IMPORTANT SAFEGUARDS

When using electrical equipment, basic safety precautions

should always be followed including the following:

READ AND FOLLOW ALL

SAFETY INSTRUCTIONS

1.Do not use outdoors.

2.Do not mount near gas or electric heaters.

3.Use caution when servicing batteries.

4.Equipment should be mounted in locations and at heights where it will not readily be subjected to tampering by unauthorized personnel.

5.The use of accessory equipment not recommended by the

manufacturer may cause an unsafe condition.

6.Do not use this equipment for other than intended use.

7.Servicing of this equipment should be performed by qualified

service personnel.

■ INSTALLING THE UNIT

1.Fasten mounting plate to wall or junction box (see Fig. 2).

2.Attach housing onto mounting bracket with hinge straps

(see Fig.2).

3.Make up AC supply connections using wire nuts. Select either black for 120 VAC, or red for 277 VAC. Cut back and insulate unused lead (see Fig. 2).

4.Connect red positive (+) battery lead to printed circuit board positive (+) battery terminal (see Fig. 3).

5.Swing chassis up and tighten retaining screws (see Fig. 1).

6.Energize AC input power.

7.Adjust emergency lamps to desired angle.

•Caution:Damage to the battery may occur if the battery is left connected for a prolonged period of time without AC power.

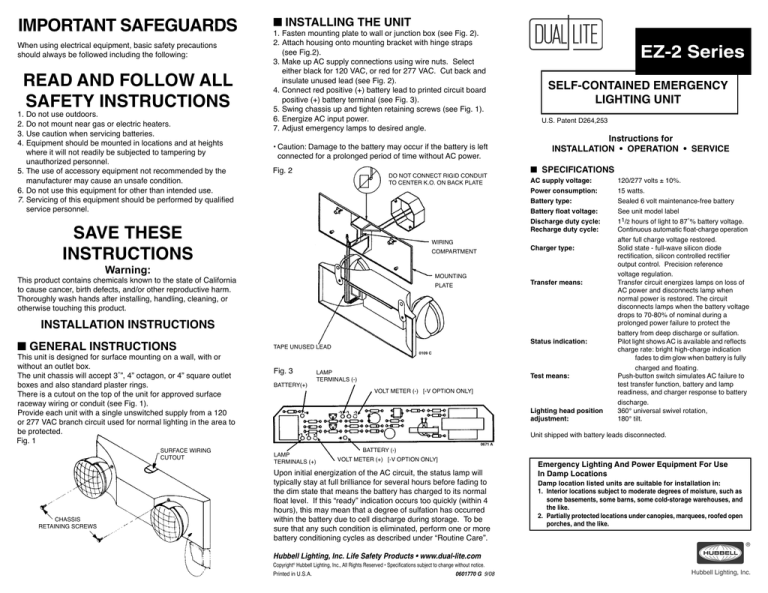

Fig. 2

DO NOT CONNECT RIGID CONDUIT

TO CENTER K.O. ON BACK PLATE

SAVE THESE

INSTRUCTIONS

WIRING

COMPARTMENT

Warning:

MOUNTING

This product contains chemicals known to the state of California

to cause cancer, birth defects, and/or other reproductive harm.

Thoroughly wash hands after installing, handling, cleaning, or

otherwise touching this product.

PLATE

INSTALLATION INSTRUCTIONS

■ GENERAL INSTRUCTIONS

This unit is designed for surface mounting on a wall, with or

without an outlet box.

The unit chassis will accept 3˚”, 4” octagon, or 4” square outlet

boxes and also standard plaster rings.

There is a cutout on the top of the unit for approved surface

raceway wiring or conduit (see Fig. 1).

Provide each unit with a single unswitched supply from a 120

or 277 VAC branch circuit used for normal lighting in the area to

be protected.

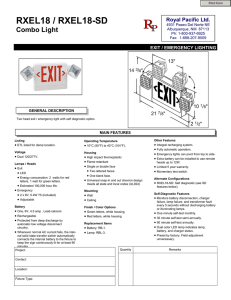

Fig. 1

SURFACE WIRING

CUTOUT

CHASSIS

RETAINING SCREWS

TAPE UNUSED LEAD

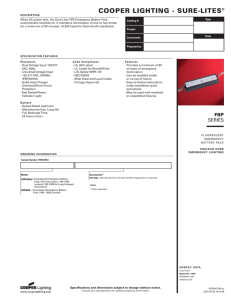

Fig. 3

BATTERY(+)

0109 C

LAMP

TERMINALS (-)

VOLT METER (-) [-V OPTION ONLY]

EZ-2 Series

SELF-CONTAINED EMERGENCY

LIGHTING UNIT

U.S. Patent D264,253

Instructions for

INSTALLATION • OPERATION • SERVICE

■ SPECIFICATIONS

AC supply voltage:

120/277 volts ± 10%.

Power consumption:

15 watts.

Battery type:

Sealed 6 volt maintenance-free battery

Battery float voltage:

See unit model label

Discharge duty cycle:

11/2 hours of light to 87˚% battery voltage.

Recharge duty cycle:

Continuous automatic float-charge operation after full charge voltage restored.

Charger type:

Solid state - full-wave silicon diode rectification, silicon controlled rectifier output control. Precision reference voltage regulation.

Transfer means:

Transfer circuit energizes lamps on loss of AC power and disconnects lamp when normal power is restored. The circuit disconnects lamps when the battery voltage drops to 70-80% of nominal during a prolonged power failure to protect the battery from deep discharge or sulfation.

Status indication:

Pilot light shows AC is available and reflects charge rate: bright high-charge indication fades to dim glow when battery is fully charged and floating.

Test means:

Push-button switch simulates AC failure to test transfer function, battery and lamp readiness, and charger response to battery

discharge.

Lighting head position

360° universal swivel rotation,

adjustment:

180° tilt.

Unit shipped with battery leads disconnected.

LAMP

TERMINALS (+)

BATTERY (-)

0671 A

VOLT METER (+) [-V OPTION ONLY]

Upon initial energization of the AC circuit, the status lamp will

typically stay at full brilliance for several hours before fading to

the dim state that means the battery has charged to its normal

float level. If this “ready” indication occurs too quickly (within 4

hours), this may mean that a degree of sulfation has occurred

within the battery due to cell discharge during storage. To be

sure that any such condition is eliminated, perform one or more

battery conditioning cycles as described under “Routine Care”.

Hubbell Lighting, Inc. Life Safety Products • www.dual-lite.com

Copyright© Hubbell Lighting, Inc., All Rights Reserved • Specifications subject to change without notice.

Printed in U.S.A.

0601770 G 9/08

Emergency Lighting And Power Equipment For Use

In Damp Locations

Damp location listed units are suitable for installation in:

1. Interior locations subject to moderate degrees of moisture, such as some basements, some barns, some cold-storage warehouses, and the like.

2. Partially protected locations under canopies, marquees, roofed open porches, and the like.

TROUBLESHOOTING CHART

SYMPTOM

POSSIBLE CAUSE

Unit blows AC supply fuse/breaker. Unit connected to 277 VAC circuit, but 120 volt input lead used.

PROCEDURE

Check AC input connections. If wrong, correct connections and try unit again, but charger module will also probably have to be replaced.

Short in unit wiring or charger module.

Check wiring. If wiring OK but disconnecting black or red lead from transformer clears short, replace charger module.

No pilot light indication when AC on. Emergency lamps may be on.

Unit connected to 120 VAC circuit, but 277 volt input lead chosen.

Check AC input connections and correct if wrong.

No red pilot light indication when AC on.

Unit connected to 277 VAC circuit, but 120 volt input lead used.

Check AC input connections. If wrong, correct connections and try unit

again, but charger module will also probably have to be replaced.

Defective charger module.

Replace module.

Pressing test switch does not light

emergency lamp(s).

If red lamp was bright before test switch

pressed, battery voltage may be below cutoff threshold.

Allow battery to charge until red light dims, and then repeat test. Battery lead may be disconnected.

If red lamp was dim before test switch pressed and does not light emergency

lamps when pressed, lamp(s) defective.

If all battery and lamp circuits check OK, replace charger module.

Defective charger/transfer module.

Prior lamp indications OK, but unit Battery partially sulfated.

fails to give full 1˚ hours of emergency lighting.

Battery defective.

Full apparent recharge occurs too quickly (within ˚ hour after

discharge to low-voltage cutoff),

and unit won’t perform 1˚ hour

test as above.

Same as causes of preceding symptom.

■ ROUTINE CARE

The battery used in these models is sealed and requires no

maintenance, but will benefit from certain operating procedures.

During routine standby operation, charger output fluctuates only

slightly in floating the battery at its full-charge voltage. But after

an AC failure and subsequent battery discharge, charger output

increases greatly to recharge the battery as quickly as cell

temperature-rise and gas-cycling considerations permit. This

vigorous charging action also agitates the electrolyte and tends

to reverse physical and chemical changes that can slowly occur

in a battery that stands for long periods without cycling. It follows

that if power failures are infrequent, occasional deliberate cycling

may extend battery life.

■ TEST CYCLING

Every three months, if there has been no power failure, press

the unit test switch for at least 30 seconds. Before the switch is

pressed, the pilot light should be glowing dimly. When the switch

is pressed, the pilot light should become bright and remain bright

when the switch is released (assuming that the emergency lights lit

while the switch was depressed). The pilot light should fade back

to its dim state within a few minutes.

Perform conditioning cycle(s) per instructions under Routine Care until short apparent recharge time symptom of sulfation no longer occurs.

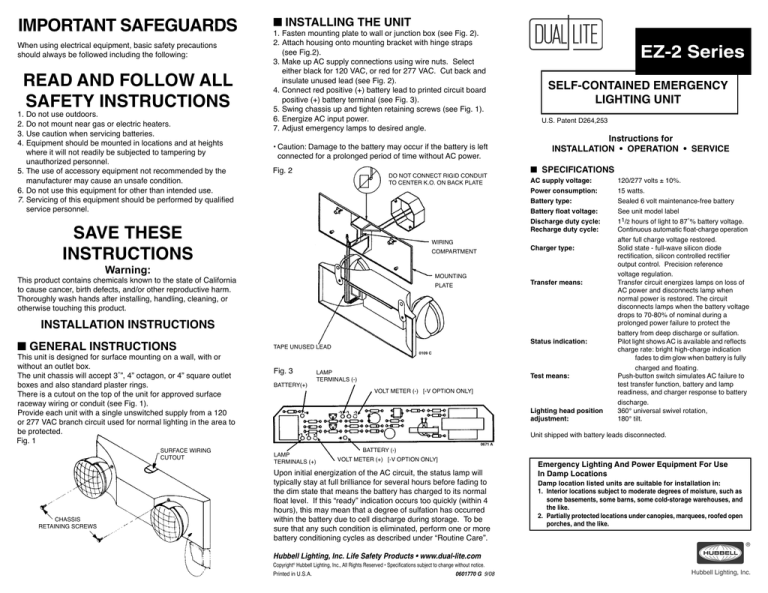

■ EMERGENCY LAMP: REPLACE

1. To remove the lamp assembly from the lamp housing, place a screwdriver into the slot (Fig. 4), and pry the lamp assembly out.

2. Insert a screwdriver into the lens slot (Fig. 5) and pry the lens from the reflector assembly.

3. Remove the defective bulb (Fig. 6). Insert a new bulb into the reflector by aligning bulb base with socket and pushing lamp firmly into socket.

4. Reassemble the lamp:

a. align the small “key”, located between the anti-

rotation tabs on the reflector assembly, with the

“keyway” adjacent to the ribbed area on the edge of the lens. (Fig. 6).

b. press the lens into the reflector assembly.

5. Rejoin lamp assembly to lamp housing:

a. orient the lamp assembly’s anti-rotation tabs to the top of the lamp housing.

b. set the bottom of the lamp assembly into the housing and dress wires neatly into the housing cavity.

c. insert a screwdriver into the slot (Fig. 4) and lever the lamp assembly into the housing.

Fig. 4

INSERT SCREWDRIVER

INTO SLOT TO

REMOVE LAMP

Conditioning charges do not increase battery capacity; replace battery.

Same procedures for causes of preceding symptom.

Fig. 5

■ CONDITIONING CYCLES

Once a year, if power failures have been infrequent or of short

duration, perform a full battery conditioning cycle. De-energize

the AC circuit to which the unit is connected and let the emergency

light(s) operate for 1˚ hours. Then restore AC power. This puts the

battery through a discharge/recharge cycle over its full intended

range, and also provides a rigorous test of overall unit operation.

See “Troubleshooting Chart” for the significance of any abnormal

indications observed during a conditioning cycle.

LENS

ANTI-ROTATION TABS

REFLECTOR ASSEMBLY

RIBBED LENS AREA

Fig. 6

TO REMOVE LAMP, GRASP FIRMLY AND PULL STRAIGHT UP

■ TAKING A UNIT OUT OF SERVICE

If a unit is to be deliberately taken out of service for an extended

period, the battery lead should be disconnected from the charger so

that the battery will go into storage in a fully charged condition.

■ CHARGER/BATTERY PRINTED CIRCUIT ASSEMBLY: REPLACE

1.De-energize AC power to unit.

2.Loosen two cover retaining screws, open unit, disconnect battery lead.

3.Disconnect AC input wires. Close cover.

4.Pull emergency lamp wires off PC assembly, remove test switch button, take out PC assembly.

To replace the assembly, simply reverse the procedure.

■ Replacement Parts List

Description

Charger Assembly Battery

Emergency Lamp

Lamp Housing

Lamp Swivel T-fitting

1300109 C

1300671 A

Part Number

See p/n label on charger transformer

See unit model label

0110258

0070145

0310020