BeagleBone Rev A6 System Reference Manual

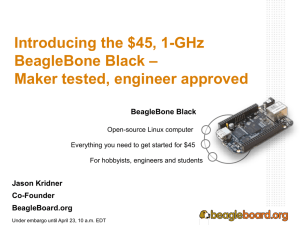

advertisement