Series

CYLINDERS WITH PROFILED BARREL

Ø 32 to 100 mm - double acting

ISO 15552-AFNOR-DIN

with pneumatic cushioning

GENERAL

Detection

Fluid

Operating pressure

Ambient temperature

Optimal max. speed

Max. speed rate

Standards

453

Type

NS

PES P-DM

Equipped for magnetic position detectors

Air or neutral gas, filtered, lubricated or not

10 bar max.

–20°C to +70°C (for higher temperatures, consult us)

1 m/s (for optimal service life)

2 m/s

ISO 15552-AFNOR NF ISO 15552-DIN ISO 15552

(replace ISO 6431-AFNOR NFE 49003-VDMA 24562)

CONSTRUCTION

Barrel

Front and rear ends

Barrel/end connection

Bearing

Cushioning seals

Cushioning

Rod

Rod nut

Piston

B

Hard anodized aluminium alloy

Aluminium alloy

With stainless steel tie-rods

self-lubricating metal

PUR (polyurethane)

Pneumatic, adjustable from both sides with captive screw

Hard chrome plated steel

Galvanized steel

Ø 32 to 80 mm: POM (polyacetal)

Ø 100-125 mm: light alloy, fitted with an annular permanent magnet

PUR (polyurethane)

Piston seals

SPECIFICATIONS

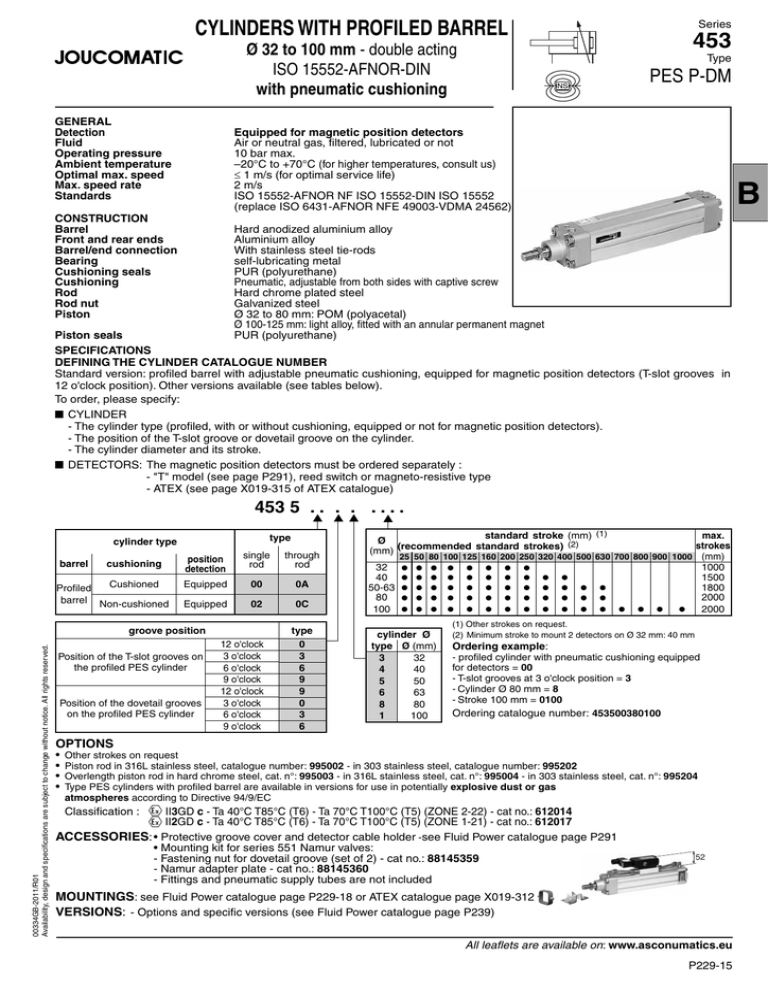

DEFINING THE CYLINDER CATALOGUE NUMBER

Standard version: profiled barrel with adjustable pneumatic cushioning, equipped for magnetic position detectors (T-slot grooves in

12 o'clock position). Other versions available (see tables below).

To order, please specify:

■ CYLINDER

- The cylinder type (profiled, with or without cushioning, equipped or not for magnetic position detectors).

- The position of the T-slot groove or dovetail groove on the cylinder.

- The cylinder diameter and its stroke.

■ DETECTORS: The magnetic position detectors must be ordered separately :

- "T" model (see page P291), reed switch or magneto-resistive type

- ATEX (see page X019-315 of ATEX catalogue)

453 5 . . . . . . . .

▼ ▼ ▼

barrel

cushioning

Cushioned

Profiled

barrel Non-cushioned

position

detection

single

rod

through

rod

Equipped

00

0A

Equipped

02

0C

00334GB-2011/R01

Availability, design and specifications are subject to change without notice. All rights reserved.

groove position

Position of the T-slot grooves on

the profiled PES cylinder

Position of the dovetail grooves

on the profiled PES cylinder

12 o'clock

3 o'clock

6 o'clock

9 o'clock

12 o'clock

3 o'clock

6 o'clock

9 o'clock

type

0

3

6

9

9

0

3

6

▼

type

cylinder type

standard stroke (mm) (1)

Ø

(recommended standard strokes) (2)

(mm)

max.

strokes

25 50 80 100 125 160 200 250 320 400 500 630 700 800 900 1000 (mm)

32 ● ● ● ● ● ● ● ●

1000

1500

40 ● ● ● ● ● ● ● ● ● ●

1800

50-63 ● ● ● ● ● ● ● ● ● ● ● ●

80 ● ● ● ● ● ● ● ● ● ● ● ●

2000

●

2000

100 ● ● ● ● ● ● ● ● ● ● ● ● ● ● ●

cylinder Ø

type Ø (mm)

3

32

4

40

5

50

6

63

8

80

1

100

(1) Other strokes on request.

(2) Minimum stroke to mount 2 detectors on Ø 32 mm: 40 mm

Ordering example:

- profiled cylinder with pneumatic cushioning equipped

for detectors = 00

- T-slot grooves at 3 o'clock position = 3

- Cylinder Ø 80 mm = 8

- Stroke 100 mm = 0100

Ordering catalogue number: 453500380100

OPTIONS

•

•

•

•

Other strokes on request

Piston rod in 316L stainless steel, catalogue number: 995002 - in 303 stainless steel, catalogue number: 995202

Overlength piston rod in hard chrome steel, cat. n°: 995003 - in 316L stainless steel, cat. n°: 995004 - in 303 stainless steel, cat. n°: 995204

Type PES cylinders with profiled barrel are available in versions for use in potentially explosive dust or gas

atmospheres according to Directive 94/9/EC

Classification :

II3GD c - Ta 40°C T85°C (T6) - Ta 70°C T100°C (T5) (ZONE 2-22) - cat no.: 612014

II2GD c - Ta 40°C T85°C (T6) - Ta 70°C T100°C (T5) (ZONE 1-21) - cat no.: 612017

ACCESSORIES: • Protective groove cover and detector cable holder -see Fluid Power catalogue page P291

• Mounting kit for series 551 Namur valves:

- Fastening nut for dovetail groove (set of 2) - cat no.: 88145359

- Namur adapter plate - cat no.: 88145360

- Fittings and pneumatic supply tubes are not included

52

MOUNTINGS: see Fluid Power catalogue page P229-18 or ATEX catalogue page X019-312

VERSIONS: - Options and specific versions (see Fluid Power catalogue page P239)

All leaflets are available on: www.asconumatics.eu

P229-15

ISO 15552 CYLINDERS WITH PROFILED BARREL - SERIE 453

DIMENSIONS AND WEIGHTS

DIMENSIONS (mm), WEIGHT (kg)

Bare cylinder

N + 1

BG

ZJ + 1

A

Ø RT

L8 + 1

M

WH

PL

PL

L2

E

VA

Ø EE

=

=

TG

= =

VD

SINGLE

ROD

CYLINDER

TG

= =

E

=

=

KW

ØB

ØB

d11

Ø MM

Ø KK

KV

d11

SW ❉

❉

ZM + 2

A

A

THROUGH

ROD TYPE

CYLINDER

L8 + 1

M

M + 1

Stroke

Stroke x 2

✻ Dimensions on flats

1

Ø

A

ØBd11

BG

E

ØEE

ØKK

KV

KW

L2

L8

M

ØMM

N

PL

ØRT SW(5)

TG

VD

VA mini

32

22

30

16

50

G1/8

M10x1,25

16

5

17

94

48

12

142

14

M6

10

32,5 ±0,5

4

4

40

24

35

16

57,5

G1/4

M12x1,25

18

6

19

105

54

16

159

16

M6

13

38 ±0,5

4

4

50

32

40

16

65

G14

M16x1,5

24

8

26

106

69

20

175

18,5

M8

17

46,5 ±0,5

4

4

63

32

45

16

79

G3/8

M16x1,5

24

8

26

121

69

20

190

17

M8

17

56,5 ±0,5

4

4

80

40

45

17

100

G3/8

M20x1,5

30

10

33

128

86

25

214

16,5

M10

22

72 ±0,5

4

4

100

40

55

17

120

G1/2

M20x1,5

30

10

35,5 138

91

25

229

21

M10

22

89 ±0,5

4

4

Ø

WH

ZJ

ZM

32

26

120

146

weight

(3)

(4)

0,560

0,365

(3) Cylinder weight with 0 mm stroke.

(4) Weight to be added per additional 100 mm length.

(5) Dimension SW changed as against standard AFNOR NFE 49 003.

40

30

135

165

0,870

0,480

50

37

143

180

1,120

0,690

Ø 50-63

16

17

63

37

158

195

1,600

0,750

Ø 80-100

21

22

80

46

174

220

2,750

1,125

100

51

189

240

3,870

1,360

Dimensional tolerances according to standard ISO 15552

All leaflets are available on: www.asconumatics.eu

P229-16

NFE 49 003

ISO 15552

00334GB-2010/R01

Availability, design and specifications are subject to change without notice. All rights reserved.

2

ISO 15552 CYLINDERS WITH PROFILED BARREL - SERIES 453

SPARE PARTS KIT

The spare parts kits apply to PES cylinder series 450 with tie-rods and PES cylinder series 453 with profiled barrel.

1

3 4(Ø100) 3 2

2

Magnet

B

Ø

cylinder type

code

(seals: 1 to 4)

32

Equipped for detector

97802343

40

Equipped for detector

97802344

50

Equipped for detector

97802345

63

Equipped for detector

97802346

80

Equipped for detector

97802347

100

Equipped for detector

97802259

NOTE: For best results, use grease supplied in each kit.

Supplementary tube (11cm3) available on request, code: 97802100

00335GB-2010/R01

Availability, design and specifications are subject to change without notice. All rights reserved.

ROD + PISTON UNIT

Ø

rod + piston unit

32

97802736 .... (1)

40

97802737 .... (1)

50

97802738 .... (1)

63

97802739 .... (1)

80

97802740 .... (1)

100

97802741 .... (1)

(1) Specify stroke length (in mm)

All leaflets are available on: www.asconumatics.eu

P229-17

ISO 15552 CYLINDERS WITH PROFILED BARREL - SERIES 453

All leaflets are available on: www.asconumatics.eu

P229-18

STANDARDISED MOUNTINGS

Series

434

for PES / PLS cylinders

conforming to

ISO 15552-AFNOR-DIN standard

MOUNTINGS CONFORMING TO ISO 15552 - AFNOR NF ISO 15552 - DIN ISO 15552 STANDARDS

A

B

C

European patent n°06 291

828.9

duty

Applications

low feet (2)

MS1

standard

duty

heavy

duty

Construction

rectangular

high foot (1) front or rear

NFE 49003-5

flange

MS3

MF1 - MF2

supplied

fixed XV (3)

centre trunnion MT4

for PES with

for PES 453

with profiled barrel

tie rods

supplied loose supplied

supplied

(4)

fixed/XV (3) loose (4)

for PLS 452

with profiled barrel

supports (2)

supplied

supplied

supplied for centre trunnion

AT4

fixed /XV (3) fixed /XV (3) fixed /XV (3)

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

stamped sheet drawn steel

steel

for cylinder Ø

32

40

50

63

80

100

125*

160*

200*

dimensions

for PES 453

with profiled barrel

43400163

43400164

43400165

43400166

43400167

43400168

43400169

43400381

43400382

page 20

43400307

43400308

43400309

43400310

43400311

page 20

steel

iron +

cast iron cast iron castbush

catalogue number

410592

410598 410564 410570 410548

410593

410599 410565 410571 410549

410594

410600 410566 410572 410550

410595

410601 410567 410573 410551

410596

410602 410568 410574 410552

410597

410603 410569 410575 410553

410554

410555

410556

page 23

page 23

page 23

steel

43400119

43400120

43400121

43400122

43400123

43400124

43400192

43400342

43400343

page 19

steel

cast iron

410564

410604

410566

410605

410606

410607

-

410570

410608

410572

410609

410610

410611

-

Aluminium

43400207

43400208

43400208

43400209

43400209

43400210

43400210

43400341

43400341

page 24

i For cylinders PES serie 450

standard

duty

heavy

duty

●

cap, detachable eye (trunnion)

MP4

●

●

construction

aluminium

+ bush

cast iron

+ steel

+ bush

for cylinder Ø

32

40

50

63

80

100

125*

160*

200*

dimensions

43400130

43400131

43400132

43400133

43400134

43400135

-

43400185

43400186

43400187

43400188

43400189

43400190

43400191

43400335

43400336

page 21

angular clevis bracket

AB3

●

●

light

alloy

cast iron

+ bush

catalogue number

43400125

43400171

43400126

43400172

43400127

43400173

43400128

43400174

43400129

43400175

43400161

43400176

43400177

43400337

43400338

page 21

●

aluminium

+ bush

cast iron

+ bush

43400383

43400384

43400385

43400386

43400387

43400388

-

43400110

43400111

43400112

43400113

43400114

43400115

43400116

43400117

43400118

page 21

i For cylinders PES serie 450

( 1) High foot sold individually

(2) Corresponds to a set of 2 parts.

(3) Trunnion supplied fixed to the barrel at dimension XV specified when ordered:

The centre trunnion code fixed and the dimension XV along with orientation code of

the trunnion with respect to the ports must be added to the cylinder code.

(example: 45000020 + options 410523 / XV = 210 + 410002)

(4) Trunnion supplied loose on cylinder barrel for on-site adjustment to required dimension:

The centre trunnion code loose and the dimension XV along with orientation code of

the trunnion with respect to the ports must be added to the cylinder code

NOTE: With the exception of the centre trunnion, mountings are delivered separately.

All leaflets are available on: www.asconumatics.eu

P229-18

Centre trunnion orientation

Trunnion axis is perpendicular to supply ports, code : 410002 (standard orientation)

● other position upon request, code : 410003

●

410002

410003

00578GB-2011/R03

Availability, design and specifications are subject to change without notice. All rights reserved.

duty

application

cap, detachable clevis

MP2

ISO 15552 - AFNOR NF ISO 15552 - DIN ISO 15552

STANDARDISED MOUNTINGS

angular clevis

bracket

spherical bearing (5)

AB5

femelle

rod clevis (7)

ISO 8140 - RP102P

AP2

spherical

rod end

ISO8139-RP103P

AP6

alignement

compensator

(6)

standard

●

●

●

●

●

●

heavy

●

●

●

●

●

●

Construction

forged steel

forged steel

forged steel

steel

steel

steel

for cylinder Ø

32

40

50

63

80

100

125*

160*

200*

43400363

43400364

43400365

43400366

43400367

43400368

43400369

-

43400372

43400373

43400374

43400375

43400376

43400377

43400378

-

43400354

43400355

43400356

43400357

43400358

43400359

43400360

-

43400001

43400002

43400003

43400003

43400004

43400004

43400005

43400006

43400006

43400242

43400243

43400244

43400244

43400245

43400245

-

dimensions

page 22

page 22

page 22

page 23

page 24

duty

cap eye with

spherical eye (5)

MP6

application

cap clevis for

spherical eye or

clevis bracket

AB6

catalogue number

43400016

43400017

43400018

43400018

43400019

43400019

43400020

43400021

43400021

page 23

For cylinders PES serie 450

*(5)These

accessories allows accurate angular compensation adjustment spherical of 4°

(6)This accessorie allows accurate angular compensation adjustment spherical of 4° and radial of 0,7 mm

(7) Ø125 to 200 mm: Clevis with axis locking pin

NOTE: With the exception of the centre trunnion, mountings are delivered separetely.

DIMENSIONS (mm), WEIGHT (kg)

rectangular FRONT OR REAR MOUNTING FLANGE - MF1 - MF2

PES-PLS type CYLINDER

E max.

ZF + 1

=

ZJ + 1

MF

=

R

=

=

4Ø FB

UF max.

TF

=

=

00578GB-2011/R01

Availability, design and specifications are subject to change without notice. All rights reserved.

=

W

Ø DH11

=

A

1 : Stroke

Ø

32

40

50

63

80

100

125

160

200

weight

A

ØD

E

22

24

32

32

40

40

54

72

72

30

35

40

45

45

55

60

65

75

50

58

70

85

105

130

157

195

238

ØFB MF

7

9

9

9

12

14

16

18

22

10

10

12

12

16

16

20

20

25

R

TF

UF

W

ZJ

ZF

32

36

45

50

63

75

90

115

135

64

72

90

100

126

150

180

230

270

86

96

115

130

165

187

224

280

320

16

20

25

25

30

35

45

60

70

120

135

143

158

174

189

225

260

275

130

145

155

170

190

205

245

280

300

0,190

0,245

0,500

0,580

1,390

1,630

4,270

6,880

12,330

All leaflets are available on: www.asconumatics.eu

P229-19

B

ISO 15552 - AFNOR NF ISO 15552 - DIN ISO 15552

STANDARDISED MOUNTINGS

DIMENSIONS (mm), WEIGHT (kg)

LOW FEET MOUNTING - MS1

A

XA + 1

PES-PLS type CYLINDER

AT

=

TG

=

AU

L8 + 1

AT

AH

2 ØAB

AU

SA + 1

AO max.

=

HIGH FOOT MOUNTING - ms3 (sold individually)

XA + 1

PES-PLS type CYLINDER

=

AT1

=

US max.

=

TG

=

=

UF

A

TR

=

=

E max.

AU

L8 + 1

AU

SA + 1

AO

AH

AT1

AH

2øAB

=

TR

=

1 : Stroke

32

40

50

63

80

100

125

160

200

ØAB

A

AO

AH

AT AT1 AU

7

10

10

10

12

14,5

16,5

18,5

24

22

24

32

32

40

40

54

72

72

11

15

15

15

20

25

25

25

35

32

36

45

50

63

71

90

115

135

4

4

5

5

6

6

8

10

12

8

8

10

10

12

12

16

-

All leaflets are available on: www.asconumatics.eu

P229-20

24

28

32

32

41

41

45

60

70

E

TR

TG

50 32 32,5

58 36 38

70 45 46,5

85 50 56,5

105 63 72

130 75 89

157 90 110

195 115 140

238 135 175

UF

US

L8

SA

XA

54 50

62 58

77 70

87 85

110 105

130 130

161 157

-

94

105

106

121

128

138

160

180

180

142

161

170

185

210

220

250

300

320

144

163

175

190

215

230

270

320

345

2x

MS1

0,150

0,190

0,395

0,445

0,790

1,400

2,330

4,860

7,900

1x

MS3

0,180

0,250

0,470

0,595

1,265

-

00578GB-2011/R01

Availability, design and specifications are subject to change without notice. All rights reserved.

weight

Ø

ISO 15552 - AFNOR NF ISO 15552 - DIN ISO 15552

STANDARDISED MOUNTINGS

E max.

=

=

TG

=

=

CBH14

DIMENSIONS (mm), WEIGHT (kg)

CAP, DETACHABLE CLEVIS MOUNTING - MP2

63 80 100 125 160 200

weight

Light alloy

0,105 0,150 0,240 0,370 0,635 0,990

-

-

Cast iron+steel 0,205 0,305 0,430 0,685 1,375 2,100 3,570 6,660 9,890

MR max.

E max.

=

=

TG

=

=

EW

= =

CAP, DETACHABLE EYE (trunnion) MOUNTING - MP4

Bore Ø

32

40

50

63

-

-

-

-

80 100 125 160 200

FL

weight

-

-

-

-

-

Cast iron+steel 0,210 0,230 0,430 0,620 1,110 1,700 3,100 5,220 7,780

STRAIGHT COMPLETE TRUNNION

WITH OR WITHOUT BUSH - MP2 + MP4

MOUNTING

To achieve the complete assembly, items MP2 and MP4 must be ordered

separately.

32 40 50 63 80 100 125 160 200

weight

Light alloy 0,190 0,240 0,410 0,620 1,080 1,745

-

-

Cast iron+steel 0,415 0,535 0,860 1,305 2,485 3,800 6,670 11,88017,670

=

32 40 50 63 80 100 125 160 200

weight

Light alloy

TG

=

FL

4Ø D

α

α

L4

H9/e8

Y

Ø CD

E max.

=

=

TG

=

=

Js14

GL

20˚

0,160 0,230 0,390 0,570 0,950 1,500 -MN 60

H9/e8

Y

Ø CK

TE

1 : Stroke

XD + 1

4Ø HB

Bore Ø

32

A

XD (PES-PLS cyl.)

22 24 32 32 40 40 54 72 72

142 160 170 190 210 230 275 315 335

Ø

32

40

50

63

80

100

125

160

200

40

50

63

80 100 125 160 200

BT CB ØCD ØD E EM EW FL GL ØHB L4

ØCK

8

10

12

12

14

15

20

25

30

26

28

32

40

50

60

70

90

90

10 6,6 50 26 26 22 21

12 6,6 58 28 28 25 24

12 9 70 32 32 27 33

16 9 85 40 40 32 37

16 11 105 50 50 36 47

20 11 130 60 60 41 55

25 14 157 70 70 50 70

30 14 195 90 90 55 97

30 18 238 90 90 60 105

6,6

6,6

9

9

11

11

14

14

18

5,5

5,5

6,5

6,5

10

10

10

10

11

UL max.

PES-PLS CYLINDER

A

EM

00578GB-2011/R01

Availability, design and specifications are subject to change without notice. All rights reserved.

FL

=

E max.

=

=

TG

=

=

Bore Ø E max.

=

COMPLETE TRUNNION MOUNTING WITH ANGULAR CLEVIS

BRACKET - WITH OR WITHOUT BUSH - MP2 + AB3

This set includes the cap, detachable clevis MP2 and the angular clevis

bracket AB3, with or without bush.

These mountings must be ordered separately

H9

Ø CD

BT

Bore Ø

MR max.

L5

0,085 0,092 0,170 0,250 0,445 0,755

Light alloy

-

E max.

=

=

TG

=

=

-

E max.

=

TG

=

=

-

=

Aluminium

B

Ø CDH9/e8

h14

UB

Y

E max.

50 TG

40 PH Js15

32 E max.

=

=

TG

=

=

Bore Ø FL

RA

UR max.

L5 MR PH RA

TE

TG

UB

UL

UR

Y

α

1,6

1,6

1,6

1,6

2,5

2,5

3,2

4

4

38

41

50

52

66

76

94

118

122

32,5

38

46,5

56,5

72

89

110

140

175

45

52

60

70

90

110

130

170

170

51

54

65

67

86

96

124

156

162

31

35

45

50

60

70

90

126

130

56

63

71

81

101

128

149

183

183

45°

50°

40°

55°

45°

35°

30°

30°

30°

11 32

13 36

13 45

17 50

17 63

21 71

26 90

31 115

31 135

18

22

30

35

40

50

60

88

90

All leaflets are available on: www.asconumatics.eu

P229-21

ISO 15552 - AFNOR NF ISO 15552 - DIN ISO 15552

STANDARDISED MOUNTINGS

DIMENSIONS (mm), WEIGHT (kg)

CAP, DETACHABLE CLEVIS MOUNTING - FOR SPHERICAL EYE

(STRAIGHT) OR ANGULAR CLEVIS BRACKET - AB6

SR max.

80 100 125 160 200

-

Ø CFF7/h9

CP

E max.

=

=

TG

=

=

EX +-0,1

= =

CAP, DETACHABLE EYE MOUNTING WITH SPHERICAL BEARING - MP6

Bore Ø 32 40 50 63 -

E max.

=

=

TG

=

=

Forged

steel 0,180 0,290 0,420 0,650 1,210 1,870 3,640

-

4˚

4˚

STRAIGHT COMPLETE TRUNNION MOUNTING, SPHERICAL

BEARING

63 80 100 125 160 200

weight

-

-

=

COMPLETE TRUNNION MOUNTING WITH ANGULAR CLEVIS

BRACKET - SPHERICAL BEARING

32 40 50 63 80 100 125 160 200

weight

Forged steel 0,370 0,530 0,910 1,200 2,400 3,200 6,710

-

TG

-

Ø CF

E max.

=

=

TG

=

=

DL

L65/1

Js14

FM

G1

4˚

4˚

180˚

10˚

Ø CF

1 : Stroke

PES-PLS CYLINDER

FM

4Ø D

H7/h9

=

E max.

=

=

TG

=

=

This set includes the cap AB6, detachable eye and the angular clevis

bracket spherical eye AB5.

These mountings must be ordered separately

Bore Ø =

=

Forged steel 0,370 0,590 0,880 1,330 2,670 4,000 7,880

E max.

TG

50 =

E max.

=

TG

=

=

40 Ø CXH7

EP

This set includes the cap AB6, clevis for spherical eye and the cap, eye

with spherical bearing MP6.

These mountings must be ordered separately

32 MS max.

80 100 125 160 200

weight

Bore Ø DL

H7/h9

XD / XN + 1

Bore Ø

32

A

XD/XN (PES-PLS cyl.)

22 24 32 32 40 40 54 72 72

142 160 170 190 210 230 275 315 335

Ø

32

40

50

63

80

100

125

160

200

40

50

63

80 100 125 160 200

CG CH CP ØCX DL E

ØCF FM

14

16

21

21

25

25

37

-

-

32

36

45

50

63

71

90

-

-

34

40

45

51

65

75

97

-

-

10 22

12 25

16 27

16 32

20 36

20 41

30 50

-

-

50

58

70

85

105

130

157

-

-

14

16

21

21

25

25

37

-

-

32,5

38

46,5

56,5

72

89

110

-

-

21

24

33

37

47

55

70

-

-

18

22

30

35

40

50

60

-

-

G2

G3 max.

TG

All leaflets are available on: www.asconumatics.eu

P229-22

4Ø S5

EN EP G1 G2 G3 K1 K2L65/1L65/2 MS

EX

10,5

12

15

15

18

18

25

-

-

K1

EN +0

- 0,1

A

31

35

45

50

60

70

90

-

-

38 51

41 54

50 65

52 67

66 86

76 96

94 124

-

-

-

-

5,5

5,5

6,5

6,5

10

10

10

-

-

8,5

8,5

10

10

11,5

12,5

16,5

-

-

15

18

20

23

27

30

40

-

-

SR Ø S5 α

11

13

18

18

22

22

30

-

-

6,6

6,6

9

9

11

11

14

-

-

40°

45°

35°

50°

40°

30°

25°

-

00578GB-2011/R01

Availability, design and specifications are subject to change without notice. All rights reserved.

-

E max.

weight

Forged

steel 0,190 0,300 0,460 0'680 1,460 2,130 4,240

Js15

63 CH

50 K2 max.

40 L65/2

32 FM

E max.

=

=

TG

=

=

Bore Ø E max.

=

=

TG

=

=

CG D10

ISO 15552 - AFNOR NF ISO 15552 - DIN ISO15552

STANDARDISED MOUNTINGS

CENTRE TRUNNION MOUNTING MT4 FOR PES 450

e9

TK1

PES 450

Ø TD

TL

MT4 type C

TM

h14

Ø

mm

XV

A

ZJ + 1

=

Dimension XV is specified on order

TG

=

=

E

=

=

UW

32

40

50

63

80

100

125

160

200

=

CENTRE TRUNNION MOUNTING MT4 FOR PES 453-PLS 452

e9

Ø TD

TL

without

detectors

Ø

mm XV

XV

min.

max.

32 71,5 74,5 + ➀

40 80,5

84 + ➀

50

87

93 + ➀

63 90,5

105 + ➀

80 103,5 117 + ➀

100 111

129 + ➀

TM

3

TG

=

E

=

=

UWA

=

=

=

ZJ + 1

Ø TDe9

ØTK2

MT4 type A

A

=

ZJ + 1

=

TG

=

E

=

without

detectors

XV

XV

min.

max.

71,5

75 + ➀

81

84 + ➀

89,5

91 + ➀

93,5 102,5 + ➀

106,5 114,5 + ➀

116,5 124 + ➀

Ø

mm

h14

TM

4

XV 2

with "T"detectors

ILS type

XV

XV

➀

min.

max.

min.

116,5

30 + ➀ 87

129,5 35,5 + ➀ 94

136 44,5 + ➀ 91

148

48 + ➀ 100

160

61 + ➀ 99

173,5

67 + ➀ 107

180 110 + ➀ 70

204 136 + ➀ 69

218 152 + ➀ 67

with "T"detectors

ILS type

XV

XV

➀

min.

max.

min.

105

41 + ➀ 64

114

51 + ➀ 63

120

60 + ➀ 60

122

72 + ➀ 51

135

84 + ➀ 52

144

96 + ➀ 48

PES 453

TL

4

with "T"detectors

MR type

XV

XV

➀

min.

max.

min.

100

46 + ➀ 54

109

56 + ➀ 53

115

65 + ➀ 50

117

77 + ➀ 41

130

89 + ➀ 42

139 101 + ➀ 38

h14

XV 2

A

with "T"detectors

MR type

XV

XV

➀

min.

max.

min.

109 37,5 + ➀ 72

120

45 + ➀ 75

127,5

53 + ➀ 74

138,5 57,5 + ➀ 81

151,5 69,5 + ➀ 82

165 75,5 + ➀ 90

175 175 + ➀ 60

199 199 + ➀ 59

213 213 + ➀ 57

PES 453 - PLS 452

h14

TK

h14

MT4 type B

(PES 453-PLS 452)

without

detectors

XV

XV

min.

max.

72

74,5 + ➀

83

82 + ➀

89,5

91 + ➀

93,5 102,5 + ➀

106,5 114,5 + ➀

114 126,5 + ➀

135 155,5 + ➀

159,5

181+ ➀

173,5 197 + ➀

32

40

50

63

80

100

with "T"detectors

MR type

XV

XV

➀

min.

max.

min.

71,5

75 + ➀ 50

81

84 + ➀ 10

89,5

91 + ➀ 7

93,5 102,5 + ➀ 1

106,5 114,5 + ➀ 2

116,5 124 + ➀ 0

with "T"detectors

ILS type

XV

XV

➀

min.

max.

min.

71,5

75 + ➀ 65

81

84 + ➀ 19

89,5

91 + ➀ 17

93,5 102,5 + ➀ 10

106,5 114,5 + ➀ 10

116,5 124 + ➀ 7

Dimension XV is specified on order

: Stroke

2 : Except when dimension XV is specified on order. the position of the trunnion may be adjusted along the unit. Consequently, the

centre trunnion is not screwed on and must be adjusted after delivery.

3 : 8 locking screws

1

: Mounting of the centre trunnion by pin (option)

SPHERICAL BEARING ROD END - AP6

ISO 8139 - RP 103 P

E max.

α

α

EN h12

AV

CM

B max.

ØCKH9/d10

H9

ØCN

α: spherical angular

compensation 4°

AX

LE

CH

CE

LF

ER max.

ØKK

ER max.

CL

00578GB-2011/R02

Availability, design and specifications are subject to change without notice. All rights reserved.

FEMALE CLEVIS - AP2

ISO 8140 - RP 102 P

ØKK

4

Ø cylinders

AV-AX

B

CE

CH

ØCK

CL

CM

32

20

26

40

43

10

20

10

40

22

32

48

50

12

24

12

50

28

41

64

64

16

32

16

63

28

41

64

64

16

32

16

80

33

48

80

77

20

40

20

100

33

48

80

77

20

40

20

125

51

65

110

110

30

55

30

160

56

84

144

125

35

70

35

200

56

84

144

125

35

70

35

+0.5

+0.15

+0.5

+0.15

+0.5

+0.15

+0.5

+0.15

+0.6

+0.15

+0.6

+0.15

+0.6

+0.15

+0.6

+0.15

+0.6

+0.15

ØCN

E

EN

ER

ØKK

LE

LF

weight

AP2

AP6

10

56

14

14

M10x1,25

20

15

0,100

0,070

12

67

16

16

M12x1,25

24

17

0,150

0,120

16

89

21

21

M16x1,5

32

22

0,330

0,220

16

89

21

21

M16x1,5

32

22

0,330

0,220

20

112

25

25

M20x1,5

40

26

0,670

0,390

20

112

25

25

M20x1,5

40

26

0,670

0,390

30

155

37

35

M27x2

54

36

1,810

1,600

35

201

43

40

M36x2

72

41

3,850

1,600

35

201

43

40

M36x2

72

41

3,850

1,600

All leaflets are available on: www.asconumatics.eu

P229-23

B

ISO 15552-AFNOR NF ISO15552 - DIN ISO15552

STANDARDISED MOUNTINGS

DIMENSIONS (mm), WEIGHT (kg)

Supports FOR CENTRE TRUNNION - AT4

=

Ød4

Ø HB

Ø CR

=

UL

TH

= =

=

C

NH

=

h14

TM

= L5 =

= L6

=

H9

FN

= =

H3

=

=

=

UL

TH

FK

=

Ø

32

40

50

63

80

100

125

160

200

A

22

24

32

32

40

40

54

72

72

C CRØd4

10,5 12 11

12 16 15

12 16 15

13 20 18

13 20 18

16 25 20

16 25 20

22,5 32 26

22,5 32 26

FK FN HB H3L5L6

15 30 6,6 6,8 71 86

18 36

9

9

87 105

18 36

9

9

99 117

20 40 11 11 116 136

20 40 11 11 136 156

25 50 13,5 13 164 189

25 50 13,5 13 192 217

30 60 17,5 17,5 245 280

30 60 17,5 17,5 295 330

NH

18

21

21

23

23

28,5

28,5

40

40

weight

Ø

32

40

50

63

80

Centre trunnion

Supports

MT4 MT4

MT4

for

monobloc

with flanges

PES 450

for 452-453

for 453

0,200

0,185

0,035

0,120

0,400

0,330

0,083

0,230

0,500

0,475

0,104

0,230

0,900

0,570

0,210

0,330

1,100

1,120

0,225

0,330

TG

32,5

38

46,5

56,5

72

89

110

140

175

TH

32

36

36

42

42

50

50

60

60

TK TK1 TK2

18 22 21

20 28 24

20 28 28

25 35 35

25 35 35

30 40 45

40 40 -

50 50 -

50 50 -

Ø

100

125

160

200

TD

TL

12

16

16

20

20

25

25

32

32

TM

50

63

75

90

110

132

160

200

250

UL

46

55

55

65

65

75

75

92

92

UW

55

58

68

84

102

145

175

220

260

UWA ZJ

64,5 120

74,5 135

91 143

94 158

130 174

145 189

175 225

220 260

260 275

weight

Centre trunnion

Supports

MT4 MT4

MT4

for

monobloc

with flanges

PES 450

for 452-453

for 453

1,860

1,520

0,420

0,580

2,550

-

-

0,580

4,170

-

-

1,030

4,200

-

-

1,030

DIMENSIONS (mm), WEIGHT (kg)

alignment CompensatOR

R

ZJ + 1

X min.

A

A

KW

A1

4˚

øKK

T (2) P (2)

W1(2)

W 2 (2)

1 : stroke

(2) : dimensions on flats

Ø cylinders

A

A1

P(2)

32

40

50

63

80

100

125

22

24

32

32

40

40

54

26

26

34

34

42

42

40

12

12

19

19

19

19

24

ØKK

KW

M10x1,25

6

M12x1,25

7

M16x1,5

8

M16x1,5

8

M20x1,5

9

M20x1,5

9

M27x2

13,5

R

73

77

106

106

122

122

147

T(2) W1(2) W2(2)

17

19

24

24

30

30

41

30

30

42

42

42

42

Ø62

19

19

30

30

30

30

54

X

radial

compensation

(mm)

weight

58

59

82

82

92

92

107

0,7

0,7

1

1

1

1

1

0,210

0,210

0,650

0,650

0,680

0,680

1,700

•Radial compensation: 0,5 to 1 mm (see table)

•Spherical angular: compensation : 4°

Note: The compensator is preset with an axial clearance of 0,05 to 0,1 - Do not reset.

All leaflets are available on: www.asconumatics.eu

P229-24

00578GB-2011/R01

Availability, design and specifications are subject to change without notice. All rights reserved.

øKK

4˚