4. Subgrade : Foundation Considerations

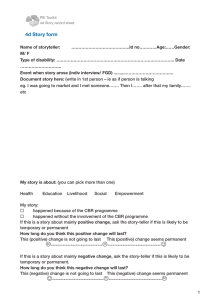

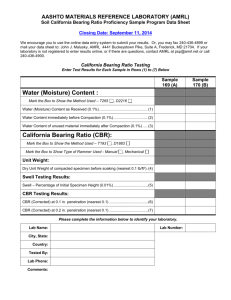

advertisement

4. Subgrade : Foundation Considerations 1. Introduction The performance of any structure is strongly dependent on the foundations. Road pavements are no exceptions and their foundations need to be fundamentally modelled using sound geotechnical engineering principles. Thus, it is very important to have sufficient information about the subgrade, which is obtained through investigation and accumulation of test results. In this way the risks regarding the subgrade can be estimated. Variation in the subgrade directly below the pavement cannot be prevented (this is a fact of nature), so it is important not to overload the subgrade at any place. The primary structural task of the pavement is to prevent too high stresses in the subgrade as shown in Figure 4.1. Sound pavement Poor pavement Low E Surfacing High E Low E Granular Base High E HIGH stresses in S/G Subgrade LOW stresses in S/G Figure 4.1 Load spreading abilities of different pavements Every pavement design method requires some knowledge of the subgrade quality as an important input parameter in analysis procedure. Until recently the most common design methods were based on the CBR value of the materials in the pavement, as determined in the CBR test. Based on CBR values of succeeding layers design charts were developed. This is called the CBR cover design method, as it aim to identify the thickness and bearing capacity of different layers above the subgrade that are needed to provide enough load-spreading to protect the subgrade. Examples of the CBR cover design are provided in the figures below. Hitchhiker’s Guide to Pavement Engineering: Prof Kim Jenkins 1 ESALs (80kN x106) E0 <0.2 0.2< E1 <0.8 0.8< E2 <3 3 < E3 <12 12 < E4 <50 Figure 4.2 CBR Cover Design Curves adapted for 80kN axles (Freeme, Marais and Walker) The procedure for calculating the CBR is shown below. Material is first compacted to densities that are representative of field density and soaked for 4 days before testing. The name CBR comes from Californian Bearing Ratio because a high quality Californian gravel was used as the reference material. Ironically, California does not use CBR any longer (but many other countries still do). Reference material (Ref) Force F F0.1’ Ref Actual material F0.1’ ∆P Displacement ∆P 0.1’’ 0.2’’ 0.3’’ Figure 4.3. CBR Test Procedure CBR (%) = F0.1’/F0.1’ Ref x 100 Typical values : Sand CBR = 10 to 15% Crushed stone CBR = 40 to 100% Hitchhiker’s Guide to Pavement Engineering: Prof Kim Jenkins 2 Researchers have tried to characterise the subgrade stiffness by using a correlation with CBR values. Shell, for example, tested in situ stiffness of sands by measuring wave propagation velocity through the sand and comparing that to laboratory measured stiffness, as shown in the Figure below. They developed an average relation as follows: E [MPa] = 10 x CBR [%] Such a correlation not very reliable, as can be seen by the variability of the relationship. In addition, it is material specific and cannot be applied to other gradations. Figure 4.3 Relationship between CBR and Dynamic Modulus (EDINAMIES) for sands (Shell) 2. Material depth In TRH4 in South Africa (Technical Recommendations for Highways: Structural design of Flexible Pavements for Interurban and Rural Roads), the subgrade is shown to play a very important role in the structural design of a road (Paragraph 6.2 6.8). The catalogue design method in the TRH4 can be used only if CBR of the subgrade is at least 15% for a depth of 150mm and decreasing gradually with depth. This is the depth below which very little influence of the loads on the subgrade can be expected. Hitchhiker’s Guide to Pavement Engineering: Prof Kim Jenkins 3 Table 4.1 Subgrade Classification for Structural Design (TRH4) Class Subgrade CBR (%) Comment SG1 >15 Good quality material, just rip and recompact SG2 7 to 15 Moderate quality, needs 150mm of CBR>15 above SG3 3 to 7 Fair quality, needs 150mm of CBR>15 + 150mm of CBR>7 above SG4 <3 Poor material, special treatment Note: It should be remembered that the standard CBR is determined after specimens have been soaked for 4 days (quite extreme but necessary to ensure that dramatic failure doesn’t occur when a material is exposed to moisture). Uniform sections In South Africa Road Categories are used to designate the importance of the road and the level of reliability for the design i.e. Categories A, B, C and D. In order to identify the classification of the subgrade one should first identify the uniform sections. There are two methods that one can use in identifying the uniform sections: a) Graphical method This method uses a graphical plot of CBR values over the centreline distance of the road. Visual distinction can help to identify the uniform sections as shown in the figure below. CBR (%) Section 1 Section 2 Section 3 Centreline Distance (m) Figure 4.4 Graphical Identification of Uniform Sections b) Cumulative Sum Method This method uses the equation below to calculate the cumulative sum value for the CBR data over the length of the road. The cumulative sum values are then plotted against centreline distance and the limits of the uniform sections are identified as the inflection points of the lines. Si = xi – x + Si-1 Where Si = cum sum of deviations of mean CBR values xi = CBR at point i x = mean CBR Si-1 = cum sum of previous point Hitchhiker’s Guide to Pavement Engineering: Prof Kim Jenkins 4 Cum Sum CBR (%) Section 1 Section 2 Section 3 Centreline Distance (m) Figure 4.4 Cumulative Sum Identification of Uniform Sections Design Reliability For each of the uniform sections, the CBRdesign value must be calculated using the reliability of the road category. There are two basic methods that can be followed for such analyses: a) Standard normal distribution method This method uses the assumption that the CBR results in a uniform section are normally distributed. This is a reasonable assumption for most cases of subgrade conditions. Thereafter the method uses a basic statistical approach. CBRdesign = x – kα. S Where CBRdesign = CBR design value given the reliability of the uniform section x = average CBR value of the subgrade in the uniform section kα = statistical coefficient for a given level of reliability S = standard deviation for the CBR values in the uniform section Table 4.2 Design reliability for Roads in South Africa (TRH4) Category A B C Description Major Interurban Lightly traffic interurban collectors and rural roads & freeways major rural rds strategic rds Approx design 95 90 80 reliability (%) 1.695 1.282 0.842 kα D Light pavements, rural access 50 0 b) Cumulative less than frequency method This method uses the distribution of only the values in the uniform section being evaluated with fitting any standard normal distribution. The reliability value can be read of a plot cumulative frequency versus CBR value, as shown in the example below for a Category B road. Example: CBR values in the uniform section: 5, 6, 7, 7, 8, 5 Hitchhiker’s Guide to Pavement Engineering: Prof Kim Jenkins 5 Cum Frequency (%) CBR Freq 60 4 0 0 50 5 2 2/7 = 28.5 40 6 1 3/7 = 42.8 7 3 6/7 = 85.7 8 1 7/7 = 100 30 Cum (%) 20 Cat B 10 CBRdesign 0 4 5 6 CBR (%) 8 Figure 4.5 Cumulative Less than Frequency Plot (example) From such a plot the CBRdesign would be identified as 4.4% for the given uniform section. Seasonal Changes The CBR test makes provision for extreme conditions i.e. 4 days of saturation. In reality, the subgrade in the outer wheelpath changes in moisture content with time i.e. from the dry season to the wet season, as shown in the figure below. The influence of climatic effects will be discussed in a separate chapter. wet season dry season Figure 4.6 Seasonal variations in moisture and CBR under a road (TRH4) Hitchhiker’s Guide to Pavement Engineering: Prof Kim Jenkins 6 3. Compaction In all aspects of material behaviour, the compaction plays a very important role. The process of compaction increases the density of a soil by packing the particles closer together with a reduction in the volume of air. Compaction influences stiffness (load spreading), shear strength, bearing capacity, permeability, porosity etc of a material. How is the compactibility of a material tested and which parameters are important? There are various standard compaction methods used in different parts of the world. Two commonly used methods are Proctor Compaction and Modified AASHTO (or Modified Proctor) Compaction (see method A7 in TMH 1 of SA). These methods are used in a laboratory to provide a benchmark for the levels of compaction that can be achieved in the field. Each method uses a standard amount of energy that is imparted on a material in a special way (a falling weight over a known height for a certain number of blows, and compaction of 5 layers in the mould). From the Modified AASHTO method, density requirements for the material in the field after compaction are determined. One of the reasons for the evolution from Proctor compaction (lower energy) to Modified AASHTO compaction (higher energy) was to keep pace with the developments and improvements in roller technology. In this way the specifications were kept more realistic. The relationship between the moisture content and achievable density during compaction is of particular importance. Based on the results of the Mod AASHTO test, the optimum moisture content necessary to achieve a certain required dry density for the material in the road, is determined. The achievable density and resulting material properties such as stiffness and shear strength etc, will determine the behaviour of the material during service life in a road pavement. Density is specified as ρdry (dry density) in kg/m3 so that it is independent of moisture content. But bulk density (aggregate plus moisture) is what is measured, so the moisture content needs to be removed mathematically from the calculation. This can be achieved using the formula below, where w = moisture content represented as a fraction. ρdry = ρbulk / (1+w) Hitchhiker’s Guide to Pavement Engineering: Prof Kim Jenkins 7 Dry Density ρd (kg/m3) Proctor-compaction of 5 layers of equal blows Max ρd OMC=x% Moisture Content (%) Figure 4.7 Moisture versus density relationship The achievable compaction is dependent on numerous factors including aggregate grading, particle shape, particle angularity, plasticity, moisture content, compaction energy etc. If the compaction energy is increased, not only will the dry density increase but the optimum moisture content reduces. A “family of curves” can be developed for a specific material that shows the changes in the moisture-density relationship relative to the compaction energy, as shown in the figure below. The influence of material gradation on compaction can be shown in a similar fashion. In Figure 4.9 it is apparent that the highest density is achieved for well graded gravel (GW), followed by well graded sand (SW), then low plasticity silt (ML), followed by low plasticity clay (CL) and then high plasticity clay (CH). Hitchhiker’s Guide to Pavement Engineering: Prof Kim Jenkins 8 DD=(1-Va/V).1000/(1/Gs+w) Figure 4.8 Influence of relationship (Craig) Compaction Energy on the Moisture-Density From the relationship given in Figure 4.8, it can be seen that the dry density is a function of the aggregate specific gravity (Gs) and moisture content (w) when the air voids are zero (Va = 0%). Improve grading Coarser grained Figure 4.9 Influence of relationship (Craig) Compaction Energy on Hitchhiker’s Guide to Pavement Engineering: Prof Kim Jenkins the Moisture-Density 9 It can be shown using the compaction moisture curve in an elementary fashion that with increasing density it is possible to maintain the strength of a plastic soil material in certain service conditions. Using Figure 4.10, it can be seen that 2 samples of the same material compacted at 17% moisture content with different compaction efforts, the material at lower density (less compaction) exceeds the plastic limit when saturated and will lose strength-supporting properties. The same material compacted to a higher level will probably remain stable. This also indicates that relationships can be found between CBR, compaction level and void content. Dry density requirements are so very important for practice, therefore. A similar situation can be ascribed to asphalt mixes. Instead of water, bitumen is used in these materials. The bitumen cannot evaporate or leach out of the material as is the case with water in granular materials and soils. However, the same principles in terms of fluids will be used in order to understand what happens during compaction. This is dealt with in another chapter. ZAV Wetting after compaction to saturation Dry Density High Compaction PL Plastic Limit Low Compaction 17% PL 25% Moisture Content Figure 4.10 Advantage of higher compaction in terms of material plasticity (Oglesby) Field Compaction Achieving optimum compaction in the field requires judicious selection of rollers. The roller selection (weight and type) is primarily judged on the gradation of the material and the depth of the layer to be compacted. Figure 4.11 provides a guideline for roller selection. In addition to this selection, rolling techniques for subgrade usually involve high amplitude, low frequency initial compaction to achieve greater depth of penetration followed by low amplitude, high frequency compaction to densify the upper part of the layer. Hitchhiker’s Guide to Pavement Engineering: Prof Kim Jenkins 10 Figure 4.11 Guide to Roller Selection (Wirtgen) References Oglesby. Highway Subgrade Structure Wirtgen. Cold Recycling Manual. Hitchhiker’s Guide to Pavement Engineering: Prof Kim Jenkins 11