Medium Voltage Distribution

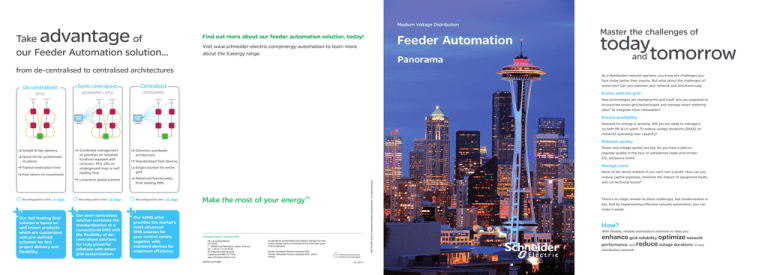

advantage

Take

of

our Feeder Automation solution...

Feeder Automation

Find out more about our feeder automation solution, today!

Visit www.schneider-electric.com/energy-automation to learn more

about the Easergy range.

Panorama

from de-centralised to centralised architectures

De-centralised

(RTU)

Semi-centralised

Centralised

(SCADA/DMS + RTU)

(SCADA/DMS)

Master the challenges of

today

and tomorrow

As a distribution network operator, you know the challenges you

face today better than anyone. But what about the challenges of

tomorrow? Can you maintain your network and simultaneously:

Evolve with the grid

New technologies are changing the grid itself. Are you prepared to

incorporate smart-grid technologies and manage smart metering

data? To integrate more renewables?

SCADA

DMS

Ensure availability

SCADA

DMS

Demand for energy is growing. Will you be ready to manage it

on both MV & LV sides? To reduce outage durations (SAIDI) on

networks operating near capacity?

Maintain quality

Quick hit for problematic

locations

Fastest restoration time

Fast return on investment

Reconfiguration time: <1

min

Our Self Healing Grid

solution is based on

well known products

which are customized

with pre-defined

schemes for fast

project delivery and

flexibility.

Combined management

of priorities on targeted

locations equiped with

reclosers, ATS, CBs on

underground loop or self

healing loop

Common worldwide

architecture

Long term global scheme

Advanced functionality

from leading DMS

Reconfiguration time: <3

Reconfiguration time: <5

min

Our semi-centralised

solution combines the

standardisation of a

conventional DMS with

the flexibility of decentralised solutions

for truly powerful

solutions with smart

grid customisation.

Power and voltage quality are key. Do you have a plan to

regulate quality in the face of unbalanced loads and stricter

CO2 emissions limits?

Standardised field devices

Manage costs

Single solution for entire

grid

min

Our ADMS offer

provides the market’s

most advanced

DMS solution for

your control centre,

together with

standard devices for

maximum efficiency.

ART.832397 © 2014 Schneider Electric Industries SAS - All rights reserved

Simple & fast delivery

Make the most of your energy tm

Schneider Electric Industries SAS

35, rue Joseph Monier

CS 30323

F - 92506 Rueil Malmaison Cedex (France)

Tel.: +33 (0) 1 41 29 70 00

RCS Nanterre 954 503 439

Capital social 896 313 776 €

www.schneider-electric.com

AMTED107018EN

As standards, specifications and designs change from time

to time, please ask for confirmation of the information given

in this publication.

Design: Schneider Electric Industries SAS

Photos: Schneider Electric Industries SAS - iStock

Printed:

This document has been

printed on recycled paper.

02-2014

None of the above matters if you can’t turn a profit. How can you

reduce capital expenses, minimize the impact of equipment faults,

and cut technical losses?

There’s no magic answer to these challenges, but modernisation is

key. And by implementing effective network automation, you can

make it easier.

How?

With flexible, reliable automation solutions to help you

enhance grid reliability, optimize network

performance, and reduce outage durations. In any

distribution network.

1

Easergy

T200 P

2

Easergy

Flite 116-SA/G200

3

4

Easergy

Flite 110-SA

Easergy

Flite 210, 230

5

6

Dedicated controller for N, U, W

reclosers, and RL sectionaliser

Overhead switch control unit

Communicating fault passage

indicator for overhead lines

Capacity

400 Easergy type devices

Phase and earth current,

directional, voltage, frequency,

harmonics

Control of 1 or 2 switches,

PM6 or other load break switches

Single-phase ammetric detector

Single-phase ammetric

detector

2

3

Pole-mounted

Phase and earth faults,

Switch monitoring and control

directional

Measurement : Current, voltage, 24VDC or 48VDC motorizations

real power, power factor, demand, Fault passage detection

phase-to-phase and phase-to-earth

harmonics, supply outages,

faults

waveform capture

Automation systems: sectionaliser,

Setting: by laptop, operator

automatic power source transfer

control panel, Scada

Measurements: I, U, P, Q, S,

Installation: mounted on the

energy and power factor cos

pole or substation frame

Concentration of Modbus slave

devices

Remote setting with WSOS5

Data and measurements archives

monitoring and control software

Electronics sealed to IP65, 316 Back-up power supply for control

unit, switch and transmission

grade stainless steel enclosure

equipment: typical autonomy 16h

Programmable logic controller

IEC 61131-3 and built-in calculation

formulas to create or tailor specific

Advanced controller dedicated functions/applications

to N, U and W Series reclosers,

and RL Series sectionaliser

Flite 116:

clip-on installation

Phase-to-phase and phase-toearth fault current detection

I and U presence measurements

Communication management

with G200

Powered by lithium battery

G200:

Pole-mounted

Data concentrator up to 9 Flite

116-SA sensors

Processing and archiving

Free I/O: 3 digital outputs and

6 digital inputs

220 Vac, solar or 12 Vdc supply

Three-phase ammetric

detectors

Three-phase directional

detectors

to

15

Integrated communication front-end

Permanent and non permanent

communications management:

phone line/GSM/GRPS/3G

radio

direct public and dedicated private line

Ethernet

Periodic call management

IEC 870-5-101 and

IEC 870-5-104

Serial DNP3 and TCP/IP

Serial Modbus and TCP/IP

Other proprietary protocols

Line installation

Wall-mounted

Phase-to-phase and

phase-to-earth fault

current detection

Indication of transient

and permanent faults

Phase-to-phase and

phase-to-earth fault

current detection

Indication of transient

and permanent faults

Phase-to-phase and

phase-to-earth fault

current detection

Indication of transient

and permanent faults

Powered by lithium

battery

Powered by lithium

battery

Pole-mounted

Phase-to-phase and

phase-to-earth fault

current detection

Transient and/or

permanent fault indicator

Fault counter

Powered by lithium

battery, solar panels or

12 Vdc depending on

model

Incorporated in the

switchgear

Phase-to-phase and

phase-to-earth fault

current detection

Measurements:

ammeter

maximeter

Self-powered by

current sensors and 3

backup supply solutions

when network is dead:

21D: super capacitor

22D Li Battery

23D/23DM: Ext DV

supply

Wall-mounted

Phase-to-phase and

phase-to-earth fault

current detection

Power supply:

Flair 279: 220 Vac

(battery-backed)

Flair 219: battery

Power supply:

Flair 510: with Li battery

Flair 570: 110/220 VAC

with backup Li battery

Flair 590: 220 VAC with

backup supercapacitor

IEC 870-5-101

Serial DNP3 and TCP/IP

Serial Modbus and TCP/IP

Accessories

Accessories

PSTN modem, GPRS/3G and fibre optic TTS (Test & Training Set)

modems

IOEX (Input Output Expander)

FTIM (Fast Trip Input Module)

SVIIS (Secondary Voltage

Injection Interface Set)

Installation tool

Signalling contacts

for RTU

Signalling contact

for RTU

1 RS485

communication port

(Flair 23DM only)

Signalling contact for

RTU

Signalling contacts for

RTU (signalling possibility

separate from phase and

neutral faults)

Two external inputs

allowing:

resetting of faulty

signalling

detector tests

14

Brain of Premset

embedded control and

monitoring system

Phase-to-phase and phase-toearth fault current detection

U, I, P, Q, S, energy and

power factor measurements

cos

Management of 3 digital

outputs and 6 digital inputs

220 Vac supply backed-up by

lead battery

Concentration of Modbus

communicating devices

Data and measurement

archives

Programmable logic controller

IEC 61131-3 and built-in

calculation formulas to create

or tailor specific functions/

applications

Radio, PSTN, GSM,

GPRS, 3G

1 communication port

1 Ethernet port (option)

Transmission interface:

PSTN, Radio, GSM, GPRS,

Ethernet, RS232, RS485

Modbus/IP,

IEC 870-5-101/104,

DNP3, DNP3/IP

IEC 870-5-101 and

IEC 870-5-104

Serial DNP3 and TCP/IP

Serial Modbus and TCP/IP

Communication protocol

Configurable via display By micro switches or

unit

push buttons & LCD unit

By micro-switches

Configurable via display

unit

Embedded web server

Local and remote configuration

Embedded web server

Local and remote configuration

Accessories

Open phase and zero

sequence sensors

External Light Indicator*

Unit for wall-mounting*

*(optional)

Open phase and zero Open phase and zero

sequence sensors

sequence sensors

External light indicator* External light indicator*

*(optional)

*(optional)

Open phase and zero

sequence sensors

Open phase and zero

sequence sensors

PM100592

Communicating fault passage

indicator for MV substation

Configuration

By micro-switches

15

Wall-mounted

Control and monitoring

through embedded devices

in MV switchgear

Premset, SM6 (end 2014)

Ensure remote

control and automated

management.

Embedded web server.

Concentration of Modbus slave devices

Local and remote

Data and measurements archives

configuration

Back-up power supply for control unit, switch and

ATS100:

transmission equipment: typical autonomy 16 hours

automatic source transfer

Programmable logic controller IEC 61131-3 and built-in with dedicated front panel.

calculation formulas to create or tailor specific functions/ Lines, generator,

applications

bus tie

IEC 870-5-101 and IEC 870-5-104

Serial DNP3 and TCP/IP

Serial Modbus and TCP/IP

Other proprietary protocols

Easergy

PS100

1 or 2 Fault Passage Indicators

functions, compatible with all

earthing systems

Switch monitoring and control 24VDC or 48VDC

motorizations

Fault passage detection phase-to-phase and

phase-to-earth faults

Automation systems: sectionaliser, automatic power

source transfer

Measurements: I, U

1 to 2 serial communication ports to SCADA/DMS

1 Ethernet port

Communication port operation management

Transmission interface: PSTN, radio, GSM, GPRS,

3G, Ethernet, dedicated line, RS232, RS485

Peer-to-peer communication in Modbus IP

MV/LV Substation

power supply

PE90718

DM103098

DM103099

Switch monitoring

and control unit

Ringmaster-mounted

Embedded in SM6

cubicle NSM for ATS

function (T200S)

Modbus

Professional communications and

database editor

Data creation via dialogue boxes

13

Easergy

Flair 200C

Communication

Option: signalling

contact for RTU

Configuration

Simulation tools and tests

PE57924G

Main functions

915 MHz short range radio

communication between G200 and

Flite 116-SA

1 SCADA/DMS communication

port transmission interface: radio,

GSM, GPRS

Local configuration with PC tool

12

Wall-mounted

By micro-switches

Embedded web server

Local and remote configuration

11

Easergy

R200, ATS100

Main functions

Configuration

Controls N, U and W series

Reclosers and RL-Series Load

Break Switch/Sectionaliser

Easergy

T200E

Control of 1 to 16 switches, Control of 4 switches,

RM6, FBX, SM6 and other dedicated to Ringmaster

cubicles

Pole-mounted

Three-phase

Three-phase ammetric

amperematric/ammetric

detectors

fault detectors with LCD.

Compatible with all types

of neutral system and

communication capability.

DIN format

Communication protocol

DNP3, IEC 870-5-101/104

Modbus/IP and DNP3/IP

Easergy

T200I

Control unit for MV and MV/LV substations

Communication

Radio, modem, GSM, V23,

1 to 2 serial communication

RS232, RS485, 10BaseT Ethernet ports to SCADA/DMS

1 Ethernet port

Communication port operation

management

Transmission interface: PSTN,

radio, GSM, GPRS,

3G, Ethernet, dedicated line,

RS232, RS485

Peer-to-peer communication in

Modbus IP

PE90717

PM57922

10

Remote

Network Monitoring

Three-phase detectors

compatible with all

neutral system types

PM6 remote control enclosure

Communication protocol

Modbus serial and TCP/IP,

IEC 870-5-101 and IEC 870-5-104

9

Easergy Flair 510,

570, 590

Can be delivered

embedded in RM6,

FBX, Flusarc and

Premset

Communication

8

8

Easergy range dedicated

remote control system

Main functions

6

PE57787

Easergy Flite 312, Easergy Flair 21D, Easergy

315, 332, 335, 382 22D, 23D, 23DM Flair 219, 279

7

PM103942

Remote

Network Control

Fault current detectors Fault current detectors Fault current detectors Fault current detectors

for an overhead network for an overhead network for an overhead network for MV substations

Network view with substation alarm

Detailed substation view

Alarm logs, archives

Direct access to substation view

via a list

Automatic sorting of alarms

and archives by substation

Online help

1

Local Fault

Indication

4

5

7

Local Fault

Indication

PE57929

PE56266

ADVC 2

Easergy

L500

Remote

Network Monitoring

Underground Network

PE90724

Remote

Network Control

Underground Network

PE57923

Recloser

Controler

Overhead Network

PE57927

Overhead Network

PE90722

at a glance

Dedicated supervision for

Easergy range

PM103550

Feeder Automation solution

Fault indicator: Flair

23DM

Control unit: SC110

Backup power supply:

PS100

Power supply and battery

charger for MV/LV

substation.

24V or 48V for motor and

IEDs supply

12V for communication

device supply

Autonomy up to 24h

90W for 24/48V permanent

load

300W 1mn for motor supply

10kV insulation

Monitoring of battery to

detect end of life through

Modbus communication