Static Electricity

advertisement

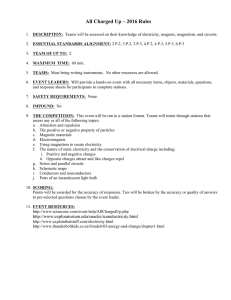

AUSTRALIA Safetycare Australia Pty. Ltd. Telephone (03) 9569 5599 Email safety@safetycare.com.au CANADA Safetycare Inc. Telephone Email (905) 631 6070 safety@safetycare.ca Safetycare Inc. Telephone Email (800) 323 6638 safety@safetycare.com USA UNITED KINGDOM Safetycare (UK) Limited. Telephone (0208) 977 8900 Email safety@safetycare.co.uk SINGAPORE SafetyMax Corp Pte. Ltd. Telephone 6750 4500 Email sales@safetymaxcorp.com MALAYSIA SafetyMax Sdn Bhd Telephone (603) 2692 5007 Email saleskl@safetymaxcorp.com 1. The information contained in this Facilitator’s guide is distributed and sold as a guide and for informational purposes only. Safetycare makes no representation or warranty as to the compliance of this program with any and all applicable laws of the purchaser's jurisdiction. 2. Safetycare's liability for any damages to the purchaser or to any other party shall not exceed the amount paid by the purchaser for the guide. In no event shall Safetycare be responsible for any indirect or consequential damages or loss of profits, even if Safetycare has been advised of the possibility of such damage. Some provinces/states do not allow the limitations or exclusion of liability for incidental or consequential damages, so the above limitations or exclusions may not apply to the purchaser. 3. This Facilitator’s Guide is supplied as part of a subscription service. This guide is only to be used during a valid subscription period. Where a subscription is not valid, this guide may not be used. Facilitator’s Guide STATIC ELECTRICITY Copyright - All Rights Reserved Static Electricity CONTENTS Introduction to the Facilitator’s Guide 3 Introduction to the Program Static Electricity 4 Transcript of the Program 5 PART 1 What Is Static Electricity? 10 PART 2 Sources of Static Electricity in the Workplace 12 PART 3 Potential Hazards 13 PART 4 Controlling Static Electricity 14 PART 5 General Guidelines 16 Assessment 17 Answers 19 Page 2 INTRODUCTION TO THE FACILITATOR’S GUIDE Static Electricity The aim of this Facilitator’s Guide, when used in conjunction with the Video program, is to provide the facilitator with discussion points important to the overall development of the program and to allow participants the opportunity of discussing the impact the program may have on current work practices and whether in fact changes may be required. The time allocated to the program will be determined by which areas are seen as important to each Organisation, the time taken to develop the points made in the program and whether other data specific to your own environment is included in addition to, or instead of, the program examples. EACH FACILITATOR SHOULD CAREFULLY READ THE GUIDE DISCUSSION NOTES SUGGESTED AND PREPARE THEIR OWN INPUT ACCORDINGLY. The program transcript is included to allow your Organisation to fully research the program content and develop specific examples critical to the performance of your own workforce. Where the Video program is made available to small or remote sections of your Organisation, some other examples or discussion points may be preferred to suit the needs of these people and if so, should be developed prior to distribution of the program. Maximum benefit will then be obtained by your people. All information included in the Facilitator’s Guide may be copied and distributed with the exception of the transcript of the Video program. Any information which is copied or distributed must only be used internally by the Organisation which purchased the guide. Page 3 INTRODUCTION TO THE VIDEO PROGRAM Duration: 13 minutes Static electricity poses a number of threats to safety, the most significant of which is the potential for it to be a source of ignition for fires and explosions. Because static electricity can occur whenever objects, substance or people move, it is a natural byproduct of many workplace processes. This program aims to increase people’s awareness of static electricity and its potential to result in serious accidents and injuries. The program examines the potential hazards associated with static electricity, ways to control static electricity, and a number of important safety precautions that should be followed when working in flammable atmospheres. The program looks at the following questions: What is static electricity? What are the common sources of static electricity in the workplace? What are the potential hazards associated with static electricity? How can static electricity be controlled? What precautions should be followed? The program is designed to provide people with a practical understanding of static electricity and how it can be controlled, and is suitable for any work environment where the presence of static electricity could pose a threat safety. Page 4 TRANSCRIPT OF THE VIDEO PROGRAM Static Electricity © Copyright Safetycare. All rights reserved We all have some knowledge of static electricity: those annoying, unexpected shocks we experience when we’re getting out of a car or when we touch a door handle after walking across a carpet. For most of us static electricity is just a nuisance. But during some workplace activities static electricity is a critical safety issue that must be addressed. What is Static Electricity? Static electricity is the electrical charge that forms when there is an excess of positive or negative charges on an object’s surface. All objects are made up of atoms. The centre of the atom, the nucleus, is made up of tiny particles known as protons and neutrons. Smaller particles, known as electrons, orbit the nucleus. Protons are positively charged. Electrons are negatively charged, and neutrons are neutral - that is, they have no electrical charge. Normally, an atom has an equal number of protons and electrons. In this balanced state the atom is neutral and has no electrical charge. When two objects come in contact, electrons CAN move from one object to the other, causing their atoms to become electrically imbalanced, and therefore electrically charged. This electrical charge is what is known as static electricity. Statically charged objects always try to restore their electrical balance so they can become neutral again. If static charges aren’t discharged they can build up on an object until they have enough energy to jump, in the form of a spark, to a grounded or less highly charged object nearby. This restores the electrical balance of the atoms, and the object becomes neutral again. The spark that can often result from the build up of static electricity can be a serious threat to safety. Sources of Static Electricity in the Workplace Static electricity can be generated whenever objects, substances or people move…so it’s not surprising that static electricity is a common by-product of many workplace activities and processes. Page 5 Including: the use of conveyor belts, rollers and pulleys the movement of substances through pipes and chutes processes involving spraying, coating, blending or mixing the wearing of synthetic or wool clothing, and walking on non-conductive flooring surfaces, most commonly, nylon carpets. The movement of liquids is another common source of static electricity in the workplace. Whether they are flowing through pipes, being mixed, pumped, filtered, agitated or poured from one container to another, ALL liquids in motion have the potential to produce static electricity. Potential Hazards There are a number of potential hazards associated with static electricity in the workplace. Including: sudden, unexpected shocks that can lead to involuntary muscle contractions and reflex actions handling problems, resulting from unwanted adhesion or repulsion of materials false readings in electronic devices, and damage to electronic circuitry. BUT by far the most serious hazard associated with static electricity is the potential for it to be a source of ignition for fires and explosions. In the vicinity of flammable vapours, gases, powders or dusts, a single static spark can have devastating consequences. For static electricity to cause a fire or an explosion four conditions need to be present at the same time. First, static charges must build up Second, these charges must possess what is called a minimum ignition energy or MIE. That is, they must be able to cause a spark The spark itself must then have enough energy to ignite the flammable substance in its vicinity. And finally, the environment must be flammable. Flammable vapours, gases, dusts or powders must be present in a flammable fuel-to-air ratio. Page 6 Control Measures As we already know the build up of static charges can lead to a number of hazards. So, it follows that the aim of most control measures is to prevent the build up of static charges or alternatively to provide a safe way for them to be dissipated before they can result in a spark. Control measures for static electricity can be categorised into two groups: ones that could be grouped under the heading of workplace engineering controls and, ones that should be included as part of safe work procedures Many workplaces use specialised equipment to aid in the control of static charges. These include various types of electrostatic neutralisers, … including high-voltage and induction neutralisers, … static collectors, and humidification equipment. However, these engineering controls should not be relied on to control static electricity, especially in flammable environments. These control measures work best when they are used in conjunction with other suitable control measures which are incorporated into safe work procedures. As most of the serious accidents and injuries that are caused by static electricity result from sparks igniting flammable vapours it is particularly important to consider the use of flammable liquids. Flammable solvents, some with low flash points, and fuels are common in many workplaces. As we already know the movement of liquids can produce significant amounts of static electricity. Everyone also knows that electricity travels well through objects that we call conductors and does not travel well, if at all, through insulators. This simple fact provides us with the main principle of how we control static problems in the workplace, and in particular how we deal with flammable liquids. What we are trying to avoid is the build up of static charges. Static electricity is, in simple terms, high voltage electricity waiting for an opportunity to discharge. If this static electricity is contained, for example, with a flammable liquid inside a non-conductive plastic container, it has no easy means of dissipating. If the same flammable liquid is inside a metal or conductive container and that container is on the ground, the static can pass easily through the metal container and dissipate into the ground. This simple principle of creating a path for electricity to flow through conductors is how static electricity can be effectively managed and is the principle behind what is commonly referred to as bonding and grounding. Page 7 Bonding involves the creation of an electrical connection between two or more conductive objects, using a conducting wire or strip. Objects that have been bonded all share the same electrical charge, which means there is no electrical imbalance between them, so sparks can NOT occur between bonded objects. Bonding however, does not eliminate the static charge. As well as being used to connect containers, bonding can also be used to connect sections of plant and equipment so that static charges in those sections can be equalised. Like bonding, grounding, also involves the electrical connection of objects. But, in the case of grounding, the connection runs from an object to the ground. Unlike bonding, grounding drains the static charges away as they are produced, eliminating the chance of sparking. Grounding works because it obeys the basic rule of electricity that states that electricity will always try to travel to the ground. If static electricity is given the chance to travel through conductors that are in contact with the ground it will dissipate. In many situations both bonding and grounding must be used together, for example when dispensing a highly flammable liquid from a main drum to a receiving container. It is important that bonding and grounding connections are always made with appropriate materials, and they are attached by soldering, welding, or suitable screws, clamps or clips. In some environments it may also be necessary to bond or ground personnel. This can be done using special anti-static wrist straps or flexible leads. There are many different situations when bonding and grounding procedures should be used. It is important to strictly adhere to any bonding or grounding steps that are included in established safe work procedures. Included in many safe work procedures you will also find steps based on the following general guidelines for dealing with static hazards. General Guidelines When pouring flammable liquids, always pour them slowly. The faster a substance flows the greater the chance that static charges will build up. Consideration should also be given to the use of anti-static additives. These will act to increase a liquid’s conductivity, lower its resistance, and enable charges to pass more easily through the container. Page 8 Liquids, gases, dusts or powders that are being transferred, discharged, decanted, or processed all have the potential to generate static charges. Again, consideration should be given to the speed or velocity of these activities. Nozzles that are used should be made of conductive materials and in some cases may need to be bonded or grounded. Generally, objects nearby or directly involved with processes that include the movement of liquids, gases, dusts or powders should be made from conductive materials and be grounded. In areas where static is a potential hazard both work surfaces and floor surfaces should be made from conductive materials, such as metal, conductive plastic, conductive rubber, untreated wood and unpainted concrete. Surfaces should be kept clean and free of oils, resins, waxes and other substances that can reduce their conductivity. Clothing is another area that may need to be addressed. Clothing made from wool, silk and synthetic fibres such as polyester and nylon can store electrical charges and can lead to sparking. In situations where this could pose a serious threat, linen or cotton garments should be worn. In some cases polyester and cotton blends can be worn but the suitability of clothing should be checked before entering any environment where it could be hazardous. Likewise, footwear should be conductive to prevent the build up of static charges. AND both clothing and footwear should be kept as clean as possible as dirt will tend to reduce their conductivity. Whenever objects, substances or people move, there is the potential for static electricity to be produced. Fortunately, in the vast majority of situations where static electricity is produced it does not pose a threat to health and safety. The key to dealing with potentially hazardous situations that involve static electricity is simply to follow safe work procedures. Everyone working in or nearby any area where static may be a threat must be fully informed of the potential dangers and be aware of all relevant safe work practices and procedures. Because static electricity is readily produced and is an invisible hazard it can easily be overlooked. Static electricity can never be eliminated but properly managed it can be effectively controlled Page 9 PART ONE WHAT IS STATIC ELECTRICITY? ANSWER: Simply put, static electricity is the electrical charge that forms when there is an excess of positive or negative charges on an object’s surfaces. Unlike electricity which is generated and travels in circuits as current, static electricity does NOT possess a current – that’s why it’s known as static. All objects are made up of atoms. The centre of the atom, known as the nucleus, contains tiny particles called protons and neutrons. Smaller particles, known as electrons orbit the nucleus. Each part of the atom is differently charged. Protons are positively (+) charged. Electrons are negatively (-) charged, and neutrons are neutral, that is, they have no electrical charge. In their normal state atoms have an equal number of protons and electrons. This creates a balanced state in which the atoms are neutral – that is, they do not have an electrical charge. For an atom to become charged it has to either gain or lose electrons. This disrupts the atom’s balance, leaving it with an electrical, or static charge. When two objects come into contact electrons from one object move to the other object, causing their atoms to become electrically imbalanced, and therefore charged. When an atom gains electrons it becomes negatively charged. When it loses electrons it becomes positively charged. So, instead of being neutral the atom now has an electrical charge, which is either positive or negative. This electrical charge is known as static electricity. Once an object becomes statically charged it will try to restore it’s electrical balance and become neutral again. When static charges aren’t discharged they will build up on an objects surface until they have enough energy to jump in the form of a spark to a less highly charged or grounded object nearby. This process restores the electrical balance of the object making it neutral again. Page 10 DISCUSSION List some situations where you have seen or experienced static electricity. In your immediate environment, try to generate static electricity. What evidence is there to indicate that static electricity has been produced? Page 11 PART TWO SOURCES OF STATIC ELECTRICITY IN THE WORKPLACE Static electricity is easily produced. It can be generated whenever objects, substances or people move. It follows then, that many workplace processes and activities can be sources of static electricity. Within the work environment, static electricity can be generated from a number of sources. Some of these include: Conveyor belts, rollers and pulleys The movement of substances through pipes and shoots Processes that involve spraying, coating, blending or mixing Synthetic or wool clothing Non-conductive flooring surfaces, especially nylon carpets Static electricity can also be generated by liquids in motion. Liquids moving through pipes, being mixed, pumped, filtered, agitated or poured from one container to another all have the potential to produce static electricity. DISCUSSION Make a list of materials that produce static electricity easily. Make a list of materials that don’t produce static electricity easily. What conditions are conducive to the generation of static electricity? (e.g. dry, humid, windy, cold etc.) Page 12 PART THREE POTENTIAL HAZARDS There are a number of potential hazards associated with static electricity in the workplace. Some of the most common hazards are: Sudden and unexpected shocks that can lead to involuntary muscle contractions and reflex actions Handling problems resulting from unwanted adhesion or repulsion of materials False readings in electronic devices Damage to electronic circuitry The MOST SERIOUS hazard associated with static electricity however, is the potential for it to be a source of ignition for FIRES and EXPLOSIONS. When a single static spark occurs in the vicinity of flammable vapours, gases, powders or dusts it can have devastating consequences. For static electricity to cause a fire or an explosion FOUR condition must be present simultaneously: 1. Static charges must build up. 2. These static charges must possess a minimum ignition energy or MIE. That is, they must be able to produce a spark. 3. The spark itself must have enough energy to ignite the flammable substance in its vicinity. 4. The environment must be flammable. DISCUSSION Has anyone experienced a fire or explosion caused by static electricity? Discuss the circumstances in which it occurred. Page 13 PART FOUR CONTROLLING STATIC ELECTRICITY The aim of most control measures is to prevent the build up of static charges or alternatively to provide a safe way for them to dissipate before they can result in a spark. Specialised equipment, such as electrostatic neutralisers, static collectors, and humidification equipment can be used to control static electricity. However, these engineering controls should not be relied on as the only means of controlling static electricity, especially in flammable environments. These kinds of control measures work best when they are used in conjunction with other suitable control measures which are included as safe work procedures. As we know, electricity travels well through objects known as conductors and does not travel well, if at all, through insulators. This simple fact underlies the central principle used in controlling static electricity, and in particular in the prevention of static electricity causing fires and explosions. As we have already said, the aim is to prevent static charges from building up. To do this, static charges must be able to dissipate. This can be done by using conductive, rather than non-conductive materials. For example, if flammable liquids are stored in conductive containers that are placed on the ground, static charges are able to dissipate and ground themselves, thereby removing the risk of ignition. Creating a path along which static charges can flow is the principle behind what is known as bonding and grounding. BONDING AND GROUNDING Bonding involves the creation of an electrical connection between two or more conductive objects, using a conducting wire or strip. Bonded objects all share the same electrical charge. This means there is no electrical imbalance between them, so sparks can not occur. It must be remembered however, that bonding does not eliminate the static charge. Grounding also involves the electrical connection of objects. In the case of grounding however, the connection runs from an object to the ground. Grounding, unlike bonding, drains static charges away as they are produced, thereby eliminating the chance of sparking. If static electricity is given the opportunity to travel through conductors that are in contact with the ground, then it will dissipate. Page 14 In many situations bonding and grounding must be used together. For example, when dispensing highly flammable liquid from a main drum to a container. Bonding and grounding connections should always be made using appropriate materials. Bonding and grounding connections should always be attached by soldering, welding, or by using suitable screws, clamps, or clips. Personnel can also be bonded and grounded by using special anti-static wrist straps or flexible leads. DISCUSSION List some control measure currently used in your work environment to control static electricity. Explain how they work. Page 15 PART 5: GENERAL GUIDELINES Below are some general guidelines that should be followed when dealing with static hazards. When pouring flammable liquids, always pour them slowly. The faster a substance flows the greater the chance that static charges will build up. Using anti-static additives will act to increase a liquid’s conductivity, lower its resistance, and enable charges to pass more easily through the container. Consideration should be given to the speed or velocity of liquids, gases, dusts or powders that are being transferred, discharged, decanted, or processed as they have the potential to generate static charges. Nozzles should be made of conductive materials and in some cases may need to be bonded or grounded. Objects nearby or directly involved with processes that include the movement of liquids, gases, dusts or powders should be made from conductive materials and be should be grounded. In areas where static is a potential hazard work surfaces and floor surfaces should be made from conductive materials, such as metal, conductive plastic, conductive rubber, untreated wood and unpainted concrete. Surfaces should be kept clean and free of oils, resins, waxes and other substances that can reduce their conductivity. Clothing made from wool, silk and synthetic fibres such as polyester and nylon can store electrical charges and can lead to sparking and therefore should be avoided. Instead, linen or cotton garments should be worn. In some cases polyester and cotton blends may be worn but the suitability of clothing should be checked before entering any environment where it could be hazardous. Footwear should be conductive to prevent the build up of static charges. Clothing and footwear should be kept as clean as possible as dirt will tend to reduce their conductivity. The key to dealing with potentially hazardous situations that involve static electricity is simply to follow safe work procedures. Everyone working in or nearby any area where static may be a threat must be fully informed of its potential dangers and be aware of all relevant safe work practices and procedures. Static electricity can never be eliminated but properly managed it can be effectively controlled. Page 16 ASSESSMENT – STATIC ELECTRICITY Name: …………………………………………… Date: ……………………………………………. I.D. (if applicable): ………………………………… Score ___________________________________________________________________ 1. Static electricity builds up when there is an excess of positive or negative ____. a) b) c) d) Liquids Friction Charges Sparks 2. Static charges can result in a spark if they are not ____. a) b) c) d) Positive Filtered Unexpected Discharged 3. Which of these is not a potential source of static electricity? a) b) c) d) Walking on nylon carpets Moving goods on a conveyor belt Stacks of boxes Pumping petrol 4. Static electricity is formed when ___. a) b) c) d) Objects move Substances move People move All of the above Page 17 5. What is the most serious potential hazard associated with static electricity? a) b) c) d) Fires and explosions Unexpected shocks Manual handling problems Respiratory problems 6. For static electricity to cause a fire or explosion, the environment must be ____. a) b) c) d) Clean Hot Flammable Outdoors 7. Electricity travels well through what? a) b) c) d) Insulators Conductors Electrons Plastics 8. Static electricity can be effectively managed through ____. a) b) c) d) Personal protective equipment Bonding and grounding Electrocution Manual handling 9. Electricity will always try to ____. a) b) c) d) Travel to the ground Cause sparks Electrocute you Power machinery 10. Flammable liquids should always be poured ____. a) b) c) d) Fast Into plastic Onto the ground Slowly Page 18 ANSWERS TO ASSESSMENT 1. c) Charges. 2. d) Discharged. 3. c) Stacks of boxes. 4. d) All of the above. 5. a) Fires and explosions. 6. c) Flammable. 7. b) Conductors. 8. b) Bonding and grounding. 9. a) Travel to the ground. 10. d) Slowly. Page 19