Proportional flow valves type QVHZO, QVKZOR

advertisement

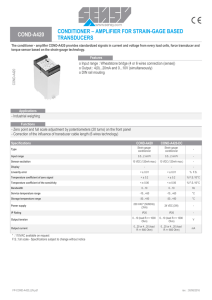

Atos spa Table F410-11/E 21018 Sesto Calende, Italy - Fax 0331 920005 Proportional flow valves type QVHZO, QVKZOR pressure compensated, direct operated, two or three way, ISO/Cetop size 03, 05 QVHZO and QVKZOR are proportional valves, direct operated, which provide compensated flow control according to the electronic reference signals. connector They operate in association with electronic drivers, see table , which supply the proportional valves with correct current signal to align valve regulation to the reference signal supplied to the electronic driver (which may be integral or Eurocard type). QVHZO-A connector metallic or plastic, see section dotted line: 1 These valves have a throttle ➀ directly operated by ZO(R) solenoids ➁ and a mechanical pressure compensator ➂ which compensates pressure variation to keep a constant ∆p across the throttle. QVKZOR-T QVHZOR-TE MODEL CODE QVKZOR – T – 10 / 65 / * ** / Design number without integral transducer as A plus integral electronics with integral transducer as T plus integral electronics 2 The coils are fully plastic encapsulated (insulation class H) and valves have antivibration, antishock and weatherproof features. Options only for -A versions: 6 = with 6 VDC coil instead of standard 12 VDC coil 18 = with 18 VDC coil instead of standard 12 VDC coil N = manual micrometric adjustment only for -AE, -TE versions: I = current reference (4÷20 mA) F = fault signal (only -TE versions) Q = with enable signal without signal zero (only -TE versions) FI = with fault signal and current reference input (only -TE versions). Valve size and configuration, see section 06 = ISO/Cetop 03; 10 = ISO/Cetop 05 Max regulated flow: for QVHZO 3 = 3,5 l/min 12 = 12 l/min 18 = 18 l/min 36 = 35 l/min 45 = 45 l/min * Synthetic fluids WG = water-glycol PE = phosphate ester Pressure compensated flow control valves QVHZO = ISO/Cetop 03 QVKZOR = ISO/Cetop 05 A = AE = T = TE = They are available in different options: • ZO(R)-A, ZO(R)-AE, for open or closed loop application; • ZO(R)-T with integral electronic transducer, ➃ featuring improved static and dynamic performances; • ZO(R)-TE as above plus integral electronics ➄. for QVKZOR 65 = 65 l/min 90 = 90 l/min Surface mounting: ISO/Cetop 03, 05 Max flow up to 45 l/min and 90 l/min respectively. Max pressure = 210 bar. HYDRAULIC CHARACTERISTICS (1) - see notes at section Hydraulic symbols Note: In three-way versions port P is open. In two-way versions port P is plugged. Port T must always be plugged. QVHZO-A QVKZOR-A Max regulated flow (2) QVHZO-TE QVKZOR-TE QVHZO-T*-06 QVKZOR-A*-10 QVKZOR-T*-10 [l/min] 3,5 12 18 35 45 3,5 12 18 35 45 [cm /min] 15 20 30 50 60 15 20 30 50 60 3 Regulating ∆p Max flow on port A QVHZO-T QVKZOR-T QVHZO-A*-06 Valve model Min regulated flow QVHZO-AE QVKZOR-AE [bar] [l/min] Max pressure 4-6 40 10 - 12 35 50 15 4-6 55 10 - 12 50 15 60 65 90 65 90 85 100 85 100 6 - 8 10 - 12 6 - 8 10 - 12 100 70 210 [bar] 70 100 210 (3) 30 25 45 35 Hysteresis [% of the regulated max flow] ≤5 ≤ 0,5 ≤5 ≤ 0,5 Linearity [% of the regulated max flow] ≤3 ≤ 0,5 ≤3 ≤ 0,5 Repeatability [% of the regulated max flow] ≤1 ≤ 0,1 ≤1 ≤ 0,1 Response time [ms] 0-100% signal variation F410 MAIN CHARACTERISTICS OF PROPORTIONAL FLOW VALVES TYPE QVHZO AND QVKZOR 3 0,4 Any position Roughness index , flatness ratio 0,01/100 (ISO 1101) -20°C to +70°C for QV*ZO(R)-A and QV*ZO(R)-T versions 0°C to +50°C for QV*ZO(R)-AE and QV*ZO(R)-TE versions Hydraulic oil as per DIN 51524 ... 535; for other fluids see section . 15 ÷ 100 mm2/s at 40°C (ISO VG 15 ÷ 100) ISO 18/15 achieved with in line filters at 10 mm value and b10 ≥ 75 (recommended) T ≤ 80°C; if T ≥ 60°C select/PE seals Supply: +15VDC / 25 mA; -15VDC / 25 mA Signal: 0 ÷ 5 QVHZO: 3 ÷ 3,3 Ω for standard 12 VDC coil; 2 ÷ 2,2 Ω for 6 VDC coil; 13 ÷ 13,4 Ω for 18 VDC coil QVKZOR: 3,8 ÷ 4,1 Ω for standard 12 VDC coil; 2,2 ÷ 2,4 Ω for 6 VDC coil; 12 ÷ 12,5 Ω for 18 VDC coil QVHZO: 2,2 A for standard 12 VDC coil; 2,75 A for 6 VDC coil; 1,2 A for 18 VDC coil QVKZOR: 2,6 A for standard 12 VDC coil; 3,25 A for 6 VDC coil; 1,2 A for 18 VDC coil QVHZO: 30 Watt; QVKZOR: 40 Watt Continuous rating (ED = 100%) Type SP-666 (plastic - black); 3 pins, cable clamp PG11, cable max. Ø 10 mm Type SP-345 (plastic - grey), 4 pins, cable clamp PG7, cable max Ø 4 ÷ 7,5 mm to be ordered Type SP-ZM-7P (metallic); 7 pins, cable clamp PG11, cable max. Ø 10 mm Type SP-ZH-7P (plastic); 7 pins, cable clamp PG11, cable max Ø 10 mm separately SP-666: DIN 43650 - ISO 4400; IP 65 (DIN 40050); VDE 0110C; SP-345: VDE 0660; IP 65 (DIN 40050); VDE 0110C; SP-ZM-7P: according to MIL-C-5015G; IP 66 (DIN 40050); SP-ZH-7P: mounting dimensions according to MIL-C-5015G; IP 67 (DIN 40050) Assembly position Subplate surface finish Ambient temperature Fluid Recommended viscosity Fluid contamination class Fluid temperature LVDT electric characteristics (-T and -TE versions) Coil resistance R at 20°C Max. solenoid current Max. power Relative duty factor Power connector W for -A and -T versions Signal connector S for -T version Single connector for -AE, -TE versions Connectors features NOTES TO TABLES AND 4 (1) Typical characteristics in table refer to valves coupled with Atos electronic drivers and operation with ISO VG-36 mineral oil at 50°C. (2) Values are referred to 3-way configuration. In the 2-way configuration, the values of min regulated flow are higher. (3) Reponse times at step signal (0%→100%) are measured from 10% to 90% of step value and are strictly referred to valve regulation. NOTES (1) Execution, Format/Connection I = plug DIN 43650-IP65, VDE 0110 on solenoid B = fast plug in standard undecal base housing, relay type S = sealed box with cable clamp binding screw type E = Eurocard 100x160 mm (plug in unit DIN 41494) X = sealed box on the valve;IP65 - DIN 40050 (2) Power supply at 24 VDC ± 10% (3) Reference signals A (option/l) = 4÷20 mA; 0÷20 mA (only for E-MI) C = 0 ÷ 10 VDC ; 0 ÷ 5 VDC (not available for E-RI) (4) Ramps options, i.e. control of rapidity on rise and fall of current and consequently of hydraulic parameters (5) Enable: to allow driver operation only with an electric enabling signal. Monitor: actual value of spool position or driving current Fault: alarm = 0 VDC; normal working = 24 VDC (6) Options to monitor anomalous operating conditions of driver (7) Integral digital electronics type E-RI-AES (open loop) and E-RI-TES (closed loop) available on request (8) Integral electronics type E-RI-TE with 12 poles connector and relevant options Z, S is also available ELECTRONIC DRIVERS 5 For full information regarding electronic drivers, see section G (8). Reference Special Max power Execution consumption Driver Ramps functions (1) (4) response signals (2) (5) (3) Valve model Models E-MI-AC-01F E-BM-AC-0*F QVHZO-A QVKZOR-A E-RP-AC-0*F E-ME-AC-0*F Alarm (6) I 40W normal C, (A) YES NO NO B 40W fast C YES NO NO S 50W fast C, (A) YES E 50W fast C, (A) YES ENABLE NO fast C, (A) YES MONIT. NO C, (A) YES ENABLE YES C, (A) NO MONIT. FAULT YES E-RI-AE-0*F (7) QVHZO-AE QVKZOR-AE X 50W E-ME-T-0*H QVHZO-T QVKZOR-T E 50W E-RI-TE-0*H (7) QVHZO-TE QVKZOR-TE X 50W high performance NO NO ELECTRIC WIRING 6 Electric wiring to reference generators must be made using shielded cables: the sheat must be connected to the power supply zero on the generator side. The power supply must be properly stabilized or rectified and filtered. For complete electric wiring with all available options, see section G USER INTERFACE E-*-AC-0*F FACTORY PRESET FUNCTIONS FACTORY PRESET FUNCTIONS ZO(R)-AE ZO(R)-TE E-ME-T-0*H SCALE ZERO ALARM SCALE PROTECTION MONITOR W S ZO(R)-A PIN 1 2 Connector W COIL LEAD COIL LEAD EARTH CONDUCTOR ZERO ALARM PROTECTION MONITOR FEEDBACK W ZO(R)-T PIN 1 2 3 4 Connector S OUTPUT SIGNAL SUPPLY -15 VDC SUPPLY +15 VDC GND Note: - electrical signals (e.g. actual - feedback signals) taken via valve electronics must not be used to switch off the machine safety functions. This is in accordance with the regolations to the European standard (Safety requirements of fluid technology systems and components hydraulics). - basic information for commissioning and start-up are present on installation notes always enclosed to the specific technical tables and relevant components. PIN A B C D E SIGNAL DESCRIPTION Power supply 24 VDC Power supply zero Signal zero Input signal + Input signal - spool position (for E-RI-TE) TECHNICAL SPECIFICATION Nominal: + 24 VDC Filtered and rectified: Vrms = 21 ÷ 33 (ripple max 2 Vpp) Reference 0 VDC 0 ÷ 10 VDC 4 ÷ 20 mA for option /I 0 ÷ 100% ↔ 0 ÷ 10 VDC (Rout = 10 KΩ); 4 ÷ 20 mA for option /I Monitor F G - driving current (for E-RI-AE) 0 ÷ 5 VDC (1V = 1A) Fault signal (only for E-RI-TE with option /F ) Alarm = 0 VDC; Normal working = 24 VDC Earth Connect only when the power supply is not conform to VDE 0551 (CEI 14/6) Regulation diagrams stated for -A, -AE, -T, and -TE version = QVHZO-*-06/3 = QVHZO-*-06/12 = QVHZO-*-06/18 = QVHZO-*-06/36 = QVHZO-*-06/45 = QVKZOR-*-10/65 = QVKZOR-*-10/90 4 3 2 Regulated flow [l/min] (reg ∆p) 1 2 3 4 5 6 7 DIAGRAMS Regulated flow [l/min] (reg ∆p) 7 7.1 7 6 5 1 Reference signal [% of max.] 1 = QVHZO 2 = QVKZOR Dotted line for 3-way versions 1 Regulated flow [%of the max.] Regulated flow/outlet pressure diagrams with inlet pressure = 210 bar Regulated flow [%of the max] 7.2 Reference signal [% of max.] Differential pressure A→B/regulated flow diagram 3-way configuration 1 = QVHZO-*-06/3, QVHZO-*-06/12 2 = QVHZO-*-06/18, QVHZO-*-06/36, QVHZO-*-06/45 3 = QVKZOR-*-10/65 4 = QVKZOR-*-10/90 2 1 Regulated flow [l/min] Pressure at port B [bar] Amplitude ratio [dB] 7.3 Differential pressure A→B [bar] Pressure at port B [bar] 2 4 3 Regulated flow [l/min] F410 8 INSTALLATION DIMENSIONS [mm] QVHZO QVHZO-A ISO/Cetop 03 Fastening bolts: 4 socket head screws M5 x 50 Seals: 4 OR 108; Diameter of ports A, B, P, T: Ø 7,5 mm (max) A = INLET PORT B = OUTLET PORT P = DISCHARGE PORT (only for 3-way versions; not used for 2-way versions) T = NOT USED (it must be plugged) Mass: 2,3 kg QVHZO-AE QVHZO-TE QVHZO-T Mass: 2,4 kg Mass: 3,3 kg Mass: 2,3 kg QVKZOR QVKZOR-A ISO/Cetop 05 Fastening bolts: 4 socket head screws M6 x 40 Seals: 5 OR 2050; 1 OR 108 Diameter of ports A, B, P, T: Ø 11,2 mm (max) A = INLET PORT B = OUTLET PORT P = DISCHARGE PORT (only for 3-way versions; not used for 2-way versions) T = NOT USED (it must be plugged) Mass: 3,8 kg QVKZOR-AE QVKZOR-TE QVKZOR-T Mass: 4,4 kg 9 Mass: 5 kg MOUNTING PLATES Size 03 05 11/01 Mass: 4 kg Model Ports location A, B, P, T 3/8" Ø Counterbore [mm] A, B, P, T – 3/8" 25,5 1,8 1/2" (1/8") 30 (16,5) 1,8 Gas ports Mass [kg] BA-202 Ports A, B, P, T underneath; BA-204 Ports P, T underneath; ports A, B on lateral side BA-302 Ports A, B, P, T (X, Y) underneath; BA-308 Ports A, B, P, T underneath; 1/2" 30 2,5 BA-428 Ports A, B, P, T underneath; 3/4" 36,5 5,5 The subplates are supplied with 4 fastening bolts M5x50 for QVHZO and M6x40 for QVKZOR. For further details see table K280. 1,2