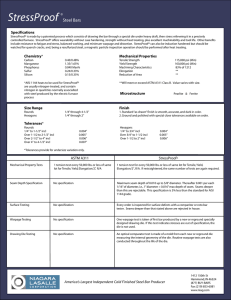

PRODUCT GUIDES - Central Steel - Central Steel and Wire Company

advertisement