technology report 03, 2012 PDF

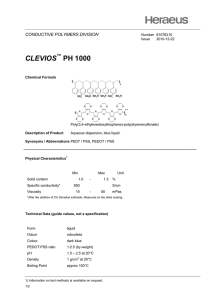

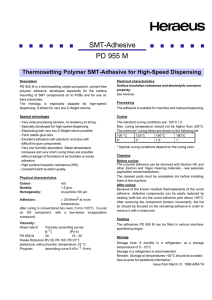

advertisement