Materials Lab 2015 - Johns Hopkins University

advertisement

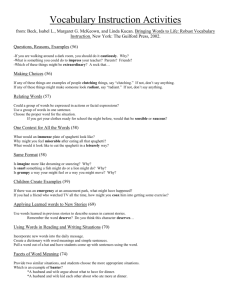

Material Testing Lab SAFETY: When completing the Materials Testing Lab activities, students must wear their goggles at all times while in the lab. You must also wear sturdy, closed-toe shoes. It is suggested that you wear disposable gloves when handling the lead shot. Please wash your hands after you complete this lab. Failure to comply with these safety requirements may result in earning no credit for the lab activity. RECORDING DATA: Record all your data in a notebook and then transfer it to an Excel data sheet. Think about the information you want to record in your lab notebook. Plan ahead to decide how you will record it in a table of rows and columns. You will be taking a lot of data so good data management is important. Don’t forget to measure the diameter for every piece of spaghetti you test. FOCUS: This laboratory includes three separate materials testing experiments to be done on spaghetti of 3 different diameters. See individual labs for respective objectives. Students will work in groups of three, and all students are required to contribute to the completion of the lab report (additional handout will provide specific details for write-up). Students are expected to put more thought into the objectives/hypotheses and communication of results since few instructions are given. BACKGROUND: Materials Science and Material Properties Materials Science involves investigating the relationships that exist between the (internal) structures and the properties of materials. A material’s properties are quantitative traits that tell us something about the nature of that material, and a material’s performance will be a product of its properties. These properties may be constant or dependent upon environmental conditions, and most important properties of materials may be grouped into six different categories: mechanical, electrical, thermal, magnetic, optical, and deteriorative. The mechanical properties of materials are most relevant to the design of structures. The mechanical properties reflect the relationship between a material’s reaction (or deformation) to an applied load or force. Examples of mechanical properties of materials are ultimate tensile/compressive strength, toughness, hardness, ductility, modulus of elasticity, and stiffness. There are three principal ways in which a load may be applied to a structural member: tension (pulling), compression (pushing), and shear (frequently applied through torsion). In this Material Testing Lab, students will perform three tests on spaghetti to determine the modulus of elasticity (Young’s Modulus, E) of spaghetti, the tensile strength of spaghetti, and to prove the format of the Euler Buckling equation. Although useful, students will not be performing shear tests of spaghetti as part of this lab. ©Johns Hopkins University (10/22/2014) Terminology TERM DEFINITION Ductility a measure of the degree of plastic deformation that has been sustained at failure. A brittle material experiences little or no plastic deformation Elastic Deformation deformation in which stress and strain are proportional. This deformation is nonpermanent, so the specimen returns to its original shape when the applied load is released. Hardness resistance to (different types of) permanent shape change when a force is applied. Hookean Solid any material that displays linear-elastic elongation. Plastic Deformation when a material is deformed beyond the area of elastic deformation and stress is no longer proportional to strain, this permanent deformation occurs. Proportional Limit the point in material testing before which elastic deformation occurs and beyond which plastic deformation occurs. Stiffness resistance to deformation. Strength ability of a material to withstand an applied stress without failure. Tensile Strength the maximum stress sustained by a material in tension. Prior to and including the tensile strength, all deformation is uniform throughout the specimen tested. However, if this stress is maintained or surpassed, necking begins to form and all subsequent deformation is confined to this neck. Toughness resistance to fracture in a material when stressed. Toughness indicates how much energy a material can absorb before rupturing. Think of chipping away at ice on a wind shield. Yield Strength the stress corresponding to the intersection between the stress-strain curve and a line parallel to the elastic portion of the stress-strain curve at a 0.002 strain offset. A material’s yield strength should be constant regardless of its cross-sectional area. Yielding plastic deformation. Young’s Modulus also known as the modulus of elasticity, E is the constant of proportionality as defined by Hooke’s Law. This modulus may be thought of as stiffness, or a material’s resistance to elastic deformation (i.e., the greater the modulus, the stiffer the material). TERM FORMULA Engr. Stress 𝜎=𝐴 UNITS 𝐹 DEFINITION MPa 0 the instantaneous force applied to a specimen over original cross-sectional area 𝐹 True Stress 𝜎=𝐴 Strain 𝜖= ∆𝑙 𝑙0 MPa the instantaneous force applied to a specimen over the instantaneous cross-sectional area none the elongation (or change in length) of a specimen divided by the original length, sometimes referred to as percent elongation Page 2 of 12 ©Johns Hopkins University (10/22/2014) M. Karweit (modified) Hooke’s Law 𝜎 = 𝐸𝜖 MPa strain is directly proportional to stress for “Hookean” materials (linear-elastic materials); this is equivalent to the spring equation Experiment 1: Tensile Test BACKGROUND: Tensile tests are one of the most common mechanical property tests. If you pull on both ends of a rod with an increasing amount of force (making sure to apply the force only along the length of the rod), at some point the rod will stretch, like silly putty, or break. The force will have exceeded the material’s yield strength. Depending on the material, the rod may simply snap in two. It also might experience plastic deformation in the form of necking (a gradual reduction in cross-sectional area) before it breaks. Under tensile loading, brittle materials tend to fracture without deformation, while ductile materials typically experience plastic deformation and necking before breaking. The force required to pull a rod apart depends on two things: the inherent strength of the material and the cross-sectional area of the rod. A cotton string is easier to break than the same size steel wire. A larger cross-section requires a larger force to pull it apart. This makes sense because a larger cross-sectional area means that there are more atomic bonds to pull apart along a fracture line, which in turn necessitates a larger force. With a circular cross-sectional area A = π R2, the force to break the rod is P k R m where the constant k depends on the material. PROCEDURE: You will measure the fracture strength of spaghetti by pulling on it using a lever arm apparatus. You will use the spaghetti epoxied to two cotter pins the previous day. 1. Start with the thinnest spaghetti. Use a micrometer to measure the spaghetti diameter. 2. For the lever-arm apparatus, the lower end of the spaghetti will be attached to a metal pin (use another cotter pin); the upper end will be attached to the lever arm via a chain and “S-hook” (see figure). Adjust the chain so that the lever arm is as level as possible. 3. Fill the bucket with BBs until the spaghetti breaks. Record the mass required to break the spaghetti. Record whether the spaghetti beaks along its length or at the glue joint. 4. Repeat for three samples of each spaghetti thickness. Measure the spaghetti thickness each time. You will have a total of 12 data points, three data points for each of the four thicknesses of spaghetti. DATA ANALYSIS AND INTRODUCTION TO EXCEL SPREADSHEETS 1. Enter your data into an Excel spreadsheet, along with the proper units. It will work best if you organize your spreadsheet in the following manner: Page 3 of 12 ©Johns Hopkins University (10/22/2014) M. Karweit (modified) 2. Add a column C where you calculate the radius of the spaghetti in the units of meters. a. First, label the column - in cell C1 type Radius (m) b. Then calculate the radius for the first sample by typing this equation into cell C2 (the = at the beginning of the calculation “tells” Excel that you wish for it to perform a mathematical calculation. =A2/1000/2 This will take the diameter in mm and convert it into meters (A2/1000) and then it will convert the diameter to a radius (1/2) c. To copy this equation: i. Click on the contents of Cell C2 ii. Hold down the Ctrl button and the C key at the same time (to copy) iii. Click on C3 and drag the mouse to highlight the cells where you want to copy the equation. iv. Hold down the Ctrl button and the V key at the same time (to paste) This will copy the equation into cells C3 and higher. 3. Add a column D where you calculate the force required to break the spaghetti. Convert your mass data into force using the equation: force = (mass)(gravity) or P= mg. To multiply in EXCEL you use * (Shift 8), not x, so you would type: =(B2/1000)*9.8 In SI units, forces are reported in units of Newtons, N (kg*m/s2), and the acceleration due to gravity,g, is 9.8m/s2. This means that you will have to convert the mass of the BB’s to the units of kilograms. If you attached the bucket of BB’s to the lever at the location most distant from the center point, the distance from the center to the bucket is 3 times the distance from the center to the spaghetti. This gives us a mechanical advantage of 3 times. You will need to multiply the force you calculated by a factor of 3. If you attached the bucket to the middle location on the arm, you gained a mechanical advantage of 2 times. If you attached the bucket to the location closest to the arm the distance between the bucket and the spaghetti is equal and there is no mechanical advantage. 4. Prepare a plot of force as a function of spaghetti radius To prepare this plot: i. Click and drag to highlight the data contents of Column D ii. Hold down the Ctrl key and click and drag to highlight the data contents of Column C Page 4 of 12 ©Johns Hopkins University (10/22/2014) M. Karweit (modified) iii. Click on the Insert tab on the top toolbar iv. Select Scatterplot and click on the top left graph style v. Click on Chart Layouts and select the top left layout style vi. Give your plot a meaningful title and label each axis. vii. Use the various graph formatting features to produce an appealing graph. 5. Inspect your graph carefully, what sort of trends do you see? Does the data appear to be linear? We would like to find the relationship between the spaghetti radius and the force it takes to break the spaghetti. Linear relationships are easy for us to understand. If your plot of force vs. radius is not linear, you will need to manipulate the data to find a linear relationship. Using logarithms will allow us to determine the mathematical relationship between force and radius. If we make the assumption that the force is a function of only the radius we can set up the following proportionality, force is proportional to the radius raised to the power x: P α Rm EQ. 1 We can convert this proportionality into an equality by adding a proportionality constant, in this case, k: P = kRm EQ. 2 How can we use this equation to determine the value of x? Taking the log of each side changes the exponential equation to a linear equation y = mx + b. The equation: 𝑃 = 𝑘 𝑅𝑚 EQ. 3 log 𝑃 = 𝑚𝑙𝑜𝑔𝑅 + 𝑙𝑜𝑔𝑘 EQ. 4 Becomes, If this is not familiar to you, please review the laws of logarithms. Plotting log P vs. log R gives a straight line with slope m and intercept log k. By plotting the logs rather than the values themselves, the straight line shows that P is proportional to R to some power. The slope is the power. Many physical relationships follow such power laws. 6. Plot log P vs. log R. To do this you will want to create a column of data for log(P) and log(R). If you would like EXCEL to calculate the log of the radius given in Cell C2, you would type the following equation in Cell E2: =log(C2) Page 5 of 12 ©Johns Hopkins University (10/22/2014) M. Karweit (modified) 7. Use the Trendline function of Excel to display the best fit line for your data. i. ii. iii. iv. v. Select a data point on the graph and right click on that datapoint. Select Add Trendline Select Linear Check the box for Display Equation on chart Check the box for Display R-squared value on chart (this is a measure of how well the equation fits the data – the closer this value is to 1.000, the better the data fits the given equation). 8. What is the equation for the relationship between P and R? Use the equation displayed on the graph after you add the Trendline. A word about units: A number without a unit is meaningless. You should always write a unit with a number. Getting a meaningful value often depends on the units you use. You sometimes need to convert one unit, like miles per hour, to another, like feet per second. Spaghetti’s yield strength (in Pascals) is equal to force (in Newtons) divided by area (in square meters). A material’s yield strength should be constant regardless of its cross-sectional area. However, imperfections and non-uniformities in a material can cause deviations in the measured values of strength. 9. In your Excel sheet, add a column for the spaghetti cross area, A = πR2. i. The EXCEL function for π is =PI() ii. To raise a value to a power in EXCEL, you use the ^ key (Shift 6) 10. Add a column for yield strength and calculate it for all your data points. 11. Do you get about the same value for all the spaghetti, independent of diameter? 12. What is the average value for the spaghetti yield strength? To calculate an average in EXCEL, you use the AVERAGE( ) function. To determine the average of the contents of cells C2 through C12, you would type the following in an empty cell in your spreadsheet: =AVERAGE(C2:C12) Page 6 of 12 ©Johns Hopkins University (10/22/2014) M. Karweit (modified) Experiment 2: Bending from Perpendicular Force Test BACKGROUND: Spaghetti bends easily when you push perpendicular to it. Now we will examine the strength of spaghetti relevant to this bending. Strength is related to bending in the following way: when a specimen is bent its material is being strained (stretched or compressed). Atoms are pushed closer together on the inside of the bend and pulled farther apart on the outside of the bend (in this figure the top of the beam experiences compression while the bottom of the beam experiences tension). Since these atoms are no longer at their equilibrium distance, they exert reactionary forces within the specimen which balance the bending load – up to a point. At some degree of bending, the specimen yields or fractures. That is, it irreversibly deforms. For brittle materials, like spaghetti, the specimen may simply fracture. For non-brittle materials like aluminum, the specimen yields and takes on a permanent deformation. These points are called the fracture strength and yield strength, respectively. If the material breaks, the atoms on the outside of the bend have been pulled too far apart to hold the material together. The material has reached its maximum strain, εmax. Pre-lab exercises: Spend 5 minutes playing with your spaghetti and make an effort to determine what affects the bending strength. As a guideline think about the following: 1. How does the magnitude of the force affect the deflection (extent of bending) 2. For a given force does a longer piece deflect more/less than a shorter piece of the same diameter 3. For two different diameters but equal length pieces, which deflects more? Now formulate a proportionality between P (force) and (a) y (deflection); (b)L (length); and (c) R (radius). For now, don’t worry about exponentials. How is strength related to bending? 1. On an atomic scale, what is going on when a sample is bent? Do the atoms on the outside and inside of the bend undergo the same force? 2. How would you expect the bending of spaghetti (brittle) to be different from the bending of annealed Aluminum (ductile)? Once the material breaks/cracks/fractures, it has reached its maximum strain and the corresponding strength is called its fracture strength. Theoretically, the relationship between the vertical deflection, y, and the bending load, P, is: 𝑃= 48𝑦𝐼𝐸 𝐿3 EQ. 5 Where: E = Young’s Modulus L = length of spaghetti (distance between supports) I = cross-sectional moment of inertia for the specimen For a circular cross section (like spaghetti), the cross-sectional moment of inertia, I, is: 𝐼= Page 7 of 12 𝜋𝑅 4 4 ©Johns Hopkins University (10/22/2014) EQ. 6 M. Karweit (modified) Simplifying, the bending load, P, is directly proportional to the deflection y. 𝑃 = 𝛼𝑦 Where: 𝛼= 12𝜋𝑅 4 𝐸 𝐿3 EQ. 7 EQ. 8 Verify that this equation agrees with our observations. Note, also, that this linear equation is congruent to Hooke’s Law. In this lab you will measure the bending deflection of spaghetti under a perpendicular load. You will then use the results to determine the Young’s Modulus and the ultimate yield strength or fracture strength of the spaghetti. PROCEDURE: The experimental procedure is simple: lay a piece of spaghetti between two supports, hang a weight mid-way between the support points, and measure the material’s deflection. The apparatus for this experiment consists of a support frame, a loading platform, and a handful of weights (BB’s). 1. Measure and record the mass of the loading platform and the BB’s Think About: How would you get an accurate measure for the weight of one BB? 2. Measure and record the distances between the three supports. 3. Measure the diameter of the thickest spaghetti. Insert the spaghetti through the eye of the swivel on the loading platform. Lay the specimen across the widest supports. Make sure that the bending load is placed midway between the supports. 4. Measure and record the deflection with the empty loading platform. 5. Begin to add BB’s. Record the number of BB’s and the deflection for each BB added. At some maximum deflection, the specimen will break. That value is especially interesting. 6. For the largest diameter of spaghetti, repeat the load vs. deflection measurement on the other two support widths. Measure and record the diameter of each spaghetti piece tested. 7. For the shortest span length only, repeat the test for the other three spaghetti thicknesses. This will give you a total of six data sets (if you test 4 different spaghetti thicknesses). DATA ANALYSIS: Enter your data into an Excel spreadsheet. Think about what columns of information you want to display. The way you display data will make your plotting simple or difficult. Make sure you include units (meters, kilograms, etc.) Enter your data into an Excel spreadsheet, along with the proper units. In Excel, use your mass data to calculate the force, P, associated with each deflection. Page 8 of 12 ©Johns Hopkins University (10/22/2014) M. Karweit (modified) For the largest diameter of spaghetti and widest separation, plot the force, P, as a function of the deflection, y. Question 1: What sort of trend do you see in your plot of force vs. deflection? Use the trendline function of Excel Chart to calculate a linear fit to the data. The slope for the line is the same as from EQ. 7 and EQ. 8. Repeat the process for each of your other data sets. (You can put them all on the same graph for easier comparison). On a clear part of your spreadsheet, summarize your data for all the data sets. Make columns for R (in meters), L (in meters), and (in Newtons/meter). Enter the values for all data sets. Add a fourth column for Young’s Modulus E. In that column, calculate E from EQ. 8. Question 2: How do the values of E compare for all the data sets? Should they be the same? Calculate the average E, which is the goal of the lab. Young’s Modulus for spaghetti should be around 4x 109 Pa. Question 3: How can we estimate the fracture or yield strength? Under a bending load, a specimen will tend to distribute the stress uniformly between the support points, i.e., the specimen will take the form of a circular arc. A little trigonometry will show that the radius of that arc, ρ, is: 𝐿 2 1 𝜌 = 2𝑦 [(2) + 𝑦 2 ] EQ. 9 As the specimen is bent, strain is imposed on the material from maximum tensile strain on the outside of the arc. At the center of the material there is a neutral plane where the strain passes from compression to tension. We can deduce the strain, ε, in the material as simply: 𝑐 𝜀=𝜌 EQ. 10 Where c is the distance from the neutral plane. To calculate εmax we need the value of ρ at which the material fractured, or yielded, and the maximum value of c for the material. In this case, c is simply R, the radius of the specimen. So: 𝑅 𝜀𝑚𝑎𝑥 = 𝜌 EQ. 11 Finally, we need to convert the maximum strain to the maximum stress (fracture or yield strength). To do this you must use Hooke’s Law: σmax= E*εmax EQ. 12 Where σmax = the maximum stress that you can expect from the material Recall that stress is force per unit area. Calculate the σmax for all the specimens you tested. From these calculations deduce the fracture strength of the different diameter spaghetti specimens. Are the experimental strengths proportional to their cross-sectional areas? Explain. Page 9 of 12 ©Johns Hopkins University (10/22/2014) M. Karweit (modified) Experiment 3: Buckling Test BACKGROUND: Although compression testing in addition to tension testing is also useful for determining such mechanical properties as yield strength, elastic modulus, ultimate strength, etc., it is particularly useful for determining the relationship between a material’s length and its compressive strength. A material in compression will fail by one of two ways: buckling or crushing. Spend 5 minutes playing with your spaghetti and make an effort to determine what affects the buckling strength. As a guideline think about the following: 1. Does the resistance to buckling increase or decrease as L decreases (D stays the same)? 2. For 2 different diameters but equal length pieces, does the thin sample buckle more or less than the thick sample? Theoretically, these observations can be summed up in an equation for the compression buckling of a rod. If you try to compress a cylindrical rod by applying an increasing force against its end, you will reach a point where the rod no longer remains straight, but begins to bend or buckle. The force at which this happens is called the Euler buckling load P. 𝐴𝐸𝜋 2 𝑃 = (2𝑘𝐿/𝑅)2 EQ. 13 Where P is the buckling load, A is the cross-sectional area of the specimen tested, E is Young’s Modulus for the material, k is a constant that depends on how the rod is held, L is the length of the specimen, R is the radius of the cylindrical specimen. For a circular rod (A = R2) held in such a way to allow free rotation at the ends (in other words, pinned), k=1 and P becomes 𝑃= 𝐸𝜋 3 𝑅4 4𝐿2 EQ. 14 Or, 𝑃= 𝐸𝜋 3 𝐷4 64𝐿2 EQ. 15 Taking an additional step and grouping the constants in EQ. 14 into a term 𝛽, 𝑅4 𝑃 = 𝛽 𝐿2 PROCEDURE: Using an apparatus similar to that shown in this figure, you will measure the axial compression force required to cause the spaghetti to buckle without breaking. Think about the information you want to record in your lab notebook. This lab will require a considerable amount of data so prepare your data table before you start. You will use 8 lengths of spaghetti for each diameter of spaghetti provided. Think About: Why don’t you want to grip the end of the spaghetti? How might holding the end affect the bending? EQ. 16 Wood Block Specimen Scale Think About: What parameters do you need to record in your lab notebook for each data measurement? Page 10 of 12 ©Johns Hopkins University (10/22/2014) M. Karweit (modified) 1. Select a reasonably straight piece of the thinnest spaghetti about 25 cm long. Measure and record the diameter and length to ±1mm. Note: when testing the other diameters of spaghetti it is important that you use the same lengths of spaghetti as you tested with the thinnest spaghetti. 2. Place a piece of masking tape on the scale to hold the bottom end of the spaghetti steady. Zero the scale. Use your fingertip or a piece of wood to press down on the spaghetti until it just begins to bend. This is difficult to do, so expect some variation in your data – record the value observed at the start of buckling. Record your best judgment of the force (in mass units) measured on the scale. How much variation do you observe (± x grams)? Does the force change as you press a little harder? 3. Break a piece off so that the spaghetti is now about 22 cm long. Measure and record the length to ±1mm. Do the buckling test and record the force when bending begins. Repeat for lengths of 19, 16, 13, 12, 11, 10, 9, 8, 7…until you can no longer obtain data. 4. Repeat for 3 more samples of varying thickness. 5. Enter your data into an Excel spreadsheet. Think about what columns of information you want to display. Include measurement units for each column. DATA ANALYSIS: Our experimental results show that the buckling load P depends on both the length L and the radius R of the spaghetti. Can we deduce an expression for the buckling load P as a function of L and R? Can we get obtain an accurate demonstration of the theoretical equation given above? Many physical phenomena follow exponential or power law relations, like the earlier bending and tension experiments. Now you will use the same approach to find the exponents for L and R, and ultimately the exponent m in the Euler Buckling equation above. For the buckling data, we might expect: P Lm R n EQ. 17 where m and n are most often integers (but sometimes halves or thirds), and β is a constant that takes into account other fixed parameters. With two variables, however, we must analyze them one at a time. We will hold one constant while analyzing the other. Part 1 – The Length Variable 1. Select the data for the thickest spaghetti. In Excel, use your mass data to calculate the force the spaghetti experienced when if first started to buckle. This is the Buckling Load, P. 2. Plot Buckling Load P (in Newtons) vs. length L (in meters). Is the plot linear? 3. Now plot Log P vs. Log L. Use the trendline function of Excel Chart to calculate the slope for the line. The slope is the value of m, the exponent for L. How does it compare with the theoretical value? 4. Repeat step 3 for the other thicknesses of spaghetti. 5. Summarize your results for all the data. Are the results similar? Calculate the average value for the exponent. What integer is it close to? Page 11 of 12 ©Johns Hopkins University (10/22/2014) M. Karweit (modified) Part II The Diameter Variable 1. For the 19-cm spaghetti, plot log P vs. log R. Your force, P, should have units of N. The radius. R, should have units of m. You will have four data points, one for each of the four thicknesses. 2. Use the trendline function of Excel Chart to calculate the slope for the line. The slope is the value of n, the exponent for R. How does it compare with the theoretical value?. 3. Repeat these calculations for another length. Choose a length that is less than 15 cm. Are the results similar? Part III Calculation of Young’s Modulus Recall that the equation for the buckling load is : P E 3 R 4 4L2 EQ. 14 E 3 If you plot P vs. R L , you should get a straight line with a slope of . You must, however, be 4 careful with units. Put all units in the mks system. 4 -2 1. Make a column in your spreadsheet for R4 L-2. For all your data, plot P vs. R4 L-2. What kind of line do you get? Use the trendline to calculate the slope of the line. 2. Using the slope, calculate E. Compare your value to the results you got for the bending lab. Page 12 of 12 ©Johns Hopkins University (10/22/2014) M. Karweit (modified)