CompactPCI Connectors acc. to PIGMG 2.0 Rev. 3.0

General

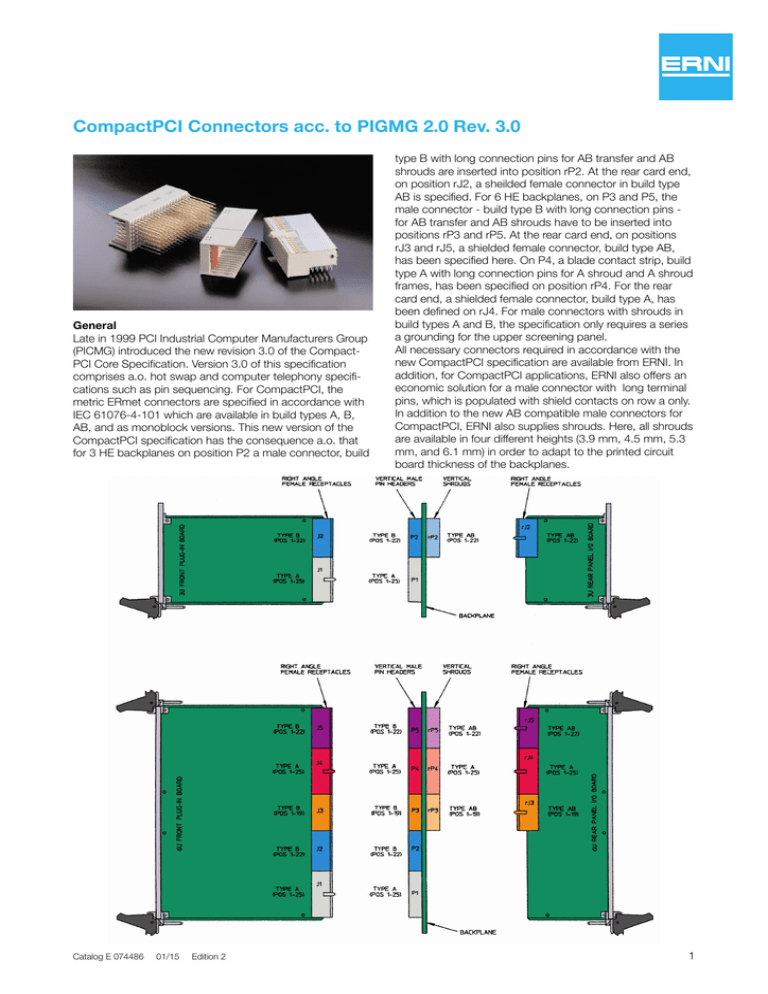

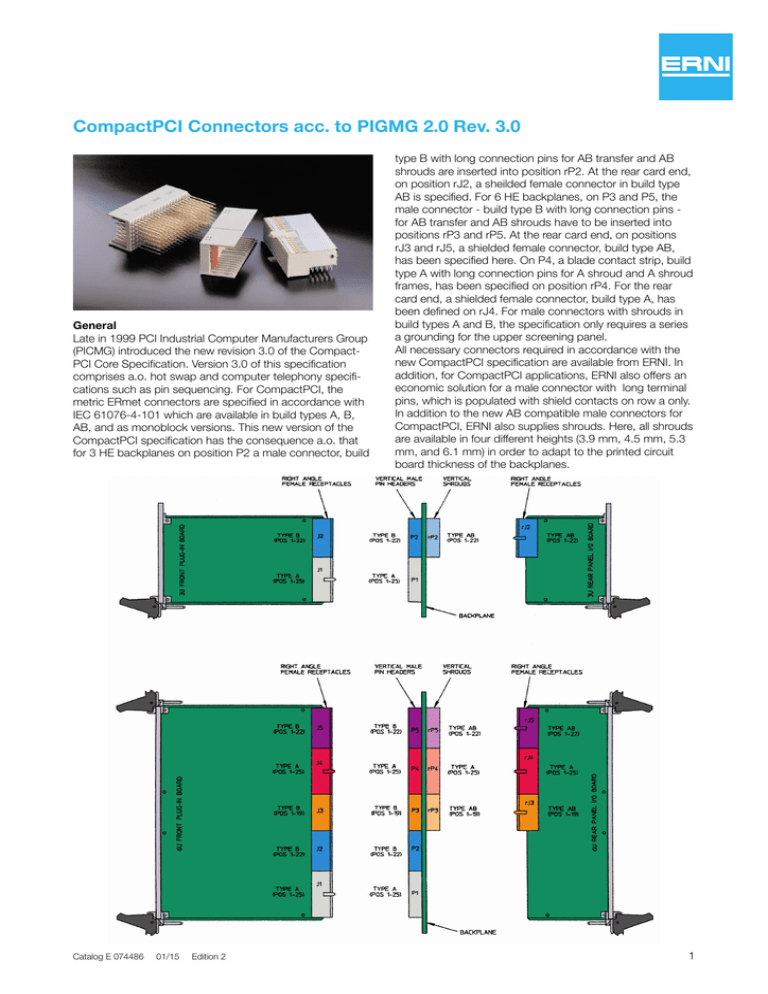

Late in 1999 PCI Industrial Computer Manufacturers Group

(PICMG) introduced the new revision 3.0 of the CompactPCI Core Specification. Version 3.0 of this specification

comprises a.o. hot swap and computer telephony specifications such as pin sequencing. For CompactPCI, the

metric ERmet connectors are specified in accordance with

IEC 61076-4-101 which are available in build types A, B,

AB, and as monoblock versions. This new version of the

CompactPCI specification has the consequence a.o. that

for 3 HE backplanes on position P2 a male connector, build

Catalog E 074486

01/15

Edition 2

type B with long connection pins for AB transfer and AB

shrouds are inserted into position rP2. At the rear card end,

on position rJ2, a sheilded female connector in build type

AB is specified. For 6 HE backplanes, on P3 and P5, the

male connector - build type B with long connection pins for AB transfer and AB shrouds have to be inserted into

positions rP3 and rP5. At the rear card end, on positions

rJ3 and rJ5, a shielded female connector, build type AB,

has been specified here. On P4, a blade contact strip, build

type A with long connection pins for A shroud and A shroud

frames, has been specified on position rP4. For the rear

card end, a shielded female connector, build type A, has

been defined on rJ4. For male connectors with shrouds in

build types A and B, the specification only requires a series

a grounding for the upper screening panel.

All necessary connectors required in accordance with the

new CompactPCI specification are available from ERNI. In

addition, for CompactPCI applications, ERNI also offers an

economic solution for a male connector with long terminal

pins, which is populated with shield contacts on row a only.

In addition to the new AB compatible male connectors for

CompactPCI, ERNI also supplies shrouds. Here, all shrouds

are available in four different heights (3.9 mm, 4.5 mm, 5.3

mm, and 6.1 mm) in order to adapt to the printed circuit

board thickness of the backplanes.

1

CompactPCI Connectors acc. to PIGMG 2.0 Rev. 3.0

Ordering Informations

Male Connectors For Backplanes

Type A With Peg

Type A With Peg And Extended Terminals

For Shrouding

Type A Without Peg And With Extended Terminals

Type B (AB Compatible) With Extended Terminals

For Shrouding

Type B (AB Compatible) With Extended Terminals

For Shrouding

Type B (AB Compatible) With Extended Terminals

For Shrouding

Type A With Extended Terminals For Shrouding

Type A With Peg And Extended Terminals

For Shrouding

Type A With Peg And Extended Terminals

For Shrouding

Type B (AB Compatible) With Extended Terminals

For Shrouding

Type B (AB Compatible) With Extended Terminals

For Shrouding

Location On

The PCB

Number Of

Positions*

Contact

Loading*

Part Number

P1

25

CB---BC

923190

P1 Special

P1

25

25

TP---PT

TS---ST

923197

923342

P2, P5

22

TSSSSS-

923345

P3

19

TSSSSST

923341

P3

P4

19

25

TSSSSSS----ST

923346

923347

P4

25

TRRRRRT

064688

P4

25

TSSSSST

103975

P5 Telecom

22

-------

923339

P2, P5

22

TSSSSST

923340

Back

Female Connectors For Daughter Cards

Location On

The PCB

Number Of

Positions*

Part Number

Type A With Shield, Without Peg

Type A With Split Shield, Partially Loaded

Type A With Split Shield, Partially Loaded

Type AB With Shield, Without Peg

Type AB With Shield, Without Peg

Type B With Upper Shield

Type B With Upper Shield

J1, J4

J4 Telecom

rJ4 Telecom

rJ2, rJ5

rJ3

J2, J5

J3

25

25

25

22

19

22

19

Shrouds For Male Connectors

Location On

The PCB

Number Of

Positions*

Height

(mm)

Part Number

Type A Shroud 25 Positions

Type A Shroud 25 Positions

Type A Shroud 25 Positions

Type A Shroud 25 Positions

Type AB Shroud 22 Positions

Type AB Shroud 22 Positions

Type AB Shroud 22 Positions

Type AB Shroud 19 Positions

Type AB Shroud 19 Positions

Type AB Shroud 19 Positions

Type AB Shroud 19 Positions

rP1, rP4

rP1, rP4

rP1, rP4

rP1, rP4

rP2, rP5

rP2, rP5

rP2, rP5

rP3

rP3

rP3

rP3

25

25

25

25

22

22

22

19

19

19

19

14.35

14.95

15.75

16.55

14.95

15.75

16.55

14.35

14.95

15.75

16.55

114436

054795

054794

054793

114426

114427

114428

114487

114488

114489

114490

Code

Number

Color

Part Number

Brilliant Blue

Cadmium Yellow

Strawberry Red

Brilliant Blue

Cadmium Yellow

Strawberry Red

043347

043345

043350

043337

043335

043340

Coding Keys

Application

Coding Keys For Male Connectors And Shrouds

Coding Keys For Male Connectors And Shrouds

Coding Keys For Male Connectors And Shrouds

Coding Keys For Female Connectors

Coding Keys For Female Connectors

Coding Keys For Female Connectors

* Length = 50mm; Pitch = 2.0mm => 50 / 2 = 25 Positions

**Cross Sectional Loading From Z To F

Catalog E 074486

01/15

Edition 2

5.0 Volts P1

3.3 Volts P1

Telecom P4

5.0 Volts J1

3.3 Volts P1

Telecom J4

1567

3456

1248

2348

1278

3567

354142

104512

104697

114809

134075

354148

354146

Back

2

Back

Metal plating of plated-through hole

Back

Metal plating of plated-through hole

Back

Metal plating of plated-through hole

Back

Metal plating of plated-through hole

Back

Metal plating of plated-through hole

Back

Metal plating of plated-through hole

Back

Metal plating of plated-through hole

Back

Metal plating of plated-through hole

Back

Metal plating of plated-through hole

Back

Metal plating of plated-through hole

Back

Metal plating of plated-through hole

Back

Metal plating of plated-through hole

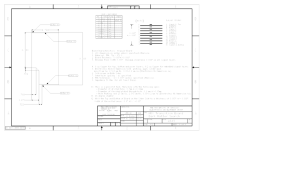

Bestueckungsplan 25

contact layout

15

11

8

5

1

e

d

c

b

a

= bestueckt - assemble

25

15

11

8

5

1

e

d

2

c

b

a

8

EE - Zone fuer

4x2=

2

2

10 x 2 =

20

Abschirmblech

8

10 x 2 =

- shielding

20

Compliant zone for

Abschirmblech

104514

durchkontaktierte

Loecher Ø 0.6 ± 0.05

thru hole

Ø 0.6 ± 0.05

- shielding

104515

50

max.

30.5

+

0.1

-

9.5

2

+

0.1

-

10.8

- 0.2

21

1.7

+

0.05

-

21.9

0.4

+ 0.2

Id.-Nr.

Anforderungsstufe

11.4

Datum

class

date

12.25

Lochbild fuer Leiterplatte

Board hole pattern

( Bestueckungsseite )

( Component mounting side )

10 x 2 =

0.1

0.6

alle Loecher

all holes

8

( 20 )

10 x 2 =

( 20 )

+

0.05

-

Back

2

durchkontaktiert,

Bohrloch 0.7

± 0.02

plated thru,

drill hole 0.7

± 0.02

f

e

c

1.5

d

b

13

11

1

2

15

5x2=

( 10 )

a

25

Metal plating of plated-through hole

Fehlende Masse und Angaben nach IEC 61076 - 4 - 101

Missing information and dimensions per IEC 61076 - 4 - 10

XXXXXXXX

Information :

Abschirmblech oben montiert

shielding mounted on top

ohne Fixierstift

2:1

XXXXX

- without locating pegs

ERmet Federleiste A

ERmet Female Type A

104512

Back

Metal plating of plated-through hole

Bestückungsplan - contact layout

2

1

e

d

c

b

a

= bestückt - assemble

2

1

4x2= 8

2

e

d

c

b

a

EE-Zone für

durchkontaktierte

Löcher [ 0.6 60.05

Compliant zone for

thru hole

[ 0.6 60.05

2

21 x 2 = 42

3-0.4

44max.

XXXX

ERNI

114809

2

22

10.8-0.2

1

21

1.760.05

2

Anforderungsstufe

class

Id.-Nr.

Lochbild für Leiterplatte

(Bestückungsseite)

11.4

Datum

date

13.85

Board hole pattern

(Component mounting side)

21 x 2 = (42)

0.1

0.6 +0.05

-

alle Löcher

all holes

2

durchkontaktiert, plated thru,

drill hole 0.7

Bohrloch 0.7

Back

2

2

1.5

1

5x2=

(10)

f

e

d

c

b

a

Metal plating of plated-through hole

Fehlende Masse und Angaben nach IEC 61076-4-101

Missing information and dimensions per IEC 61076-4-101

Information :

Abschirmblech oben

shielding mounted on top

All rights

Only for

To insure that this is the

version of this drawing,

contact one of the ERNI

before

Subject to modification

prior

Drawing will not be

Toleranc

2:1

Scal

Designation

ERmet Federleiste AB 22

ERmet Female Type AB 22

Elektroapparate

D-73099

114809

I

Back

Metal plating of plated-through hole

Bestückungsplan / contact layout

22

1

e

d

c

b

a

= bestückt / assembled

22

1

4x2=8

2

e

d

c

b

a

2

21 x 2 = 42

Abschirmblech / shielding

EN-Zone für

durchkontaktierte

Löcher Ø0,6 ±0,05

3 -0,4

44 max.

2

10,8

21

1,9

compliant zone for

thru hole Ø0,6 ±0,05

11,4

Metal plating of plated-through hole

1)

Board hole pattern

(Component mounting side

Lochbild für Leiterplatte

(Bestückungsseite)

Ø

0.6 ±0.05 Durchmesser des metallisierten Loches

Ø

0.6 ±0.05 Diameter of finished plated-through hole

Ø

0.7 ±0.05 Bohrungsdurchmesser des Loches

Ø

0.7 ±0.05 Diameter of drilled hole

21 x 2 = (42)

0,05

alle Löcher

Schichtaufbau im metallisierten Loch

siehe Zeichnung 114406

2

1)

Metal plating of plated through hole

see drawing 114406

5 x 2 = (10)

f

e

d

c

1,5

all holes

b

a

1

2

22

Back

Fehlende Maße und Angaben nach IEC 61076-4-101

Missing information and dimensions per IEC 61076-4-101

shielding mounted on top

Anforderungsstufe 2 / class 2

BA2

Copyright by ERNI GmbH

Proprietary notice pursuant to ISO 16016 to be observed.

Abschirmblech oben montiert

Information:

Tolerances

2:1

Scale

All Dimensions

in mm

All rights reserved.

Only for Information.

To ensure that this is the latest

version of this drawing, please

contact one of the ERNI companies

before using.

Designation

Subject to modification without

prior notice.

Drawing will not be updated.

ERmet Federleiste B22

ERmet Female Type B22

354148

www.ERNI.com

b

25.06.2012

Index

Date

Class

ERMB22

I

A3

Back

Metal plating of plated-through hole

14,8

H

3,9

14,35

11,6

12

49,9

2

6x2=

Back

2

2

10 x 2 =

20

8

10 x 2 =

20

Dimension Nr.

Tolerances

5:1

Scale

Material

16.55

054794

15.75

054795

14.95

114436

14.35

Ident-Nr.

Mass H

I.D. number

dimension H

Consider protection memo from DIN 34

054793

All Dimensions

in mm

All rights reserved.

Only for information.

To insure that this is the latest

version of this drawing, please

contact one of the ERNI companies

before using.

Subject to modification without

prior notice.

Drawing will not be updated.

Index

Modification Nr.

Date

Date

Name

Tool-Nr.:

siehe Einzelteile

see pieceparts

Designation

ERmet A Übergaber. m. Klemmst

ERmet A Shroud with clamp part

Elektroapparate GmbH

054792

D-73099 ADELBERG

Name

O:00010255.SZN

Class

D

H

3,9

14,35

11,6

43,9

21 x 2 =

42

2

14,8

2

6x2=

15,4

12

Back

Dimension Nr.

114428

16.55

114427

15.75

114426

14.95

114425

14.35

Tolerances

Scale

Ident-Nr.

Maß H

I.D.number

dimensions H

Consider protection memo from DIN 34

All Dimensions

in mm

Date

All rights reserved.

Only for information.

To insure that this is the latest

version of this drawing, please

contact one of the ERNI companies

before using.

Subject to modification without

prior notice.

Drawing will not be updated.

Index

Modification Nr.

Date

Name

Material

5:1

Tool-Nr.:

siehe Einzelteile

see pieceparts

Designation

ERmet AB 22 Überga. m. KLemmst.

ERmet AB 22 Shroud with clamp

Elektroapparate GmbH

114429

D-73099 ADELBERG

Name

O:00010299.SZN

Class

D

3,9

H

14,35

11,6

37,9

18 x 2 =

36

2

14,8

2

6x2=

15,4

12

Back

Dimension Nr.

114490

16.55

114489

15.75

114488

14.95

114487

14.35

Tolerances

5:1

Scale

Material

Ident-Nr.

Maß H

I.D.number

dimensions H

Consider protection memo from DIN 34

All Dimensions

in mm

Date

All rights reserved.

Only for information.

To insure that this is the latest

version of this drawing, please

contact one of the ERNI companies

before using.

Subject to modification without

prior notice.

Drawing will not be updated.

Index

Modification Nr.

Date

Name

Tool-Nr.:

siehe Einzelteile

see pieceparts

Designation

ERmet AB 19 Überg. m. Klemmst.

ERmet AB 19 Shroud with clamp.

Elektroapparate GmbH

114486

D-73099 ADELBERG

Name

O:00010296.SZN

Class

D

Catalog E 074482 02/00 Edition 1

Coding Keys

Ordering Information

Coding keys for male connectors and shrouds

Coding keys for female connectors

Coding Key

Coding Key

Code Colour

No.

Part Number

Code Colour

No.

Part Number

Pastel Orange

3568 RAL 2003

Fincke 00233197

043342

Pastel Orange

1247 RAL 2003

Fincke 00233197

043332

Steel Blue

3478 RAL 5011

Fincke 00251197

043343

Steel Blue

1256 RAL 5011

Fincke 00251197

043333

Slate Grey

3467 RAL 7015

Fincke 00235197

043344

Slate Grey

1258 RAL 7015

Fincke 00235197

043334

Cadmium Yellow

3456 RAL 1021

Fincke 00252197

043345

Cadmium Yellow

1278 RAL 1021

Fincke 00252197

043335

Reseda Green

2578 RAL 6011

Fincke 00237197

043346

Reseda Green

1346 RAL 6011

Fincke 00237197

043336

Brilliant Blue

1567 RAL 5007

Fincke 00245197

043347

Brilliant Blue

2348 RAL 5007

Fincke 00245197

043337

Blue/Lilac

1356 RAL 4005

Fincke 00246197

043348

Blue/Lilac

2478 RAL 4005

Fincke 00246197

043338

Ocher Yellow

4678 RAL 1024

Fincke 00313197

043349

Ocher Yellow

1235 RAL 1024

Fincke 00313197

043339

Strawberry Red

1248 RAL 3018

Fincke 00312197

043350

Strawberry Red

3567 RAL 3018

Fincke 00312197

043340

Nut Brown

1236 RAL 8011

Fincke 00272197

043351

Nut Brown

4578 RAL 8011

Fincke 00272197

043341

Mounting Device

For Coding-Keys

053593

http://Connect.ERNI.com/contact/

Back

Back

Back

Back

Back

Back

Schichtaufbau im metallisierten Loch fuer EE-Kontakt

Metal plating of plated-through hole for EE-contact

ø 0.7

Durchmesser des

metallisierten Loches

Diameter of finished

plated-through hole

ø 0.6

+ 0.02

-

+ 0.05

-

min. 0.1

min. 25 µm Cu

Bohrungsdurchmesser

des Loches

Diameter of drilled hole

Restringbreite

Restring width

Back

max. 15 µm

Sn / SnPb

fuer Einpresszone D = 0.72

for press-fit zone D = 0.72

10:1

Lochaufbau D=0.6

Hole design D=0.6

114406