Why Read The Instructions

advertisement

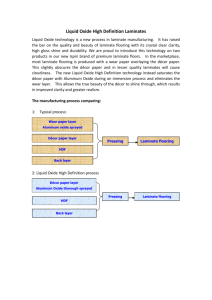

It’s ‘Only’ Laminate Flooring, So Why Read the Instructions? by Bob Middleton T he evolution of hard surface flooring today has truly given the consumer an amazing selection of color, texture and application options. As more products with unique applications enter the marketplace it becomes even more imperative that professional installers take the time to read, ask questions and understand the manufacturer’s written instructions. 12 www.fcimag.com To illustrate the need for installers and flooring inspectors to keep up-to-date with the varied application methods, it’s important to know everything you can about the product going in. For the purposes of this article, let’s take a look at laminate flooring. First, let’s focus on the construction and application of the product, then we’ll talk more specifically about the instructions. May/June 2013 Laminate construction and ratings. Laminate offerings in today’s market have proliferated. Many feature ceramic or hand-scraped textures while others Students work with laminate flooring during a CFI training event in Kansas City earlier this year. Photo courtesy of CFI. can have embossed patterns mimicking nature so well you can’t stop admiring the installed floor. Boiling it down to the basics, An AC3 rating is just about perfect for light commercial and residential use, whereas laminates having higher commercial AC5 ratings are sure to quickly wear holes through socks! the top surface of laminate flooring usually consists of a firstquality photographic décor paper, a core constructed with a high-density fiber board (HDF) and a melamine backing added for extra stability. The total construction is then heated and 14 www.fcimag.com May/June 2013 pressed under thousands of lbs. per sq. inch, producing a very strong plank. However, care must be taken as laminate edges are susceptible to chipping from shipping/handling or during assembly when using tapping blocks and other related tools. Due to its construction, laminates are very scratch- and moisture-resistant, though not entirely impervious to either. Many quality laminates are equipped with a built-on pre-attached pad on the back that will satisfy most condominium and apartment association requirements for sound isolation; those that do not will require an underlayment. Many styles are available in a variety of finishes: from traditional matte to UV-cured and high-gloss. Quality laminates will feature an aluminum oxide protective wear layer and feature a numerical Abrasion Criteria (AC) rating of 1 to 5, indicating the overlay film resistance to abrasion, impact, stains and cigarette burns. Having a rating verifies that the product has been tested for the effects of furniture legs, casters, swelling along its edges and so on. CFI instructor Bob Gillespie (standing) explains the finer points of laminate flooring installation. Photo courtesy of CFI. Educated laminate costumers will shop AC ratings. An AC3 rating is just about perfect for light commercial and residential use, whereas laminates having higher commercial AC5 ratings are sure to quickly wear holes through socks! In general, laminate warranty coverage is stated in years and is related to the product’s wear layer and thickness. Depending on the manufacturer, warranties are only applicable to adherence to the instructions, foot traffic and board construction. Issues with moisture, scratches and denting are viewed as site-related for which the manufacturer has no direct control over, and are often disclaimed. Laminate applications. Laminates also have a variety of fitment or assembly methods, each directly related to the design of a manufacturer’s locking system. Terms such as glueless, lockand-fold, angle-angle, tap-and-lock or Uniclic are used not only to describe the way a particular laminate is to be assembled, but can also reflect licensing agreements between brands. Because laminates are not being permanently attached to the subfloor, the product can also be a smart choice for radiant heat and cement applications. Laminates have found their way to wall and ceiling applications as well, due to their lighter weight as compared to heavier solid wood. Laminates can be installed in one room then later disassembled and installed in another. Some laminates even feature a metal locking system that can be ruined if not installed correctly the first time. Why read the instructions? As a professional installer you may have heard some in the business say, “I’ve been installing (whatever product) this way for 10 years and don’t need to read the instructions.” However, how do you know the installer hasn’t been installing the materials wrong for 10 years? This type of thinking is tantamount to “rolling the dice” for potential claims, and ignores the fact that flooring products and trends do change, as well as advancements in technologies. Installation methodologies do get revised to address the needs of jobsite conditions or limitations. Discerning installers will take the time needed to read and better understand the instructions in an effort to identify and avoid potential failures. When an installation fails, flooring inspectors will use the installation instructions as a guide to determine whether the flooring was installed as per manufacturer’s specifications. This is all the more reason to read and follow the instructions. General requirements. Reading the directions can be an enlightening discovery of tips and procedures! Following are just some examples of what manufacturers will generally require: Acclimate products according to the instructions. The work area must be climate-controlled to the recommended temperature and humidity values (this means that the electrical and HVAC needs to be fully operational). For applications on cement, obtain a moisture reading using a Calcium Chloride or RH test. Installations should not proceed until the source of high moisture has been identified and corrected. Do not install laminates in an area with a sump-pump or fl oor drain. When installing over cement use 6-8 mil polyethylene film plastic or equivalent as a moisture barrier; however, do not use polyethylene film plastic over wood subfl oors as wood structures and components need to breathe. Note directions for board assembly, left-to-right or right-to-left. To ensure best overall appearance in shade and color, install fl ooring from several boxes. Do not install flooring in a “stair-stepped” pattern as this can weaken the total floor and may cause flooring to separate. Ensure the subfloor is flat to within 3/16” in 10’ or 1/8” in 6’ (3/16” is the thickness of three stacked quarters; 1/8” is the equivalent of a grain of rice). Room areas exceeding the recommended distance in length or width will need T-moldings as expansion breaks. The recommended expansion spacing must be placed around the perimeter of the installed area and all fixed objects. Do not install laminates under fixed or permanent cabinetry. When laminates are used to overlay stair treads and risers, omit the use of underlayment. When an installation fails, flooring inspectors will use the installation instructions as a guide to determine whether the flooring was installed as per manufacturer’s specifications. This is all the more reason to read and follow the instructions. Attach all stair components using flexible urethane adhesives; For safety, laminate stair nosing must be both glued and nailed. Putting it all together. Now, keep in mind that a variety of laminate application methods exist, and each can have their own unique joint assembly and limitations of use. Therefore, before starting installation, floor installers are wise to read the manufacturer’s written instructions and when in doubt ask questions – especially when a particular application seems out of the ordinary. Adhering to the manufacturer’s instructions can promote a more positive experience between all parties concerned, from the manufacturer, to the installer and customer, as well as keeping you and your crew out of the “tall grass” of costly claims! FCI Bob Middleton has been in the flooring business for over 30 years as an installer and consultant. He is an ICFI, NWFA and LEES Certified Professional and a NALFA Installer/Inspector. As Lumber Liquidators Technical & Installation Manager, he conducts installer training sessions and participates in product warranty reviews. He also contributes to Lumber Liquidators’ blog and Twitter, BobVila.com’s “Fix It Forum,” and other industry sites. May/June 2013 www.fcimag.com 15