Copyright © 1991 ASM International®

All rights reserved.

www.asminternational.org

ASM Handbook, Volume 4: Heat Treating

ASM Handbook Committee, p 601-619

Defects and Distortion in Heat-Treated

Parts

Anil Kumar Sinha, Bohn Piston Division

MOST OF THE PROBLEMS in heattreated parts are attributed to faulty heattreatment practices (such as overheating and

burning, and nonuniform heating and quenching), deficiency in the grade of steels used,

part defect, improper grinding, and/or poor

part design. This article discusses overheating and burning, residual stresses, quench

cracking, and distortion in some detail and

offers some suggestions to combat them.

Most of these conditions result in a characteristic appearance of the treated parts that

can be easily recognized by simple inspection. Some of these factors do not produce

any distinguishing features in the semifinished or finished part. In particular, some of

the visual evidence does not recognize the

presence of overheating and burning and the

development of residual stresses leading to

distortion, quench cracking, and eventual

failure of the heat-treated parts; metallurgical

laboratory examination is needed to establish

these problems that contribute significantly to

the service performance of the part. Tool

designers must also be aware of the problems

and difficulties in manufacture, heat treatment, and use.

Overheatin 8 and Burning of

Low-Alloy Steels

When low-alloy steels are preheated to

high temperature (usually > 1200 °C, or 2200

°F), prior to hot mechanical working (such as

forging) for a long period, a deterioration in

the room-temperature mechanical properties

(particularly tensile ductility and impact

strength or toughness) can be obtained after

the steel has been given a final heat treatment

(comprising reaustenitizing, quenching, and

tempering) (Ref 1-3). Linked with the impaired mechanical properties is the appearance of intergranular matte facets on the

normal ductile fracture surface of an impact

specimen. This phenomenon is known as

overheating and has been a matter of concern, especially in the case of steel forgings.

Overheating has also been noticed in steel

castings (due to variation in pouring temper-

ature and effectiveness of the proprietary

grain inoculants applied to the mold surface),

in heavily ground parts, and in affected zones

of welds (Ref 4). The usual practice is to

reject the overheated products as being unsuitable for service.

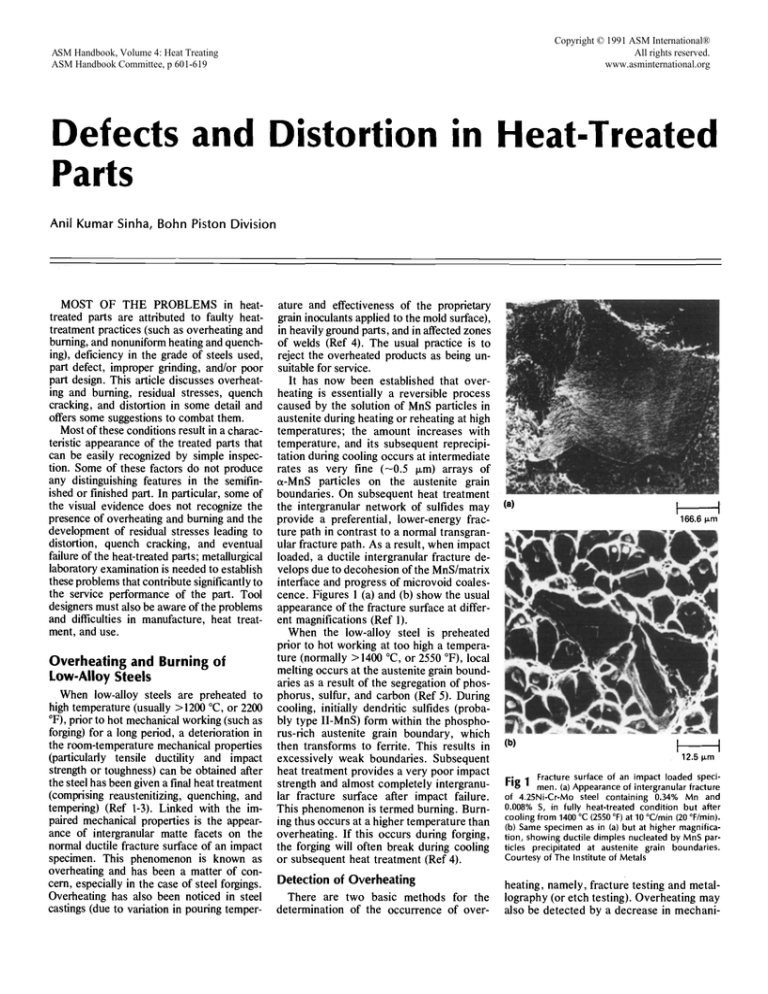

It has now been established that overheating is essentially a reversible process

caused by the solution of MnS particles in

austenite during heating or reheating at high

temperatures; the amount increases with

temperature, and its subsequent reprecipitation during cooling occurs at intermediate

rates as very fine ( - 0 . 5 i~m) arrays of

a-MnS particles on the austenite grain

boundaries. On subsequent heat treatment

the intergranular network of sulfides may

provide a preferential, lower-energy fracture path in contrast to a normal transgranular fracture path. As a result, when impact

loaded, a ductile intergranular fracture develops due to decohesion of the MnS/matrix

interface and progress of microvoid coalescence. Figures 1 (a) and (b) show the usual

appearance of the fracture surface at different magnifications (Ref 1).

When the low-alloy steel is preheated

prior to hot working at too high a temperature (normally > 1400 °C, or 2550 °F), local

melting occurs at the austenite grain boundaries as a result of the segregation of phosphorus, sulfur, and carbon (Ref 5). During

cooling, initially dendritic sulfides (probably type II-MnS) form within the phosphorus-rich austenite grain boundary, which

then transforms to ferrite. This results in

excessively weak boundaries. Subsequent

heat treatment provides a very poor impact

strength and almost completely intergranular fracture surface after impact failure.

This phenomenon is termed burning. Burning thus occurs at a higher temperature than

overheating. If this occurs during forging,

the forging will often break during cooling

o r subsequent heat treatment (Ref 4).

Detection of Overheating

There are two basic methods for the

determination of the occurrence of over-

166,6 ~rn

I 12.5 p,rn I

Fracture surface of an impact loaded specimen. (a) Appearance of intergranular fracture

of 4.25Ni-Cr-Mo steel containing 0.34% Mn and

0.008% S, in fully heat-treated condition but after

cooling from 1400 °C (2550 °F) at 10 °C/min (20 °F/rain).

(b) Same specimen as in (a) but at higher magnification, showing ductile dimples nucleated by MnS particles precipitated at austenite grain boundaries.

Courtesy of The Institute of Metals

Fig 1

heating, namely, fracture testing and metallography (or etch testing). Overheating may

also be detected by a decrease in mechani-

602 / Process and Quality Control Considerations

Table 1 Etching characteristics of overheated and burned steels

Reagent

2.5% nitric acid in ethyl

alcohol

Saturated aqueous solution

o f ammonium nitrate

Aqueous 10% nitric acid +

10% sulfuric acid

85% orthophosphoric acid

(Fine's reagent)

Oberhoffer's reagent

Method

Action on overheated steel

Swab surface for 30 s

Electrolytic, specimen anode,

current density 1.0 A cm -2

(6.5 A in. -2)

Etch for 30 s, swab surface;

repeat three times, then

repolish lightly

Electrolytic, specimen anode,

current density 0.15 A cm -2

(1.0 A in.-2), etching time 15

min

Swab surface for 30 s

Action on burned steel

May produce grain contrast, but

not indicative of overheating

White boundaries outlining

preexisting grains

White boundaries outlining

preexisting austenite grains

Black boundaries outlining

preexisting austenite grains

Black boundaries outlining

preexisting austenite grains

White boundaries outlining

preexisting austenite grains

Does not differentiate between

overheated and nonoverheated

steel

Attacks inclusions at grain

boundaries

Does not differentiate between

Shows phosphorus segregation at

grain boundaries

overheated and n o n o v e r h e a t e d

steel

Source: Ref 13

cal properties. But such changes are not

very marked unless overheating temperature is high or overheating is too prolonged

or severe; in some instances the mechanical

properties do not change, even after the

observation of extensive faceting. Usually

the two methods mentioned above should

be used in conjunction with some measure

of toughness by impact or other testing in

order to get a clear understanding of the

degree and severity of overheating (Ref 2).

Fracture Testing. The direction of fracture

testing is important in steels manufactured

by conventional methods. It has been observed by some workers (Ref 6) that the

longitudinal fracture test specimens parallel

to the rolling direction do not exhibit facering until the corresponding transverse fractures display extensive faceting. However,

the testing direction in electroslag-refined

(ESR) steels has been found to be insignificant (Ref 7).

The scanning electron microscope is considered to be the best and most convenient

tool to detect the facets on the overheated

fracture surfaces. These facets are characterized by small, well-defined, ductile dimples; each dimple is usually nucleated, presumably by fine arrays of inclusion

particles: a-MnS particles (Fig 1) in Mnbearing steels (Ref 8, 9) or chromium sulfides in Mn-free steels (Ref 10, 11).

It is now well recognized that the fracture

test specimen should always be tested in the

toughest possible state (for example,

quenched and highly tempered [in the range

600 to 650 °C, or I 110 to 1200 °F] steels after

high-temperature austenitization) because

this condition is most prone to overheating

effects. Baker and Johnson (Ref 5) have

suggested that an increased proportion of

facets in the fracture specimens with increasing tempering temperature is attributed to the corresponding increase of the

plastic zone size. In this case a slight

amount of weakening will be sufficient to

impart faceting because the grain boundary

strength becomes lower (Ref 2). It should be

noted that the existence of facets in the

fractured specimens is not always associat-

ed with a lowering of impact strength (Ref

12).

Metallography (or Etch Testing). The most

widely used etchant technique uses

Austin's reagent (aqueous solution of 10%

nitric and 10% sulfuric acids), ammonium

persulfate, molten zinc chloride, saturated

solution of picric acid at 60 °C (140 °F), and

an electrolytic etch based on saturated

aqueous ammonium nitrate. Table 1 shows

the etching characteristics of overheated

and burned steels (Ref 13). The etchant

procedure with Austin's etchant is as follows: The sectioned specimen is etched for

30 s in the etchant, removed, washed off,

and repeated three times. If the steel has

been overheated, the original austenite

grain boundaries will be preferentially attacked, and a black network of etch pits will

be observed under the microscope (Ref 14).

According to Preece and Nutting (Ref 13),

the best results are obtained when ammonium nitrate etch is applied on the sectioned

steel specimen in the fully heat-treated condition where this etchant preferentially attacks the matrix (original austenite grains),

leaving the grain boundary unaffected

(which appears as a white network).

Bodimeade (Ref 15) concluded that all these

etchants did not cope with mildly overheated low-sulfur steels. Table 2 is a summary

of the results of potentiostatic etching techniques carried out by McLeod (Ref 12)

using nitric-sulfuric, saturated aqueous picric acid (at 60 °C, or 140 °F), and ammonium

nitrate etchants. He considered that when

the suitable etching conditions were established, the potentiostatic etching method

rendered more reliable and reproducible

results as compared with the conventional

etching techniques. However, the same

problem with mildly overheated low-sulfur

steels still persisted. Hence, the use of etch

tests for low-sulfur low-alloy steels is not

recommended for the detection of mild

overheating.

Detection and Effects of Burning

Burning is not commonly encountered.

The two etchants (namely, nitric-sulfuric

acid and ammonium nitrate solution) used

for overheating can be successfully employed for detecting burning. When applied

to burned steels, these etchants react in a

manner opposite to that of overheated

steels. Preece and Nutting (Ref 13) found

ammonium nitrate solution to be the ideal

reagent to detect this phenomenon. Other

reagents are Stead's and Oberhoffer's reagents, which may also be used to check the

burning effect. However, these etchants are

unable to differentiate between overheated

and nonoverheated steels.

Factors Affecting Overheating

The occurrence and severity of overheating depend principally on important factors,

notably steel composition, temperature,

cooling rate, and method of manufacture.

Composition. Sulfur is the constituent

that greatly influences overheating. For

steels with less than 0.002 wt% sulfur, overheating does not occur; this is because of

the very low volume fraction of sulfides

formed. However, the commercial production of such very-low-sulfur steels (for example, ESR steels) is expensive. Above this

level of sulfur, the overheating onset temperature rises with the increasing amount of

sulfur. It has now been explained that steels

with low sulfur content (0.01 to 0.02%) are

more prone to this defect than those with

high sulfur content (>0.3%) because the

transgranular strength is high, and therefore

a small amount of grain-boundary sulfide

precipitation is enough to induce intergranular failure (Ref 16). The phosphorus content has been regarded with the most concern in connection with burning. At

constant phosphorus level, there is an increase in the overheating temperature with

the increase of sulfur content, whereas the

burning onset temperature decreases. Burning temperature is reduced with the increase

in phosphorus content. At low sulfur contents, a wide gap between overheating and

burning temperatures exists. For example,

in the case of vacuum remelted steels, the

temperature gap between the onset of overheating and burning is - 3 0 0 to 400 °C (-570

Defects and Distortion in Heat-Treated Parts / 603

Table 2 Summaryof potentiostatic etching experiments

Solution

Saturated aqueous

ammonium

nitrate

Aqueous 10% nitric

acid + 10%

sulfuric acid

Anodic loop

voltage, mV

-400

200

-250

Saturated aqueous

picfic acid at

60°C (140 °F)

100

produces cracking and distortion of the

parts (Ref 2).

Best etching conditions

Observed effect

Slight general

etching

Vigorous

dissolution

of specimen;

formation of

flaky black

film

Milder attack;

large black

pits in

mildly

etched

matrix

No real,

positive

indication of

overheating

Voltage, mV

2200 (for 2

min)

Observed effect

Classic white

boundaries on a

dark background

None

About -250

(for 30 s)

None

Discontinuous

array of

grain-boundary

pits and some

random pits

within grains

Comments

Operates best in the

transpassive region at

>+1500 mV; time at

any potential is

important

Underetching: random

array of black pits

Overetching: uniform

black surface film

Most aggressive etchant

of the three examined

Polish lightly after etching

to eliminate matrix

etching effects

Anodic loop very weak,

necessitating long

etching times because

current density is very

low; Teepol additions

gave no improvement

Source: Ref 12

to 750 °F) and there is a remote possibility

of burning occurring within the forging

range, unless the overheating is severe (Ref

2). However, at high sulfur content the gap

becomes narrow.

Temperature. To avoid overheating, care

must be exercised in choosing a correct

heating temperature so that uneven heating,

flame impingement, and so forth, do not

occur (Ref 3).

Cooling Rates. The cooling rate through

the overheating range affects the size and

dispersion of intergranular et-MnS particles.

The intermediate cooling rate generally employed, 10 to 200 °C/min (20 to 360 °F/min),

gives rise to maximum faceting as well as to

the greatest loss in impact strength. However, slow and rapid cooling rates will suppress overheating. At very slow cooling

rates, the sulfide particles become large,

small in number, and more widely dispersed, and they have no more deleterious

effects than the other inclusions already

present. At rapid rates, the sulfide inclusions are too fine to produce any damaging

effect (Ref 17).

Methods of Manufacture. Electroslagremelted steels are less susceptible than

vacuum-remelted steels, presumably due to

the difference in oxygen level. Similarly,

nickel steels are more prone to overheating.

Vacuum-remelted steels have a lower overheating temperature than some comparable

air-melted steels.

Prevention of Overheating and

Burning

F o r preventing overheating of steels, a

properly selected temperature should lie

between a temperature low enough for the

metal to be safe and high enough to be

sufficiently plastic. The better the temperature control, the better the compromise.

Severe overheating can be reduced to

mild overheating by soaking the steel at

1200 °C (2200 °F); with care, it may be

removed completely. Hot working through

the overheating range to a low finish temperature is also reported to remove the

effects of overheating.

The alloying additions with a greater sulfide-forming tendency, such as calcium, zirconium, cerium ( - 0 . 3 % of the melt), or

mixed rare earth metals (in the form of

misch metal containing 52% Ce, 25% La,

and 12% Nd), have been shown to increase

significantly both the overheating temperature and mechanical properties of the steel

(for example, ductility and toughness). Provided that a high Ce/S ratio (>2) existed, a

complete change in sulfide morphology occurred in low-alloy steels where the elongated MnS inclusion occurring in the untreated steel was totally replaced by small

globular type-I rare earth sulfides and oxysulfides of high thermal stability even after

austenitizing at 1400 °C (2550 °F) (Ref 2).

This treatment does not show intergranular

faceting. Burning can also be avoided in the

same way by treating with calcium, zirconium, cerium, or mixed rare earth addition to

form refractory, less-soluble sulfides.

Control of Cooling Rates. Control of cooling rates is not a practical method for large

forgings because extremely slow cooling is

prohibitively time consuming and causes

excessive scaling and decarburization, and

rapid quenching from high temperatures

Reclamation of Overheated Steel

Severely overheated steels can often be

completely restored by any of the following

heat treatments:

• Repeated normalizing (as many as six)

starting at temperatures 50 to 100 °C (90

to 180 °F) higher than usual, followed by

a standard normalizing treatment (Ref 2)

• Repeated oil-hardening and tempering

treatments after prolonged soaking at 950

to 1150 °C (1740 to 2100 °F) in carburizing

atmosphere. Rehardening more than

three times is not advisable

• Soaking at 900 to 1150 °C (1650 to 2100

°F) for several hours. This causes growth

of MnS particles by the Ostwald ripening

process and results in an excessive scale

formation and a loss of dimensional accuracy of the forgings

Residual Stresses

Heat treatment often causes stress- and

strain-related problems such as residual

stress, quench cracks, and deformation and/

or distortion. The residual stress may be

defined as the self-equilibrating internal or

locked-in stress remaining within a body with

no applied (external) force, external constraint, or temperature gradient (Ref 18, 19).

There are two types of residual stresses:

• M a c r o - or long-range residual stress is a

first-order stress that represents an average of body stresses over all the phases in

polyphase

materials.

Macroresidual

stresses act over large regions as compared to the grain size of the material.

Traditionally, engineers consider only

this type Of residual stress when designing mechanical parts

• Microresidual stress, also t e r m e d tesselated stress or short-range stress is a

second-order or texture stress, which is

associated with lattice defects (such as

vacancies, dislocations, and pile-up of

dislocations) and fine precipitates (for example, martensite) (Ref 20-22). Microresidual is the average stress across one

grain or part of the grain of the material.

This information is indispensable in

studying the essential behavior of material deformation

These two types of residual stresses may

also be classified further as a tensile or

compressive stress located near the surface

or in the body of a material. This section

focuses on the effects, development, control, and measurement of long-range residual stresses.

Effects of Residual Stress

The major effects of residual stress include dimensional changes and resistance to

604 / Process and Quality Control Considerations

Surface residual stress (root of notch), ks•

-200

-160

-120

-80

-40

1100 8645 notch cold rolled I 8645 notch warm rolled

0.25 notch radius/~I 0.25 notch radius

1045 j

825

~.

._E

-~

=

~i~ J

/

I-"~.~/

• j14B35

"

temper~--

Specimen

6.75

275 -I

i

160

120

.....

t e , ~ , e r e d • \ ~\ ~ , temperecl

I 8630-N ~ \

I tempered~

8630

I

40

18645

I

I shot peenedI

untempered

a~-,,,,L//

I 1045~,,

tempered

550

0

.~

.E_

80

°~

N

X ~ / o i l quenched

~

I

~'~1

8660 oil uenched

8645 - - " ~

~. /

tempered [ ~ ' ~ - ~ _ ~

40

L_ 1.750 in.

0

-1375

Fig 2

L1.550 in. diam

~

8645 oil quenched

60° V-notch

1

diam

0.025 root radiu

Compression ~--~-Tension

i

i

I

I

-1100

-825

-550

-275

0

Surface residual stress (root of notch), MPa

"¢'

0

275

Effect of surface residual stress on the endurance limit of selected steel. All samples were water

quenched except as shown, and all specimen dimensions are given in inches. Source: Ref 23, 24

crack initiation. Dimensional changes occur

when the residual stress (or a portion of it)

in a body is eliminated. In terms of crack

initiation, residual stresses can be either

beneficial or detrimental, depending on

whether the stress is tensile or compressive.

Compressive Residual Stress. Because residual stresses are algebraically summed

with applied stresses, residual compressive

stresses in the surface layers are generally

helpful because the built-in compressive

stresses can reduce the effects of imposed

tensile stresses that may produce cracking

or failure. Compressive stresses therefore

contribute to the improvement of fatigue

strength and resistance to stress-corrosion

cracking in a part and an increase in the

bending strength of brittle ceramics and

glass (Ref 22).

Figure 2 shows that the endurance limit

fatigue strength of selected steels increases

with the surface residual compressive stress

developed by specific heat treatment and

surface processing. It is also apparent that,

in the presence of high compressive stress,

a poor microstructure in steel samples has a

small influence on good endurance limit

fatigue strength (Ref 23-25). These fatigue

improvements are of great significance in

components, particularly where stress raisers, such as notches, keyways, oil holes,

and so forth, are highly desirable in the

design of components (for example, crankshafts, half-shafts, and so on) (Ref 26).

Many fabrication methods have been developed to exploit this phenomenon. Prestressed parts (including shrink-fits, prestressed concrete, interference fits, bolted

parts, coined holes, wire-wound concrete

pipe), mechanical surface working processes (such as shot peening, surface roiling, lapping, and so on) of hardened ferrous

Table 3 Summary of compressive and tensile residual stresses at the surface of the parts

created by the common manufacturing processes

Compression at the surface

Surface working: shot peening, surface rolling,

lapping, and so on

Rod or wire drawing with shallow penetration(a)

Rolling with shallow penetration(a)

Swaging with shallow penetration(a)

Tube sinking of the inner surface

Coining around holes

Plastic bending of the stretched side

Grinding under gentle conditions

Hammer peening

Quenching without phase transformation

Direct-hardening steel (not through-hardened)

Case-hardening steel

Induction and flame hardening

Prestressing

Ion exchange

Tension at the surface

Rod or wire drawing with deep penetration

Rolling with deep penetration

Swaging with deep penetration

Tube sinking of the outer surface

Plastic bending of the shortened side

Grinding: normal practice and abusive conditions

Direct-hardening steel (through-hardened)(b)

Decarburization of steel surface

Weldment (last portion to reach room temperature)

Machining: turning, milling

Built-up surface of shaft

Electrical discharge machining

Flame cutting

(a) Shallow penetration refers to ~<1%reduction in area or thickness; deep penetration refers to ~1%. (b) Depends on the efficiency of

quenching medium. Source: Ref 22

and nonferrous alloys, and surface hardening treatments are widely used to produce

residual compressive stresses at the component surface.

Residual tensile stresses at the surface of a

part are usually undesirable because they

can effectively increase the stress levels;

may cause unpredicted stress-corrosion

cracking (due to the combined effect of

stress and environment), fatigue failure,

quench cracking, and grinding checks at

low external stresses; and tend to reduce

fatigue life and strength of a part. In this

case the extent of residual stresses may be

closer or even larger than the strength of the

material.

Residual tensile stresses in the interior of

a component also may be damaging because

of the existence and consequence of defects

that serve as stress raisers in the interior

part. The uncommon phenomenon of delayed cracking, in the absence of adverse

environments and large applied stresses,

has now been attributed to the action of

residual stresses on minute defects in the

material (Ref 26). For example, a 17.5 cm

(6.9 in.) diam × 125 cm (49.2 in.) long steel

shaft exploded into several pieces while

lying free of any applied loads, on a laboratory floor. Under normal loading, it would

have required a tensile strength larger than

150 MPa (22 ks•) to rupture the shaft.

Hence, the understanding of residual stress

formation is very important, and this must

be given due consideration in the manufacture and performance analysis of processed

parts (Ref 26).

Development of Residual Stress in

Processed Parts

Variations in stresses, temperature, and

chemical species within the body during

processing cause the production of macroresidual stresses. Various manufacturing

processes such as forming, machining, heat

treatment, shot peening, casting, welding,

flame cutting, and plating render their characteristic residual stress pattern to processed parts. Table 3 lists a summary of

compressive and tensile residual stresses at

the surface of parts fabricated by common

manufacturing processes.

I n heat-treated parts, residual stresses

may be classified as those caused by a

thermal gradient alone, and a thermal gradient in combination with a structural

change (phase transformation). When a

steel part is quenched from the austenitizing

temperature to room temperature, a residual stress pattern is established due to a

combination of thermal gradient and local

transformation-induced volume expansion.

Thermal contraction develops nonuniform thermal (or quenching) stress due to

different rates of cooling experienced by

the surface and interior of the steel part.

Transformational volume expansion induces transformation stress arising from

Defects and Distortion in Heat-Treated Parts / 605

Table 5

Table 4 Changes in volume during the

transformation of austenite into different

phases

a function of carbon

content ( % C )

Spheroidized pearlite

---, austenite

Austenite ~

martensite

Spheroidized pearlite

martensite

Austenite ~ lower

bainite

Spheroidized pearlite

lower bainite

Austenite ~ upper

- 4 . 6 4 + 2.21 × (% C)

4.64 - 0.53 x (% C)

1.68 x (% C)

0.78 x (% C)

4.64 - 2.21 x (% C)

Spheroidized pearlite

upper bainite

0

Source: Ref 4

the transformation of austenite into martensite or other transformation products

(Ref 27). Table 4 lists the changes in volume during the transformation of austenite

into different structural constituents (Ref

28).

Thermal Contraction. The relation between the thermal stress ~th during cooling

and the corresponding temperature gradient

in the component is given by:

E-

=

(Eq

AT" ct

where E is the modulus of elasticity, and tx

is the thermal coefficient of expansion of

the material. It is thus apparent that thermal

stresses are greatest for materials with high

elastic modulus and coefficient of thermal

expansion. Temperature gradient is also a

function of thermal conductivity. Hence, it

is quite unlikely to develop high-tempera-

?

Water quenched

100 mm (4 in.)

specimen

1000

~

c

~-

1700 ou-

w

1100 ~

500

~.

u

0

1

10

600

E

100 ~103 Time, s

_

•

e~

E

o

e~

E

o

D e v e l o p m e n t of thermal a n d residual stresses

in the longitudinal direction in a 100 m m (4 in.)

diameter steel bar on w a t e r q u e n c h i n g from the austenitizing t e m p e r a t u r e , 850 °C (1560 °F). Transformation stresses are not taken into c o n s i d e r a t i o n . Source:

Ref 30

Fig 3

Metal

GPa

psi x 10 6

10-6/K

Pure iron (ferrite)

Typical austenitic steel

Aluminum

Copper

Titanium

206

200

71

117

125

30

29

10

17

18

12

18

23

17

9

Thermal conductivity

10-6pF

7

10

13

9

5

W m -1 k -l

Btu in./ft 2 • h • ° F

80

15

201

385

23

555

100

1400

2670

160

Source: Ref 29

4.64 - 1.43 × (% C)

bainite

tYth

Coefficient of

expansion

Modulus of elasticity

Change in volume, %, as

Transformation

Relevant physical properties in the development of thermal stresses

ture gradients in good thermal conductors

(for example, copper and aluminum), but it

is much more likely in steel and titanium

(Ref 29). Another term involving thermal

conductivity, called thermal diffusivity

(Dth), is sometimes used in context with

temperature gradient. It is defined a s D t h =

k/pc, where k is the thermal conductivity, p

is the density, and c is the specific heat. It is

clear that low Oth (or k) promotes large

temperature gradient or thermal contraction. It should be emphasized that large size

of the part and high heating or cooling rates

(severity) of quenching medium also augment temperature gradients leading to large

thermal contraction.

Table 5 lists some of the relevant material

properties that affect thermal and residual

stresses (Ref 29).

Residual Stress Pattern Due to Thermal

1)Contraction. Residual stress is developed

during quenching of a hot solid part that

involves thermal volume changes without

solid-state phase transformation. This situation also exists when a steel part is cooled

from a tempering temperature below the A t.

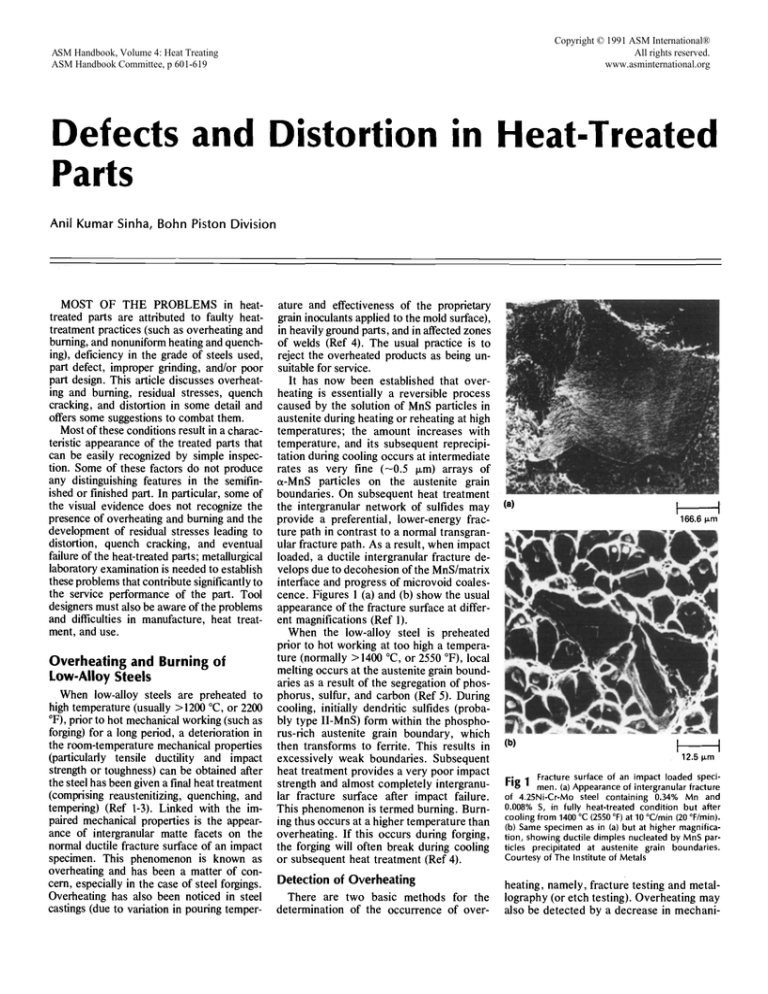

Figure 3 shows the development of longitudinal thermal and residual stresses in a 100

mm (4 in.) diam steel bar on water quenching from the austenitizing temperature, 850

°C (1560 °F) (Ref 30). At the start of cooling,

the surface temperature S falls drastically as

compared to the center temperature C (top

left sketch of Fig 3). At time w, the temperature difference between the surface and

core is at a maximum of about 550 °C (1020

°F), corresponding to a thermal stress of

1200 MPa (80 tons/in. E) due to linear differential contraction of about 0.6%, if relaxation does not take place. Under these

conditions, tensile stresses are developed in

the case with a maximum value of a (lower

diagram), corresponding to time w in the

upper diagram, and the core will contract,

producing compressive stresses with a maximum of b. The combined effect of tensile

and compressive stresses on the surface and

core, respectively, will result in residual

stresses as indicated by curve C, where a

complete neutralization of stress will occur

at some lower temperature u. Further decrease in temperature, therefore, produces

longitudinal, compressive residual stresses

at the surface and the tensile stresses at the

core, as shown in the lower right-hand

diagram of Fig 3. Figure 4(a) is a schematic

illustration of the distribution of residual

stress over the diameter of a quenched bar

due solely to thermal contraction in the

longitudinal, tangential, and radial directions (Ref 19).

The maximum residual stress attained on

quenching increases as the quenching temperature and quenching power of the coolant are increased. Tempered glass is made

by utilizing quenching techniques in which

glass is heated uniformly to the annealing

temperature and then surface cooled rapidly

by cold air blasts. This produces compressive surface stresses to counteract any tensile bending stress, if developed during

loading of the glass, thereby increasing its

load-carrying capacity (Ref 31).

Residual Stress Pattern Due to Thermal

and Transformational Volume Changes (Ref

32). During quench hardening of a steel (or

other hardenable alloy) part, hard martensite forms at the surface layers, associated

with the volume expansion, whereas the

remainder of the part is still hot and ductile

austenite. Later, the remainder austenite

transforms to martensite, but its volumetric

expansion is restricted by the hardened

surface layer. This restraint causes the central portion to be under compression with

the outer surface under tension. Figure 4(c)

illustrates the residual stress distribution

over the diameter of a quenched bar showing volume expansion associated with phase

transformation in the longitudinal, tangential, and radial directions (Ref 19). At the

same time during the final cooling of the

interior, its contraction is hindered by the

hardened surface layers. This restraint in

contraction produces tensile stresses in the

interior and compressive stresses at the

outer surface. However, the situation as

shown in Fig 4(c) prevails, provided that the

net volumetric expansion in the interior,

after the surface has hardened, is larger

than the remaining thermal contraction. In

some particular conditions, these volumetric changes can produce sufficiently large

residual stresses that can cause plastic deformation on cooling, leading to warping or

distortion of the steel part. While plastic

deformation appears to reduce the severity

of quenching stresses, in most severe

quenching the quenching stresses are so

high that they do not get sufficiently released by plastic deformation. Consequently, the large residual stress remaining may

606 / Process and Quality Control Considerations

I

+~

Ii

Longitudinal

Longitudinal

.~_

I

I

T j

i

I

Tangential

I

Tang?ntial

I

t-'--->'

I

Radial

(a)

I

L = longitudinal

T= tangential

R = radial

Rad al

(b)

(el

Schematic illustration of the distribution of residual stress over the diameter of a quenched bar in the

F i g 4 longitudinal, tangential, and radial directions due to (a) thermal contraction and (c) both thermal and

transformational volume changes. (b) Schematic illustration of orientation of directions. Source: Ref 19

reach or even exceed fracture stress of

steel. This localized rupture or fracture is

called quench cracking (Ref 32, 33).

It should be emphasized again that for a

given grade of steel, both large size of the

part and higher quenching speed contribute

to the larger value of thermal contraction,

as compared to the volumetric expansion,

of martensite. In contrast, when the parts

are thin and the quenching rate is not high,

thermal contraction of the part subsequent

to the hardening of the surface will be

smaller than the volumetric expansion of

martensite. Similarly, for a given quenching

rate, the temperature gradients decrease

with decreasing section thickness, and consequently the thermal component of the

residual stress is also decreased (Ref 24).

Figure 5(a) shows the continuous cooling

transformation diagram of DIN 22CrMo44

low-alloy steel exhibiting austenitic decomposition with the superimposed cooling

curves of the surface and center in round

bars of varying dimensions. If the largediameter (100 mm, or 4 in.) bar is water

quenched (that is, for slack quenching),

martensitic transformation occurs at the

surface, and pearlitic + bainitic transformations occur at the center, resulting in a

residual stress pattern (top of Fig 5) similar

to that due solely to thermal stress (Fig 4a).

During the rapid quenching of the mediumsize (30 mm, or 1.2 in.) bar diameter, the

start of bainite transformation at the center

coincides approximately with the transformation of martensite on the surface. This

results in compressive stresses at both the

surface and center, with tensile stresses in

the intermediate region (middle of Fig 5).

When the smaller-diameter (10 mm, or 0.4

in.) bar is drastically quenched (for example, in brine), the entire bar transforms to

martensite. This is associated with very

little temperature variation between the surface and the center of the part. In this

situation, tensile residual stress is developed at the surface and compressive stress

at the center of the bar (bottom, Fig 5) (Ref

34, 35).

Although the shallower hardening steels

exhibit higher surface compressive stresses,

deep hardening steels may develop moderately high surface compressive stresses

with severe water quenching. When these

deep hardening steels are through-hardened

in a less efficient quenchant, they may

exhibit surface tensile stresses (Ref 24, 31).

Rose has pointed out the importance of

transformations of core and surface before

and after the stress reversal. According to

him the tensile surface residual stress occurs when the core transforms after, and the

surface transforms before, the stress reversal (Fig 4c and bottom of Fig 5), whereas

compressive surface residual stress takes

place when the core transforms before, and

the surface transforms after, the stress reversal (top of Fig 5). His analysis is capable

of explaining complex stress patterns for

various combinations of part sizes, quenching rate, and steel hardenability (Ref 21).

However, the residual stress pattern in the

hardened steels can be modified either with

different transformation characteristics or

during the tempering and finish-machining

(after hardening) operations.

Residual Stress Pattern after Surface Hardening. In general, thermochemical and ther-

mal surface-hardening treatments produce

beneficial compressive residual stresses at

the surface.

Carburized and Quenched Steels. When

low-carbon steels are carburiZed and

quenched, first the core transforms at high

temperature (600 to 700 °C, or ll00 to 1300

°F) to ferrite and pearlite with the attendant

relaxation of any transformation stresses.

Later, the high-carbon case transforms to

martensite at much lower temperature (less

than 300 °C, or 570 °F), accompanied by

volume expansion and under conditions of

no (or minimum) stress relaxation. As a

result, residual compressive stress is developed in the case with a maximum at the

surface.

Large differences in carbon level between

the case and the core determine the sequence of phase transformation on cooling

after carburizing and the resultant development of compressive residual stress in the

case. Likewise, compressive residual stress

in the case increases as the core carbon

content decreases. Increasing case depth

reduces the contribution from the low-carbon core in the development of compressive

stress in the case, thereby adversely affecting the fatigue properties (Ref 36).

In actual practice, a maximum compressive stress develops at some distance away

from the surface (Fig 6 and 7). This effect

occurs because of the presence of retained

austenite, the extent of which depends on

steel composition, carbon content of the

case, quenching temperature, and severity

of quench. According to Koistinen (Ref 38)

and Salonen (Ref 39) the peak compressive

stress takes place at 50 to 60% of the total

case depth corresponding to about 0.5 to

0.6% carbon level, which produces a low

retained austenite content and martensite

hardness around the maximum. Another

factor that might influence this compressive

residual stress profile is that the martensite

formed in the lower-carbon regions of the

case is of the lath type, which also affects

the retained austenite content (Ref 20). The

reversal sign of residual stress takes place at

or near the case/core interface. Later, when

Koistinen's theory was applied to the measured data, it appeared that the position of

Defects and Distortion in Heat-Treated Parts / 607

1000

1.0

1830

800

, ~

Distribution of

residual stresses

1470

600 ~

~

+20

1110

c"

+3

o 0.5

8

400

\

~._

750

200

" ~

~

390

Surface Center

0

1000

-20

-3

m -40

-6

~

1830

800 ~

~

1470

~ Center

•~ +20

E

-o ,

c.-~_

400

-

750

200

er

0

X

E

390

"o

.o

-20

Surfacel

1000

Surface ~

+3 "~

•"o

"~

(

30 mm

diam

600

~.._....

-3

400 " ' ~-~,........._.

750

nter

1

10

100

Time, s

Surface

+3

1110

0

/

0

Center

+20 [

1470

103

(a)

I~/0

mm

-20 ~¢

diam

0

m

.9_

ttCompressive

Distance from the surface

Relationship between carbon content, re-

-3

Center

Surface

+ = Tensile stresses

- = Compressive stresses

(b)

(a) Continuous cooling transformation diagrams of DIN 22CrMo44 steel showing austenitic decompoFig 5 sition with the superimposed cooling curves of the surface and center during water quenching of round

bars of varying dimensions. (b) The corresponding residual stress pattern developed because of thermal and

transformational volume changes. Source: Ref 34, 35

maximum compressive stress depends on

severity of quenching, total case depth,

steel hardenability, and so forth (Ref 21,

40). Figure 7 shows the details of generation

of axial stress distribution of a carburized

gear (made from deeper hardening steel)

during quenching. In the early stages, the

contour lines of equal stress were largely

unaffected by the surface profile. Later a

zone of high compressive stress distribution

occurred in the central portion of the teeth,

which remained until the end of the quench

(Ref 37).

In nitriding, like carburizing, a compressive residual stress is set up in the surface

layers. High-temperature nitriding produces

a little relaxation of stresses, whereas lowtemperature nitriding imparts a maximum

residual stress. In nitrocarburizing, improvement in residual surface compressive

stress and fatigue strength depends on the

hardness and depth of diffusion zone. These

properties, in turn, decrease with increasing

carbon and alloy content (that is, increased

hardenability). During quenching, after ni-

Tensile

o

1830

800

o

trocarburizing, a (macro-) compressive residual stress is produced in the compound

layer and gamma prime phase (Ref 41).

When nitrocarburized parts are rapidly

quenched, the above properties are further

enhanced (Ref 42).

In borided steel processed at 900 °C (1650

°F), a high compressive residual stress is

developed at the surface layers (Fig 8),

which consists of FeB and Fe2B phases (Ref

43); this is attributed to the lower thermal

expansion coefficient and the larger specific

volume in a borided layer compared to that

in a ferrite matrix (Ref 18, 43).

In an induction-hardened steel part, a

compressive surface residual stress is produced when wear-resistant hard martensite

(with slightly lower density) is formed on

the surface of a section concurrently with

volume expansion while nonhardened core

remains essentially unchanged (Fig 9) (Ref

44, 45). The magnitude of the compressive

stress, which is affected by both thermal

contraction and martensite formation, may

be a considerable fraction of the yield

Fig 6 tained austenite, and residual stress pattern. It

shows the development of peak compressive stress

some distance away from the surface. Source: Ref 20

strength, which permits the application of

significantly higher stresses than could normally be possible in fatigue loading. As in

the carburizing practice, the surface compressive residual stresses are usually found

to increase, with depth below the surface

(Ref 45) (Fig 9, Ref 44). A fairly sharp

transition to a tensile state takes place near

the hardness drop-off between the case and

unhardened surrounding material. With an

increase in distance from the steep transition, the tensile condition gradually fades

away toward zero stress (Ref 44). In induction hardening, an increase in hardenability

changes the depth at which transition from

compressive to tensile stress occurs. The

increase in the rate of heating produces an

increase in the maximum compressive and

tensile residual stresses without affecting

the mode of stress distribution (Ref 46).

Residual Stress in Other ProcessingSteps.

As welding progresses, the temperature distribution in the weldment becomes nonuniform and varying as a result of localized

heating of the weldment by the welding heat

source. During the welding cycle, comprising heating and cooling, complex strains

develop in the weld metal and adjacent

areas. As a result, appreciable residual

stresses remain after the completion of

welding. Since the weld metal and heataffected zone contract on cooling (Fig 10a),

they are restrained by the cool adjacent

part. This produces tensile residual stress in

608 / Process and Quality Control Considerations

Carburized SNC815

300

-900

Gz = 2 0 0 M P a

-600

100

(

3OO

~

-300

~100

0300

-600

Distance from surface, in.

-900

-600

60~j

l

i

300

500

0

0.002

0.004

0.006

-- 50

0

0

0

z~ ~

#_

/xA z, /x A

-500

~

- -100

-150

-1000 ~ •

o

•

'~ -1500

300

-2500

0

--200

© FeB

• Fe2B

/x Ferrite

•

-2000

600

0

- -50

0

- -250

~

"~

(b

rr

- -300

0

0

0.10

0.05

0.15

Distance from surface, mm

t= 3 s

Fig 7

Axial stress distribution (given in MPa) in carburized gear during quenching process. Source: Ref 37

the weldment region and compressive residual stress in the surrounding base metal

region (Fig 10b).

In general, a steep residual stress gradient

is developed because of the steep tendency

of the thermal gradient. This may, in turn,

lead to hot cracking (between columnar

grains) or severe center line cracking in the

weld area (Ref 48). Catastrophic failures of

welded bridges and all-welded ships are

mostly attributed to the existence of large

and dangerous tensile residual stress in

them (Ref 49).

The grinding step in manufacturing is

important, since it is always utilized to

produce the finished surface. It has been

shown that gentle surface grinding, using a

soft sharp wheel and slow downfeed, produces compressive residual stress at the

surface, whereas conventional (normal

practice) and abrasive grinding result in

surface tensile stresses of very high magnitude (Fig l l) (Ref 22, 50). However, the

Distance from surface, in.

400 (58)

A

#_

Residual stress distribution of FeB and Fe2B

layers in borided steel processed at 900 °C

(1650 °F). Source: Ref 18, 43

Fig 8

60 s

30 s

200 (29)

0.08 0.16 0.24 0.32 0.40

500 gm Knoop test

3 m m case

I

I

I

Is ss

8O

o

r~

60 -r-

gentle grinding method is expensive from

the viewpoint of operating time and wear of

the wheel.

As a result of temperature gradient during

cooling, castings develop compressive stresses at the surface and tensile stresses in the

interior (Ref 22). However, transient temperature gradient and phase transformation occurring during the early stages of solidification and cooling of continuous steel castings

in the mold may give rise to the development

of harmful residual stresses leading to the

formation of cracks (Ref 51).

Chemical processes such as electroplating, scale formation, and corrosion of metals can produce residual stresses due to

coherency strains arising from the matching

tendency of crystal structures of the outer

surface product with the crystal structure of

the adjacent layer (Ref 22). Residual stresses are also introduced when heat-treated

parts are subjected to successive heating

and cooling cycles during service conditions.

Residual Stress in the Heat-Treated Nonferrous Alloys. In nonferrous alloys, notably

age-hardenable aluminum alloys, copperberyllium alloys, certain nickel-base super-

A

g_g

"~

tr

-400 (-58)

/

Hardness

2

4

6

8

10

Distance from surface, m m

20 ,~

u,l

0

12

F i g 9 A typical hardriess and residual stress profile

in induction-hardened (to 3 ram, or 0.12 in.,

case depth) and tempered (at 260 °C, or 500 °F) 1045

steel. Source: Ref 44

i

i

i

i

i

i

i

i

i

i

I

i

i

400

\

\

o

%

(b)

Fig 10 (a) The transverse shrinkage occurring in

butt weldments. (b) Longitudinal residual

stress patterns in the weldment and surrounding regions. This also shows longitudinal shrinkage in a butt

weld. Source: Ref 47

-

9O

-

60

L~

-- Abrasive

30

0

-%

- Gentle

~. - 2 0 0

E

o

-400

120

Conventional

~

Yl

(a)

/\.

600

200

r,~

-200 (-29)

Depth below surface, mil

3.15

6.3

9.45

12.6

800

~:

Residual stress

Compression Tension

40 ~

0

alloys, and so on, a significant amount of

thermal stress is generated during quenching prior to precipitation hardening. The

quenching process in this condition does

not invariably involve a phase change; rather, this is confined to the postquenching

aging treatment. In other nonferrous alloys

such as uranium and titanium alloys, the

final structural condition is not obtained by

a slow cool.

When high-strength titanium alloy is

quenched from a solution annealing temperature of 850 to 1000 °C (1560 to 1830 °F), it

develops large residual stress caused by

poor thermal conductivity of titanium leading to high-temperature gradient. This problem can, however, be avoided by stressrelief annealing at 650 to 700 °C (1200 to

1290 °F), which produces a slight reduction

in mechanical properties. When a highstrength aluminum age-hardening alloy is

rapidly quenched from the solution temper-

,-, . . . .

-

-30

-60

0

80

160

240

320

Depth below surface, pm

Residual stress distribution after gentle, conF i g 1 1 ventional, and abrasive grinding of hardened 4340 steel. Source: Ref 22

Defects and Distortion in Heat-Treated Parts / 609

Table 6 A compiled summary of the maximum residual stresses in surface heat-treated

steels

Residual stress (longitudinal)

Steel

832M13 (type)

805A20

805A20

805A ! 7

805A17

897M39

905M39

Cold-rolled steel

Heat treatment

MPa

Carburized at 970 °C (1780 °F) to 1 mm (0.04 in.) case with

0.8% surface carbon

Direct-quenched

Direct-quenched, - 8 0 °C ( - 110 °F) subzero treatment

Direct-quenched, - 9 0 °C (-130 °F) subzero treatment,

tempered

Carburized and quenched

Carburized to 1.1-1.5 mm (0.043-0.06 in.) case at 920 °C

(1690 °F), direct oil quench, no temper

Carburized to 1.1-1.5 mm (0.043-0.06 in.) case at 920 °C

(1690 °F), direct oil quench, tempered 150 °C (300 °F)

Nitrided to case depth of about 0.5 mm (0.02 in.)

Induction

Induction

Induction

Induction

hardened,

hardened,

hardened,

hardened,

untempered

tempered 200 °C (390 °F)

tempered 300 °C (570 °F)

tempered 400 °C (750 °F)

280

340

200

240-340(a)

190-230

ksi

40.5

49.0

29.0

35.0--49.0

27.5-33.5

400

150-200

58

22-29

400--600

800-1000

1000

650

350

170

58.0-87.0

116.0-145.0

145.0

94.0

51

24.5

(a) Immediately subsurface, that is. 0.05 mm (0.002 in.). Source: Ref 29

ature, high thermal and residual stresses are

induced due to high coefficient of expansion

of aluminum. Uphill quenching from liquid

nitrogen temperature ( - 196 °C, or - 320 °F)

in a steam blast alleviates this problem. This

induces stresses opposite in sign to those

developed on water quenching from the

solutionizing and cancels out their effect.

This is followed by aging of the alloy in the

conventional manner (Ref 29).

Fast polyalkylene glycol (PAG) quenching of solution-treated aluminum alloys

tends to reduce residual stress levels because of its more uniform heat extraction

rate (thermal shock is smaller, and thereby

machining is less likely to produce further

distortion), thereby helping solve major and

long-standing distortion problems among

aluminum workpieces (Ref 52).

Control of Residual Stresses in

Heat-Treated Parts

Table 6 lists some typical values of maximum residual stresses developed in the

surface-hardened steels that have been reported in the literature (Ref 29). It is worth

noting that there is a marked influence of

tempering on the residual stress level. Tempering must be accomplished at about 150

°C (300 °F) to maintain 50 to 60% retention

of the residual stress level obtained after

quenching because a higher tempering temperature greatly reduces surface compressive stresses. However, a higher stressrelief temperature (-600 °C, or 1110 °F) is

used for mechanically deformed components (for example, hot-rolled bars) or components with tensile surface residual stresses. Alternatively, serious residual tensile

stresses may be avoided effectively by gentle grinding of the surface.

Measurement of Residual Stresses

There are two methods of measuring residual stresses: the destructive method, also

called the dissection method, and the nondestructive methods comprising mainly

x-ray diffraction, neutron diffraction, ultrasonic, and magnetic methods.

Destructive (or Dissection) Method. This

method is old but reasonably accurate,

practically nondestructive, uses well-established methods, and can be employed in

confined situations at site (Ref 53). However, it is tedious, time consuming, and expensive (Ref 54). The other drawbacks are the

destructive, or at best semidestructive nature of the method, and its ability to measure only the macroresidual stresses. The

hole-drilling method is used extensively for

measuring residual stresses, which depends

on the dissection approach. It consists of

the mounting of strain gages or a threeelement strain-gage rosette on the surface

and measurement of strains. Then a rigidly

guided milling cutter is used to drill a small,

straight, circular, perpendicular, and fiatbottomed hole not exceeding 3.2 mm (0.125

in.) at the center of the rosette and into the

surface of the component being analyzed.

Strain redistribution occurring at the surface in the surrounding area of the hole

(resulting from the residual stress relief) is

then measured with the previously installed

strain gages. The residual stress is calculated at a large number of points in a surface

from the strain measurements using the

well-established method (Ref 22, 28). To

minimize the introduction of spurious

strains by the grinding operation, the rate of

metal removal should be less than 3.125 x

10-4 m/s (1.23 × 10-2 in./s), and readings

are recorded after 15 min of the end of the

grinding process to ensure that any heat

generated has been dissipated (Ref 55).

Nondestructive Methods. The main difficulty with the nondestructive methods is that

measurements of crystallographic lattice parameters, ultrasonic velocities, or magnetization changes are made that are indirectly

related to the residual stress. The above

quantities are usually dependent on the stress

and material parameters (such as metallurgical textures), which are difficult to quantify

(Ref 54, 56).

The x-ray diffraction method is the wellestablished technique for measuring both

macro- and microresidual stress nondestructively. In most instances, the x-ray diffraction

method has been employed to provide quantitative values for residual stress profiles in

surface or fully hardened components (Ref

57). This technique depends on the determination of lattice strains and the stress-induced

differences in the lattice spacing. Macroresidual strain is measured from the shift of diffraction lines in the peak position using the

so-called nonlinear SinZC method from which

residual stress is calculated (Ref 57). For the

measurement of microstrain the Voigt singleline method is applied (Ref 58). Precision in

lattice strain measurement of the order of

0.2% is possible.

Portable x-ray diffraction equipment is

now commercially available in various

forms that allow stress measurement to be

made very quickly (ranging from 4 to 30 s).

The main drawbacks are that it cannot be

applied to noncrystalline materials such as

plastics, and it is only capable of measuring

residual stresses of materials very close to

the surface under examination. That is, the

measurement is purely surface related (a

depth of 0.01 mm, or 0.4 mil, is commonly

quoted) (Ref 59).

Neutron radiography or diffraction, used

for polycrystalline materials, has a much

deeper penetration than x-rays, but has

major safety problems and the disadvantage

of being nonportable.

Ultrasonic method for evaluating residual

stress involves ultrasonic stress birefringence or sonoelasticity; this depends upon

the linear variation of the velocities of

sound in a body (that is, ultrasonic waves)

with the stress. This method has the potential for greater capability, versatility, and

usefulness in the future (Ref 53, 56). However, this has the disadvantage, in common

with the magnetic methods, that it requires

transducers shaped to match the surface

being inspected (Ref 60).

The magnetic method is based on the

stress dependence of the Barkhausen noise

amplitude. Each time an alternating magnetic field induced in a ferromagnetic material is reversed, it generates a burst of

Barkhausen noise. The peak amplitude of

the burst, as determined with an inductive

coil near the surface of the component

material, varies with the surface stress level. Since Barkhausen noise depends on

composition, texture, and work hardening,

it is necessary in each application to use

calibrated standard (reference) samples

with the same processing history and composition as the component being analyzed.

This method is used to measure residual

610 / Process and Quality Control Considerations

stresses well below the yield strength of the

ferromagnetic materials. This method is

rapid, and the measurements are made with

the commercially available portable equipment. However, this method is limited to

only ferromagnetic materials (Ref 56).

Thermal evaluation for residual stress analysis (TERSA) is a new nondestructive method that is in an experimental stage. It has the

advantage that it is completely independent,

remote, and noncontacting. It consists of

merely directing a controlled amount of energy from a laser energy source into the volume

of the material being inspected and then making a precise determination of changes in the

resulting temperature rise by infrared radiometry. However, the working instrument will

also require some form of display to enable

visual examination to be made of any highstressed regions (Ref 60).

Quench Cracking

Anything that

produces

excessive

quenching stress is the basic cause of cracking. Quench cracking is mostly intergranular, and its formation may be related to

some of the same factors that cause intergranular fracture in overheated and burned

steels. The main reasons for cracking in

heat treatment are: part design, steel

grades, part defects, heat-treating practice,

and tempering practice (Ref 61).

Part Design. Features such as sharp corners, the number, location, and size of holes,

deep keyways, splines, and abrupt changes in

section thickness within a part (that is, badly

unbalanced section) enhance the crack formation because while the one (thin) area is

cooling quickly in the quenchant, the other

(thick) area immediately adjacent to it is cooling very slowly. One solution to this problem

is to change the material so that a less drastic

quenchant (for example, oil) can be employed. An alternate solution is to prequench,

that is, to cool it prior to the rest of the part.

This will produce an interior of the hole or

keyway that is residually stressed in compression, which is always desirable for better

fatigue properties (Ref 61). The third solution

is a design change, and the fourth is to use a

milder quenchant.

Steel Grades. Sometimes this can be

checked by means of a spark test, whereas at

other times a chemical analysis must be

made. In general, the carbon content of steel

should not exceed the required level; otherwise, the risk of cracking will increase. The

suggested average carbon contents for water,

brine, and caustic quenching are given below:

Method

Induction hardening

Furnace hardening

Shape

Carbon, %

Complex

Simple

Complex

Simple

Very simple, such

as bar

0.33

0.50

0.30

0.35

0.40

A decrease in carbon content from 0.72 to

0.61% has been shown to slightly increase

the thermal crack resistance of rimquenched railroad wheels (Ref 62).

Because of segregation of carbon and

alloying elements, some steels are more

prone than others to quench cracking.

Among these steels, 4140H, 4145H, 4150H,

and 1345H appear to be the worst. A good

option is to replace the 4100 series with the

8600 series. An additional disadvantage

with the use of 1345H steel is the manganese floating effect, which leads to very

high manganese content in the steel rolled

from the last ingot in the same heat. Similarly, dirty steels (that is, steels with more

than 0.05% S, for example, AISI 1141 and

1144) are more susceptible to cracking than

the low-sulfur grades. The reasons for this

are that they are more segregated in alloying

elements, the surface of this hot-rolled highsulfur steel has a greater tendency to form

seams, which act as stress raisers during

quenching, and they are usually coarse

grained (for better machinability), which

increases brittleness and therefore promotes cracking. If these high-sulfur grades

are replaced by calcium-treated steels or

cold-finished leaded steels, this problem

can be obviated (Ref 61).

Part Defects. Surface defect or weakness

in the material may also cause cracking, for

example, deep surface seams or nonmetallic

stringers in both hot-rolled and cold-finished bars. Other defects are inclusions,

stamp marks, and so forth. For large-seam

depths, it is advisable to use turned bars or

even magnetic particle inspection. The forging defects in small forgings, such as seams,

laps, flash line, or shearing crack, as well as

in heavy forgings, such as hydrogen flakes

and internal ruptures, aggravate cracking.

Similarly, some casting defects, for example, in water-cooled castings, promote

cracking (Ref 50).

Heat-Treating Practice. Higher austenitizing temperatures increase the tendency

toward quench cracking. Similarly, steels

with coarser grain size are more prone to

cracks than fine-grain steels because the

latter possess more grain-boundary area to

stop the movements of cracks, and grain

boundaries help to absorb and redistribute

residual stresses. An outstanding contributor to severe cracking is improper heattreating practice, for example, nonuniform

heating and nonuniform cooling of the component involved in the heat-treatment cycle. It is a good heat-treating practice to

anneal alloy steels prior to the hardening

treatment (or any other high-temperature

treatment, for example, forging, welding,

and so forth) because this produces grainrefined microstructure and relieves stresses

(Ref 63).

Water-Hardening Steel. The water-hardening steels are most susceptible to cracks if

they are not handled properly. Soft spots

(

Typical appearance of thumbnail check as

chipping chisel. Source:Ref 64

Fig 1 2 soft spot on

are most likely to occur in the water-hardening steels, especially where the tool is

grabbed with tongs for quenching. Normally the cleaned surface shows adequate hardening and the scaled surface insufficient

hardening, which can be examined with a

file. Soft spots may occur from the use of

fresh water, or water contaminated with oil

or soap. Most large tools emerging from

hardening operations contain some soft

spots. However, accidental soft spots in the

wrong place should be investigated, and

steps must be taken to eliminate them.

Figure 12 shows the typical appearance of

a thumbnail check as soft spot on chipping

chisels, which occurs on the bit near the

cutting edge. The cracks enclosing the soft

spots should be avoided by switching to

brine quench (Ref 64).

Air-Hardening Steel. Similarly, when air

hardening steels are improperly handled,

they are likely to crack. For example,

avoidance of tempering treatment or use of

oil quenching in air-hardening steel can lead

to cracking. However, the common practice

in the treatment of air-hardening steels is

initially to quench in oil until "black"

(about 540 °C, or 1000 °F), followed by air

cooling to 65 °C (150 °F) prior to tempering.

As compared to air cooling right from the

quenching temperature, this practice is totally safe and minimizes the formation of

scale.

Polymer quenchants have found well-established use in the quenching of solutiontreated aluminum alloys, hardening of plain

carbon steels with less than 0.6% C, spring

steels, boron steels, hardenable stainless

steels, and all carburizing and alloy steels

with section thickness greater than about 50

mm (2 in.), through-hardening and carburizing steel parts, and induction and flamehardening treatments because of their numerous

beneficial

effects,

including

elimination of soft spots, distortion, and

cracking problems associated with trace

Defects and Distortion in Heat-Treated Parts / 611

4.7 ~m

Fig 13

Microcracking in a Ni-Cr steel. Source: Ref 67

water contamination in quenching oils (Ref

65).

Agitation is an important parameter in

polymer quenching applications both to ensure a uniform polymer film around the

quench part and to provide a uniform heat

extraction from the hot part to the adjacent

area of quenchant by preventing a buildup

of heat in the quench region.

Salt bath cooling of induction-hardened

complex-shaped cast iron parts reduces

danger of cracking, which is usually experienced when air cooling followed by hotwater quenching is used (Ref 66).

Decarburized Steel. Decarburization usually arises from insufficient protection as a

result of plant failure (for example, defective furnace or container seals, defective

valves), poor process control (for example,

insufficient atmosphere-monitoring equipment, poor supervision), or the existence of

decarburizing agents in the furnace atmosphere (for example, CO2, water vapor, and

Hz in the Endogas (Ref 61, 67).

A partially decarburized surface on the

part occurring during tool hardening also

contributes to cracking because martensite

transformation is completed therein well

before the formation of martensite in the

core. Decarburized surface on the tools has

reduced hardness, which will lead to premature wear and scuffing. Partial decarburiza-

tion must be avoided, especially on all deephardening steels, either by providing some

type of protective atmosphere during the

heating operation, stock removal by grinding, or carbon restoration process. In addition to protective atmosphere, salt baths,

inert packs, or vacuum furnaces may be

used to obtain the desired surface chemistry

on the tools or dies. The fact that the better

and more consistent performance of the

tools is observed after regrinding reveals

the existence of partial decarburization remaining.

Carburized Alloy Steel. Two types of

peculiar cracking phenomena prevail in the

carburized and hardened case of the carburized alloy steels: microcracking and tip

cracking. Microcracking of quenched

steels are small cracks appearing across or

alongside martensite plate (Fig 13) (Ref 67)

and the prior austenite grain boundaries

(Ref 68). They form mostly on those

quenched steel parts that contain chromium and/or molybdenum as the major alloying elements with or without nickel content and where the hardening is done by

direct quenching.

Microcracks are observed mostly in

coarse-grained structures, such as large

martensite plates. This is presumably because of more impingements of the larger

plates of martensite by other large plates.

Another cause of microcracking is the increased carbon content of martensite (that

is, increased hardenability), which is a function of austenitizing temperature and/or

time (Ref 67). This finding was established

for 8620H steel, which has a higher austenitizing temperature prior to quenching

where there is a greater tendency to microcrack (Ref 69). This problem can be avoided

by selecting a steel with less hardenability

(that is, with less austenitizing temperature). Another solution is to change the

heat-treating cycle to carburizing, slow

cooling to black temperature, reheating to,

for example, 815 or 845 °C (1500 or 1550 °F),

and quenching (Ref 61). Microcracking in

case-hardened surfaces may be aggravated

by the existence of hydrogen, which tends

to absorb during carburizing. However, this

hydrogen-enhanced microcracking can be

eliminated by tempering the carburized

parts at 150 °C (300 °F) immediately after

quenching. Tempering exhibits an additional beneficial effect in that it has the ability to

heal the microcracks due to the volume

changes and associated plastic flow that

develop during the first stage of tempering

(Ref 70). No adverse report on the influence

of microcracks on the mechanical properties has been noted; however, the controlling factors should be varied so as to keep

the incidence of microcracks to a minimum

(Ref 67).

Tip cracking refers to the cracking that

appears in the teeth of carburized and

quenched gears and runs partly or fully to

the ends of the teeth in a direction parallel

to the axis of the part. Many heat treaters

have solved this problem to a great extent

by decreasing the carbon content and case

depth to the minimum acceptable design

level or by copper plating the outer diameter of the gear blank prior to hobbing (Ref

66).

Nitrided Steels. The nitrided cases are

very brittle. Consequently, cracking may

occur in service prior to realizing any improved wear and galling resistance. This

can be avoided by a proper tool design, for

example, incorporating all section .changes

with a minimum radius of 3 mm (0.125 in.).

Tempering Practice. The longer the time

the steel is kept at a temperature between

room temperature and 100 °C (212 °F) after

the complete transformation of martensite

in the core, the more likely the occurrence

of quench cracking. This arises from the

volumetric expansion caused by isothermal

transformation of retained austenite into

martensite.

There are two tempering practices that

lead to cracking problems: tempering too

soon after quenching, that is, before the

steel parts have transformed to martensite

in hardening, and skin tempering, usually

observed in heavy sections (=>50 mm, or 2

in., thick in plates and >75 mm, or 3 in., in

diameter in round bars).

612 / Process and Quality Control Considerations

It is the normal practice to temper immediately after the quenching operations. In