“Today`s op amps have wider bandwidth, operate

advertisement

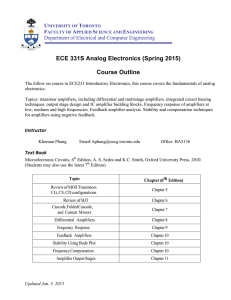

Analog tut.qxp:ADVERTORIAL TEMP 15/4/08 15:20 Page 24 Advertisement Feature Opportunity The future for the operational amplifier. By Reza Moghimi and Craig Wilson. H uge advances have been made in semiconductor processing and circuit design in the four decades since the first IC op amp was introduced. IC manufacturers have employed these advances to design nearly ‘ideal’ amplifiers. Although unachievable by definition, the ideal op amp has provided a target for analogue designers. The ideal amplifier is noiseless, has infinite gain, infinite input impedance, zero bias current and zero offset voltage. It is also free and takes up no space. These assumptions are made to come up with the simple transfer functions shown in many text books. In reality, amplifier selection today is quite complex. This is due, in part, to the variety of system design requirements and the multitude of circuit configurations. There are many performance trade offs and manufacturers such as Analog Devices have worked to provide a portfolio of capabilities to meet user needs. Amplifier designers continue to push the technology envelope and this trend will continue for the foreseeable future. Manufacturers combine new processes, package options and manufacturing capabilities to produce parts that are, in effect, ‘perfect’ for many of today’s challenging applications. Every application requires a different combination of specifications and the number of amplifiers available continues to expand to fit those needs. Comparing equivalent devices, today’s op amps have wider bandwidth, operate at lower voltages, consume less current, fill less pcb area and cost less than older parts. This trend will ADI’s AD8506 op amp is designed for portable applications such as medical equipment. continue as signal to noise requirements increase and as real world signal processing takes place in more of our home appliances and industrial equipment. Where we’ve been A quick historical look reveals amplifiers (LM709) that required external compensation and external offset adjust components. The majority of these products were processed on 2in wafers using a bipolar process. Dual inline and TO-99 can were the only packaging choices and the major application segment was industrial instrumentation. Low power meant drawing a few milliamps current from ±15V supplies. Manufacturers specified only dc parameters, yields were low and prices were high. In today’s world of precision amplifiers, small signal designers concerns themselves with critical factors such as low supply current, low offset, low noise and low bias current. The latest amplifiers use innovative designs and processes to deliver performance that continues to exceed user’s expectations. Design engineers push to optimise each specification using circuit and production test techniques, including autozero, the Digitrim trimming process, fuse blowing and laser trimmed resistors, thus creating amplifiers that are close to ideal in a few specific parameters. As an example, state of the art amplifiers specify offset voltages as low as a few microvolts. Significant advances have occurred in all aspects of process technology. These advances allow amplifier design engineers to take the maximum performance and functionality from every technology. CMOS process technologies have benefited from advances driven by the digital microprocessor world and amplifier designers have used this superior performance at lower costs. Traditionally, ultra high performance amplifiers were designed in the bipolar world. Now, however, analogue amplifier designers have been able to overcome the higher voltage noise inherent to CMOS processes, allowing them to combine low noise with super low bias current (made possible by the oxide insulated gate). Manufacturers continue to develop “Today’s op amps have wider bandwidth, operate at lower voltages, consume less current, fill less pcb area and cost less than older parts.” 24 www.newelectronics.co.uk 22 April 2008 Analog tut.qxp:ADVERTORIAL TEMP 15/4/08 15:41 Page 25 SPONSORED TUTORIAL Mixed Signal & Analogue y knocks proprietary manufacturing processes, such as industrial CMOS (iCMOS) from Analog Devices. This process provides the lowest noise CMOS amplifier (2.7nV/rtHz at 10kHz) and a super low supply current amplifier (1µA per amplifier). Many high performance op amps still use bipolar processes, which offer significant benefits in analogue design and few performance tradeoffs. New industrial bipolar processes, such as ADI’s iPolar trench isolation process, have shrunk die sizes dramatically by including state of the art processing techniques as well as devices such as JFETS. These new developments in process technologies have allowed amplifier designers to develop products with incredible performance parameters. As an example, the AD8599 ultra low distortion op amp pushes total harmonic distortion down to –105dB and broadband noise down to nearly immeasurable levels (1nV/rtHz at 1kHz). In the world of high speed amplifiers, ultra fast processes have allowed devices with slew rates of 310V/µs and unity gain bandwidths of 600MHz. These performance enhancements are all possible while also continuing to shrink the die size. This has enabled package sizes to become incredibly small, to levels that are hardly detectable by the naked eye. Where are we going? For applications powered by single AA cell or nickel metal hydride (NiMH) batteries, size and power consumption are primary concerns. Operating supply voltages are already down to 1.8V and are decreasing. The AD8500, with its 1µA supply current, is the best choice when precision, low voltage operation and low power consumption are all required. The drive towards single cell operation is on Figure 1: AD8556 block diagram DIGIN VCLAMP VDD VDD d/a converter logic VPOS 1 EMI filter VDD A1 2 3 A5 EMI filter VSS VSS VSS VDD A3 EMI filter VNEG EMI filter –in +in VDD A2 VDD EMI filter VSS VOUT A4 VSS VSS VSS filt/digout and precision amplifiers will be available when needed. To save power, many products will require intelligent shutdown circuits. Integrating other functions with amplifiers can also reduce system errors. For example, the digitally programmable sensor signal amplifier with EMI filter (see figure 1) has brought many previously unachievable benefits (gain adjustment, offset adjustment and fault detection circuitry) to the sensor signal conditioning world. Further increases in integration can include linearity correction, frequency shaping, or other functions to create more complete solutions. Manufacturing and design trends will continue to bring lower priced, better specified and smaller parts to users. Existing issues such as rail to rail performance and power consumption will see continuous improvement and amplifiers will get closer to their ‘ideal’ state. Continued advances in process and packaging technologies will continue to enable more integration within smaller packages, allowing increased functionality and performance. Amplifiers will begin to integrate other functions, again within very small packages. Advances in package material sets will allow even tighter parametric specifications. The future will also bring products that are easier to design into systems. Manufacturers will place more emphasis on design tools for amplifiers. Traditional PSPICE models will be replaced by more elaborate ones that include more amplifier parameters. Additional tools will help to analyse stability, ac and dc errors. Using SPICE models to represent the general behaviour of a selected amplifier, designers can select a component, quickly configure a circuit, apply a signal and evaluate the amplifier’s general performance on the web. With online parametric evaluation tools, users can now conduct real time simulations quickly and efficiently and troubleshoot potential problems across various parameters and architectures. Wizard tools will be developed for the web to provide expert knowledge to designers’ problems 24 hours a day. ■ Author profiles: Reza Moghimi, an Applications Engineering Manager and Craig Wilson, a Technologist, are with Analog Devices’ Precision Signal Processing Group. For more information, go to www.analog.com www.newelectronics.co.uk 22 April 2008 25