0-10VDC, 1mA MAX

D

E

F

GND

11

12

13

14

+

FEEDBACK FROM

DAMPER ACTUATOR

0 - 10 VDC

Figure 3.

Damper analog input wiring

Wiring the Outputs

Table 1 shows the output configuration for the CC.

Table 1.

Custom Controller Outputs

ANALOG

CONTROL OPERATION

Terminal 11 (D)

Damper output signal

Terminal 12 (E)

Not Active

Terminal 13 (F)

Analog input

DIGITAL OUTPUTS

Doc. #560309000—A 7/30/04

CONTROL OPERATION

Terminal 21 (A)

Fan

Terminal 22 (B)

Cooling 2

Terminal 23 (C)

Heating 2

Terminal 24 (D)

Not Active

Terminal 25 (E)

Heating 1

Terminal 26 (F)

Cooling 1

5

Custom Controller Installation Instructions

Damper Analog Output

The analog output terminals are listed under the Analog Outputs label, immediately

to the right of the input connections (see Figure 2). Connect the damper to the CC

at Terminal 11 (analog output D). This is a 0 to 10-VDC, 1 mA maximum

connection. Terminals 13 (output F) and 14 are used as an analog input for a

feedback signal from a damper actuator (see “Wiring the Inputs”). Terminal 12

(output E) is not active.

Relay Outputs

The digital relay output terminals are located at the far right side of the terminal

strip under the Relay Outputs label (see Figure 2). Terminals 21 through 26

(outputs A through F) are the actual output connections. Figure 2 and Table 1

can be used to determine the proper connections. Digital relay output D is not

active because of the analog damper connection.

The digital relay outputs tie in directly to the six relay output status LEDs located

on the case of the CC. The relay output status LEDs match the status of the

relay.

§

§

If the contact is closed, the relay is energized and the LED is on.

If the contact is open, the relay is de-energized and the LED is off.

Terminal 20 is for one side of a 24-volt source to be controlled (switched)

through outputs A through F. The relay outputs are isolated from the other

connections to permit the additional power source. One transformer can be used

to power both the CC and the relay outputs if the transformer has enough

capacity.

Network

Communications

A suitable two-conductor shielded cable (Novar Controls WIR-1010 or

equivalent recommended) should be used to make the communication

connections between the CC and the module communications terminals of the

executive module. On the CC, the connections are Terminals 17, 18, and 19,

located under the Module Network label. The plus (+) and minus (–) connections

must be made correctly.

CAUTION!

6

The Shield connection is not a ground like the other

common grounds on the terminal strip. It is dedicated for

communications only. Do not connect any other grounds

to the Shield connection (Terminal 18).

Doc. #560309000—A 7/30/04

Custom Controller Installation Instructions

Setting the Module

Address

Every Logic One module must have a unique address for the executive module to

identify it. Addresses are assigned in the software during programming. The

system printout shows the address of the CC being installed.

Set the switches with the correct address from 00 to 63 (see Figure 4) and record

the setting on the module address label. The address switches are located in the

center of the terminal strip (see Figure 2).

NOTE! Address 00 should not be used by the CC if it is operating

on an Executive Controller (EC) or Savvy. The IOM

section of the EC or Savvy uses address 00.

Figure 4.

Doc. #560309000—A 7/30/04

Custom Controller address settings

7

Custom Controller Installation Instructions

Checking Installation

The following items should be checked to verify proper installation.

§

Turn on the power to the CC and the rooftop or air-handling unit and its

control circuitry. If the executive module is operating properly, the CC begins

to control the air-handling equipment in about 3 minutes (after performing a

self-diagnostic check and establishing communications with the executive

module).

§

A schedule status indicator LED is located on the module’s case above the

terminal strip. If the module is communicating properly, this LED should be

flashing according to the schedule mode.

— When the CC is in scheduled off mode, the LED is off and flashes on

briefly when communicating.

— When the CC is in scheduled on mode, the LED is on and flashes off

briefly when communicating.

§

If a timed override switch has been installed and programmed, it can be tested

for proper operation by pressing it during a scheduled off mode. The LED

flashes rapidly until the override period ends.

§

The six relay output status LEDs indicate the status of each active digital output.

Verify that the LEDs are lit when the corresponding digital output is on.

§

Monitor the executive module. If any faults or malfunctions still exist, they

are picked up by the executive module and announced by alarm messages.

The CC’s setpoints can be altered from the executive module’s keypad, and

the status display can be monitored for proper equipment response.

Model and Part Numbers

Use the part numbers shown in Table 2 to order the appropriate Novar Controls

parts.

Table 2.

Novar Controls Part Numbers

PRODUCT

Custom Controller

8

MODEL NO.

PART NO.

—

738008000

Futura Temperature Sensor (20° to 127°F)

FTS-3 with temperature adjustment

potentiometer

FTS-3

FTS-3A

732403000

732401000

Remote Temperature Sensor (for use with

UVC, ETC, HPC Plus, and ETM-3051)

RTS-UVC

736003000

Wall-Mount Temperature Sensor (for use with

UVC, ETC, HPC Plus, and ETM-3051)

WTS-UVC

736002000

Two-conductor shielded cable (Belden

equivalent #8761)

WIR-1010

709001000

Doc. #560309000—A 7/30/04