quality manual qm2000 - UTC Aerospace Systems

advertisement

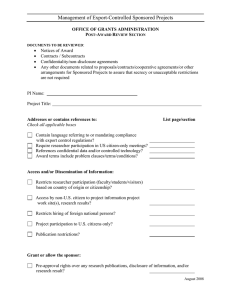

This document or file does not contain export controlled technology or technical data Issue 07 October 2014 QUALITY MANUAL QM2000 1.0 GENERAL INFORMATION 1.1 Contents 1.0 General Information 1.1 Contents 1.2 Review & Control of This Manual 1.3 ACE (Achieving Competitive Excellence) 2.0 Definitions 3.0 Scope 4.0 Quality Management System 4.1 General Requirements 4.2 Documentation Requirements 5.0 Management Responsibility 5.1 Management Commitment 5.2 Customer Focus 5.3 Quality Policy 5.4 Planning 5.5 Responsibility, Authority & Communication 5.6 Management Review 5.7 Safety Policy 6.0 Resource Management 6.1 Provision of Resources 6.2 Human Resources 6.3 Infrastructure 6.4 Work Environment 7.0 Product Realisation 7.1 Planning of Product Realisation 7.2 Customer-Related Processes 7.3 Design & Development 7.4 Purchasing 7.5 Production Service & Provision 7.6 Control of Monitoring & Measuring Equipment 8.0 Measurement, Analysis & Improvement 8.1 General 8.2 Monitoring & Measurement 8.3 Control of Non-Conforming Product 8.4 Analysis of Data 8.5 Improvement Appendix 1: ISO 9001 / BS EN 9100 (AS9100) Approval Certificate Appendix 2: AS9100 Compliance Matrix Appendix 3: HS Addendum Procedure Appendix 4: External Distribution List KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Page 2 of 38 Issue 07 October 2014 QUALITY MANUAL QM2000 Page 3 of 38 1.2 Review & Control of This Manual This Quality Manual may only be altered with the signed approval of the Site Lead and Quality Assurance Manager. It is configured and issued by the Configuration Manager and reviewed annually (or sooner if necessary). The table below is supplementary, to provide a quickly accessible reference to changes. ISSUE 5 6 7 DATE FEB 12 JAN 13 OCT 14 AMENDMENT Amended to address the requirements of BS EN ISO 9100:2009 / AS9100 (Rev. C). Paragraph 1.3 ‘ACE (Achieving Competitive Excellence)’ added. Paragraph 2.0 ‘Definitions’ updated. Paragraph 3.0 ‘Scope’ updated. Paragraph 3.3 ‘Oxygen Breathing’ removed. Paragraph 3.4 ‘Safety Devices’ renumbered to 3.3. Paragraph 4.1 ‘General Requirements’ updated. Paragraph 4.1.1 ‘Outsourced Processes’ added. Paragraph 4.1.2 ‘Core Process Mapping’ added. Paragraph 4.2.2 ‘Quality Manual’ updated. Paragraph 7.1.2 ‘Risk Management’ updated. Paragraph 7.5.5 ‘Preservation of Product’ updated. Appendix 2 ‘AS9100 Compliance Matrix’ updated. Appendix 3.1 ‘Sequence & Interaction Between Processes’ updated. Appendix 4 ‘External Distribution List’ added (ref. iAudit action 4853234). Amended to reflect new UTAS business entity (HS / Goodrich merger). iAudit action 6624689 refers. Paragraphs updated: 1.3.1, 5.3, 5.5.2, 5.7, 7.1.3, 7.1.4, 8.2.1. Figures updated: 1, 2, 3 (company organisation charts). Appendices updated: 1 (BSI certificate), 3 (Para. 7.1), 4 (SNECMA contact name). References to HS procedures updated to new UTAS procedures (where applicable). Contact e-mail address updated. Amended to reflect updated SIS business unit. iAudit actions 8354321 and 8354351 refer. Steve Brown (Site Lead) replaces Peter McArdle (General Manager). UTAS logo added to front page. References to Rail products removed. References to SDE department removed; replaced by Engineering & Technology department. Paragraph 5.3 ‘Quality Policy’ updated to reflect revised UTAS policy. Paragraph 7.5.1.1 ‘Production Process Verification’ updated to cover AS9100 requirements and FAIRs. Figure 1 ‘UTC Organisation Chart’ updated. Figure 2 ‘Company Organisation Chart’ updated. Figure 3 removed. Appendix 2 ‘AS9100 Compliance Matrix’ updated; reference to QP.24 and QP.32 removed; obsolete. Appendix 3, paragraph 7.1 ‘KG Organisation Chart’ removed (now refers back to Figure 2). Appendix 4 ‘External Distribution List’ updated; SNECMA contact name amended. Paragraph 4.1.2 amended with new Core Process Map. This manual is a controlled document within the quality system, however uncontrolled copies can be distributed to any interested party. This Manual is intended to be used as a public document that displays this company’s commitment to achieving quality in all our activities. Hard copies are circulated to Department Heads and Managers. An electronic version of this Quality Manual is available from ‘X:\Quality\Quality Manuals’. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 4 of 38 1.3 ACE (Achieving Competitive Excellence) 1.3.1 What is ACE? • United Technologies Corporation’s (UTC) standard operating system; the way we all work. • Practiced every day by everyone to improve and maximise quality and the flow of value to the customer. • Process oriented, data driven, customer focused. • Drives relentlessly to close gaps between actual results and goals. • Utilised to improve business results. ACE Operating System Leadership Continuous Improvement Large Scale Improvement Process Management In Process Out In Process Out In Expectations Process Out A Typical Process Work Group Supplier (Internal or External) Upstream Processes Passport Metrics & Goals Input Business Feedback Customer Process Lean Process: Lean Processing Setup Reduction Mature Process: Process Certification Standard Process: Standard Work Standard Environment: 5S & TPM (Internal or External) Output Employee Feedback (“turnbacks”) Downstream Processes Customer Feedback (“escapes”) Quality Clinic Activities MFA Mistake Proofing QCPC RRCA MFA The ‘ACE Criteria’ document describes the process steps required to attain the levels of achievement. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 5 of 38 2.0 DEFINITIONS For the purposes of this document the terms and definitions stated in ISO 9000:2005 apply. The Sequence and interaction between processes is detailed in Appendix 3.1. The following terms used in BS EN ISO 9100:2009 / AS9100 (Rev. C) to describe the supply chain have been changed to reflect the vocabulary currently used: Key Characteristic: The features of a material, process, or part whose variation has a significant influence on product fit, performance, service life, or manufacturability. 3.0 SCOPE This Quality Manual outlines KG’s plan to satisfy the requirements of ISO 9001 and the additional aerospace requirements of BS EN 9100 / AS9100. There are no exclusions to any clauses of BS EN 9100 / AS9100. Procedures to cover compliance to BS EN 9100 / AS9100 are listed in Appendix 2 of this manual. Where applicable this Manual should be read in conjunction with the following European Aviation Safety Agency (EASA) Expositions: • EASA Part 21 POE Production Organisation Exposition (POE-01). • EASA Part 145 MOE Maintenance Exposition (MM01). • FAA Supplement To MOE-01 (FMOE-01). This Manual is applicable to all activities conducted at Mathisen Way, Colnbrook, Slough, SL3 0HB, UK, and covers the following range of products: 3.1 Fire Protection Linear, point and optical fire / overheat detectors, including associated control electronics and extinguishers for the Military and Aerospace markets. 3.2 Compressed Gas Inflation Aircraft and marine flotation equipment including cylinder / valve assemblies and associated accessories. Aircraft emergency slide equipment including containers, cylinder / valve assemblies, and associated accessories. 3.3 Safety Devices Aerospace crash switches, explosion detection units, and associated accessories. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 FIGURE 1: UTC ORGANISATION CHART KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Page 6 of 38 Issue 07 October 2014 QUALITY MANUAL QM2000 Page 7 of 38 4.0 QUALITY MANAGEMENT SYSTEM 4.1 General Requirements A quality management system is established, documented, implemented, and maintained in accordance with ISO 9001 requirements, and the additional aerospace requirements of BS EN 9100 / AS9100. Its effectiveness is continually improved through the use of the Quality Policy, quality objectives, audits, data analysis, corrective / preventive action, and Management Review (procedures QP.35 [Management & Business Review] and UTAS-PRO-0007 [Management Review] apply). Any required quality management system approvals and any other approvals, certificates, ratings, licenses, and permits required by the applicable statutory and regulatory requirements are obtained and maintained. The quality management system also addresses customer and applicable statutory and Authority quality management system requirements. KG will: a) Determine the processes needed for the quality management system and its application throughout KG; b) Determine the sequence and interaction of these processes (Appendix 3.1 refers); c) Determine criteria and methods needed to ensure the operation and control of processes is effective; d) Ensure the availability of resources and information necessary to support these processes; e) Monitor, measure (where applicable), and analyse these processes; and f) Implement actions necessary to achieve planned results and continual improvement of these processes. Processes are managed in accordance with the requirements of BS EN 9100 / AS9100. 4.1.1 Outsourced Processes Where process that affect product conformity to requirements are outsourced KG maintain control over such processes. The type and extent of control to be applied to these outsourced processes is defined within the quality management system. Outsourced processes include: a) Processing (Including Machining, Heat Treatments, Welding / Brazing, Painting and Plating) b) Assembly (ie. ‘Build To Print’) c) Calibration d) Scanning of quality records e) Qualification testing Control of these processes is supported by product checks and audits of the applicable suppliers. Procedure UTAS-PRO-0008 [Work Transfer] applies. 4.1.2 Core KG Process The following processes are deemed to be our Core internal processes. The relationships are detailed in the Process Map on the following page. a) Sales and Customer Services (Including Contract/Order Review) b) Design c) Purchasing (Including Inter-Group Spares) d) Manufacture / Assembly e) Repair and Overhaul KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Core KG Process Map KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Page 8 of 38 Issue 07 October 2014 QUALITY MANUAL QM2000 Page 9 of 38 4.2 Documentation Requirements 4.2.1 General Quality management system documentation includes: a) Documented statements of Quality Policy and quality objectives; b) A Quality Manual; c) Documented procedures and records required by BS EN 9100 / AS9100; d) Documents / records determined by KG to be necessary to ensure the effective planning, operation, and control of its processes (eg. Quality Plans); and e) A documented Safety Policy and safety objectives. Personnel have access to and are aware of relevant quality management system documentation. 4.2.2 Quality Manual A Quality Manual is established and maintained, which includes: a) Scope of the quality management system (including details of and justification for any exclusions); b) Documented procedures established for the quality management system (or reference to them); c) A description of the interaction between the processes of the quality management system (see Appendix 3.1 of this Manual); and d) A description of the processes and procedures (as applicable) used for: • Establishing and maintaining proficiency of personnel; • Establishing and maintaining rosters for certifying staff / personnel; • Establishing and maintaining the training program; • Establishing and maintaining current approved technical data; • Performing preliminary inspection of all articles that are maintained (where applicable); • The acceptance of incoming articles; • Inspecting all articles that have been involved in an accident for hidden damage before maintenance, repair and overhaul is performed; • Conducting maintenance processes in compliance with customer, statutory and regulatory requirements; • Performing final inspection and ‘return to service’ of maintained articles; and • Governing work performed at another location. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 10 of 38 4.2.3 Control of Documents Documents required by the quality management system are controlled. Records are a special type of document and are controlled according to the requirements stated in paragraph 4.2.4. A documented procedure is established to define the controls needed to: a) Approve documents for adequacy prior to issue; b) Review, update, and re-approve documents (as necessary); c) Ensure changes and the current revision status of documents are identified; d) Ensure relevant versions of applicable documents are available at points of use; e) Ensure documents remain legible and readily identifiable; f) Ensure documents of external origin deemed necessary for the planning and operation of the quality management system are identified and their distribution controlled; and g) Prevent unintended use of obsolete documents, and apply suitable identification to them if they are retained for any purpose. Procedures QP.08 [Documentation Control & Change Control] and UTAS-PRO-0001 [Document & Data Control] apply. 4.2.4 Control of Records Records providing evidence of conformity to requirements and of effective operation of the quality management system are controlled. A documented procedure is established to define the controls needed for the identification, storage, protection, retrieval, retention, and disposition of records. This procedure defines the method for controlling records created / retained by suppliers. Records remain legible, readily identifiable, and retrievable. Procedures QP.33 [Control of Records] and UTAS-PRO-0002 [Control of Records] apply. 5.0 MANAGEMENT RESPONSIBILITY 5.1 Management Commitment Top management provide evidence of their commitment to the development and implementation of the quality management system, and to continually improve its effectiveness by: a) Communicating the importance of meeting customer, statutory, and regulatory requirements; b) Establishing a Quality Policy; c) Establishing quality objectives; d) Conducting Management Reviews; e) Ensuring the availability of resources; f) Establishing a Safety Policy; and g) Establishing safety objectives. Procedure UTAS-PRO-0007 [Management Review] applies. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 11 of 38 5.2 Customer Focus Top management ensure customer requirements are determined and met, with the aim of enhancing customer satisfaction. Top management ensure product conformity and on-time delivery performance are measured, and that appropriate action is taken if planned results are not (or will not be) achieved. KG conduct an annual customer Market Feedback Analysis (MFA). MFA uses market data, customer feedback and reliability data to provide insight into customer perspectives and expectations of performance. MFA is used to: • Capture and analyse market data to consistently improve deliverables; • Uncover patterns in feedback data that point to sources of customer problems; and • Monitor the effectiveness of corrective actions and their implementation. 5.3 Quality Policy “Kidde Graviner is committed to achieving competitive excellence and providing our customers with products and services designed, produced and maintained to meet or exceed their expectations by: • Complying with all customer, statutory and regulatory requirements; • Enabling employees to achieve business and professional goals; • Continually improving processes through the ACE Operating System; • Extending Kidde Graviner quality management practices throughout the Supply Chain; and • Promoting a highly ethical environment.” Adapted from UTAS-POL-0001 [Management System Manual] (issue 01, 06-JAN-2014, paragraph 5.3). 5.4 Planning 5.4.1 Quality Objectives Top management ensure quality objectives, including those needed to meet requirements for product, are established at relevant functions / levels within KG. Quality objectives are measurable and consistent with the Quality Policy. 5.4.2 Quality Management System Planning Top management ensure: a) Planning of the quality management system is carried out in order to meet requirements given in paragraph 4.1, as well as the quality objectives; and b) The integrity of the quality management system is maintained when changes to the quality management system are planned and implemented. 5.4.3 Safety Objectives Top management ensure safety objectives, including those needed to meet requirements for product, are established at relevant functions and levels within the organisation. Safety objectives are measurable and consistent with the Safety Policy. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 12 of 38 5.5 Responsibility, Authority & Communication The company organisation charts is shown in Figure 2. 5.5.1 Responsibility & Authority Top management ensure responsibilities and authorities are defined and communicated within KG. 5.5.1.1 Accountable Executive Manager Top management appoint a Manager with corporate authority to ensure that all necessary resources are obtained to complete and finance any required maintenance in accordance with KG, customer, and Authority requirements. 5.5.1.2 Maintenance Manager(s) Top management appoint a Manager responsible for ensuring that all maintenance required is carried out in accordance with KG, customer, and Authority requirements. If required, multiple Managers may be appointed to oversee the operation of each major area of activity (eg. product line). 5.5.2 Management Representative Top management appoint a QA Manager, a member of KG’s management who irrespective of other responsibilities has responsibility and authority that includes: a) Ensuring processes needed for the quality management system are established, implemented, and maintained; b) Reporting to top management on the performance of the quality management system (including any ACE continuous improvement activities) and any need for improvement; c) Ensuring the promotion of awareness of customer requirements throughout KG; and d) The organisational freedom and unrestricted access to top management to resolve quality management issues. 5.5.3 Internal Communication Top management ensure appropriate communication processes are established, and communication takes place regarding the effectiveness of the quality management system. FIGURE 2: COMPANY ORGANISATION CHART GENERAL MANAGER SITE LEAD QUALITY MANAGER CUSTOMER SERVICES MANAGER ENGINEERING & TECHNOLOGY MANAGER PRODUCTION MANAGERS KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. MATERIALS HANDLING MANAGER Issue 07 October 2014 QUALITY MANUAL QM2000 Page 13 of 38 5.6 Management Review Procedures QP.35 [Management & Business Review] and UTAS-PRO-0007 [Management Review] apply. 5.6.1 General Top management review the quality management system at planned intervals to ensure its continuing suitability, adequacy, and effectiveness. This review includes assessing opportunities for improvement and the need for changes to the quality management system (including the Quality Policy and quality objectives). The review also includes assessing opportunities for improvement and the need for changes to the Safety Policy and safety objectives. Records from Management Reviews are maintained. 5.6.2 Review Input The input to Management Review includes information on: a) Results of audits (including internal, customer, and third-parties); b) Customer feedback; c) Process performance and product conformity; d) Status of preventive and corrective actions; e) Follow-up actions from previous Management Reviews; f) Changes that could affect the quality management system; g) Recommendations for improvement; h) Results of audits and requests for corrective action from Authorities and customers; i) The achievement, adequacy and effectiveness of the personnel training program; and j) Changes to Authority requirements that could impact KG. 5.6.3 Review Output The output from the Management Review includes any decisions and actions related to: a) Improvement of the effectiveness of the quality management system and its processes; b) Improvement of product related to customer requirements; and c) Resource needs. 5.7 Safety Policy Top management ensure that the Safety Policy: a) Is appropriate to KG’s purpose; b) Includes a commitment to comply with requirements and continual safety improvement; c) Provides a framework for establishing and reviewing safety objectives; d) Is communicated and understood within KG; and e) Is reviewed for continuing suitability. KG Safety Policy and procedure UTAS-PRO-0009 [Safety Policy] apply. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 14 of 38 6.0 RESOURCE MANAGEMENT 6.1 Provision of Resources KG determine and provide the resources needed to: a) Implement / maintain the quality management system and continually improve its effectiveness; and b) Enhance customer satisfaction by meeting customer requirements. KG have a system to continually assess the availability of tools, technical data, and necessary qualified personnel to ensure the safe completion of the maintenance, repair and overhaul activities. 6.2 Human Resources 6.2.1 General Personnel performing work affecting conformity to product requirements are competent on the basis of appropriate education, training, skills, and experience. Personnel required to be certified meet and maintain the applicable eligibility Authority requirements. A process exists for the qualification and surveillance of non-certified personnel who perform maintenance, repair and overhaul exercises. 6.2.2 Competence, Training & Awareness Top management: a) Determine the necessary competence for personnel performing work affecting conformity to product requirements; b) Provide training or take other actions to achieve the necessary competence (where applicable); c) Evaluate the effectiveness of the actions taken; d) Ensure that personnel are aware of the relevance and importance of their activities and how they contribute to the achievement of the quality objectives; e) Maintain appropriate records of education, training, skills and experience; f) Ensure personnel performing maintenance, repair and overhaul services and release of articles are qualified and certified in accordance with Authority and customer contract requirements; g) Establish a training program (initial and recurrent) to ensure personnel performing specific tasks remain current in terms of procedures, Human Factors, technical knowledge, and applicable Authority requirements; and h) Ensure recurring training is provided that covers changes in relevant Authority requirements, company procedures, and maintenance standards of articles being repaired or overhauled. 6.3 Infrastructure The infrastructure needed to achieve conformity to product requirements is determined, provided, and maintained. Infrastructure includes (as applicable): a) Buildings, workspace and associated utilities; b) Process equipment (both hardware and software); c) Supporting services (such as transport, communication, or information systems); and d) Suitable facilities acceptable to applicable customers and Authorities for performing maintenance, repair and overhaul services away from KG’s fixed location. However should a situation arise where shortcomings are identified through internal audits or review of a new contract / order, top management ensure that appropriate action is taken to rectify the situation. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 15 of 38 6.4 Work Environment The work environment needed to achieve conformity to product requirements is determined and managed. However should a situation arise where a new regulation or contract / order requires a change to the work environment, top management ensure that the environment is conducive to product conformance before work commences on that contract / order. 7.0 PRODUCT REALISATION 7.1 Planning of Product Realisation OUTSOURCE QP.10 PLAN QP.11 REVIEW QP.04 MAKE QP.11 DESPATCH QP.17 DESIGN QP.07 MANAGEMENT ACTIVITIES ACE ACTIVITIES RESOURCES MEASUREMENTS Diagram i, Product Realisation. The processes needed for product realisation are planned and developed. Planning of product realisation is consistent with the requirements of the other processes of the quality management system. In planning product realisation the following are determined (as appropriate): a) Quality objectives and requirements for the product; b) The need to establish processes / documents and to provide resources specific to the product; c) Required verification, validation, monitoring, measurement, inspection, and test activities specific to the product and the criteria for product acceptance; d) Records to provide evidence that the realisation processes and resulting product meet requirements; e) Configuration management appropriate to the product; f) Resources to support the use and maintenance of the product; and g) Safety objectives and requirements for the product. The output of this planning is in a form suitable for KG’s method of operations. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 16 of 38 7.1.1 Project Management As appropriate to KG and the product, product realisation is planned and managed in a controlled manner to meet requirements at acceptable risk within resource and schedule constraints. 7.1.2 Risk Management A process for managing risk to the achievement of applicable requirements is established, implemented and maintained. This includes (as appropriate) risk to KG and the product: a) Assignment of responsibilities for risk management; b) Definition of risk criteria (eg. likelihood, consequences, risk acceptance); c) Identification, implementation and management of actions to mitigate risks that exceed the defined risk acceptance criteria; and d) Acceptance of risks remaining after implementation of mitigation actions. An annual Enterprise Risk Management (ERM) assessment is conducted across the business by the Finance department. A copy of the output and resulting actions resides in the U:\Common\Risk Assessments directory. HS procedures SP0124 [Product Life Cycle Risk Assessment] and UTAS-PMO-PRO-1507 [Risk Management For Programme Management] also apply. 7.1.3 Configuration Management A configuration management process is established, implemented and maintained. This includes as appropriate to the product: a) Configuration management planning; b) Configuration identification; c) Change control; d) Configuration status accounting; and e) Configuration audit. Procedures QP.20 [Configuration Control] and DOP.50 [Configuration Control] apply. 7.1.4 Control of Work Transfers A process to plan and control the temporary or permanent transfer of work (eg. from one facility to another, from KG to a supplier, from one supplier to another) and to verify the conformity of the work to requirements is established, implemented and maintained. UTAS Procedure UTAS-PRO-0008 [Work Transfer] applies. 7.2 Customer-Related Processes 7.2.1 Determination of Requirements Related To The Product KG determine: a) Requirements specified by the customer (including delivery and post-delivery activities); b) Requirements not stated by the customer but necessary for specified or intended use (where known); c) Statutory and regulatory requirements applicable to the product; and d) Any additional requirements considered necessary by KG. Procedure QP.04 [Contract Review] applies. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 17 of 38 7.2.2 Review of Requirements Related To The Product Requirements related to the product are reviewed. These reviews are conducted prior to any commitment to supply a product to the customer (eg. submission of tenders, acceptance of contracts / orders, acceptance of changes to contracts / orders, etc.), and ensure that: a) Product requirements are defined; b) Contract / order requirements differing from those previously expressed are resolved; c) KG has the ability to meet the defined requirements; d) Contractual requirements are reviewed so that special requirements of the product are determined (eg. scope of work, technical data, delivery requirements, requirements regarding sub-contracting or work); and e) Risks (eg. new technology, short delivery time-scales, etc.) have been identified. Records of the results of the review and actions arising from the review are maintained in accordance with procedure QP.33 [Quality Records]. Where a customer provides no documented statement of requirement, requirements are confirmed before acceptance. Where product requirements are changed the relevant documents are amended and appropriate personnel are made aware of the updated requirements. Contract amendment processes include provisions for disposition of out-of-scope defects discovered during maintenance. 7.2.3 Customer Communication Effective arrangements for communicating with customers are determined and implemented in relation to: a) Product information; b) Enquiries, contracts, or order handling (including amendments); and c) Customer feedback (including customer complaints). KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 18 of 38 7.3 Design & Development KG is responsible for the design of modifications / technical data, including repair solutions. Procedure QP.07 [New Product Design & Development Control] applies. 7.3.1 Design & Development Planning The design and development of product is planned and controlled. During the design and development planning KG determine: a) The design and development stages; b) The review, verification, and validation appropriate to each design and development stage; and c) The responsibilities and authorities for design and development. Where appropriate the design and development effort is divided into distinct activities, and for each activity the tasks, necessary resources, responsibilities, design content, input and output data, and planning constraints are defined. The different design and development tasks to be carried out are based on the safety and functional objectives of the product in accordance with customer, statutory, and regulatory requirements. Design and development planning considers the ability to produce, inspect, test, and maintain the product. The interfaces between different groups involved in design and development are managed to ensure effective communication and clear assignment of responsibility. Planning output is updated (as appropriate) as the design and development progresses. 7.3.2 Design & Development Inputs Inputs relating to product requirements are determined and records maintained. These include: a) Functional and performance requirements; b) Applicable statutory and regulatory requirements (including the use of recyclable material in the product design process); c) Information derived from previous similar designs (where applicable); and d) Other requirements essential for design and development. Inputs are reviewed for adequacy. Requirements are complete, unambiguous, and do not conflict with one-another. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 19 of 38 7.3.3 Design & Development Outputs Design and development outputs are in a form suitable for verification against the design and development input, and are approved prior to release. Design and development outputs: a) Meet the input requirements for design and development; b) Provide appropriate information for purchasing, production, and for service provision; c) Contain (or reference) product acceptance criteria; d) Specify the characteristics of the product that are essential for its safe and proper use; and e) Specify (as applicable) any critical items, including any key characteristics and specific actions to be taken for these items. Data required to allow the product to be identified, manufactured, inspected, used, and maintained is defined, including for example: • Drawings, part lists, and specifications necessary to define configuration / design features of the product; and • Material, processes, manufacturing, and assembly data needed to ensure conformity of the product. 7.3.4 Design & Development Review At suitable stages systematic reviews of design and development are performed in accordance with planned arrangements to: a) Evaluate the ability of the results of design and development to meet requirements; b) Identify any problems and propose necessary actions; and c) Authorise progression to the next stage. Participants in such reviews include representatives of functions concerned with the design and development stage(s) being reviewed. Records of the results of the reviews and any necessary actions are maintained. 7.3.5 Design & Development Verification Verification is performed in accordance with planned arrangements to ensure that the design and development outputs have met the design and development input requirements. Records of the results of the verification, and any necessary actions are maintained. 7.3.6 Design & Development Validation Design and development validation is performed in accordance with planned arrangements to ensure that the product is capable of meeting the requirements for the specified application or intended use (where known). Wherever practicable validation is completed prior to the delivery or implementation of the product. Records of the results of validation and any necessary actions are maintained. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 20 of 38 7.3.6.1 Design & Development Verification & Validation Testing Where tests are necessary for verification and validation these are planned, controlled, reviewed, and documented to ensure and prove the following: a) Test plans / specifications identify the product being tested, resources being used, define test objectives and conditions, parameters recorded, and relevant acceptance criteria; b) Test procedures describe method of operation, performance of tests, recording of results; c) The correct configuration of the product is submitted for the test; d) The requirements of the test plan and the test procedure(s) are observed; and e) The acceptance criteria are met. 7.3.6.2 Design & Development Verification & Validation Documentation At the completion of design / development, reports, calculations, test results, etc., demonstrate that the product definition meets the specification requirements for all identified operational conditions. 7.3.7 Control of Design & Development Changes Design and development changes are identified and records maintained. The changes are reviewed, verified, validated (as appropriate), and approved before implementation. The review of design and development changes includes evaluation of the effect of the changes on constituent parts and product already delivered. Design and development changes are controlled in accordance with KG’s configuration management process. Procedures QP.20 [Configuration Control] and DOP.50 [Configuration Control] apply. Records of the results of the review of changes and any necessary actions are maintained. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 21 of 38 7.4 Purchasing 7.4.1 Purchasing Process KG ensures that purchased product conforms to specified purchase requirements (procedures QP.10 [Control of Purchased Product & Service], QP.15 [Non-Conforming Materiel] and UTAS-PRO-0004 [Control of Nonconforming Product] apply). The type and extent of control applied to the supplier and the purchased product is dependent upon the effect of the purchased product on subsequent product realisation or the final product. KG is responsible for the conformity of all products purchased from suppliers, including product from sources defined by the customer. Procedures QP.10 [Control of Purchased Product & Service] and QP.12 [Purchaser Supplied Material] apply. KG ensure that suppliers hold the required approvals and certificates. Additionally KG’s purchasing process satisfy applicable Authority requirements pertaining to the use of non-certified suppliers. Suppliers are evaluated and selected based on their ability to supply product in accordance with requirements. Criteria for selection, evaluation, and re-evaluation are established. Records of the results of evaluations, and any necessary actions arising from the evaluation are maintained. KG will: a) Maintain a register of suppliers that includes approval status (eg. approved, conditional, disapproved) and the scope of the approval (eg. product type, process family) (ref. CCD.101 [Approved Vendor List]); b) Periodically review supplier performance (the results of these reviews are used as a basis for establishing the levels of controls to be implemented); c) Define the necessary actions to take when dealing with suppliers that do not meet requirements; d) Ensure (where required) both KG and suppliers use customer-approved special process sources; e) Define the process, responsibilities and authority for the approval status decision, changes of the approval status, and conditions for controlled use of suppliers depending on their approval status; f) Determine and manage the risk when selecting and using suppliers; and g) Take appropriate measures to prevent the purchase of counterfeit and suspect unapproved parts. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 22 of 38 7.4.2 Purchasing Information Purchasing information describes the product to be purchased including (where appropriate): a) Requirements for approval of product, procedures, processes, and equipment; b) Requirements for qualification of personnel; c) Quality management system requirements; d) The identification and revision status of specifications, drawings, process requirements, inspection / verification instructions, and other relevant technical data; e) Requirements for design, test, examination, inspection, verification (including production process verification), use of statistical techniques for product acceptance, related instructions for acceptance, and (as applicable) critical items including key characteristics; f) Requirements for test specimens (eg. production method, number, storage conditions) for design approval, inspection / verification, investigation or auditing; g) Requirements regarding the need for the supplier to: • Notify KG of non-conforming product; • Obtain KG’s approval for non-conforming product disposition; • Notify KG of changes in product / process, changes of suppliers, changes of manufacturing facility location, and (where required) obtain KG’s approval; and • Flow down to the supply chain the applicable requirements (including customer requirements). h) Records retention requirements; i) Right of access by KG, our customer, and Authorities to the applicable areas of all facilities at any level of the supply chain involved in the order and to all applicable records; j) Specific Authority approval requirements; k) Format and content of KG’s release documentation package; and l) Conditions under which defects and unairworthy conditions are reported and dispositioned. The adequacy of specified purchase requirements is ensured prior to communication to the supplier. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 23 of 38 7.4.3 Verification of Purchased Product Inspection or other activities necessary for ensuring that purchased product meets specified purchased requirements are established and implemented. Verification activities may include: • Obtaining objective evidence of the quality of the product from the supplier (eg. accompanying documentation, certificate of conformity, test records, statistical records, process control records); • Inspection and audit at the supplier’s premises; • Review of the required documentation; • Inspection of products upon receipt; and • Delegation of verification to the supplier, or supplier certification. Where purchased product is released for production / maintenance use pending completion of all required verification activities it is identified and recorded to allow recall and replacement if it is subsequently found that the product does not meet requirements. Where KG delegates verification activities to the supplier the requirements for delegation are defined and a register of delegations maintained. Where KG (or its customer) intend to perform verification at a supplier’s premises the intended verification arrangements and method of product release are stated in the purchasing information. Verification by the customer is not used as evidence of effective control of quality by KG’s supplier and does not absolve KG of the responsibility to provide acceptable product, nor does it preclude subsequent rejection by the customer. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 24 of 38 7.5 Production & Service Provision Procedure QP.11 [Manufacturing Control] applies. 7.5.1 Control of Production & Service Provision Production and service provisions are planned and carried-out under controlled conditions which include (as applicable): a) The availability of information that describes the characteristics of the product; b) The availability of work instructions (as necessary); c) The use of suitable equipment; d) The availability and use of monitoring and measuring equipment; e) The implementation of monitoring and measurement; f) The implementation of product release, delivery, and post-delivery activities; g) Non-conforming product; h) Evidence that all production / maintenance and inspection / verification operations have been completed as planned, as otherwise documented and authorised, or in accordance with technical data that has been approved (as applicable) by the design data approval holder or an approved design organisation that is acceptable to the Authority; i) Provision for the prevention, detection, and removal of foreign objects (including tools); j) Monitoring and control of utilities and supplies (eg. water, compressed air, electricity, chemical products) to the extent they affect conformity to product requirements; k) Criteria for workmanship specified in the clearest practical way (eg. written standards, representative samples, or illustrations) in accordance with applicable technical data; l) Compliance with reference standards, quality plans, manufacturers’ recommendations, customer specifications / documented procedures; m) Maintaining a list of approved maintenance / repair process capabilities / current ratings; n) Assuring that maintenance operations do not adversely affect areas outside the scope of the planned maintenance; and o) The equipment, tools and materials are those recommended by the manufacturer of the article or are at least equivalent to those recommended by the manufacturer and acceptable to the customer / Authority. Planning considers the following (as appropriate): • The establishment of process controls and the development of control plans where key characteristics have been identified; • The identification of in-process verification points (when adequate verification of conformance cannot be performed at a later stage of realisation); • The design, manufacture, and use of tooling so that variable measurements can be taken (particularly for key characteristics); and • Special processes (eg. welding, brazing, plating). KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 25 of 38 7.5.1.1 Production Process Verification New maintenance processes are documented, qualified, and approved by the customer / Authority. KG use a representative item from the first production run of a new part or assembly to verify that the production processes, production documentation and tooling are capable of producing parts and assemblies that meet requirements. This process is repeated when changes occur that invalidate the original results (eg. engineering changes, manufacturing process changes, tooling changes). Procedures QP.42 [First Article Inspection (FAI)] and UTAS-PRO-0024 [First Article Inspection (FAI)] apply. 7.5.1.2 Control of Production Process Changes Personnel authorised to approve changes to production processes are identified. Changes affecting processes, production equipment, tools, or software programs are controlled and documented. The results of changes to production processes are assessed to confirm that the desired effect has been achieved without adverse effects to product conformity. Procedure QP.08 [Documentation Control & Change Control] applies. 7.5.1.3 Control of Production Equipment, Tools, & Software Programs Production equipment, tools and software programs used to automate and control / monitor product realisation processes are validated prior to release for production, and are maintained. Maintenance equipment, tools and programs used to automate and control / monitor product realisation processes are those defined by the technical data or demonstrated as equivalent prior to use. Equipment, tools and programs are maintained and inspected periodically. Procedures QP.09 [Calibration], QP.11 [Manufacturing Control], QP.13 [Inspection & Testing] and UTAS-PRO-0021 [Calibration] apply. Storage requirements (including periodic preservation / condition checks) are defined for production equipment or tooling in storage. 7.5.1.4 Post-Delivery Support Post-delivery support provides (as applicable) for the: a) Collection and analysis of in-service data; b) Actions to be taken (including investigation and reporting) when problems are detected after delivery; c) Control and updating of technical data; d) Approval, control, and use of repair schemes*; and e) Controls required for off-site work (eg. work undertaken at the customer’s facilities)**. * KG do not conduct repair schemes. Customer returned product is overhauled / maintained to KG Component Maintenance Manuals (CMMs) or to the original manufacturing documentation. ** KG do not conduct off-site working. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 26 of 38 7.5.2 Validation of Processes For Production & Service Provision KG validate any processes for production and service provision where the resulting output cannot be verified by subsequent monitoring or measurement, and as a consequence deficiencies become apparent only after the product is in use or the service has been delivered. These processes are often referred to as ‘special processes’ (eg. welding, brazing, and plating). Validation demonstrates the ability of these processes to achieve planned results. Arrangements for these processes are established including (as applicable): a) Defined criteria for review and approval of the processes; b) Approval of equipment and qualification of personnel; c) Use of specific methods and procedures; d) Requirements for records; and e) Re-validation. 7.5.3 Identification & Traceability The product is suitably identified throughout product realisation (where appropriate). The identification of the configuration of the product is maintained in order to identify any differences between the actual configuration and the agreed configuration. Product status with respect to monitoring and measurement requirements is identified throughout product realisation. When acceptance authority media are used (eg. stamps, electronic signatures, passwords) appropriate controls for the media are established. Where traceability is a requirement the unique identification of the product is controlled and records are maintained. Traceability requirements can include: • Identification to be maintained throughout the product life; • The ability to trace all products manufactured from the same batch of raw material or from the same manufacturing batch to the designation (eg. delivery, scrap); • For an assembly the ability to trace its components to the assembly and then to the next higher assembly; and • For products a sequential record of production (manufacture, assembly, inspection). Procedures QP.20 [Configuration Control] and DOP.50 [Configuration Control] apply. 7.5.4 Customer Property KG exercise care with customer property while it is under our control or being used by us. KG identify, verify, protect, and safeguard customer property provided for use. If any customer property is lost, damaged, or otherwise found to be unsuitable for use this is reported to the customer. Records are maintained. The verification includes verification of the appropriate release document. At KG this only applies in two (2) areas; repairs and investigations. Customer supplied product is not used for incorporation into manufacture. Procedures QP.12 [Purchaser Supplied Material] and DOP.11 [Repairs] apply. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 27 of 38 7.5.5 Preservation of Product In order to maintain conformity to requirements the product is preserved during internal processing and delivery to the intended destination. Preservation includes identification, handling, packaging, storage, and protection (as applicable). Preservation also applies to constituent parts of a product. Foreign Object Damage (FOD) is controlled using UTAS procedures PR017 [Foreign Object Damage Prevention Program] and UTAS-PRO-0016 [Foreign Object Damage Prevention]. To prevent unintended use items intended for maintenance use are segregated from items not intended for maintenance. Preservation of product also includes (where applicable in accordance with product specifications and applicable statutory and regulatory / Authority regulations) provisions for: a) Cleaning; b) Prevention, detection, and removal of foreign objects; c) Special handling for sensitive products; d) Marking and labelling (including safety warnings); e) Shelf life control and stock rotation; and f) Special handling for hazardous materials. Procedures QP.01 [Shelf Life & Storage Instructions] and QP.17 [Handling, Storage, Packaging, Preservation & Delivery] apply. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 28 of 38 7.6 Control of Monitoring & Measuring Equipment KG determine the monitoring and measurement to be undertaken and the monitoring and measuring equipment needed to provide evidence of conformity of product to determined requirements. A register of monitoring and measuring equipment is maintained and the processes employed for their calibration / verification (including details of equipment type, unique identification, location, frequency of checks, check method, and acceptance criteria) are defined. Processes are established to ensure that monitoring and measurement can be carried out and is carried out in a manner that is consistent with the monitoring and measurement requirements. Environmental conditions are suitable for the calibration, inspection, measurement, and tests conducted. Where necessary to ensure valid results measuring equipment is: a) Calibrated or verified (or both) at specified intervals or prior to use against measurement standards traceable to international or national measurement standards (where no such standards exist, the basis used for calibration / verification is recorded); b) Adjusted or re-adjusted as necessary; c) Identified in order to determine its calibration status; d) Safeguarded from adjustments that would invalidate the measurement result; and e) Protected from damage and deterioration during handling, maintenance, and storage. A process for the recall of monitoring and measurement equipment requiring calibration or verification is established, implemented and maintained. The validity of previous measuring results is assessed and recorded when the equipment is found not conforming to requirements. Appropriate action is taken on the equipment and any product affected. Records of the results of calibration and verification are maintained. When used in the monitoring and measurement of specified requirements the ability of computer software to satisfy the intended application is confirmed prior to initial use and reconfirmed as necessary. Procedures QP.09 [Calibration] and UTAS-PRO-0021 [Calibration] apply. 8.0 MEASUREMENT, ANALYSIS & IMPROVEMENT 8.1 General KG through the implementation of our ACE (Achieving Competitive Excellence) operating system plan and implement the monitoring, measurement, analysis and improvement processes needed to: a) Demonstrate conformity to product requirements; b) Ensure conformity of the quality management system; and c) Continually improve the effectiveness of the quality management system. This includes determination of applicable methods (including statistical techniques) and the extent of use. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 29 of 38 8.2 Monitoring & Measurement 8.2.1 Customer Satisfaction As one of the measurements of the performance of the quality management system, information relating to customer perception as to whether KG have met customer requirements is monitored. The methods for obtaining and using this information are determined. Information to be monitored and used for the evaluation of customer satisfaction includes (but is not limited to) product conformity, on-time delivery performance, customer complaints, and corrective action requests. KG develop and implement plans for customer satisfaction improvement that address deficiencies identified in these evaluations and assess the effectiveness of the results. Market Feedback Analysis (MFA) is conducted at regular intervals to identify areas where improvement is needed. This process is defined under the company ACE operation system. Procedure QP.45 [Customer Complaints] applies. 8.2.2 Internal Audit Audits are conducted at planned intervals to determine whether the quality management system: a) Conforms to the planned arrangements, to the requirements of BS EN 9100 / AS9100, and to KG’s established quality management system requirements; and b) Is effectively implemented and maintained. An audit program is planned taking into consideration the status and importance of the processes and areas to be audited as well as the results of previous audits. The audit criteria, scope, frequency, and methods are defined. Selection of Auditors and conduct of audits ensures objectivity and impartiality of the audit process. Auditors do not audit their own work. A documented procedure is established to define the responsibilities and requirements for planning and conducting audits, establishing records, and reporting results. Records of the audits and their results are maintained. The management responsible for the area being audited ensure that any necessary corrections and corrective actions are taken without undue delay to eliminate detected non-conformities and their causes. Follow-up activities include the verification of the actions taken and the reporting of verification results. Procedure QP.03 [Quality Auditing] and UTAS procedure UTAS-PRO-0003 [Internal Quality Audit Auditor Requirements] apply. 8.2.3 Monitoring & Measurement of Processes Suitable methods for monitoring and (where applicable) measurement of the quality management system processes are applied. These methods demonstrate the ability of processes to achieve planned results. When planned results are not achieved corrective action is taken (as appropriate). In the event of process non-conformity KG: a) Take appropriate action to correct the non-conforming process; b) Evaluate whether the process non-conformity has resulted in product non-conformity; c) Determine if the process non-conformity is limited to a specific case or whether it could have affected other processes or products; and d) Identify and control any non-conforming product. Procedure QP.37 [Statistical Process Control (SPC)] applies. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 30 of 38 8.2.4 Monitoring & Measurement of Product Characteristics of the product are monitored and measured to verify that product requirements have been met. This is carried out at appropriate stages of the product realisation process in accordance with the planned arrangements. Evidence of conformity with the acceptance criteria is maintained. Procedures QP.13 [Inspection & Testing], QP.14 [Sampling], QP.16 [Indication of Inspection Status] and QP.19 [Sample Reports] apply. KG provide objective evidence that all maintenance operations have been completed as planned. Measurement requirements for product or service acceptance are documented. This documentation may be part of the production documentation, but does include: a) Criteria for acceptance / rejection (typically in the form of drawings or Q sheets); b) Where in the sequence measurement and testing operations are performed; c) A record of the measurement results; d) Type of measurement equipment required, and specific instructions associated with its use; and e) Identification of which inspection and testing operations are to be verified / witnessed. When critical items (including key characteristics) have been identified they are controlled and monitored in accordance with the established process. When sampling inspection is used as a means of product acceptance the sampling plan is justified on the basis of recognised statistical principles and appropriate for use (ie. matching the sampling plan to the criticality of the product and to the process capability). Defects discovered during maintenance that are outside the scope of the maintenance contract are identified and processed in accordance with customer and Authority requirements. Where product is released for production / maintenance use pending completion of all required measurement and monitoring activities it is identified and recorded to allow recall and replacement if it is subsequently found that the product does not meet requirements. Records indicate the person(s) authorising release of product for delivery to the customer. Where required to demonstrate product qualification records provide evidence that the product meets the defined requirements. The release of product and delivery of service to the customer does not proceed until the planned arrangements have been satisfactorily completed, unless otherwise approved by a relevant Authority and by the customer (where applicable). All documents required to accompany the product are present at delivery. Procedures are implemented for the preparation and completion of Authority documentation (eg. conformity determinations, airworthiness approvals, release certificates, approval for return to service after maintenance, export documentation). First Article Inspections (FAIs) are carried out in accordance with AS9102, and procedures QP.42 [First Article Inspection (FAI)] and UTAS-PRO-0024 [First Article Inspection (FAI)] (where applicable). KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 31 of 38 8.3 Control of Non-Conforming Product Products which do not conform to product requirements are identified and controlled to prevent unintended use or delivery. A documented procedure is established to define the controls and related responsibilities and authorities for dealing with non-conforming product. These procedures define the responsibility and authority for the review and disposition of non-conforming product and the process for approving personnel making these decisions. Where applicable KG deal with non-conforming product by one or more of the following ways: a) Taking action to eliminate the detected non-conformity; b) Authorising its use, release, or acceptance under concession by a relevant authority and (where applicable) by the customer; c) Taking action to preclude its original intended use or application; d) Taking action appropriate to the effects or potential effects of the non-conformity when non-conforming product is detected after delivery or use has started; and e) By taking actions necessary to contain the effect of the non-conformity on other processes or products. KG’s non-conforming product control process provides for the timely reporting of delivered non-conforming product including product that may affect safety and reliability. Dispositions of ‘use-as-is’ or ‘repair’ are only used after approval by an authorised representative of the organisation responsible for design. If the non-conformity results in a departure from the contract requirements, dispositions of ‘use-as-is’ or ‘repair’ are not used unless specifically authorised by the customer. Product dispositioned for scrap is conspicuously and permanently marked or positively controlled until physically rendered unusable. When non-conforming product is corrected it is subject to re-verification to demonstrate conformity to requirements. Records of the nature of non-conformities and any subsequent actions taken including concessions obtained are maintained. Procedures QP.06 [Corrective & Preventive Action], QP.15 [Non-Conforming Materiel], UTAS-PRO-0004 [Control of Nonconforming Product], UTAS-PRO-0005 [Corrective Action] and UTAS-PRO-0006 [Preventive Action] apply. 8.4 Analysis of Data Appropriate data is determined, collected, and analysed to demonstrate the suitability and effectiveness of the quality management system and to evaluate where continual improvement of the effectiveness of the quality management system can be made. This includes data generated as a result of monitoring and measurement and from other relevant sources. The analysis of data provides information relating to: a) Customer satisfaction; b) Conformity to product requirements (typically scrap, rework, and concessions); c) Characteristics and trends of processes / products (including opportunities for preventive action); d) Suppliers (including rejects and delivery performance); and e) Human Factors events. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 32 of 38 8.5 Improvement 8.5.1 Continual Improvement The effectiveness of the quality management system is continually improved through the use of the Quality Policy, quality objectives, audit results, analysis of data, corrective and preventive actions, and Management Review. Implementation of improvement activities is monitored to evaluate the effectiveness of the results. KG also aim to train all employees in ACE quality tools and techniques and aim for involvement in improvement projects. For more details on the ACE programme please refer to paragraph 1.3 of this Manual. 8.5.2 Corrective Action Action is taken to eliminate the causes of non-conformities in order to prevent recurrence. Corrective actions are appropriate to the effects of the non-conformities encountered. A documented procedure is established to define requirements for: a) Reviewing non-conformities (including customer complaints); b) Determining causes of non-conformities; c) Evaluating the need for action to prevent occurrence of non-conformities; d) Determining and implementing actions needed; e) Records of results of action taken; f) Reviewing effectiveness of corrective actions taken; g) Flowing down corrective action requirements to a supplier when it is determined that the supplier is responsible for the non-conformity; h) Specific actions where timely / effective corrective actions are not achieved; i) Determining if additional non-conforming product exists based on the causes of the nonconformities and taking further action when required; and j) Evaluating the need for ‘Human Factors’ actions to prevent occurrence of non-conformities. Procedures QP.06 [Corrective & Preventive Action] and UTAS-PRO-0005 [Corrective Action] apply. 8.5.3 Preventative Action Actions are determined to eliminate the causes of potential non-conformities in order to prevent their occurrence. Preventive actions are appropriate to the effects of the potential problems. A documented procedure is established to define requirements for: a) Determining potential non-conformities and their causes; b) Evaluating the need for actions to prevent recurrence of non-conformities; c) Determining and implementing actions needed; d) Records of results of actions taken; e) Reviewing effectiveness of the preventive actions taken; and f) Evaluating the need for ‘Human Factors’ actions to prevent recurrence of non-conformities. Procedures QP.06 [Corrective & Preventive Action] and UTAS-PRO-0006 [Preventive Action] apply. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 APPENDIX 1: ISO 9001 / BS EN 9100 (AS9100) APPROVAL CERTIFICATE KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Page 33 of 38 Issue 07 October 2014 QUALITY MANUAL QM2000 Page 34 of 38 APPENDIX 2: AS9100 COMPLIANCE MATRIX PARA. TITLE PROCEDURE(S) 4.2.1 General Documentation Requirements QP.08 4.2.2 Quality Manual QM2000 4.2.3 Control of Documents QP.08, UTAS-PRO-0001 4.2.4 Control of Records QP.33, UTAS-PRO-0002 5.1 Management Commitment QP.35, QM2000 5.2 Customer Focus QM2000 5.3 Quality Policy QM2000 5.4 Planning QM2000 5.5 Responsibility, Authority & Communication QM2000 5.6 Management Review QP.35, QM2000, UTAS-PRO-0007 5.7 Safety Policy Environmental, Health & Safety Policy, UTAS-PRO-0009 6.1 Provision of Resources QM2000 6.2 Human Resources QP.18 6.3 Infrastructure QM2000 7.1 Planning of Product Realisation QP.02, QP.04, QP.20, QP.37, DOP.50, SP0124, UTAS-PMO-PRO-1507 7.2 Customer-Related Processes QP.04, QP.05, QP.45 7.3 Design & Development QP.07 7.3.1 Design & Development Planning QP.04 7.3.2 Design & Development Inputs QP.20 7.3.3 Design & Development Outputs QP.07, QP.29 7.3.4 Design & Development Review QP.07, QP.20 7.3.5 Design & Development Verification QP.07, QP.29 7.3.6 Design & Development Validation QP.07, QP.20, QP.29, UTAS-PRO-0027 7.3.7 Design & Development Changes QP.07, QP.20 7.4.1 Purchasing Process QP.10, QP.12, QP.15, UTAS-PRO-0008, 0012, 0014, 0029, 0030 7.4.2 Purchasing Information QP.10, QP.12, QP.15, UTAS-PRO-0012, 0014, 0029, 0030 7.4.3 Verification of Purchased Product QP.10, QP.12, QP.15, UTAS-PRO-0012, 0014, 0029, 0030 7.5.1 Control of Production & Service Provision QP.08, QP.09, QP.10, QP.11, QP.13, QP.42, UTAS-PRO-0028 7.5.2 Validation of Processes For Production & Service Provision QP.08, QP.09, QP.10, QP.11, QP.13, QP.42, UTAS-PRO-0028 7.5.3 Identification & Traceability QP.20, QP.23, DOP.50 7.5.4 Customer Property QP.12, QP.36, DOP.11 7.5.5 Preservation of Product QP.01, QP.17, QP.21, QP.22, QP.27, QP.36, UTAS-PRO-0016 7.6 Control of Monitoring & Measuring Devices QP.09, UTAS-PRO-0011, 0021 8.1 Measurement, Analysis, & Improvement (General) QP.45, 8.2.2 Internal Audits QP.03, UTAS-PRO-0003 8.2.3 Monitoring & Measurement of Processes QP.03, QP.06, UTAS-PRO-0026 8.2.4 Monitoring & Measurement of Product QP.13, QP.14, QP.16, QP.19, QP.40, QP.42, UTAS-PRO-0024 Control of Non-conforming Product QP.06, QP.06a, QP.15, UTAS-PRO-0004, -0025 8.5.2 Correction Action QP.06, (QP.38), UTAS-PRO-0005, 0032 8.5.3 Preventive Action QP.06, (QP.38), UTAS-PRO-0006 8.3 KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 35 of 38 APPENDIX 3: UTAS ADDENDUM PROCEDURE 0. INTRODUCTION This procedure documents the addendum to Kidde Graviner’s QM2000 [Quality Manual] as required by DP400.3 [QMS Requirements] paragraph 4.2.2 ‘Quality Manual’. 1. POLICIES & DEFINITIONS 1.1 Policies Hamilton Sundstrand (HS) Division Policies DP400 [HS QMS Requirements], DP400.3 [QMS Requirements], and DP400.4 [Aerospace QMS Requirements] apply. The HS DPs listed above, the Quality Manual, and QP procedures comprise the Quality Management System (QMS) as implemented at Kidde Graviner, Colnbrook, Slough, SL3 0HB, UK. 2. SCOPE OF THE QMS KG’s QMS covers the design, manufacture, overhaul and repair of mechanical and electrical components for fire, overheat and smoke detection systems, fire extinguishing systems, explosion suppression systems, aircraft crash systems, temperature switches, guided weapon safety and arming mechanisms, marine engine safety systems, and high pressure gas storage systems for aerospace, vehicle, marine and industrial markets (including commercial and military applications), and spares for the above equipment. KG supports engineering in new product development providing the resources to build and test new production with engineering design and contract review responsibility residing in-house. KG is a CAA / FAA approved Repair Facility (ref. EASA Part 145: UK.145.00880, FAA Part 145: K35Y190Y). 3. EXCLUSIONS There are no exclusions to any ISO 9001 or BS EN 9100 / AS9100 clauses in KG’s QMS. KG has implemented the quality system requirements described in UTAS-POL-0001 [UTAS Management System Manual] and DP400, DP400.3 and DP400.4. 4. OUTSOURCED PROCESSES 4.1 Externally Outsourced Processes KG outsources equipment calibration to Calmet Laboratory Services. Outsourced processes are monitored by verifying that ISO 9001 / AS9100 approvals are maintained. 4.2 Shared Services KG do not outsource any processes to UTAS shared / central functions. 5. QMS DOCUMENTATION A controlled copy of the QMS Cross-Reference Matrix contains all the Level I, II and III (working level) documentation that supports KG’s QMS. 6. SEQUENCE & INTERACTION OF PROCESSES A description of KG’s QMS processes, their interaction, and the Level III instructions that pertain to each process are defined within the appropriate elements of the QMS flow-down matrix. Refer to Appendix 3.1 of this procedure for the ‘Sequence & Interaction between Processes’. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 36 of 38 7. TOP MANAGEMENT Top management is defined as KG’s Site Lead and his direct reports (as shown in paragraph 7.1). The QA Manager is the Management Representative for quality. The QA Manager has the responsibility and authority to stop manufacturing processes which are not compliant to requirements. Any challenges to these decisions are submitted to the Site Lead for resolution. In the absence of this resolution the QA Manager’s direction must be followed. The Accountable Executive Manager and Maintenance Manager for the Repair Station is KG’s Site Lead. 7.1 KG Organisation Chart Please refer to Figure 2 of this document for Kidde Graviner’s organisation chart. 8. ABBREVIATIONS CAA Civil Aviation Authority (UK). DP.000 Division Policy (Legacy Hamilton Sundstrand). EASA European Aviation Safety Agency. FAA Federal Aviation Authority (US). ISO International Organisation For Standardisation. KG Kidde Graviner. QA Quality Assurance. QMS Quality Management System. QP.00 Quality Procedure (KG). UTAS United Technologies Aerospace Systems. UTAS-PRO-0000 Procedure (UTAS). KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 37 of 38 APPENDIX 3.1: SEQUENCE & INTERACTION BETWEEN PROCESSES OPERATIONS CUSTOMER 4.0 QMS WITH PROCEDURES FOR: 4.2.3 CONTROL OF DOCUMENTS, AND 4.2.4 CONTROL OF RECORDS 5.6 MANAGEMENT REVIEW 8.2 MONITORING, ANALYSIS & IMPROVEMENT PROCEDURES FOR: 8.2.2 INTERNAL AUDIT 8.5.2 CORRECTIVE ACTION 8.5.3 PREVENTIVE ACTION 6.3 INFRASTRUCTURE 7.2 CUSTOMER-RELATED PROCESSES BUSINESS UNIT ORDER REQUEST REQUIREMENTS INTERFACE (ENGINEERING) 5.4 PLANNING OEM / AIRLINE RETURN PROCESS RETURNS INTERFACE PURCHASING INTERFACE RECEIVING INSPECTION & TEST SUPPLIER PQA INTERFACE PASS INSPECTION / TEST? 8.2.2 INTERNAL AUDIT 7.5.5 HANDLING & STORAGE MODIFICATION REQUIREMENT yes yes 7.5 ASSEMBLY 7.6 CONTROL OF MONITORING & MEASURING DEVICES 8.2.4 IN-PROCESS MONITORING OF PRODUCT PRODUCT OK? no no CUSTOMER COMPLAINT? no yes 8.2.4 FINAL MEASURING & TEST OF PRODUCT PRODUCT OK? END no yes SHIPPER PREP INTERFACE 7.5.5 + 7.5.1(f) PRESERVATION OF PRODUCT & DELIVERY CUSTOMER 8.3 CONTROL OF NON-CONFORMING PRODUCTS 6.2 HUMAN RESOURCES Additionally, each department have their own SIPOCs (Supplier / Input / Process / Output / Customer) charts displayed on their ACE information boards. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed. Issue 07 October 2014 QUALITY MANUAL QM2000 Page 38 of 38 APPENDIX 4: EXTERNAL DISTRIBUTION LIST When this Quality Manual is amended, revised copies should be sent to the following organisations: Company Name Contact Name Contact E-Mail Address SNECMA (Safran Group) Stephane Varmancourt stephane.varmancourt@snecma.fr Please note that all copies sent out are considered ‘uncontrolled’ and ‘for information only’. It is the organisation’s responsibility to ensure they hold an up-to-date issue. KG PROPRIETARY – subject to restrictions on cover page. Uncontrolled if printed.