Robots vs. Cheap Labor,

Who Wins?

How Humans Interact

with Machines (HMI)?

New Embedded

Technology Trends

Real World Connected Systems Magazine. Produced by Intelligent Systems Source

Vol 17 / No 2 / FEBRUARY 2016

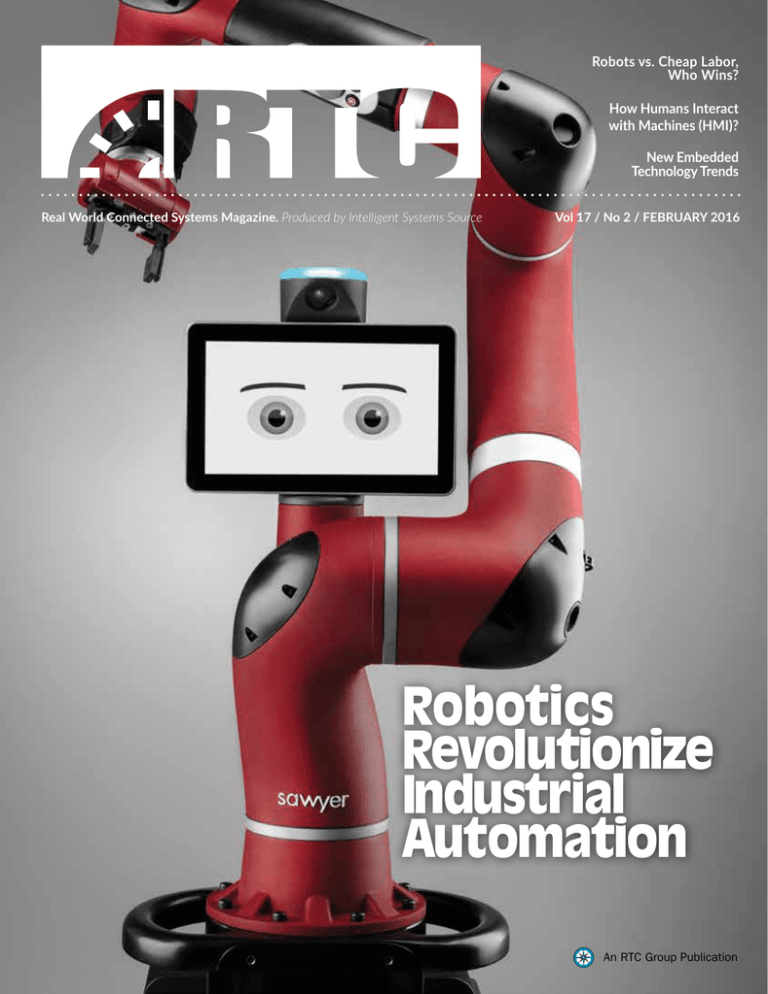

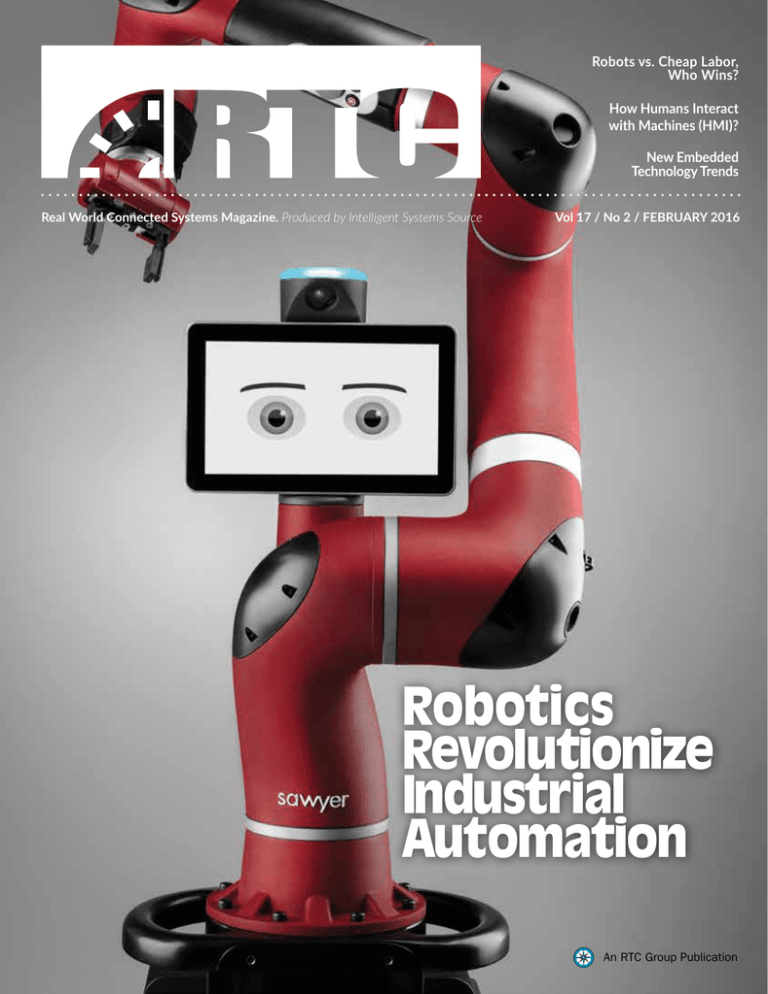

Robotics

Revolutionize

Industrial

Automation

An RTC Group Publication

CONTENTS

Real World Connected Systems Magazine. Produced by Intelligent Systems Source

HUMAN-MACHINE-INTERACTION

16

2.0: The Human-Machine-Interaction

(HMI) market and technologies

by John Koon, Editor-in-Chief

17

2.1: Touch and Touchless human-machineinteraction (HMI) sensor market

by Jennifer Colegrove, Touch Display Research Inc.

14

Robotics Revolutionize

Industrial Automation

EDITORIAL

05

Robotic and Linear Motions Revolutionize

Industrial Automation

by John Koon, Editor-in-Chief

ROBOTIC REVOLUTIONIZES

INDUSTRIAL AUTOMATION

06

1.0: Robotics Revolutionize Industrial Automation

08

1.1: How Robotics Revolutionize

Industrial Automation

by John Koon, Editor-in-Chief

by Bob Doyle, Robotic Industries Association (RIA)

10

1.2: Future of Industrial Automation

12

1.3: Disrupting the Industrial Automation Space

13

1.4: Services and people are important to the

Industrial Internet of Things

by Jim Pinto, consultant

20

by David Olsen, Renesas Electronics America Inc.

24

26

2.4: The Future of HMI: Integrate or Die

27

2.5: InduSoft Web Studio Brings HMI

Innovations to Paper Winding Machine

by Jim Lawton, Rethink Robotics

15

1.6: Imagining the Possibility of

Predictive Maintenance

by Christine A. Frank, Dell

by By Patrick Hanley, Atmel Corporation

by Melinda Corley, InduSoft

SURVEY OF EMBEDDED

TECHNOLOGIES

30

3.0: Leading Embedded Manufacturers

Provide Clues of the Future

by John Koon, Editor-in-Chief

31

3.1: SWaP Systems Leveraging FMC’s

Bring the Latest Technology to the DoD

by Pierrick Vulliez, 4DSP

32

3.2: 3U VPX™ switch adds

ExpressFabric® capability

by Nigel Forrester, Concurrent Technologies

34

by Rich Carpenter, GE’s Automation & Controls team

1.5: Collaborative Robots and the New Normal

in Manufacturing

2.3: Give Me What I Want

(Not What I Asked For)

by Jason Williamson, Altia, Inc.

3.3: Boxes Becoming Boards—Technology

Transition in VPX

by Ken Grob, Elma Electronic Inc.

36

3.4: Rugged, Tactical LTE Networks for

Military and First Responders

by John Long, LCR Embedded Systems

by John Bender, ABB

14

2.2: Enhancing Embedded Designs with

HMI Displays

37

3.5: Making Trains Safer Down Under

39

3.6: New FireWire Expansion Module for

Mini PCIe Sockets

by Stephen Cunha, MEN Micro

by Len Crane, VersaLogic Corporation

40

3.7: Rugged Optic Interconnects Open

New Possibilities for HPEC Systems in

Harsh Environment

by Michel Têtu, Reflex Photonics Inc.

RTC Magazine FEBRUARY 2016 | 3

RTC MAGAZINE

WHY CHOOSE

NOVASOM?

NOVAsom Industries provides the added

value of design creativity, offering tailormade solutions to both industrial and

multimedia markets. We specialize in

proposing innovative options to improve

productivity, time to market, and reach a

truly competitive advantage.

PUBLISHER

President

John Reardon, johnr@rtcgroup.com

Vice President

Aaron Foellmi, aaronf@rtcgroup.com

EDITORIAL

In addition to the embedded computing

industry, NOVAsom is involved in the newest

high level video technologies, including 4K

displays. The 2 key differences that make us

stand out are our 32/64 bit full architecture

and the ability to provide interface to ANY

display/sensor combination.

5

single board computer

Editor-In-Chief

John Koon, johnk@rtcgroup.com

ART/PRODUCTION

Art Director

Jim Bell, jimb@rtcgroup.com

Graphic Designer

Hugo Ricardo, hugor@rtcgroup.com

8

ADVERTISING/WEB ADVERTISING

Z

Eastern U.S. and EMEA Sales Manager

Ruby Brower, rubyb@rtcgroup.com

(949) 226-2004

single board computer

6

single board computer

Western Regional Sales Manager

John Reardon, johnr@rtcgroup.com

(949) 226-2000

single board computer

BILLING

7

single board computer

Controller

Trudi Walde, trudiw@rtcgroup.com

(949) 226-2021

7b

smart delivery

5

8

full development kit

full development kit

NOVAsom8© is a module card designed with

a System On Module (SOM) architecture

full development kit

full development kit

based on quad core ARM Cortex-A9 from

512MB to 4GB of 64 bit DDR3 Memory.

6

Z

• Processor CortexA9 Freescale

• IMX6 Quad Core

full development kit

• 4GB RAM Memory

• 32GB FLASH Memory (eMMC)

• USD memory slot

• SATA II

• Ethernet 10/100/1000

• USB host/device and OTG

• HDMI (High-Definition

Multimedia Interface)

7

TO CONTACT RTC MAGAZINE:

Home Office

The RTC Group, 905 Calle Amanecer, Suite 150,

San Clemente, CA 92673

Phone: (949) 226-2000

Fax: (949) 226-2050

Web: www.rtcgroup.com

Published by The RTC Group

Copyright 2016, The RTC Group. Printed in the United States.

All rights reserved. All related graphics are trademarks of

The RTC Group. All other brand and product names are the

property of their holders.

www.novasomindustries.com

5

single board computer

4 | RTC Magazine FEBRUARY 2016

6

single board computer

8

single board computer

Z

single board computer

EDITORIAL

Robotics and Linear Motions

Revolutionize Industrial

Automation

by John Koon, Editor-In-Chief

At a recent ATX show in Anaheim, California (February 2016), one demo that caught my

attention was the new ActiveMover. I saw a few

shiny metal blocks spinning in circle much like

race cars running on the race tracks with great

precision. This unit, shown for the first time in

North America, was manufactured by Rexroth

(Bosch Group). As seen in the photo 1 and 2,

each of these metal blocks which were referred

to as workpiece pallets were held by strong

magnets greater than 1000 Newtons (the force

is equivalent to approximately 225 pounds). The

workpiece pallets can move with a speed up to

500 feet per minute carrying weights up to 22

pounds.

This demo gave us a glimpse of what future

robotic motion looks like. Whether a factory

is building cars or electronic assembly boards,

the production processes require 2D and 3D

motions to put the parts together. In the case

of automotive plants, you may see a major

robot arm moves around to picking up heavy

parts and assemble them to the frame of an

automotive. For electronic assembly boards,

it can be a pick-and-place machine. Watching

“board stuffing” in action placing components

on the circuit assembly boards can be quite

fascinating. Compare with human workers,

robots can work tirelessly, improves productivity and reduce errors. While Industrial

Internet-of-Things are touted as the solution

to future manufacturing productivity, it goes

beyond just connecting millions of sensors

together. Data management and use are a

big part of it. “Just having connected devices

producing data points is of little use, unless

those data points can be acted upon in a meaningful way. Only then will real change occur,”

explained John Bender, senior vice president of

product management at ABB. In this issue of

the RTC Magazine, we will explore the various

aspects of industrial automation including the

future outlook. Experts from GE, Bosch Rextroth, ABB, Rethink Robotics, Dell and Robotic

Industries Association (RIA) will share their

Bosch Rexroth ActiveMover is capable of high repeatability of +/- 0.01 mm and reversible operation. Image

courtesy of Bosch Rexroth.

experiences and ideas.

How human beings interact with machines

Contrary to some sci-fi movies that smart

machines become so smart that they program

themselves and take over the world, almost all

robotics and industrial automation systems

need programming by human beings. Depends

on the sophistication of the systems, some

require high level programming, others C++

and the like. The interaction between human

and machine is a topic commonly known as the

Human-Machine-Interaction or Human-Machine-Interface (HMI). The common HMI is

touch-screen display allowing a user to interact

with the machine (usually the behind-thescene programming is already done at this

point). HMI has great potential. The most

popular HMI are verbal and touch input. Other

methods such as brain wave, hand and eye

movements are still in the research stage. One

area of interest making a lot of progress is motion sensing. In the medical field, a wearable

device can detect the motion of a person falling

and send for help. This will provide peace of

mind to those who have aging parents living by

themselves.

Where embedded technologies are heading?

The Embedded Tech Trends conference

(January 2016) invited a group of embedded

manufacturers to Houston to share the latest

development. At this event, we saw more

optical products including controllers and

connectors are being deployed. Other technologies such as PCI, Mini PCIe, Firewire and

VPX remained strong. New VPX standard was

being established with many supporters. Other

technologies including FPGA and System-onchip will continue to gain momentum. In this

issue, w invited some of these manufacturers to

share their experiences.

Workpiece pallet (an ActiveMover component) has

width of 165 mm for holding fixture <500 mm and

embedded magnets of 1000 Newtons. Image courtesy

of Bosch Rexroth.

RTC Magazine FEBRUARY 2016 | 5

1.0 ROBOTICS REVOLUTIONIZE INDUSTRIAL AUTOMATION

Robotics revolutionize

Industrial Automation

by John Koon, Editor-In-Chief

Robotics are gaining significant recognition lately in increasing efficiency in manufacturing. Even China started to implement robotics to augment its relatively low labor cost pool. The

combination of robotics, Internet-of-Things and meaningful use

of data can increase productivity, create predictive maintenance;

reduce downtime means big savings. Potentially, the proper

implementation of robotics can disrupt the industry by creating

6 | RTC Magazine FEBRUARY 2016

a class of manufacturers much more competitive than those

who don’t. Additionally, the use of robotics is also broadening

because of its unique characteristics and precision. In this section, we have invited experts from GE, ABB, DELL and Rethink

Robotics to share their experiences. Finally, Jim Pinto, a leading

consultant of industrial consultant, will discuss what the future

of Industrial Automation will look like.

RTC Magazine FEBRUARY 2016 7

1.1 ROBOTICS REVOLUTIONIZE INDUSTRIAL AUTOMATION

How Robotics Revolutionize

Industrial Automation

Automation is on the move, becoming more approachable for human operators and

more cost-effective for buyers. The physical and philosophical fence keeping humans

and robots separate is starting to diminish in connection with technology moving at

warp speed and the reasons to automate are multiplying.

by Bob Doyle, Robotic Industries Association (RIA)

The potential of Industrial Internet-of-Things (IIoT) is limitless. Not only does IIoT provide limitless ways to solve problems;

it is also a worldwide phenomenon. Here we include an example

of how IIoT can transform supply chains. But first we must

overcome two hurdles. We need to have a secured network, and

standardization. Security is the most important aspect, but it is

difficult to achieve because it is a moving target. Sometimes I

wonder if there are unadvertised hacker-schools teaching them

new ways to hack.

8 | RTC Magazine FEBRUARY 2016

So where we go for answers? Whom do we trust? Some time

ago, a local news station broadcasted that a box was placed in

front of the ATM of a bank. On the box was a note saying, “ATM

not working. Place your deposits in the box.” The broadcaster went on to say that the thief got away with an unspecified

amount of cash. We laugh, because we know better than to trust

such a statement. When it comes to security, whom do you

trust? Do we rely on the company’s reputation and experience,

or on our friends’ referrals? Here we turn to Green Hills for

free as a collaborative robot with humans. As of today, Baxter

has been sold and deployed in manufacturing and production

facilities throughout North America.

Stäubli Corporation, of South Carolina has produced robotics

designed specifically for the packaging, food and life science

industries. The TX2-40 CS9 has extensive safety features specific

to the human and robot collaboration including the safe stop,

safe tool, safe zone and safe speed features.

Robotics Education

KUKA KORE Robotic Education Cart provides portable training for technical

education programs. Image courtesy of KUKA Robotics Corporation.

Robotic organizations gather at the Automate conference (held

in Chicago every other year) to demonstrate, interact and show

case real-world robotic applications. The conference provides the

attendees with the latest trends in robotics such as robot safety,

bin picking, and 3D-printed grippers. In all cases, the trend for

robotic companies seems to be moving past the assembly lines,

in the goal of producing collaborative robots that improve precision and increase productivity— while being safe enough to

work together with humans. This is how robotics revolutionizes

industrial automation.

An additional, recent trend within the robotics industry pertains to training for technical education. Robots will be important instruments in helping the industry improve potential skills

gaps by providing portable training options. KUKA, of Shelby

Township, Michigan is one of the first robotics companies to

produce a Robotic Education Cart that provides this method of

technical education.

Robotics for Medical Purposes

ReWalk Robotics, of Marlborough, Massachusetts has

produced a robotic exoskeleton called the ReWalk Personal,

which is the only powered exoskeleton with U.S. Food and Drug

Administration clearance to date.

This robotic “skeleton” helps individuals with spinal cord

injuries to walk. Inventions for medical purposes such as the

robotic exoskeleton are expected to populate factory floors

and warehouses, blurring the distinctions between industrial,

collaborative and service robots. Indeed the robotic industry is

touching many areas of our lives.

Beyond the Assembly Lines

As the Automate conference reveals, robotics companies are

striving to incorporate robotics in various industries. A recent

exhibitor that has stood out in terms of specialty is Schneider

Packaging Equipment Company, Inc., of Brewerton, New York

who specializes exclusively in end-of-line packaging solutions.

Their Fully Automatic, Random Water-Activated Tape Case Sealer accommodates a wide variety of box sizes, and after automatically determining the box size, applies a special water-activated

tape that creates a stronger bond than pressure tape.

Another recent noteworthy exhibitor is Applied Manufacturing Technologies, LLC, of Orion, Michigan, which specialize

in robotic automation engineering and integration for material

handling. Their FANUC R-2000 robot and multiple ATI tool

changer demonstrates overall robotic flexibility and versatility.

One of the most revolutionary robots in the collaborative

robot category belongs to Rethink Robotics Inc., of Boston, Massachusetts. Rethink has produced a paradigm-shifting collaborative robot called “Baxter.” The Baxter robot works uncaged and

Robotic exoskeleton helps individuals with spinal cord injuries to walk. Image

courtesy of ReWalk Robotics, Inc.

RTC Magazine FEBRUARY 2016 | 9

1.2 ROBOTICS REVOLUTIONIZE INDUSTRIAL AUTOMATION

Future of Industrial Automation

Automated production equipment today is smaller and cheaper, and requires fewer

operators with better education and advanced skills. These operators simply don’t

like to work on a time-card-punching production-line environment. They prefer the

stimulating, innovative, fast-changing, adaptive atmosphere of small companies,

with personal incentives and performance-based rewards.

by Jim Pinto, consultant

Today, high-volume products are relatively easily outsourced

to third-world countries where production-line work requires

minimal training and provides upward mobility for low-skilled

workers.

It’s not that foreign labor is cheap – American labor is too

expensive for the kind of work that remains after manufacturing is automated. So, big production facilities are simply going

out of style in advanced countries, and large manufacturing

plants are becoming obsolete.

In the future, there will be millions of small- and medium-sized businesses that will benefit from new materials. 3D

printers will economically produce a wide variety of products

in small numbers.

10 | RTC Magazine FEBRUARY 2016

For smaller companies, robots are generally too inflexible

and require too much financial investment. But the next generation of robots will be cheaper and easier to set up, and will

work with people rather than replace them.

Internet of Things (IoT)

The primary drive for automation IoT is to significantly

reduce operating expenditures when automation devices,

sensors and actuators become Internet-enabled devices. It’s the

next huge leap in productivity because there are major advantages to be derived from the acquisition and organization of

previously unthinkable amounts of data.

The inflection point will occur when literally everything

is connected with inexpensive and easy-to-install wireless

networks. Industrial IoT will become self-organizing, self-configuring, self-healing, scalable to large sizes, with very low

energy consumption, low cost, simple to install and based on

global standards.

Chinese companies spend more on worker training and enterprise-management software. And 91% of U.S. plants are more

than a decade old, vs. 54% in China.

China Leads in Manufacturing

The new buzzwords are “transformational outsourcing.”

Many are discovering that outsourcing is really about corporate growth – making better use of skilled U.S. staff, and even

job creation in the United States, not just cheap wages abroad.

The cost savings from global outsourcing are small compared

to the enormous gains in efficiency, productivity, quality and

revenues that can be achieved by fully leveraging local as well

as offshore talent.

What is stunning about China is that the huge country

competes both with very low wages and high tech. Chinese

competition offers half the price of any alternatives. This has

been a big factor in the loss of about 3-5 million manufacturing jobs since 2000. If China’s growth stalls, as it is doing right

now in 2015/2016, the resulting glut will turn into another

export wave and disrupt American industry.

America’s industrial base has eroded to a dangerous level.

U.S. companies are no longer investing in much new capacity, and the ranks of U.S. engineers are thinning. By contrast,

the number of Chinese engineers is growing by over 350,000

annually. Young workers and managers are willing to put in

12-hour days and work weekends, with entrepreneurial zeal to

do whatever it takes to advance.

In a survey of Chinese and U.S. manufacturers by Industry

Week, 54% of Chinese companies cited innovation as one of

their top objectives, while only 26% of U.S. respondents did.

Outsourcing

RTC Magazine FEBRUARY 2016 | 11

1.3 ROBOTICS REVOLUTIONIZE INDUSTRIAL AUTOMATION

Disrupting the Industrial

Automation Space

The emergence of the Internet of Things (IoT) and the Industrial Internet is significantly

transforming the way we think about automation systems. GE’s Automation & Controls

team believes this is driving a change in the way automation and control systems are

developed and is therefore introducing disruptive technology into the controls space to

take advantage of this trend.

by Rich Carpenter, GE’s Automation & Controls team

The Internet of Things (IoT) and the Industrial Internet are

the Industrial Internet out of the box. In other words, the large

the new normal for today’s factories and infrastructure. Howequipment that GE provides to customers, whether for a wind

ever, there is quite a bit more to the Industrial Internet than just

application, a gas turbine, locomotive or other industrial machine,

collecting high-speed data from miles of connected infrastructure. is shipped with the required connectivity in place to bring data to

Without a meaningful way to optimize and process data, the imthe Industrial Internet. Once the data is available and organized

mense scope of information being generated by today’s machines

centrally, it can be mined for insights that are then used to drive

poses a real challenge for engineers and operators.

improved operational results. We believe, that like connected

That’s why companies are making their control systems smarter people, connected machines can operate with more intelligence.

by connecting them to information outside of their normal, local

As a result, the new control systems from GE are connected by

field of view. This helps the control system to make economically

default. Doing so greatly simplifies customers’ experience with a

stronger decisions to help optimize the overall business. Original

new control system as they can connect to industrial clouds like

Equipment Manufacturers (OEMs) are connecting their equipGE’s Predix with just a few simple steps.

ment, no matter how distributed, to central locations where they

The connected control system is then able to take advantage of

can run analytics for anything from predictive diagnostics to

Predix services like Asset Performance Management and Brilliant

avoid unplanned downtime to improved operational efficiency to

Manufacturing, which are focused on preventing unplanned

achieve higher output at lower costs.

downtime via predictive diagnostics using technology like SmartFor example, GE’s Power Conversion business is using Industri- Signal and reducing production losses. Since the control system

al PCs (IPCs) from GE’s Automation & Controls team as control

is naturally connected to Predix, it’s easy for customers to enable

units on multiple shipboard applications, including variable frethese services to improve their overall operations. See figure.

quency drives, automation systems and dynamic

positioning systems. These IPCs are critical

components, acting as the brains of their drives

and propulsion and control systems. Power

Conversion was previously using many different

controllers, so the convergence onto one model

has been beneficial. Now, the team is moving

towards one hardware platform for their control

systems, reducing the number of spare parts that

they and their customers need to stock.

With this example in mind, GE’s Automation

& Controls team believes the emergence of IOT

and the Industrial Internet is driving a change

in the way automation and control systems are

developed and is therefore introducing disruptive technology into the controls space to take

advantage of this trend. GE is changing the

GE is speaking the language of industry and bringing together industrial engineering with sensors,

way equipment is serviced by connecting it to

software and big data analytics to create brilliant machines

12 | RTC Magazine FEBRUARY 2016

1.4 ROBOTICS REVOLUTIONIZE INDUSTRIAL AUTOMATION

Expert Opinion: Services and

people are important to the

Industrial Internet of Things

by John Bender, senior vice president of product management, ABB

The emergence of the Industrial Internet of Things (IIoT) as the

hot industrial topic is based on the well-founded perception that

sharing information across the operations and information technology boundaries within an organization will drive improved

business performance. At ABB, we heartily agree, though not

without the integration of an organization’s services and people.

Only when IIoT, services and people are considered together

will real change occur. Just having connected devices producing

data points is of little use, unless those data points can be acted

upon in an impactful way. Real change requires the application of

deep domain knowledge and conversion of data into information

that can be easily used and acted upon by people to help them

focus on what is important and remove noise and distractions.

RTC Magazine FEBRUARY 2016 | 13

1.5 ROBOTICS REVOLUTIONIZE INDUSTRIAL AUTOMATION

Collaborative Robots and the

New Normal in Manufacturing

Manufacturers’ needs are shifting, and they have been unable to automate 90 percent of

tasks that traditional automation has been unable to reach. Currently, manufacturers recognize that they need to be more responsive to market changes, ready to deliver on customer preferences and able to innovate faster and more efficiently than their competitors.

Collaborative robots are pioneering a new generation of manufacturing innovation on the

factory floor, and shifting the way that businesses compete.

by Jim Lawton, chief product and marketing officer, Rethink Robotics

As personalization becomes the de facto standard in society, and

consumers demand more customization in every facet of their daily

lives, factories need to be more nimble and flexible than ever before.

New parts, processes and production lines need to be implemented quickly and efficiently in order to serve fluctuating customer

demands. While automating tasks with robots on the factory floor

has been in place for decades, traditional industrial robots are poorly

suited for the new shifts in production: Most of these expensive

robots can only perform a single task, take up a large amount of

space and need to operate behind safety caging. In fact, more than 90

percent of physical tasks performed in manufacturing environments

can’t be practically or economically automated by industrial robots.

Companies are turning to truly collaborative robots to fill this

automation gap. For example, Baxter and Sawyer are able to adapt to

real-world variability, can change applications quickly and perform

tasks like humans do. The result: Manufacturers across industries get

the fast-to-deploy, easy-to-use and versatile automation solution they

need to increase flexibility, lower costs and accelerate innovation.

Manufacturers have been unable to deploy traditional robots

in the factory because of extensive programming time and costs.

This new generation of robots are not programmed, but are trained

by demonstration, meaning that virtually anyone can train robots

to complete tasks simply by showing them what to do. Unlike

traditional industrial robots that take hundreds of hours to program,

and require a highly paid engineer or consultant with programming

expertise, Baxter and Sawyer can be trained to perform a task in

a matter of minutes. With a true train-by-demonstration method,

employees with little to no technical background can deploy and

redeploy automation quickly and effectively, therefore saving time

and money.

Another significant concern for traditional industrial robots is

the ability to work in semi-structured manufacturing environments.

Now, robots like Baxter and Sawyer are able to deal with real-world

variability, reliably feel their way into fixtures designed for human

hands and shift among various tasks quickly. Collaborative robots

are now deployed in a wide variety of industries, including plastics,

14 | RTC Magazine FEBRUARY 2016

Baxter and Sawyer are smart, collaborative robots that are perfectly suited for

today’s manufacturing environment, as they are able to adapt to real-world

variability, can change applications quickly and perform tasks like humans do.

contract manufacturing, electronics, automotive, metal fabrication,

consumer goods and research and education. The robots are not limited to those spaces; they are adaptable to virtually any environment,

and can be used for tasks that cross numerous industries, including

packaging, line loading and unloading, kitting, machine tending,

circuit board testing and material handling. Automating these tasks

enables human workers to complete tasks that require higher cognitive ability, thereby increasing workforce efficiency and retention.

Collaborative robots are revolutionizing the factory floor, and

this new generation of technology is changing the game and helping

companies excel in the new manufacturing normal.

1.6 ROBOTICS REVOLUTIONIZE INDUSTRIAL AUTOMATION

Imagining the Possibility of

Predictive Maintenance

Refining business models and opening up new opportunities for companies in today’s

competitive atmosphere.

by Christine A. Frank, Industrial IoT Lead, Dell

PdM can help to identify a small problem early, which may result in saving you from a big one in the future.

Data is all around us. We now see things in data we never

dreamt possible, like allowing for greater insight into your machine or process of the when, where and how. Today, the buzz is

all around us about predictive maintenance (PdM) and the ways it

is helping companies achieve complete optimization and maximum profitability. It can be applied to planes, trains, automobiles,

manufacturing, oil and gas, utilities, hospitals, hotels or anything

that creates data. Operations Technology (OT) companies used

to focus on preventative maintenance (PM) which seemed like

a “good enough” approach. Or we would schedule downtime to

replace “things” that may or may not need to be replaced. We now

know that not only is this inefficient but it can cost as much as

40% more than a PdM approach.

Companies today are doing more with less -- less qualified

personnel, an aging workforce, expectations to increase profitability and speed up the supply chain. How can companies continue

to perform and outpace the competition if they aren’t looking at

the bottom line? We need to start utilizing the data from sensors,

actuators, etc. Running the assets into the ground is not efficient or

smart. A system failure at beer brewing manufacturer during peak

production before the Fourth of July for example would be cata-

strophic – up to $100,000 per hour catastrophic! And an example

like this could have easily been avoided by just applying PdM.

Collecting data from sensors, actuators and other “things” isn’t

anything new, but the opportunity in the analytics is what’s the

most exciting to me. We are currently working with SAP, and they

are providing customers real solutions to their big data needs by

offering interoperability to multiple systems across many business

units in real-time. Our Edge Gateways enable industrial users

to monitor and connect a wide variety of sensor and machine

data from equipment, like batteries and valves to smart analytic

systems. Through our work with SAP, that data can be stored in

SAP SQL Anywhere and intelligently streamed then processed in

SAP HANA. This allows users in remote sites, like the middle of

the ocean for oil and gas companies, to quickly recognize when

a piece of equipment is on the brink of malfunctioning before

negative business impact occurs.

The move to PdM isn’t going to happen overnight for every company, but knowing it’s possible and already happening is powerful.

PdM can help to identify a small problem early, which may result

in saving you from a big one in the future. Evolution takes time, but

data-driven innovation is here to stay! See diagram.

RTC Magazine FEBRUARY 2016 | 15

2.0 HUMAN-MACHINE-INTERACTION

The Human-Machine-Interaction

(HMI) market and technologies

by John Koon, Editor-In-Chief

Depends on your preference, HMI can mean human-machine-interface or human-machine-interaction. According to

Touch Display Research Inc., the HMI sensor market has grown

over the years. Revenue was $2 billion in 2006. It expects to hit

$36 billion by 2020. A market cannot be ignored. Dr. Colegrove

will go into details explaining the various types of technologies

16 | RTC Magazine FEBRUARY 2016

used and strategy recommendation. In this section, Renesas will

discuss the HMI design ideas and considerations. Atmel and Altia will share their insights on HMI. Finally, Indusoft (owned by

Schneider Electric) will present a case study on how HMI helped

a paper pulp company improve their performance.

2.1 HUMAN-MACHINE-INTERACTION

Touch and Touchless humanmachine-interaction (HMI)

sensor market

With touch panels becoming ubiquitous, the touch industry is also undergoing rapid

change. Touch Display Research Inc. constantly surveys all of the leading manufacturers in the touch screen industry, ITO replacement material industry and touchless

control suppliers, we analyze the market situation, identify the hot touch trends and

provide accurate market forecasts.

by Jennifer Colegrove, Ph.D. CEO and Principal Analyst, Touch Display Research Inc.

Introduction

The Touch panel market has been growing explosively since

2006. As the first industry analyst to write a comprehensive

touch screen industry report in 2006, I feel very fortunate to have

witnessed our touch screen engineers, technicians, and managers

grow our industry through hard work and constant innovation. In

spite of a global economic recession over the last couple of years

the market has continued to grow at handsome rate.

Touch Display Research forecast1 the touch module revenue will

reach $36 billion by 2020, from just $2 billion in 2006. See figure 1.

Touch screen suppliers, especially those projected capacitive

touch suppliers have been mostly profitable during 2007 and

2009. But fast forward to 2016, the competition is fierce, many

touch screen suppliers have encountered net losses or even went

bankrupt. New business strategies are needed to become a leader

or maintain a leadership position in today’s touch industry.

ITO-Replacement: Non-ITO

Transparent Conductors

ITO is still the mainstream transparent conductor used

on touch panels, however, due to the high cost, fragility, long

process steps, ITO-replacements have become one of the hot

trends. There are over 10 types of ITO replacement technologies; we have placed them into 6 categories: metal mesh, silver

nanowire, carbon nanotube, conductive polymer, graphene and

other transparent conductor technologies. In addition there are over 200

companies or research institutes that

are currently working on ITO-replacements2.

Each technology has its Pros and

Cons. There are many characteristics

to compare when choosing a transparent conductive material, sheet

resistance, transmissivity, conductivity, haze, optical appearance and cost

by way of example. Here we compare

cost and conductivity. See figure 2.

ITO-replacement, such as metal

mesh, silver nanowire could provide

touch sensor at lower cost, thinner,

lighter weight, higher conductivity

and larger size.

Touch Display Research forecasts

that

non-ITO transparent conductor

Figure 1: Touch Module Market Forecast. Source: Touch Display Research Inc, 2016.

RTC Magazine FEBRUARY 2016 | 17

2.1 HUMAN-MACHINE-INTERACTION

High

Conductivity

esh

tal M

Me

W

er N

Silv

Gra

phe

ITO

Low

Conductivity

ne

CNT

Conductive

Polymer

Source: Touch Display Research,

ITO-replacement report 2016

Research forecasts that the touchless HMI market will grow

rapidly in the next several years. There are many opportunities

for OEMs, ODMs, semiconductor companies, and software

companies.

Over 220 touchless sensor suppliers, system integrators, and

brand companies working on touchless HMI sensors. Camera-based gesture technology attracted 58 companies working

on it; 49 companies are active on motion sensor fusion; 30

companies are active on voice recognition. See figure 3.

High cost

Low cost

Figure 2: Comparison of ITO replacements, cost vs conductivity. Source: Touch

Display Research, ITO-replacement: non ITO transparent conductor technologies, supply chain and market forecast report, 2013, 2014, 2015 and 2016.

market revenue will reach $13 billion by 2023. However, not all

companies are growing and you need to be very selective.

Touchless Human-Machine-Interaction

(HMI) Sensor Market

Gesture-control, voice-recognition, eye-tracking and many

other touchless sensors provide the benefit of convenience,

safety, hygiene, authentication, fun and coolness. Touch Display

Figure 3: Touchless HMI Sensor Technologies and Companies. Source: Touch

Display Research, Touchless HMI Sensor Market 2015 Report, October 2015.

Setting the SWaP Standard in

Ethernet Switches

• COTS products for military

and industrial applications

• Managed, unmanaged

• MIL-STD 810, MIL-STD 461,

MIL-STD 1275, IP 67/68

• Up to 28 ports and 10 Gbps

• Advanced Network features

DISTRIBUTED BY

www.militaryethernet.com

www.middlecanyon.com • sales@middlecanyon.com • 408.718.7854

18 | RTC Magazine FEBRUARY 2016

Touch Display Research forecasts the touchless HMI sensor

market will reach $20 billion by 2016 and $44 billion by 2021.

See figure 4.

Summary and business strategy recommendations

The touch screen module market is forecasted to grow to $36

billion by 2020, from just $2 billion in 2006, which will throw up

many new opportunities in the fast changing touch industry:

We recommend metal mesh for simple design with large

volume, or pursue large format touch panels; silver nanowire for

display, lighting and EMI; and conductive polymer for EMI, anti–

static applications; Carbon NanoTube for mobile/wearable devices

with the benefits of flexibility, low reflections and low haze.

Touchless HMI, such as gesture-control, voice-recognition,

eye-tracking and many other touchless sensors provide the

benefit of convenience, safety, hygiene, authentication, fun and

coolness. We recommend touchless HMI sensors to automotive

industry, baby care/health care industry, and augmented reality

and virtual reality applications.

Figure 4: Touchless HMI Sensor Market forecast to 2021. Source: Touch Display Research, Touchless HMI Sensor Market Report, October 2015.

References

1. Touch Display Research Inc. Monthly report: “Touch and Emerging Display” report, 2014, 2015 and 2016

2. “ITO replacement: non ITO transparent conductor technologies, supply chain and market forecast” report, Touch Display Research Inc. 2013-2016.

3. “Touchless Human-Machine Interaction Sensor Market”, Touch Display Research Inc. 2013-2016

Plug and Play Ethernet

Switching and Routing

• COTS products for military

and industrial applications

• Managed, unmanaged

• Up to 28 ports and 10 Gbps

• Conformally coated

• Wide temperature range

complies to MIL-STD 810

• Carrier/evaluation boards

available

DISTRIBUTED BY

www.militaryethernet.com

www.middlecanyon.com • sales@middlecanyon.com • 408.718.7854

RTC Magazine FEBRUARY 2016 | 19

2.2

HUMAN-MACHINE-INTERACTION

Enhancing Embedded Designs

with HMI Displays

The ways in which users access and consume graphical data continues to evolve. The

display that is right for your particular design and the chipset that you need to implement it depends on the technical demands placed upon your product and the market

expectations within your target segment.

by David Olsen, Staff Product Marketing Manager, Renesas Electronics America Inc.

In the beginning…

Humans have always been compelled to record, display, and

transport information. It is thought that we started using papyrus scrolls - perhaps, the first mobile communications medium

- as far back as 4000 B.C. Today, the rollable, semi-transparent

organic LED (OLED) display screens used on advanced LED

television panels harken back to those ancient scrolls with a

notable similarity in form that suggests that a common thread

has been passed down through the millennia. That thread is the

desire to share information in an easy-to-understand way for the

reader (or “user”) and to make it portable. See Figure 1 (1 (a)

and 1 (b)

In today’s age of intelligent and sophisticated consumer

electronic media, does every embedded device need a digital

display, and if so what kind? Let’s explore some of the tradeoffs

that underlie these questions – questions that must be grappled

Figure 1a: Ancient Egyptian Book of the Dead papyrus scroll (~2000 B.C.).

20 | RTC Magazine FEBRUARY 2016

with by every embedded systems designer as they embark upon

a new project.

Evolution of Embedded Electronic Display

Technology

So the story goes, the designers of the Eniac [ref] – one of the

earliest electronic digital computers – felt no need to put any type

of display indicators on it. After all, why would you need anything

more than punch cards to convey output to the user? Eventually,

it was decided that neon tubes should be added to show the operators the values of the CPU registers to make it easier to debug programs. To this day, many modern devices have a similarly Spartan

display, often composed of nothing more than a bank of simple

LEDs. Cable modems, dishwashers, and many other appliances

are such examples.

As simple as the LED is - at least in terms of appearance and

function, the first digital LED watches had a lot of caché in their

Figure 1b: LG Display’s rollable OLED display panel. Source: LG Display

day – possibly just as much as a modern-day smart phone. A

Hamilton Pulsar P2 digital watch [ref] was even worn by none

other than James Bond – the undisputed spymaster of product

placement – in 1973’s “Live and Let Die,” causing a run on the

product after movie-goers realized that the technology was real

and not just a prop. See Figure 2

When commercially-available liquid crystal technology

emerged in the late 70’s, LED segment displays were eventually

replaced. Still, it was almost 20 years before mechanical buttons

could start being replaced by a practical touch-screen LCD display on industrial control panels and early electronic organizers.

Capacitive touch displays – which are considered “table stakes”

in any smart phone – did not start to make in-roads until

around 2007, the year that Apple released the first iPhone. Today, vivid high-definition LCD touch screens are becoming commonplace on everyday devices thermostats, washing machines,

and high-end refrigerators. As a result of the so-called “iPhone

effect,” consumers have recalibrated their expectations for what

they should expect in a user interface (UI). Nonetheless, there

still are certain classes of products for which a very simple UI is

still sufficient and effective.

Design Considerations

What should you be thinking about before introducing a

display into your product? Enhanced displays can certainly add

functionality, improve aesthetics, and help differentiate your product, warranting a higher price for it in the market. Nonetheless,

the display panel, associated circuitry, and design software will

introduce additional manufacturing cost.

For instance, external memory chips may be needed for the

graphics frame buffering. This will add cost to the bill of materials

(BOM) and necessitate additional voltage regulators and power

management integrated circuits (PMICs) on the printed circuit

board (PCB). More pins will also be needed to connect to the

memory device, which may require a larger chip, and additional

PCB layers will be needed to route all the signals. The display panel, itself, will add cost, as will the on-board LCD controller if one

is not included in your microcontroller (MCU) or microprocessor

(MPU). A good commercial graphics design tool should also be

Figure 2: LG Display’s rollable OLED display panel. Source: LG Display

considered to help implement the graphical user interface (GUI).

So, what do you do? It depends on the metric is your company

most interested in: profits or sales. Clearly, both are important,

but if your primary goal is top-line growth (i.e., sales), then you

must consider whether you will be able to charge more for the

added functionality you are bringing to the table. If your primary

metric is the bottom line (i.e. profit), then you have to pay very

careful attention to whether or not the presumed added sales will

offset your increased cost. Do you want to be seen as a technology

leader? If so, then you can’t afford to have a sub-standard UI.

Do you need to have a capacitive touch display or will something simpler do? The “pros” of a capacitive touch display are that

it looks great, feels high-end, brings familiarity in today’s smart

phone age, and adds the convenience of multi-touch and gesture

recognition. The “cons” include the cost adder that the capacitive

touch display brings to the system, a 10-15% decrease in luminance compared to a non-touch-sensitive display panel due to the

additional glass layers that the light must penetrate to reach the

user’s eye, the need for higher-powered back-lighting, and potential lifespan issues compared to a simple display.

What about a resistive touch? The pros are that it is tougher

and more robust than a capacitive touch screen; it has a tactile

feel; it can respond to implements like a fine point stylus, gloves,

or tools; it is better for hand-writing recognition than capacitive touch; and it is cheaper. The cons include the cost adder

LCD DISPLAY TYPE

PROS

CONS

Capacitive touch

•Good Looks

•High-End Feel

•Familiarity

•Utility

•Higher Cost

•Decreased Luminance

•Higher Power And Shorter Lifespan Than Non-Touch Display

Resistive Touch

•Tougher and cheaper than capacitive Touch displays

•Provides tactile feel

•Can use any implement to write on it

•Good hand-writing recognition

•Higher cost than mechanical buttons

•Slower responsiveness and lower image quality than capacitive touch

•Decreased luminance, higher power and shorter lifespan than non-touch

display

Non-Touch

•Sharp image quality

•Long life-span

•Inexpensive

•Requires mechanical button interface to interact with system

•Not considered “new”

technology

Segment

•Inexpensive

•Very low power

•Limited flexibility

Table 1: LCD display comparison landscape. Source: Renesas Electronics America Inc.

RTC Magazine FEBRUARY 2016 | 21

2.2

HUMAN-MACHINE-INTERACTION

vs. mechanical buttons, slower responsiveness than capacitive

touch, an approximately 20% reduction in display luminance vs.

a non-touch screen, and it is considered “old” technology. That

said, many modern airplane cabins use a resistive touchscreen

in-flight entertainment system, which makes for a very enjoyable and usable product.

Let’s not forget about segment displays. They are cost effective,

ultra-low power, and very simple even though they have somewhat limited use. Then again, digital triathlon watches, fitness

monitors, and electronic multi-meters have segment displays, and

they are perfectly well-matched to the job at hand. And, you rarely

need to change the batteries. See Table 1

How to Select the Right

Hardware

provides microcontrollers (MCUs) and microprocessors (MPUs)

that can be used in platforms with wide-ranging complexity, from

driving simple segment LCD displays (e.g., with the RL78 MCUs),

to basic- and medium-resolution displays (using the RX MCU and

Renesas Synergy™ Platform), to WXGA displays buffered entirely

out of high-speed on-chip SRAM (with RZ/A MPUs), all the way

to 1080p displays (with the RZ/G families of MPUs with DDR3

memory controllers, 3D graphics accelerators, and video codecs).

Plus, they work with a variety of operating systems and middleware to simplify your design implementation process. See Figure 3

The Future of HMI Displays

While you are wrestling with today’s human machine interface

(HMI) design challenges, you probably want to keep one eye

There are several questions to consider:

•W

hat is the problem you are trying

to solve?

•W

hat specifications are required to

achieve your functional goals?

•W

hat are your customers’ expectations

for a product in this market (in terms of

screen resolution, 2D/3D graphics, need

for video decompression, etc.)?

•A

re there any other special restrictions in

terms form factor, power dissipation, etc.?

Armed with those answers, you can look

to the major semiconductor vendors to assess

whether their product line-up maps to your

product roadmap. As an example, Renesas

Figure 3: An example of the representative display capabilities by various Renesas semiconductor

devices. Source: Renesas Electronics America Inc.

DevicePort Ethernet enabled Port Replicator

“A game changing solution, simplifies your I/O system.”

・ Quick Expansion

・ Easy Maintenance

◆ SUNIX Patented Powered COM Design

• USA 12/761,408

• China 200910054897.5

• Taiwan 91000303

◆ Data Buffer When Ethernet Disconnected

Dat

Pin 9

Barcode scanner

5V

・ I/O Redirection

・ Cost Saving

Card Reader

Bank VM management

22 | RTC Magazine FEBRUARY 2016

Supermarket checkout

◆ Permission Management Keeps System Secured

Password:

a

DevicePort

Manager

PC

Fits various commercial system structures

Post office front desk

・ COM Off-Line Mapping

・ Powered COM Feature

Small retailer counter

DevicePort in

local area network

Medical facility solution

Access point

PC with

10/100 ethernet

Factory automation

Entrance management

on where things are going, too. Trends in HMI include open-air

hand-gesture recognition, heads-up projection with pre-distortion

to map flat images onto curved surfaces, holographic projection,

flexible, wearable displays, microelectromechanical systems

(MEMS), as well as highly ergonomic free-form transparent

displays. Free-form displays also hold a lot of promise, wherein

transparent compound semiconductors, like IGZO (indium gallium zinc oxide) can be shaped into a variety of configurations to

minimize use of materials and improve aesthetics and functionality. With this technology, there is the potential to embed electronic

displays into everyday things like windows

and bathroom vanity mirrors so that you can

read the news or check the weather while

brushing your teeth before work.

tations within your target segment. While today’s technologies

are harbingers of further integration of displays into things like

clothing, mirrors, car bodies and dashboards, will customers be

willing to pay more for an enhanced and more attractive UI? It

still all comes down to customer tastes and preferences, availability of competing products, and the price, quality and brand name

of your product.

High-Performance, High-Speed

FPGA Computing

And In the End…

The display that is right for your design

and the chipset that you need to implement

it depends on the technical demands placed

upon your product and the market expec-

acromag.com/FPGAs

RTC

PRODUCT

GALLERY

XMC Modules Feature

Xilinx® Artix®-7 FPGA

Acromag’s high-performance XMC & PMC

FPGA modules feature a user-customizable

Xilinx® FPGA. These modules allow you

to develop and store your own instruction

sets in the FPGA for a variety of adaptive

computing applications.

▪ High-speed serial interface on rear P15

connector for PCIe Gen 1/2 (standard),

Serial RapidI/O, 10Gb Ethernet,

Xilinx® Aurora

Select from several models with up to

410K logic cells optimized for logic, DSP,

or PowerPC. The high-speed memory

and fast bus interfaces rapidly move data.

▪ High-speed interfaces on rear P16

connector for customer-installed soft cores

An FPGA engineering design kit and

software utilities with examples

simplify your programming and

get you started quickly.

▪ DMA support provides data transfer

between system memory and the

on-board memory

•Two versions: plug-in I/O, conduction-cooled

•Reconfigurable Artix®-7 FPGA, 200k logic cells

•Quad DDR3 SDRAM 128M x 16-bit

▪ 32M x 16-bit parallel flash memory for

MicroBlaze® FPGA program code storage

▪ 34 SelectI/O or 17 LVDS pairs plus 2 global

clock pairs direct to FPGA via rear P16 port

▪ Support for Xilinx® ChipScope™

Pro interface

Embedded Computing & I/O Solutions

•32M x 16-bit parallel flash memory for MicroBlaze™

FPGA program code storage

•4-lane high-speed serial interface for PCIe

Acromag

Phone: (877) 295-7085

FAX: 248-624-9234

Email: solutions@acromag.com

Web: www.acromag.com

VPX Carriers

I/O Modules

VME SBCs

SFF Embedded Computers

www.acromag.com • solutions@acromag.com • 877-295-7085

RTC Magazine FEBRUARY 2016 | 23

2.3 HUMAN-MACHINE-INTERACTION

Give Me What I Want

(Not What I Asked For)

The key to great relationships is communication. When it comes to mass market

devices, there is no relationship that’s more important that the one between your

product and its user – and the place where the user communicates with your

product is its human-machine-interface (HMI).

by Jason Williamson, Altia, Inc.

24 | RTC Magazine FEBRUARY 2016

When designing HMIs for the mass market, getting the HMI

right is critical to a lasting relationship with its users – the

mass market – which is the ultimate test of product success.

When it comes to designing the HMI, however, miscommunication between the various members of a development team

– software engineers, hardware engineers, artists, usability

experts and all the rest – is especially common. In this article,

we’ll discuss the most common – and avoidable – miscommunication pitfalls that HMI teams run into all the time.

Not knowing what you have –

until it’s too late

It’s all too common that a hardware prototype that comes

out at the end of engineering development is the first time that

engineers, designers and stakeholders get their hands on the

concept. At this stage it’s usually far too late and too expensive

to go back and fix the performance, appearance or usability

problems that unfailingly arise with Product 1.0. This is the

reason why you end up seeing so many products that make

you scratch your head and say, “Now why in the world did they

do it that way?” HMI teams need to have a working model – on actual embedded hardware – in the first stage of the

development process. Getting on hardware early is one of the

primary advantages of using an end-to-end development tool.

Not getting customer feedback early –

and often

Once teams have a realistic working model, they must

use that model to get the concept in front of a wide range of

potential customers. PC-based computer simulations offer an

excellent early-feedback ecosystem. However, there is no substitute for getting real touchscreens and embedded processors

into your tests. Problems like reactivity, latency, hard-to-read

iconography and more can really start to emerge once all the

pieces are in place.

Using words to describe graphics

and behaviors

We’ve all seen HMI specification documents that are as long

as War and Peace. You have to get pretty wordy when you’re

describing an animated, interactive user interface with all of

the aspects needed to thrill and captivate users. Inevitably

there are things you just don’t capture – or can’t fully think

through – until you see it and try it out firsthand. Naturally,

being able to mock up interactive concepts that demonstrate

the behavior is an invaluable supplement to any written specification. Plus, wouldn’t it be great if you could use those conceptual models all the way through the development process…

and into production?

the areas where misunderstandings and omissions most often

creep in. The design starts out one way and gradually morphs

into an unrecognizable failure by project’s end. Additionally,

sometimes it isn’t just a misinterpretation of the specification.

Depending on the capabilities of the tools used in each of the

project’s phases, it’s not uncommon that the assets cannot be

duplicated exactly. What’s more, there could be a host of limitations to consider with respect to memory, display and processor speed. For example, when a software engineer approach

the design without knowing the real capability of the hardware

platform, it is possible to deliver a system that the embedded

“Inevitably there are things

you just don’t capture – or

can’t fully think through –

until you see it and try it out

firsthand.”

hardware cannot support. As development progresses and

hardware specifications become more available, piecemeal

tradeoffs are made all along the chain. It’s imperative that the

tool chain is available to the various members of the team to

allow those assets to be carried forward for the sake of fidelity

as well as shortening the development time.

For clear communication and a better HMI,

a model is key

Behavior specifications, hardware requirements and limitations, user experience, software design, system integration

– these are just a few of the many important components of

HMI design that can result in a tangled mess in the product

development process if the people involved aren’t communicating successfully. A working model – developed with a

model-based development tool – is the best way to facilitate

the communication required and at the end deliver a successful HMI that customers will want.

Re-creating assets from group to group

Carrying assets through development and into production

is exactly what effective HMI development teams do when

they’re armed with the right tool. Re-creating assets in a

variety of different tools isn’t just a waste of time – it’s one of

RTC Magazine FEBRUARY 2016 | 25

2.4 HUMAN-MACHINE-INTERACTION

The Future of HMI:

Integrate or Die

Touchscreen HMI trends typically start with smartphones and then follow behind for

nearly all electronic devices. The current trend is touch sensor integration that leads to

thinner, lighter devices, clearer optics, and innovative new capabilities.

by Patrick Hanley, Atmel Corporation

Touchscreens are the heart of today’s human-machine interface

(HMI), and the future can be summed up in three little words:

integrate or die. Touchscreen HMI for nearly any application is

driven by smartphones, with continuing demand for thinner

designs, lighter weight, and clearer optics, as well as features such

as moisture immunity, stylus capability, and narrow bezels. These

features—and future demands on LCD—are being accomplished

through display integration that reduces the number of layers in

the total stack-up, typically using one of three common implementations: on-cell, hybrid in-cell, or full in-cell. See figure1.

Single Layer On-Cell (SLOC) combines the touch transmit (Tx)

and touch receive (Rx) functionality on the top side of the color

filter glass and under the cover glass. (Figure 1 shows options on

where the touch sensor can be integrated within the stack-up.)

This approach has been widely adopted for both handsets and

larger formats such as tablets and other embedded applications.

Advantages include the ability to create bezel-less designs due to

more efficient routing from the touch controller, as well as lighter

weight due to the compressed sensor stack. However, the design is

more complex than a traditional out-cell or discrete touch display,

so is typically more expensive.

A continuation of this display integration effort is the hybrid

in-cell approach. This offers partial touch integration with Tx

functionality within the LCD stack-up, but leaves Rx outside

the LCD stack-up. The total stack is therefore reduced, offering

improvements in thickness and weight, but hybrid in-cell adds

more complexity for display manufacturers and OEMs. Hybrid

in-cell is unlikely to be widely used for larger format displays, and

OEMs who aren’t currently invested in this approach may choose

to make the jump to full in-cell implementation.

The future of HMI is being manifested in flagship smartphone

handsets that use full in-cell implementation, which is currently

available from a limited number of display manufacturers. This

approach embeds both the Tx and Rx electrodes inside the display

on the TFT backplane, directly on the VCOM, and eliminating

the need for an independent touch sensor layer. The result is a

thinner, lighter display with increased clarity due to fewer stackup layers. While in-cell implementation adds manufacturing

complexity, the reduction in sensor layers helps reduce overall

costs. However, timing limitations between the display and touch

sensor mean this approach is available today only for smaller

screen sizes.

Future high-end HMI applications will demand integrated

in-cell capability for large and high-resolution displays, which will

require innovative new touch controller technologies that address

shared timing limitations. And these applications will incorporate

leading-edge integrated sensor capabilities such as touch classification detection that automatically adjusts for environmental and

usage requirements such as the presence of moisture or the use of

glove or stylus.

Figure 1

The Atmel® maXTouch® controller offers

on-cell and in-cell capabilities for a range

of discrete or integrated implementations, which can be incorporated within

different layers of a typical LCD stack-up.

26 | RTC Magazine FEBRUARY 2016

2.5 HUMAN-MACHINE-INTERACTION

Case Study: InduSoft Web

Studio Brings HMI Innovations

to Paper Winding Machine

Eletrônica KGEL needed a better, more intuitive interface for a paper winding machine and

chose InduSoft web Studio for a new HMI with a ‘Friendly’ interface. The new interface

has not only increased the efficiency of the machine, but the techniques used to develop

the project have already been applied to other interface designs for Eletrônica KGEL.

by Melinda Corley, InduSoft

Eletrônica KGEL in Brazil was tasked with designing the

interface for a paper winding machine badly in need of a friendlier supervisory system that could be applied to countless new

customers in the pulp and paper industry.

The HERGEN 1200m/min (Tissue) with WEG commands

used a 10’’ color HMI with RS485 serial communication. After

10 years of use, the HMI faced problems with the touchscreen

features that resulted in the loss of information. The machine

was difficult to use for both operators and maintenance personnel, and many hours were lost during production due to the

sluggish interface. The machine could not monitor individual

users, and operators often could not retrieve data.

Eletrônica KGEL started development on an HMI to replace the old one, but due to high prices, began searching for

alternatives that would keep the project within the budget. After

researching solutions to replace the HMI, Eletrônica KGEL

discovered InduSoft Web Studio, which had a native communication driver with the CL200 PLC.

The Challenge

A new, intuitive interface was a requirement for the project.

One aspect that already worked well was the HMI touchscreen

feature. They designed a system using the Panel PC that supported the touchscreen interface system, processing, and refrigeration in one single panel. With the design and the project budget

Figure 1: Touch Module

Market Forecast. Source:

Touch Display Research Inc,

2016.

RTC Magazine FEBRUARY 2016 | 27

2.5 HUMAN-MACHINE-INTERACTION

finalized, they were able to present a cost effective and powerful

multi-touch HMI solution.

The Solution

The project was divided into the HMI application and the construction of the panel. Eletrônica KGEL recognized that the project could be improved beyond a simple retrofit of the previous

application. They decided that it would be a waste of investment

to use software like InduSoft Web Studio without taking full

advantage of its potential. With all the InduSoft documentation

and online information, they were able to quickly implement

many of the features in the HMI software.

The landing screen has operator commands and basic

information. The machine has push-button control, leaving the

HMI with only with a few commands. On the main screen the

operator has important information, such as the status of the

drivers, machine status, and machine speed, among others. The

main menu gives access to submenus.

They created an option for operation maintenance. For example, if the operator tried to enable the machine but it failed, the

operator can click on “Enable Machine”. When the operator does

that, a screen full of information regarding the issue appears. It

is also possible to know who shut down the command to enable

the machine. The operator can also click the alarm list, where

all errors of the machine are registered. In addition to the diagnostics, the operator can load a notepad to write tips to other

machine operators in case a similar error occurs.

The Results

After some on-site testing, Eletrônica KGEL realized the

implementation of the HMI application could be used in other

applications. They collected the necessary information to begin

the development of a new, improved project that uses the same

concepts for industrial machine interfaces using InduSoft Web

Studio. They began creating an application prototype that could

be offered to other KGEL customers.

The machine using the InduSoft Web Studio HMI is now easy

to operate, and maintenance is much easier, which has improved

the machine functionality and uptime dramatically.

Rugged Rack Server Storage

at a Very Exceptional Value.

Benefit from proven server design, manufacturing and delivery

experience to support your organization’s data-center computing

needs and total-cost-of-ownership (TCO) objectives.

Middle Canyon 2U rack-mount server leverages modular-design

principles to provide a robust, highly-configurable and energyefficient platform.

Middle Canyon’s server products incorporate the latest processor,

memory and storage technology with thermally-optimized

mechanical designs and advanced power solutions to increase your

organization’s networking performance and energy efficiency.

your fast, flexible and responsive partner.

13469 Middle Canyon Rd., Carmel Valley, CA 93924

sales@middlecanyon.com • www.middlecanyon.com

28 | RTC Magazine FEBRUARY 2016

Made in

the USA

“GRAND” 2U RACK MOUNT SERVER

• Dual Intel® Xeon® E5-2600 v3 series (Haswell-EP)

• Memory Slots: 16 DDR4 RDIMM / LRDIMM / UDIMM up to 2133 MHz

• Intel® C610 (Wellsburg) PCH Platform Controller Hub

• Expansion Slots: 4 PCI-E 3.0 x8 Full-Height Half-Length via riser slots OR

2 PCI-E 3.0 x16 (x16 mechanical) Full-Height Half-Length via riser slots,

1 PCI-E 3.0 x8 mezzanine slot

• Up to 12 Hot-Swap 3.5” SAS/SATA rotational or solid state drives OR Up

to 24 Hot-Swap 2.5” SAS/SATA rotational or solid state drives

For a full description/capabilities check out www.middlecanyon.com

Embedded/IoT Solutions

Connecting the Intelligent World from Devices to the Cloud

Long Life Cycle · High-Efficiency · Compact Form Factor · High Performance · Global Services · IoT

IoT Gateway

Solutions

Compact Embedded

Server Appliance

Network, Security

Appliances

High Performance /

IPC Solution

E100-8Q

SYS-5028A-TN4

SYS-5018A-FTN4 (Front I/O)

SYS-6018R-TD (Rear I/O)

Cold Storage

4U Top-Loading 60-Bay Server and

90-Bay Dual Expander JBODs

Front and Rear Views

SYS-5018A-AR12L

SC946ED (shown)

SC846S

• Low Power Intel® Quark™, Intel® Core™ processor family, and

High Performance Intel® Xeon® processors

• Standard Form Factor and High Performance Motherboards

• Optimized Short-Depth Industrial Rackmount Platforms

• Energy Efficient Titanium - Gold Level Power Supplies

• Fully Optimized SuperServers Ready to Deploy Solutions

• Remote Management by IPMI or Intel® AMT

• Worldwide Service with Extended Product Life Cycle Support

• Optimized for Embedded Applications

Learn more at www.supermicro.com/embedded

© Super Micro Computer, Inc. Specifications subject to change without notice.

Intel, the Intel logo, Intel Core, Intel Quark, Xeon, and Xeon Inside are trademarks or registered trademarks of Intel Corporation in the U.S. and/or other countries.

All other brands and names are the property of their respective owners.

RTC Magazine FEBRUARY 2016 | 29

3.0 SURVEY OF EMBEDDED TECHNOLOGIES

Figure 1: AMD’s new secret weapon - 3rd generation G-series products offer 4K multimedia capability with scalable and optimized performance.

Leading Embedded Manufacturers

Provide Clues of the Future

by John Koon, Editor-In-Chief

Embedded Technologies are in constant flux. Not only more emphasis is put on Internet-of-Things, companies are constantly shifting

gears to adjust to the new marketing dynamics. For example, AMD

is making a lot of pre-announcements on products to be introduced

at Embedded World (Feb 2016) in Nuremburg, Germany while

Intel is rather quiet. AMD introduced the 3rd generation embedded

G-series SoC with new optimized graphics and computation power.

It is scalable and supports the 4K multimedia requirements. The dual

channel OOR4 memory has built-in error-correction code (ECC)

enhancement. Let us see what additional market share this series will

bring AMD. (Figure 1).

30 | RTC Magazine FEBRUARY 2016

At the recent Embedded Tech Trends meeting, I caught up with a

few leading suppliers in the embedded space to get a sense where the

market is heading. In the following reports, 4DSP, Concurrent Technologies, Elma, LCR, MEN Micro, ReflectPhotonics and VersaLogic

will discuss their latest developments.

3.1 SURVEY OF EMBEDDED TECHNOLOGIES

SWaP Systems Leveraging FMC’s

Bring the Latest Technology to

the DoD

Low power and high performance ruggedized platforms are not only made possible by

advances in technology but also by the smart use of industry standards. The DoD benefits greatly from the associated costs and time savings.

by Pierrick Vulliez, 4DSP

The increasing demand for embedded computing systems to

power intelligence, surveillance, and reconnaissance (ISR) applications as well as Electronic Warfare (EW) solutions is driving

the need for the rapid prototyping and deployment of reconfigurable COTS (commercial off-the-shelf) hardware platforms that

combine high performance and flexibility. There are a number of

ways of implementing advanced solutions to serve the needs of

airborne ISR and EW processing applications but manufacturers

are required to develop lighter and more compact solutions that

deliver an increased level of performance while constrained by

Size, Weight and Power (SWaP) profiles. It is therefore essential

that the embedded sensor processing subsystems that must contend with the greatly increased volumes of data being collected

by these sensors take advantage of both the parallel computing

resources offered by low-power and efficient FPGAs and the

capabilities of modern ADCs packaged in small form factors

such as the FPGA Mezzanine Card (FMC – VITA 57.1). When

combined with high-performance wideband or GHz-capable

ADCs, FPGAs are essential to digitizing the analog input from a

sensor and then processing the acquired data stream.

A flexible FPGA-based architecture in a compact size such as

the 4DSP CESCC820 (VITA 75) can be combined with the latest

Figure 1

The CESCC820 (Compact Embedded System) is a ruggedized, small form factor

embedded system designed to provide a complete and generic processing

platform for data acquisition, signal processing, and communication.

Figure 2

The FMC432 is a dual 10 Gigabit

Ethernet (10GBASE-T) FPGA

Mezzanine Card with two RJ45

connectors available on the front

panel.

in wideband ADCs and high-speed, high-resolution DACs and

10Gb Ethernet digital communication on FPGA Mezzanine

Cards ( FMC - VITA 57). The CESCC820 is a ruggedized, small

form factor embedded system designed to provide a complete

and generic processing platform for data acquisition, signal processing, and communication. With a low power Intel CPU and a

high performance Xilinx Ultrascale FPGA, the CESCC820 flexibility is greatly enhanced by the ability to select I/O functionality from a wide range of FMCs. They provide a standard form

factor and modular interface to the FPGA and offer the best I/O

approach outside of a monolithic solution by leveraging a consistent FPGA and CPU baseline system architecture. FMCs can

be selected as needed to build an ultra-high-speed analog transceiver to handle both low-latency signal processing in either air

or conduction-cooled configurations while also handling data

movement functions. Such a configuration offers a high level of

flexibility, as subsystems can be simply upgraded over time with

new technology as it becomes available. The 4DSP FMC product

line, with its wide range of digital and analog I/O, enable system