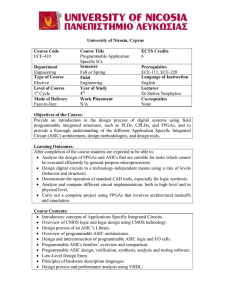

Programmable Logic Devices

advertisement