Supplemental Manual for DeviceNet

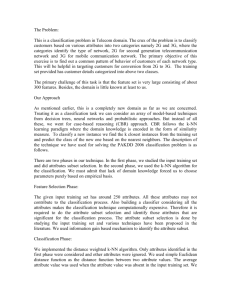

advertisement