Economics of Power Factor Correction

© 2013 Eaton. All rights reserved.

Understanding Utility Bills

• Kilowatt hours (kWH) – kWH consumption is

measure of electrical energy that has been used

during the billing period. Consist of a unit rate

times accumulated kWH reading from the meter.

• Fuel charge adjustment – Monthly charge

based on the cost of fuel used to produce power

each month. Typically a unit charge times kWH.

• Kilowatt demand – Based on maximum recorded kW demand interval

for the month and represents how much a utility has to provide in terms

of transformers, wire and generation capability. Typically a unit charge

times max kW demand interval for the month.

• Power factor penalties – Charged by some utilities. Usually based on

falling below a minimum PF level. Penalties vary widely among utilities.

© 2013 Eaton. All rights reserved.

2

What is Power Factor?

Inductive loads (motors) require two kinds of

power

• Real Power (kW) – that actually performs

the work

• Reactive Power (kvar) – that maintains the

electromagnetic field

Real power(kW)

𝜃

Reactive power(kvar)

Apparent power(kVA)

• Apparent Power (kVA) – total power,

vector sum of kW and kvar

Real power kW

= cos 𝜃

Apparent power kVA

Expressed in a percentage or decimal number (95% or 0.95) and also

with an added “Lag” or “Lead” term.

Power Factor is a measure of efficiency =

© 2013 Eaton. All rights reserved.

4

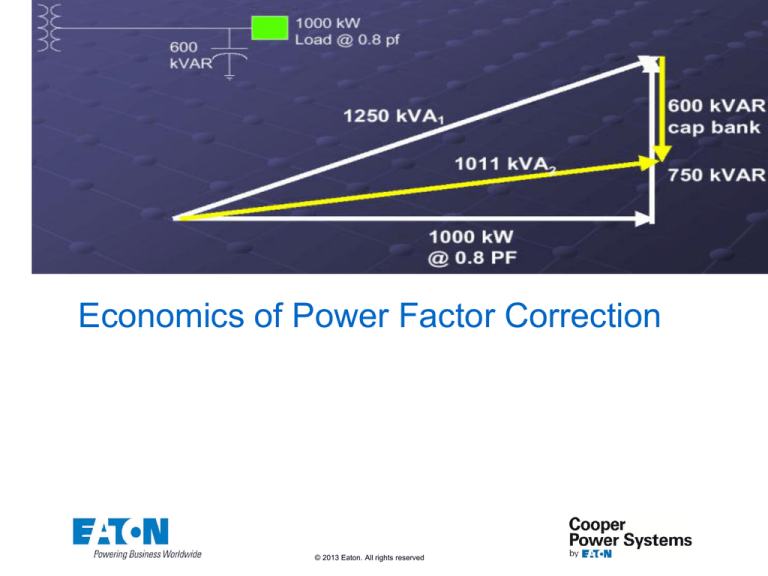

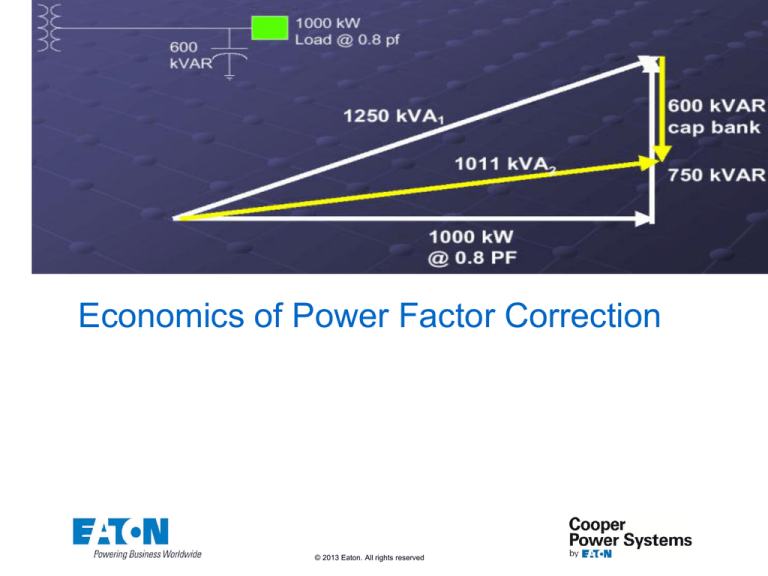

PF Correction

kW =1000

kvar=150

kVA =1010

1000 kW

load@

@.99

.8

load

lagging

PF PF

kvar=750

kVA =1250

600 kvar

Add 600 kvar

capacitor

• Present load at 1000 kW and 80% lagging PF

• Adding capacitors improves PF by providing leading kvar.

• Capacitors cancel the effects of the lagging kvar required by

inductive loads. PF improved to 99%.

• Use capacitors to correct PF to desired value based on utility

penalties

© 2013 Eaton. All rights reserved.

5

Typical PF by Industry and by Operation

Industry

Auto parts

Brewery

Cement

Chemical

Coal mine

Clothing

Electroplating

Foundry

Forge

Hospital

Machine manufacturing

Metalworking

Office building

Oil-field pumping

Paint manufacturing

Plastic

Stamping

Steelworks

Textile

Tool, die, jig

Power Factor

75-80

76-80

80-85

65-75

65-80

35-60

65-70

75-80

70-80

75-80

60-65

65-70

80-90

40-60

55-65

75-80

60-70

65-80

65-75

60-65

Operation

Air compressor:

External motors

Hermetic motors

Metal working:

Arc welding

Arc welding with

standard capacitors

Resistance welding

Machining

Melting:

Arc furnace

Inductance furnace

60Hz

Stamping:

Standard speed

High speed

Spraying

Weaving:

Individual drive

Multiple drive

Brind

© 2013 Eaton. All rights reserved.

Power Factor

75-80

50-80

35-60

40-60

40-60

40-65

75-90

100

60-70

45-60

60-65

60

70

70-75

6

HV and LV Recommendations

Low Voltage capacitors

• Applicable for secondary (LV) or primary (HV) metering

• located closest to inductive load for optimum loss reduction and

voltage boost

• Can be switched with the load

• Solutions for harmonic issues can be more complex

Medium Voltage capacitors

• Applicable for primary metering on HV side of the transformer

• Less expensive installed cost per kvar

• Simplifies solutions for harmonic issues

© 2013 Eaton. All rights reserved.

8

Medium Voltage Solution Options

• Pole Mounted Rack

•

Group fuse protection

•

Fixed or switched, single or multi step

•

Lowest cost solution

• Open Rack Design

•

Individual fuse protection

•

Unbalance protection scheme required

•

Fixed or switched, single or multi step

•

Fenced area required

•

Moderate cost solution

• Metal Enclosed

•

Current limiting fuses or fusesless designs

•

Fixed or switched, single or multi step

•

Reduced space requirements, indoor or outdoor

•

Fully assembled and tested

•

Most costly solution

© 2013 Eaton. All rights reserved.

9

Savings Analysis

Multiplier

kVAR charge

kVAR added

Month

Mar-12

Apr-12

May-12

Jun-12

Jul-12

Aug-12

Sep-12

Oct-12

Nov-12

Dec-12

Jan-13

Feb-13

0.39523

$2.60

2000

Max kW

Max kvar Base kvar1 Excess kvar2

Penalty3

4020

1961

1589

372 $

968

3948

3296

1560

1736 $

4,513

4011

2391

1585

806 $

2,095

4276

1869

1690

179 $

465

4426

3536

1749

1787 $

4,645

4383

3645

1732

1913 $

4,973

3632

3281

1435

1846 $

4,798

3937

3344

1556

1788 $

4,649

3883

2859

1535

1324 $

3,443

3891

2394

1538

856 $

2,226

3724

2891

1472

1419 $

3,690

3616

1446

1429

17 $

44

Total $

36,509

1

Base kvar = Max kW x Multiplier

2

Excess kvar = Max kvar - Base kvar

New kvar

-39

1296

391

-131

1536

1645

1281

1344

859

394

891

-554

3

Penalty = Excess kvar x kvar Charge

• Power factor penalty = $2.60/kvar for all excess kvar

• Excess kvar = Max kvar - (Max kW for the Billing Period x .39523)

• Annual savings = $36,000

• Possible solution - 2000 kvar metal enclosed bank. Could range from

$30-90K depending on steps. Payback 1-3 years.

© 2013 Eaton. All rights reserved.

10

Harmonics

• Harmonic producing loads can lead to

Fundamental

• Capacitors fuse operations and failed capacitors

• Transformer heating

Distorted Waveform

• Motor heating

3rd Harmonic

0

• VFD malfunction

5th Harmonic

• Increased neutral currents

• Common harmonic producing loads

• Power electronic equipment (drives, rectifiers, inverters, computers, etc.)

• Rotating machines (generators, motors)

• Iron saturating devices (transformers)

• Arcing devices (welders, arc furnaces, florescent lights, etc.)

• Harmonic Study should always be performed in conjunction with

power factor correction capacitors when there are significant sources

of harmonics in the system.

© 2013 Eaton. All rights reserved.

11

Engineering Service’s Harmonic Analysis

•

Do field measurements

• This is a recommended but optional step to

benchmark system

•

Develop system model

• Transformers, lines, loads, harmonic sources,

switches

•

Power Flow analysis to determine

• Reactive power needs

• Location of capacitors

• Capacitor bank ratings (steps)

•

Harmonic analysis:

• Impact of capacitors on harmonic performance

• Analyze alternatives to comply with harmonic

distortion requirements

© 2013 Eaton. All rights reserved.

12

Total Solutions Process

Pre Installation

Installation Support

Maintenance

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Utility bill analysis

PF correction

Harmonic studies

Filter design

Acceptance testing

Installation

Verify protection

Commissioning

Training

© 2013 Eaton. All rights reserved.

Capacitor testing

Switch testing

Control testing

Thermography

Service contracts

13

© 2013 Eaton. All rights reserved.

14