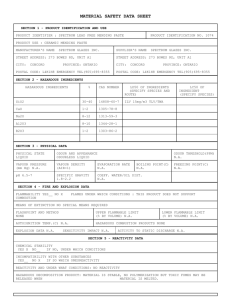

Ceramic decorating materials - Verband der Mineralfarbenindustrie

advertisement