gicc project write-ups - lighting phase 1

advertisement

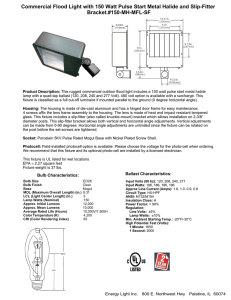

ATTACHMENT A GICC Detailed Project/ECM Write-Ups Lighting - Phase 1 LIGHTING SYSTEMS ECM GICC-14 Four-Foot T8 Fluorescent Lamp Upgrade Existing Conditions: Lighting throughout select areas within the facility includes four-foot, 32-watt T8 fluorescent lamps and standard-powered electronic ballasts. These lamps are located within a variety of fixture types, but predominantly four-foot troffers, with lamp quantities ranging from one to four. The predominant T8 lamp is a Philips Alto II F32T8/TL735 PLUS with the predominant ballast a Philips Advance Centium ICN. Other ballasts are used and most all ballasts surveyed are compatible with lower wattage T8 lamps. Fixtures utilizing 32-watt T8 lamps are located in the following general areas: • • • • Administration Kitchen Back of House Miscellaneous Support Areas Operational hours vary based on space utilization. Light levels also vary based on application with many within acceptable standards. Fixture Input Wattages vary based on various lamp-ballast combinations. The following table lists input power for each lamp-ballast combination based on Advance (Philips) ballasts. No. Lamps One-Lamp Two-Lamp Three-Lamp Four-Lamp Input Wattage 29 56 85 111 The standard fluorescent T8 lighting system—once the model of efficiency, can itself be upgraded with newer, more efficient T8 lamp and ballast options. Newer T8 systems can offer other advantages, including longer lamp life, better lumen maintenance and higher color rendering capability. Savings often come as a result of acceptable lower light levels; however this analysis and utilization of the Philips ballast appears to result in a light level reduction on only a few percent. Recommendation: This project proposes replacing the existing 32-watt T8 lamps with comparable new 28-watt T8 lamps. The proposed lamp is a Philips F32T8/ADV841/EW/LL ALTO 28W. It should be noted that these lamps may reduce light levels slightly and can be more expensive than the typical 32-watt lamp. This project is based on the existing ballasts being compatible with the 28-watt lamps and that the 28-watt lamps can be retrofitted into the existing fixtures. This appears to be the case after site investigations and the 28-watt lamp exhibits the lowest life-cycle cost. Per the ballast manufacturer’s specifications, the electronic ballasts currently used for the 32-watt lamps will operate with the 28-watt T8 lamps and will consume the following input wattages: No. Lamps One-Lamp Two-Lamp Three-Lamp Four-Lamp Input Wattage 26 48 73 94 Savings (watts) (Per Fixture) 3 8 12 17 To meet GICC energy reduction goals with regards to LEED certification, this project recommends the immediate replacement of the 32-watt lamps. The construction costs assume this is done with sub-contract labor. The resulting 32-watt lamps can be used in other City of College Park facilities at their discretion. No salvage value is accounted for and costs do include disposal costs. The scope includes about 850 fixtures. ECM GICC-15 Par 38 LED Lamp Retrofit Existing Conditions: Lighting throughout select areas within the facility includes various PAR lamps. PAR stands for “parabolic aluminized reflector” and they are designed to control light more precisely (i.e. track/spot light or recessed). The number represents the diameter of the bulb in 1⁄8 of an inch. PAR 30 and PAR 38 lamps are utilized in fixture designations AB, AD, and AH. They are located primarily in the meeting rooms as well as the green rooms and certain conference rooms. Operational hours vary based on space utilization. Light levels are not as significant as these lights are intended more for accent than full illumination. The following table lists input power for each PAR lamp observed: Lamps PAR 30 PAR 30 PAR 38 Input Wattage 50 75 90 There are an estimated 372 PAR type lamps surveyed; primarily of halogen type. Recommendation: This project proposes replacing the various PAR lamps with LED equivalents. The proposed lamps will replace the existing lamps one-for-one and will simply screw-in the existing fixture. The following lamp retrofits are proposed: Lamp Existing Wattage Proposed Wattage Savings (watts) (Per Fixture) PAR 30 PAR 30 PAR 38 50 75 90 13 13 18 37 52 72 To meet GICC energy reduction goals with regards to LEED certification, this project recommends the immediate replacement of the PAR lamps. The construction costs assume this is done with sub-contract labor. The remaining PAR lamps can be used in other City of College Park facilities at their discretion. No salvage value is accounted for and costs do include disposal costs. ECM GICC-18 Surface Parking Lot and Exterior Lighting Retrofit Existing Conditions: Exterior lighting, including a 596,000 sq ft surface parking lot, consists of a variety of fluorescent and metal halide type fixtures. The surface parking lot includes two distinct fixtures utilizing single and double head pole lights with 8" side arms. Each head uses a 400-watt metal halide lamp with 23,500 mean rated vertical lumens and CCT of 4000. The delivered lumens are estimated at about 70% or 16,450. The main loading dock is lighted by 250-watt high bay metal halide fixtures. The 250W MH lamp is rated for initial/mean vertical lumens of 20,800/13,500, respectively, at a color temperature of 4200K and CRI of 65. The high bay fixture has a light loss factor of 0.54. The loading dock also includes wall mounted flood light fixtures designed to shine inside the trucks when loading and unloading. They were originally designed with a 1000-watt T3 halogen lamp but appear to have been downsized to utilize a 500-watt halogen T3 lamp. The 500W T3 lamp is rated for 11,000 initial lumens at a color temperature of 3000K. It is estimated that these lights are illuminated with the other general loading dock lights as they appear to be switched at a panel. Exhibit Storage and the Chiller Plant Building include 175W wall-pack. The wall packs located on the storage building are on a photocell while the chiller building exterior lighting is switched. The operating hours of the photocell lights can be accurately predicted but those on the chiller plant, unless added to a timer, should have their operating hours confirmed with GICC personnel. The 175W MH lamp is rated for initial/mean vertical lumens of 13,000/8400, respectively, at a color temperature of 3600K and CRI of 70. The existing lighting fixture efficiency is estimated near 50%. Other site lighting includes a curved pole, double-head fixture, bollard lights, and grade mounted accent or flood lights. The curved pole lights utilize two, 150W T6 ceramic metal halide lamps. These T6 lamps are rated at 13,200 initial lumens and 8900 to 9600 mean lumens with electronic metal halide ballast. The bollard lights utilize 35W CMH T6 lamps. The on-grade floodlights utilize 250W metal halide lamps with total initial lumens of 21,000 (estimated CU=0.598) and color temperature of 4200K. Using average hourly weather data for Atlanta, it is estimated that the sun is “down” 4007 hours per year. This value was used to estimate the operating hours of most exterior fixtures on time clocks or day light sensors. Existing fixtures and their proposed retrofits are summarized in the table below under “Recommendation”. Recommendation: This project proposes replacing various exterior lighting fixtures/lamps with energy savings retrofits; primarily LED. The parking lot fixture manufacturer has a direct LED replacement for the existing metal halide types. To match the delivered mean lumens (16,450) and brightness (4000K), a nominal 188-watt LED fixture (16,390 lumens) is proposed with Type III distribution pattern. Final photometric analysis can confirm the wattage and accommodate GICC preferences on light levels. The loading dock high bay fixtures will be replaced with a 100W LED equivalent fixture. The loading dock flood lights will be replaced with LED types similar to Maxlite Model ELLF135UW50. This fixture can be provided as a bright 5000K or softer 2700K. The 5000K fixture is estimated but should be confirmed in final lighting design with GICC personnel. The fixture is rated at up to 12,400 delivered lumens matching that of the existing fixture. The 175W wall packs will be replaced by equivalent nominal 60W LED fixtures. The 250W surface/grade floodlight replacement is more complex. The high light output of the existing metal halide lamp is matched by a 166W equivalent LED. The same fixture manufacturer has a LED replacement; however, the replacement fixture is wider. The existing fastener spacing of the existing ballast box is 18.25” and it is mounted on a concrete pad only an inch or two wider. The new replacement fixture is just over 24” wide yet its mounting plate should fit on the existing concrete pad. Existing exterior lighting types and any proposed retrofits are included in the table below. Table: Lighting Retrofit Summary – Exterior and Parking Lot Lighting Existing Fixture Type Double, Pole Mounted, Metal Halide Parking Lot Fixture, 2X400W (Exist. Fixture Type ‘EHA’) Single, Pole Mounted, Metal Halide Parking Lot Fixture, 400W (Exist. Fixture Type ‘EHB’) Industrial High Bay, Loading Dock, Metal Halide, 250W (Exist. Fixture Type ‘H’) Retrofit Measure Current Watts Per Fixture New Watts Per Fixture SAVINGS Replace each head with equivalent LED-188W Shoebox Type Fixture w/ 8" Arms 912 (456 ea) 376 (188 ea) 536 Replace each head with equivalent LED-188W Shoebox Type Fixture w/ 8" Arms 456 188 268 Replace with 100W LED equivalent (CCT may need to increase to 5000K) 290 100 190 Halogen Flood Lights, Loading Dock, WallMounted, 500W (Exist. Fixture Type ‘H1’) Replace with new 135W equivalent LED fixture 500 135 365 Wall Pack, 175W Metal Halide, Exhibit Storage and Chiller Plant (Exist. Fixture Type ‘O’) Replace with new nominal 60W equivalent LED fixture 210 56 154 On Grade, Surface Mounted, Floodlight, Clear Metal Halide, 250W T15 (Exist. Fixture Type ‘EHF’) Replace fixture with equivalent 165W LED floodlight 290 166 124 Double, Curved Pole Mounted, Ceramic Metal Halide T6 Fixture, 2X150W No Change; difficult to match current fixture style and configuration 336 (168 ea) N/A N/A On Grade, bollard Light, 35W Ceramic Metal Halide No Change; no suitable replacement 35 ea N/A N/A To meet GICC energy reduction goals with regards to LEED certification, this project recommends the immediate replacement of the fixtures or lamps after detailed engineering and specification. The construction costs assume sub-contract labor. Any remaining fixtures can be retained and/or used in other City of College Park facilities at their discretion. No salvage value is accounted for and costs do include