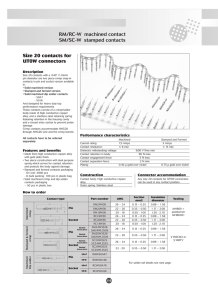

F Series Catalog

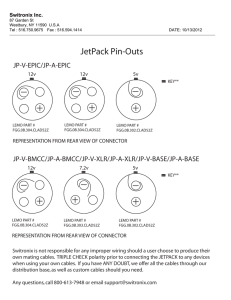

advertisement