Introduction to Environmental Ratings

Anderson Peeples

Associate Design Engineer, CCS-Inc.

CCS-Inc.

www.ccs-inc.com

December 13, 2012

Introduction to Environmental Ratings

In the world of industrial electronics, there are phrases that simply don’t hold much weight

when describing a system. The problem with such phrases (e.g. “waterproof” and “airtight”) is that these descriptions alone do not provide a quantitative measure of their

meaning. To address this issue, many organizing bodies have developed design standards

for engineers. Serving as a reference to customers, these standards provide specific criteria

for the intended protection rating of a system. The National Electrical Manufacturers

Association (NEMA) and the International Electrotechnical Commission (IEC) supply two of

the most predominant standards, NEMA Ratings and Ingress Protection (IP) Ratings

respectively.

---

NEMA Ratings

To help define the protective qualities of electronic system enclosures, NEMA has developed

a rating system for enclosures containing components less than 1000 volts. These ratings

are defined in the NEMA 250 standard and are separated into two categories: enclosures

used in Non-Hazardous Locations1, and enclosures used in Hazardous Locations2. Each set

of ratings is further divided into indoor and outdoor use, detailing features such as corrosion

resistance, fabrication requirements, material selection, and gasket aging.

Within the NEMA rating system, various industry standards have been adopted. For

example, in many non-hazardous industrial applications, such as industrial automation and

food packaging facilities, NEMA 4 and NEMA 4X have become the de facto standards. This is

due to the fact that NEMA 4 is the minimum enclosure rating that provides protection

against ingress of water. 3 This is important for applications where equipment may

frequently need to be hosed down for cleaning purposes. The addition of the “X” suffix

indicates that the system has further properties that limit its susceptibility to corrosion.

In addition to NEMA ratings, UL 50/508 and CSA C22.2 No. 94 are also used to define

protection ratings for enclosures in North America. These ratings utilize a similar numbering

method for specifying the protection level of a system. Unlike NEMA ratings, which can be

certified by the manufacturer, UL and CSA require testing by a certified lab to qualify an

enclosure’s environmental rating.

1

Appendix A - Table 1

Appendix A - Table 2

3

Appendix A - Tables 3 and 4

2

CCS-Inc.

www.ccs-inc.com

December 13, 2012

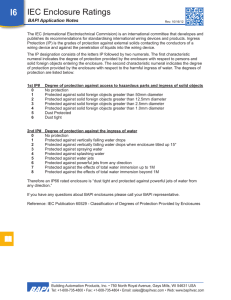

IP Ratings

Rather than, or often in conjunction with, specifying a NEMA rating for an electronic

enclosure or system, manufacturers may specify an Ingress Protection, or IP, Code. IP

codes are classified in the IEC International Standard 60529. These codes aim to provide a

concise, but comprehensive, explanation of the protection provided and testing required for

an enclosure or system.

General IP codes utilize the prefix “IP” followed by two numerals4; for example, IP65. The

first numeral in the code designates the degree to which the system is protected against

solid foreign objects. The second numeral indicates the degree to which the system is

protected against liquid ingress. As the numerical value increases, the system protection

increases. In the event that either test parameter (solid or liquid protection) is not specified,

the numeral for that portion is replaced with an X. For example, when testing a system only

for liquid ingress per classification #6, the code would be IPX6.

In addition to particulate and liquid protection ratings, IP codes may also include letters to

signify further aspects of the system. A letter may be appended to the code to specify the

degree of protection against hazardous parts.5 Additionally, a supplemental letter may be

appended to the code to signify safety information about the system.6 With these options, a

full IP code may take the form as shown in Figure A.7

Figure A. IP Code Format

As with NEMA ratings, IEC’s IP ratings are “self-certifying,” meaning that they do not

require third party test labs to certify enclosure designs. This leaves testing up to the

manufacturer of the equipment.

4

Appendix A - Tables 5 and 6

Appendix A - Table 7

6

Appendix A - Table 8

7

An additional number may be added to indicate the impact resistance of the enclosure, though this is not

included in the IEC 60529 standard.

5

CCS-Inc.

www.ccs-inc.com

December 13, 2012

Though NEMA ratings and IP codes both aim to clarify and quantify environmental

protection for electronic systems, there are key differences between the two standards.

Unlike NEMA ratings, IEC IP ratings do not specify fabrication practices, corrosion

protection, or risk of explosion. For this reason, it is possible to have a NEMA rated

enclosure that may satisfy all requirements for IP certification; however, a less stringent IP

rating may not meet NEMA requirements.8

Determining the Appropriate Rating for Your Project’s Needs

Due to the wide variety of ratings and enclosure protections available, choosing which rating

is most appropriate for your application can be a daunting task. CCS Engineers are happy to

help you analyze your system’s environment to determine what solution would best fit your

project’s needs. To discuss your situation in detail with one of our engineers, contact us

today.

8

Appendix A - Table 9

CCS-Inc.

www.ccs-inc.com

December 13, 2012

Appendix A – Rating Criteria

Table 1. NEMA Enclosure Types for Non-Hazardous Locations

Type Standard

1

Enclosures constructed for indoor use to provide a degree of protection to personnel

against access to hazardous parts and to provide a degree of protection of the

equipment inside the enclosure against ingress of solid foreign objects (falling dirt).

2

Enclosures constructed for indoor use to provide a degree of protection to personnel

against access to hazardous parts; to provide a degree of protection of the equipment

inside the enclosure against ingress of solid foreign objects (falling dirt); and to provide

a degree of protection with respect to harmful effects on the equipment due to the

ingress of water (dripping and light splashing).

3

Enclosures constructed for either indoor or outdoor use to provide a degree of

protection to personnel against access to hazardous parts; to provide a degree of

protection of the equipment inside the enclosure against ingress of solid foreign objects

(falling dirt and windblown dust); to provide a degree of protection with respect to

harmful effects on the equipment due to the ingress of water (rain, sleet, snow); and

that will be undamaged by the external formation of ice on the enclosure.

3R

Enclosures constructed for either indoor or outdoor use to provide a degree of

protection to personnel against access to hazardous parts; to provide a degree of

protection of the equipment inside the enclosure against ingress of solid foreign objects

(falling dirt); to provide a degree of protection with respect to harmful effects on the

equipment due to the ingress of water (rain, sleet, snow); and that will be undamaged

by the external formation of ice on the enclosure.

3S

Enclosures constructed for either indoor or outdoor use to provide a degree of

protection to personnel against access to hazardous parts; to provide a degree of

protection of the equipment inside the enclosure against ingress of solid foreign objects

(falling dirt and windblown dust); to provide a degree of protection with respect to

harmful effects on the equipment due to the ingress of water (rain, sleet, snow); and

for which the external mechanism(s) remain operable when ice laden.

3X

Enclosures constructed for either indoor or outdoor use to provide a degree of

protection to personnel against access to hazardous parts; to provide a degree of

protection of the equipment inside the enclosure against ingress of solid foreign objects

(falling dirt and windblown dust); to provide a degree of protection with respect to

harmful effects on the equipment due to the ingress of water (rain, sleet, snow); that

provides an additional level of protection against corrosion and that will be undamaged

by the external formation of ice on the enclosure.

4

Enclosures constructed for either indoor or outdoor use to provide a degree of

protection to personnel against access to hazardous parts; to provide a degree of

protection of the equipment inside the enclosure against ingress of solid foreign objects

(falling dirt and windblown dust); to provide a degree of protection with respect to

harmful effects on the equipment due to the ingress of water (rain, sleet, snow,

splashing water, and hose directed water); and that will be undamaged by the external

formation of ice on the enclosure.

4X

Enclosures constructed for either indoor or outdoor use to provide a degree of

protection to personnel against access to hazardous parts; to provide a degree of

protection of the equipment inside the enclosure against ingress of solid foreign objects

(windblown dust); to provide a degree of protection with respect to harmful effects on

the equipment due to the ingress of water (rain, sleet, snow, splashing water, and

hose directed water); that provides an additional level of protection against corrosion;

and that will be undamaged by the external formation of ice on the enclosure.

5

Enclosures constructed for indoor use to provide a degree of protection to personnel

CCS-Inc.

www.ccs-inc.com

December 13, 2012

6

6P

12

13

against access to hazardous parts; to provide a degree of protection of the equipment

inside the enclosure against ingress of solid foreign objects (falling dirt and settling

airborne dust, lint, fibers, and flyings); and to provide a degree of protection with

respect to harmful effects on the equipment due to the ingress of water (dripping and

light splashing).

Enclosures constructed for either indoor or outdoor use to provide a degree of

protection to personnel against access to hazardous parts; to provide a degree of

protection of the equipment inside the enclosure against ingress of solid foreign objects

(falling dirt); to provide a degree of protection with respect to harmful effects on the

equipment due to the ingress of water (hose directed water and the entry of water

during occasional temporary submersion at a limited depth); and that will be

undamaged by the external formation of ice on the enclosure.

Enclosures constructed for either indoor or outdoor use to provide a degree of

protection to personnel against access to hazardous parts; to provide a degree of

protection of the equipment inside the enclosure against ingress of solid foreign objects

(falling dirt); to provide a degree of protection with respect to harmful effects on the

equipment due to the ingress of water (hose directed water and the entry of water

during prolonged submersion at a limited depth); that provides an additional level of

protection against corrosion and that will be undamaged by the external formation of

ice on the enclosure.

Enclosures constructed (without knockouts) for indoor use to provide a degree of

protection to personnel against access to hazardous parts; to provide a degree of

protection of the equipment inside the enclosure against ingress of solid foreign objects

(falling dirt and circulating dust, lint, fibers, and flyings); and to provide a degree of

protection with respect to harmful effects on the equipment due to the ingress of water

(dripping and light splashing).

Enclosures constructed for indoor use to provide a degree of protection to personnel

against access to hazardous parts; to provide a degree of protection of the equipment

inside the enclosure against ingress of solid foreign objects (falling dirt and circulating

dust, lint, fibers, and flyings); to provide a degree of protection with respect to harmful

effects on the equipment due to the ingress of water (dripping and light splashing);

and to provide a degree of protection against the spraying, splashing, and seepage of

oil and non-corrosive coolants.

CCS-Inc.

www.ccs-inc.com

December 13, 2012

Table 2. NEMA Enclosure Types for Hazardous Locations

Type Standard

7

Enclosures constructed for indoor use in hazardous (classified) locations classified as

Class I, Division 1, Groups A, B, C, or D as defined in NFPA 70.

8

Enclosures constructed for either indoor or outdoor use in hazardous (classified)

locations classified as Class I, Division 1, Groups A, B, C, and D as defined in NFPA 70.

9

Enclosures constructed for indoor use in hazardous (classified) locations classified as

Class II, Division 1, Groups E, F, or G as defined in NFPA 70.

10

Enclosures constructed to meet the requirements of the Mine Safety and Health

Administration, 30 CFR, Part 18.

Table 3. Comparison of Specific Applications of Enclosures for Indoor Non-hazardous

Locations

Provides a Degree of Protection Against

1* 2* 4 4X 5 6 6P 12 12K 13

the Following Conditions

Access to hazardous parts

X

X X

X

X X X

X

X

X

Ingress of solid foreign objects (falling dirt)

X

X X

X

X X X

X

X

X

Ingress of water (Dripping and light slapping)

X X

X

X X X

X

X

X

Ingress of solid foreign objects (Circulating

X

X

X X

X

X

X

dust, lint, fibers, and flyings**)

Ingress of solid foreign objects (Settling

X

X

X X X

X

X

X

airborne dust, lint, fibers, and flyings**)

Ingress of water (Hosedown and splashing

X

X

X X

water)

Oil and coolant seepage

X

X

X

Oil or coolant spraying and splashing

X

Corrosive Agents

X

X

Ingress of water (Occasional temporary

X X

submersion)

Ingress of water (Occasional prolonged

X

submersion)

*These enclosures may be ventilated.

**These fibers and flyings are nonhazardous materials and are not considered Class III type

ignitable fibers or combustible flyings.

CCS-Inc.

www.ccs-inc.com

December 13, 2012

Table 4. Comparison of Specific Applications of Enclosures for Outdoor Non-hazardous

Locations

Provides a Degree of Protection Against 3 3X 3R* 3RX 3S 3SX 4 4X

the Following Conditions

Access to hazardous parts

X

X

X

X

X

X

X

X

Ingress of water (Rain, snow, and sleet**)

X

X

X

X

X

X

X

X

Sleet***

X

X

Ingress of solid foreign objects (Windblown

X

X

X

X

X

X

dust, lint, fibers, and flyings)

Ingress of water (Hosedown)

X

X

Corrosive agents

X

X

X

X

Ingress of water (Occasional temporary

submersion)

Ingress of water (Occasional prolonged

submersion)

*These enclosures may be ventilated.

** External operating mechanisms are not required to be operate when the enclosure is

covered.

***External operating mechanisms are operable when the enclosure is ice covered.

Table 5. IP Characteristics – Protection against Solid Foreign Objects

First

Test Means

Numeral

0

No test required

1

Rigid sphere without handle or guard - 50mm Diameter

2

Rigid sphere without handle or guard - 12.5mm Diameter

3

Rigid steel rod with edges free from burrs - 2.5mm Diameter

4

Rigid Sphere without handle or guard - 50mm Diameter

5

Dust chamber with or without underpressure

6

Dust chamber with underpressure

CCS-Inc.

www.ccs-inc.com

6

6P

X

X

X

X

X

X

X

X

X

X

X

X

ice

Test Force

50N ± 10%

30N ± 10%

3N ± 10%

1N ± 10%

December 13, 2012

Table 6. IP Characteristics – Protection against Water Ingress

Second

Test Means

Numeral

0

No test required

1

Drip box

2

Drip box with 15° tilt

Flow

Rate

Duration of

Test

1mm/min

3mm/min

Water spray at ±60° from vertical, no more than

200mm from EUT

Water spray at ±180° from vertical, no more than

200mm from EUT

Water jet from 6.3 mm diameter nozzle at a distance of

2.5-3 m

0.7l/min

10 min

2.5 min for

each

position

10 min

0.07l/min

10 min

12.5l/min

6

Water jet from 12.5 mm diameter nozzle at a distance

of 2.5-3 m

12.5l/min

7

Immersion tank

Water Depth: 0.15m above enclosure top, 1m above

bottom

Immersion tank

Water Depth: Specified by manufacturer

1 min/m2

At least 3

min

1 min/m2

At least 3

min

30 min

3

4

5

8

By

agreement

Table 7. IP Characteristics – Additional Letter for Hazardous Parts

Additional

Level of Protection

Letter

A

Protected against access with the back of the hand

B

Protected against access with a finger

C

Protected against access with a tool

D

Protected against access with a wire

CCS-Inc.

www.ccs-inc.com

December 13, 2012

Table 8. IP Characteristics – Additional Safety Information

Supplementary Significance

Letter

H

High-voltage apparatus

M

Tested for harmful effects due to the ingress of water when the movable

parts of the equipment are in motion

S

Tested for harmful effects due to the ingress of water when the movable

parts of the equipment are stationary

W

Suitable for use under specified weather conditions and provided with

additional protective features or processes

Table 9. NEMA – IP Comparison

IP Rating Needed

IP20

IP22

IP24

IP53

IP54

IP55

IP66

IP67

IP68

Minimum NEMA Rating Required

1

2

3R, 3RX

5

12, 12k, 13

3, 3X, 3S, 3SX

4, 4X

6

6P

NEMA 250-2003. Copyright National Electrical Manufacturers Association. Reprinted by

permission.

The author thanks the International Electrotechnical Commission (IEC) for permission to

reproduce Information from its International Publication IEC 60529 ed.2.1 (2001). All such

extracts are copyright of IEC, Geneva, Switzerland. All rights reserved. Further information

on the IEC is available from www.iec.ch. IEC has no responsibility for the placement and

context in which the extracts and contents are reproduced by the author, nor is IEC in any

way responsible for the other content or accuracy therein.

IEC 60529 ed.2.1 Copyright © 2001 IEC Geneva, Switzerland.www.iec.ch

CCS-Inc.

www.ccs-inc.com

December 13, 2012

Appendix B – Organizing and Standards Bodies

National Electrical Manufacturers Association

1300 North 17th Street

Suite 1752

Rosslyn, Virginia 22209

Phone: 703-841-3200

Fax: 703-841-5900

International Electrotechnical Commission

3, rue de Varembé

P.O. Box 131

CH - 1211 Geneva 20, Switzerland

Phone : +41 22 919 02 11

Fax : +41 22 919 03 00

Canadian Standards Association

178 Rexdale Blvd.

Toronto, Ontario

Canada M9W 1R3

Phone: 800-463-6727

Underwriters Laboratories

2600 N.W. Lake Rd.

Camas, WA 98607-8542

Phone: 1-877-854-3577

Fax: 1-360-817-6278

CCS-Inc.

www.ccs-inc.com

December 13, 2012