Sample chapter

advertisement

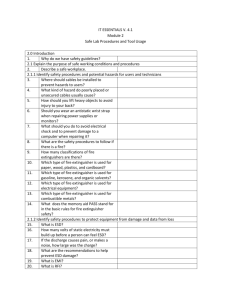

Chapter 12 ESD Earlier we said that advancements in technology were bringing new challenges for those involved with the operation and maintenance of modern passenger aircraft. One of those challenges is associated with the handling of semiconductor devices that are susceptible to damage from stray electric charges. This is a problem that can potentially affect a wide range of electronic equipment fitted in an aircraft (see Fig. 12.1) and can have wide ranging effects, including total failure of the LRU but without any visible signs of damage! Electrostatic Sensitive Devices (ESD) are electronic components and other parts that are prone to damage from stray electric charge. This problem is particularly prevalent with modern LSI and VLSI devices but it also affects other components such as metal oxide semiconductor (MOS) transistors, microwave diodes, displays, and many other modern electronic devices. Extensive (and permanent) damage to static sensitive devices can result from mishandling and inappropriate methods of storage and transportation. This chapter provides background information and specific guidance on the correct handling of ESD. Figure 12.1 Part of the avionics bay of a modern passenger aircraft containing LRUs which use large numbers of electrostatic sensitive devices (ESD) 12.1 Static electricity Static electricity is something that we should all be familiar with in its most awesome manifestation, lightning (see Fig. 12.2). Another example of static electricity that you might have encountered is the electric shock received when stepping out of a car. The synthetic materials used for clothing as well as the vehicle’s interior are capable of producing large amounts of static charge which is only released when the hapless driver or passenger sets foot on the ground! When two dissimilar, initially uncharged nonconducting materials are rubbed together, the friction is instrumental in transferring charge from one material to the other and consequently adecs12 page 1 Figure 12.2 Lightning (a natural example of static electricity) results from the build up of huge amounts of static charge Monday, September 18, 2006 08:54 Composite 132 raising the electric potential that exists between them. 12.1.1 The triboelectric series The triboelectric series classifies different materials according to how well they create static electricity when rubbed with another material. The series is arranged on a scale of increasingly positive and increasingly negative materials. The following materials give up electrons and become positive when charged (and so appear as positive on the triboelectric scale) when rubbed against other materials: • • • • • • • • • • • • • Air (most positive) Dry human skin Leather Rabbit fur Glass Human hair Nylon Wool Lead Cat fur Silk Aluminium Paper (least positive). The following are examples of materials that do not tend to readily attract or give up electrons when brought in contact or rubbed with other materials (they are thus said to be neutral on the triboelectric scale): • Cotton • Steel The following materials tend to attract electrons when rubbed against other materials and become negative when charged (and so appear as negative on the triboelectric scale): • • • • • • • adecs12 page 2 Wood (least negative) Amber Hard rubber Nickel, copper, brass and silver Gold and platinum Polyester Polystyrene Aircraft digital electronic and computer systems • • • • • • • Saran Polyurethane Polyethylene Polypropylene Polyvinylchloride (PVC) Silicon Teflon (most negative). The largest amounts of induced charge will result from materials being rubbed together that are at the extreme ends of the triboelectric scale. For example, PVC rubbed against glass or polyester rubbed against dry human skin. Note that a common complaint from people working in a dry atmosphere is that they produce sparks when touching metal objects. This is because they have dry skin, which can become highly positive in charge, especially when the clothes they wear are made of man-made material (such as polyester) which can easily acquire a negative charge. The effect is much less pronounced in a humid atmosphere where the stray charge can leak away harmlessly into the atmosphere. People that build up static charges due to dry skin are advised to wear all-cotton clothes (recall that cotton is neutral on the triboelectric scale). Also, moist skin tends to dissipate charge more readily. Human hair becomes positive in charge when combed. A plastic comb will collect negative charges on its surface. Since similar charges repel, the hair strands will push away from each other, especially if the hair is very dry. The comb (which is negatively charged) will attract objects with a positive charge (like hair). It will also attract material with no charge, such as small pieces of paper. You will probably recall demonstrations of this effect when you were studying science at school. Electric charge can also be produced when materials with the same triboelectric polarity are rubbed together. For example, rubbing a glass rod with a silk cloth will charge the glass with positive charges. The silk does not retain any charges for long. When both of the materials are from the positive side of the triboelectric scale (as in this example) the material with the greatest ability to generate charge will become positive in charge. Similarly, when two materials that are both from the negative end of the triboelectric scale are rubbed together, the one with the Monday, September 18, 2006 08:54 Composite ESD greatest tendency to attract charge will become negative in charge. Representative values of electrostatic voltages generated in some typical working situations are shown in Table 12.1. Note the significant difference in voltage generated at different values of relative humidity. Key Point Very large electrostatic potentials can be easily generated when different materials are rubbed together. The effect is much more pronounced when the air is dry. Test your understanding 12.1 Explain, in relation to electric charge, what happens when a glass rod is rubbed with a polyester cloth. Test your understanding 12.2 Explain the importance of the triboelectric series. Give ONE example of a material from the positive end of the triboelectric scale and ONE example of a material from the negative end of the triboelectric scale. 133 12.2 Static sensitive devices All modern microelectronic components are prone to damage from stray electric charges but some devices are more prone to damage than others. Devices that are most prone to damage tend to be those that are based on the use of field effect technology rather than bipolar junction technology. They include CMOS logic devices (such as logic gates and MSI logic), MOSFET devices (such as transistors), NMOS and PMOS VLSI circuits (used for dynamic memory devices, microprocessors, etc). Microwave transistors and diodes (by virtue of their very small size and junction area) are also particularly static sensitive as are some optoelectronic and display devices. If in doubt, the moral here is to treat any semiconductor device with great care and to always avoid situations in which stray static charges may come into contact with a device. Printed circuit board assemblies can also be prone to damage from electrostatic discharge. In general, printed circuit board mounted components are at less risk than individual semiconductors. The reason for this is that the conductive paths that exist in a printed circuit can often help to dissipate excessive static charges that might otherwise damage un-mounted semiconductor devices (there are no static dissipative paths when a transistor, diode or integrated circuit is handled on its own). Table 12.2 provides a guide as to the relative susceptibility of various types of semiconductor device to damage from static voltages. Table 12.1 Representative values of electrostatic voltages generated in typical work situations Situation adecs12 page 3 Typical electrostatic voltage generated 20% relative humidity 80% relative humidity Walking over a wool/nylon carpet 35 kV 1.5 kV Sliding a plastic box across a carpet 18 kV 1.2 kV Removing parts from a polystyrene bag 15 kV 1 kV Walking over vinyl flooring 11 kV 350 V Removing shrink wrap packaging 10 kV 250 V Working at a bench wearing overalls 8 kV 150 V Monday, September 18, 2006 08:54 Composite 134 Aircraft digital electronic and computer systems Table 12.2 Representative values of static voltage susceptibility for different types of semiconductor Type of device Typical static voltage susceptibility CMOS logic 250 V to 1 kV TTL logic 550 V to 2.5 kV Bipolar junction transistors 150 V to 5 kV Dynamic memories 20 V to 100 V VLSI microprocessor 20 V to 100 V MOSFET transistors 50 V to 350 V Thin film resistors 300 V to 3 kV Silicon controlled rectifiers 4 kV to 15 kV 12.3 ESD warnings Static sensitive components (including printed circuit board cards, circuit modules, and plug-in devices) are invariably marked with warning notices. These are usually printed with black text on yellow backgrounds, as shown in Figures 12.3 to 12.7. Figure 12.4 ESD warning notice (third from bottom) in the avionics bay of a Boeing 737 12.4 Handling and transporting ESD Special precautions must be taken when handling, transporting, fitting and removing ESD. These include the following: Figure 12.3 A typical ESD warning label adecs12 page 4 1. Use of wrist straps which must be worn when handling ESD. These are conductive bands that are connected to an effective ground point by means of a short wire lead. The lead is usually fitted with an integral 1 MΩ resistor which helps to minimise any potential shock hazard to the wearer (the series resistor serves to limit the current passing through the wearer in the event that he/she may come into contact with a live conductor). Wrist straps are usually stored at strategic points on the aircraft (see Figure 12.5) or may be carried by maintenance Monday, September 18, 2006 08:54 Composite ESD technicians. Figure 12.6 shows a typical wrist strap being used for a bench operation whilst Figures 12.7 and 12.8 show ESD warning notices associated with the wearing of wrist straps 2. Use of heel straps which work in a similar manner to wrist straps 3. Use of static dissipative floor and bench mats 4. Avoidance of very dry environments (or at least the need to take additional precautions when the relative humidity is low) 135 Figure 12.7 ESD wrist strap stowage notice Figure 12.8 ESD wrist strap warning notice Figure 12.5 Typical on-board stowage for a wrist strap 5. Availability of ground jacks (see Fig. 12.6) 6. Use of grounded test equipment 7. Use of low-voltage soldering equipment and anti-static soldering stations (low-voltage soldering irons with grounded bits) 8. Use of anti-static insertion and removal tools for integrated circuits 9. Avoidance of nearby high-voltage sources (e.g. fluorescent light units) 10. Use of anti-static packaging (static sensitive components and printed circuit boards should be stored in their anti-static packaging until such time as they are required for use). Figure 12.6 Using a wrist strap for a bench operation (note the grounding jack connector) adecs12 page 5 Note that there are three main classes of materials used for protecting static sensitive devices. These are conductive materials (such as Monday, September 18, 2006 08:54 Composite 136 metal foils, and carbon impregnated synthetic materials), static dissipative materials (a cheaper form of conductive material), and socalled anti-static materials (these are materials that are neutral on the triboelectric scale, such as cardboard, cotton, and wood). Of these, conductive materials offer the greatest protection whilst anti-static materials offer the least protection. Key Point Stray static charges can very easily damage static-sensitive devices. Damage can be prevented by adopting the correct ESD handling procedures. Test your understanding 12.3 Which one of the following semiconductor devices is likely to be most susceptible to damage from stray static charges? 1. A dynamic memory 2. A silicon controlled rectifier 3. A bipolar junction transistor. Test your understanding 12.4 Which one of the following situations is likely to produce the greatest amount of stray static charge? 1. Removing a PVC shrink wrap on a dry day 2. Walking on a vinyl floor on a wet day 3. Sitting at a bench wearing a wrist strap. Test your understanding 12.5 Aircraft digital electronic and computer systems 12.5 Multiple choice questions 1. A particular problem with the build-up of static charge is that: (a) it is worse when wet (b) it is invariably lethal (c) it cannot easily be detected. 2. The typical resistance of a wrist strap lead is: (a) 1 Ω (b) 1 kΩ (c) 1 MΩ. 3. Which one of the following devices is most susceptible to damage from stray static charges: (a) a power rectifier (b) a TTL logic gate (c) a MOSFET transistor. 4. The static voltage generated when a person walks across a carpet can be: (a) no more than about 10 kV (b) between 10 kV and 20 kV (c) more than 20 kV. 5. Which of the materials listed is negative on the triboelectric scale? (a) glass (b) silk (c) polyester. 6. When transporting ESD it is important to: (a) keep them in a conductive package (b) remove them and place them in metal foil (c) place them in an insulated plastic package. 7. To reduce the risk of damaging an ESD during soldering it is important to: (a) use only a low-voltage soldering iron (b) use only a mains operated soldering iron (c) use only a low-temperature soldering iron. 8. Which one of the following items of clothing is most likely to cause static problems? (a) nylon overalls (b) a cotton T-shirt (c) polyester-cotton trousers. Explain the difference between conductive and static dissipative materials for ESD protection. adecs12 page 6 Monday, September 18, 2006 08:54 Composite