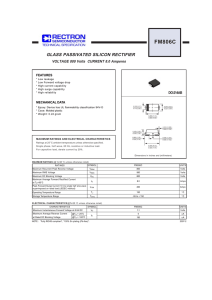

SINGLE-PHASE BRIDGE RECTIFIER KBPC35005 THRU

advertisement

MEI KBPC35005 MB3505 Lead Free RoHS Compliant THRU THRU SINGLE-PHASE BRIDGE RECTIFIER VOLTAGE RANGE KBPC3510 MB3510 CURRENT 50 to 1000 Volts 35 Ampere FEATURES Low cost This series is UL recognized High forward surge current capability Integrally molded heatsink provide very low thermal resistance. High isolation voltage from case to lugs. High temperature soldering guaranteed: 260°C/10 second, at 5 lbs. (2.3kg) tension. · · MECHANICAL DATA Case: Metal case Terminal: Plated 0.25" (6.35mm) lug. Polarity: Polarity symbols marked on case. Mounting: Thru hole for #10 screw, 20 in,- lbs. Torqute Max. Weight: 1.02 ounce, 29gram MAXIMUM RATINGS AND ELECTRICAL CHARACTERISTICS Ratings at 25 ambient temperature unless otherwise specified Single phase, half wave, 60Hz, resistive or inductive load. For capacitive load derate current by 20% Maximum Repetitive Peak Reverse Voltage Maximum RMS Voltage Maximum DC Blocking Voltage Maximum Average Forward Rectified Output Current, at TC = 50 (Note 1,2) Peak Forward Surge Current 8.3ms single half sine - wave superimposed on rated load (JEDEC method ) Rating for Fusing (t<8.3ms) Maximum Instantaneous Forward Voltage Drop per bridge element at 17.5A Maximum DC Reverse Current at rated TA = 25 DC blocking voltage per element TA Isolation Voltage from case to lugs. Typical Thermal Resistance (Note 1,2) Operating Temperature Range Storage Temperature Range KBPC KBPC KBPC KBPC KBPC KBPC KBPC SYMBOLS 35005 3501 3502 3504 3506 3508 3510 UNIT MB3505 MB351 MB352 MB354 MB356 MB358 MB3510 VRRM Volts VRMS Volts VDC Volts I(AV) Amps IFSM Amps It 2 As VF Volts 2.0 (-65 to +150) (-65 to +150) A mA VAC /W IR VISO R TJ TSTG 1. Unit mounted on 9" X 3.5" X 4.6" (23cm X 9cm X 11.8cm)Al. finned Plate. 2. Bolt down on heat-sink with silicon thermal compound between bridge and mounting sutfae for maximum heat transfer efficiency with # 10 screw. 2 MEI Lead Free RoHS Compliant KBPC35005 MB3505 RATINGS AND CHARACTERISTIC CURVES FIG.1-DERATING CURVE FOR FIG.2-MAXIMUM NON-REPETITIVE PEAK OUTPUT RECTIFIED CURRENT FORWARD SURGE CURRENT PER ELEMENT 35 700 Heat Sink Mounting CURRENT,(A) 9"X 3.5"X 4.6" Thick (23 X 9 X 11.8cm) 20 AL.Finned Plate Single Phase Half Wave 60Hz 10 Inductive or Resistive 600 8.3ms Single Half Sine-Wave Tj (JEDEC Method) =T j max 500 CURRENT, (A) PEAK FORWARD SURGE 30 AVERAGE FORWARD OUTPUT KBPC3510 THRU MB3510 1 Cycle 400 300 200 100 Load 0 1 0 0 25 50 75 125 100 150 2 4 6 8 10 20 40 60 100 175 NUMBER OF CYCLES AT 60 Hz CASE TEMPERATURE, ( ° C) CHARACTERISTICS FIG.4-TYPICAL REVERSE FIG.3-TYPICAL FORWARD CHARACTERISTICS PER BRIDGE ELEMENT PER BRIDGE ELEMENT 100 100 1.0 Tj =25 ° C Pulse Width=300uS 1%Duty Cycle 0.1 10 (uA) INSTANTANEOUS REVERSE CURRENT, 10 (A) INSTANTANEOUS FORWARD CURRENT, Tj =100 ° C 1.0 Tj =25 ° C 0.1 0.01 0.01 0.4 0.6 1.0 0.8 1.2 1.4 1.6 1.8 60 40 20 0 120 100 80 PERCENT OF RATED PEAK INSTANTANEOUS FORWARD VOLTAGE,(V) REVERSE VOLTAGE,(%) FIG.6-MAXIMUM POWER DISSIPATION FIG.5-TYPICAL JUNCTION CAPACITANCE PER BRIDGE ELEMENT 100 T j=25 ° C f=1MHz V sig =50mV p-p 10 0.1 1.0 10 REVRESE VOLTAGE,(V) 100 80 (W) 100 AVERAGE POWER DISSIPATION OF BRIDGE, JUNCTION CAPACITANCE,(pF) 1000 Tj =T j max 60 Capacitive Load 40 Resistive or Inductive 20 Load 0 0 5 10 15 20 25 30 AVERAGE OUTPUT CURRENT, (A) 35 140