Product Catalogue (English)

XPEX SERIES

Explosion Proof Edge Lit LED Exit Light

•

Class I, Division 1, Groups C & D

•

Class II, Division 1, Groups E, F & G

•

Class III

•

Class I, Zone 1, Groups IIA, IIB,

•

Zone 2, Groups IIA, IIB + H2 & IIC

•

UL 844, 8750 & UL924

•

UL 1598A Marine Outside Type

•

Temperature Class (T-Rating)-T6

•

Patent No. 7,287,347

•

IP65

E

P

X

1

3 hours emergency operation standard with NiCad battery backup.

XPEX SERIES

Explosion Proof LED Edge Lit Exit Light

Available in wall/pendant or end mount configurations.

Copper-free cast aluminum housing with baked-on epoxy powder finish 1/2" NPT conduit hubs.

Fully integrated electronic circuit board and components.

Exit Signs with Red or

Green Legends Euro exit and other custom exits available. White or other color LED circuit boards and panels available.

Maintenance free LED light source with 25+ years life expectancy.

Acrylic edge lit single face or double face panel.

Patent Number 7,287,347

XPEX series fixture uses a maintenance free LED light source with a 25 year life expectancy. Emergency fixtures meet or exceed NFPA70, NFPA101, EPA Energy Star and OSHA requirements. These fixtures are also suitable for installation in wet or damp locations where salt water spray is possible.

2

RIG-A-LITE

XPEX Series

Explosion Proof • UL 844 • UL 924 • UL 1598A Marine Outside Type • Factory Sealed

Catalog Number Logic

XPE X

1 2 3 4 5 6

1

BASIC SERIES

XPEX Explosion Proof LED Exit Light

Class I, Division 1, Groups C, & D

Class II, Division 1, Groups E, F & G

Class III

Class I , Zone 1, Groups IIA, IIB,

Zone 2, Groups IIA, IIB + H2 & IIC

Marine Outside Type

UL 1598A, 8750, 844 & 924

IP65

Temperature Class (T-Rating)-T6

2

NUMBER OF FACES

1 = Single Face

2 = Double Face

3

4

LEGEND COLOR

R = Red

G = Green

VOLTAGE/FREQUENCY

DT = 120/277V 60HZ

24 = 220-240V 50/60HZ

Other voltages available- consult factory

5

6

MOUNTING

WP = Wall/Pendant Mounting

EB = End Bracket

OPTIONS 1

EM = Emergency Battery Backup

EU = Green Running Man Exit Legend

SD = Self Diagnostics

X = Exit Legend in Other Languages

Language Must Be Specified

1 Consult factory for pricing.

Maximum Input Power

Red no battery- 1.5 Watts

Red with battery- 2.5 Watts

Green no battery- 2.3 Watts

Green with battery- 3.0 Watts

Operating Temperature Range

Temperature Rating- T6

Red Legend

+10° C Minimum to +55° C Maximum

Green Legend

+10° C Minimum to +40° C Maximum

Catalog logic is for explaining catalog number structure only. Not all combinations are possible; consult factory for catalog numbers not listed in charts.

w w w . r i g a l i t e . c o m 3

4

XPEX Series

Explosion Proof • UL 844 • UL 924 • UL 1598A Marine Outside Type • Factory Sealed

XPEX Series Fixture Dimensions (inches)

A C

B

XPEX SERIES

XPEX LED Exit Sign/Light

A

14.88

Dimensions (inches)

B

16.00

C

3.69

Boxed

Weight

14 lbs.

Shipping Volume

(Boxed Fixtures)

1.24 cu. ft.

RIG-A-LITE

Revised: 09/21/2010

INSTALLATION DATA SHEET

XPEX SERIES

DANGER!

Do not install or service unless area is known to be nonhazardous.

WARNING!

Electrical Power must be turned off before and during installation and maintenance.

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

1. This fixture should be installed in strict accordance with the National Electrical Code and any local requirements.

2. This fixture should be mounted in locations and at heights where it will not readily be subjected to tampering by unauthorized personnel.

3. To prevent ignition of hazardous atmospheres, disconnect fixture from the supply circuit before opening. Keep tightly closed when in operation. To reduce risk of fire or explosion, do not install where the marked operating temperature exceeds the ignition temperature of the hazardous atmosphere(s).

4. Do not mount near gas or electric heaters.

5. Do not let power supply cords touch hot surfaces.

6. The use of accessory equipment not recommended by the manufacturer may cause an unsafe condition.

7. Do not use this equipment for other than intended use.

8. Installation and servicing of this fixture should be performed by qualified personnel.

SAVE THESE INSTRUCTIONS

MAINTENANCE:

All maintenance procedures are to be performed only when the atmosphere surrounding the fixture is non-hazardous.

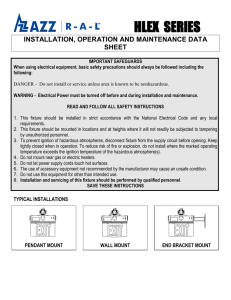

TYPICAL INSTALLATIONS:

PENDANT MOUNT WALL MOUNT END BRACKET MOUNT

Revised: 09/21/2010

INSTALLATION DATA SHEET

XPEX SERIES

INSTALLATIONS:

These fixtures are provided with ½” NPT hubs.

Pendant Mount

1.

Loosen the set screw provided in the top hub

.

2. Attach conduit to the top hub, making sure that at least five full threads are engaged and conduit is tight as per the

requirements of the NEC.

3. Tighten set screw.

4. Remove junction box cover and pull supply wires into junction box. Attach Black lead for 120V or Orange lead for

277V, White lead for Neutral and Green lead for Ground and cap unused lead. Replace junction box cover.

Wall Mount

1. Install Wall Mount Plate to the back of the fixture by means of two each ¼ - 20 Flat Head screws provided. Flat Head

screws must be securely fastened. Install the fixture to the wall by means of the Wall Mount Plate using two 5/16 in.

bolts (not provided).

1/4-20 FLAT HEAD

SCREWS

USE 5/16 BOLTS

(NOT PROVIDED)

2. Attach conduit to the top hub, making sure that at least five full threads are engaged and conduit is tight as per the

requirements of the NEC.

3. Remove junction box cover and pull supply wires into junction box. Attach Black lead for 120V or Orange lead for

277V, White lead for Neutral and Green lead for Ground and cap unused lead. Replace junction box cover.

End Bracket Mount

1. Install End Bracket to wall using four 5/16 in. Bolts (not provided). Install fixture to the End Bracket using two each

¼-20 Hex Head screws, lock washers and flat washers provided.

1/4-20 HEX HEAD SCREWS

2. Attach conduit to the top hub, making sure that at least five full threads are engaged and conduit is tight as per the

requirements of the NEC.

3. Remove junction box cover and pull supply wires into junction box. Attach Black lead for 120V or Orange lead for

277V, White lead for Neutral and Green lead for Ground and cap unused lead. Replace junction box cover.

XPEX EM SERIES

INSTALLATION, OPERATION AND MAINTENANCE DATA

SHEET

IMPORTANT SAFEGUARDS

When using electrical equipment, basic safety precautions should always be followed including the following:

DANGER - Do not install or service unless area is known to be nonhazardous. This Exit Sign has more than one power supply connection.

WARNING - Electrical Power must be turned off before and during installation and maintenance.

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

1. This fixture should be installed in strict accordance with the National Electrical Code and any local requirements.

2. This fixture should be mounted in locations and at heights where it will not readily be subjected to tampering by unauthorized personnel.

3. To prevent ignition of hazardous atmospheres, disconnect fixture from the supply circuit before opening. Keep tightly closed when in operation. When AC power is disconnected, the battery power will be live.

4.

To reduce risk of fire or explosion, do not install where the marked operating temperature exceeds the ignition temperature of the hazardous atmosphere(s).

5. Do not mount near gas or electric heaters.

6. Do not let power supply cords touch hot surfaces.

7. Do not attempt to service the battery inside this fixture. This fixture incorporates a sealed, no maintenance battery that is not field replaceable. Contact RAL for information on factory replacements.

8. The use of accessory equipment not recommended by the manufacturer may cause an unsafe condition.

9. Do not use this equipment for other than intended use.

10.

Installation and servicing of this fixture should be performed by qualified personnel.

SAVE THESE INSTRUCTIONS

TYPICAL INSTALLATIONS

PENDANT MOUNT WALL MOUNT END BRACKET MOUNT

INSTALLATIONS

These fixtures are provided with ½” NPT hubs.

Pendant Mount

1. Loosen the set screw provided in the top hub.

2. Attach conduit to the top hub, making sure that at least five full threads are engaged and conduit is tight as per the requirements of the NEC.

3. Tighten set screw.

Wall Mount

1. Install Wall Mount Plate to the back of the fixture by means of two each ¼-20 Flat Head screw provided. Flat Head screw must be securely fastened. Install the fixture to the wall by means of the Wall Mount

Plate using two 5/16 in.

Bolts (not provided).

2. Attach conduit to any of the three

½” NPT hubs on the fixture, making sure that at least five full threads

1/4-20 FLAT HEAD

SCREWS

4. Remove junction box cover and pull supply wires into junction box. Attach Black lead for 120V or Orange lead for 277V, White lead for Neutral and Green lead for

Ground. Replace junction box cover.

USE 5/16 BOLTS

(NOT PROVIDED) are engaged and conduit is tight as per the requirements of the

NEC.

3. Remove junction box cover and pull supply wires into junction box.

Attach Black lead for 120V or

Orange lead for 277V, White lead for Neutral and Green lead for

Ground. Replace junction box cover.

End Bracket Mount

1. Install End Bracket to wall using four 5/16 in. Bolts (not provided). Install fixture to the End Bracket using two each ¼-20 Hex Head screws, lock washers and flat washer provided.

1/4-20 HEX HEAD SCREWS

2. Attach conduit to hub on the fixture, making sure that at least five full threads are engaged and conduit is tight as per the requirements of the NEC.

3. Remove junction box cover and pull supply wires into junction box. Attach Black lead for 120V or Orange lead for 277V, White lead for Neutral and Green lead for

Ground. Replace junction box cover.

MAINTENANCE

All maintenance procedures are to be performed only when the atmosphere surrounding the fixture is nonhazardous.

1. Visually inspect the Red LED marked “AC”. It should be illuminated when AC power is on.

2. Test the emergency operation of the fixture once every 3 months. Exit Sign should illuminate under battery power when

AC power is removed from the fixture.

3. Conduct a 90 minute discharge test once a year. Exit Sign should illuminate under battery power for at least 90 minutes

when AC power is removed from the fixture.

4. Replace battery only with RAL part # B310011.

5. This fixture contains sealed Ni-Cad batteries. Used Ni-Cad batteries may not be disposed of in the municipal solid waste

Stream. Ni-Cad batteries must be recycled or disposed of properly. For information on local recycling drop off points, phone toll free 1-800-BATTERY.

Rig-A-Lite Partnership, Ltd. 8500 Hansen Road Houston TX 77075

Tele: (713)9430-0340 Fax: (713)943-8354 Email: info@rigalite.com

XPEX EM SERIES

EMERGENCY BATTERY REPLACEMENT DATA

SHEET

IMPORTANT SAFEGUARDS

When using electrical equipment, basic safety precautions should always be followed including the following:

DANGER - Do not install or service unless area is known to be nonhazardous. This Exit Sign has more than one power supply connection.

WARNING - Electrical Power must be turned off before and during installation and maintenance.

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

1. This fixture should be installed in strict accordance with the National Electrical Code and any local requirements.

2. This fixture should be mounted in locations and at heights where it will not readily be subjected to tampering by unauthorized personnel.

3.

To prevent ignition of hazardous atmospheres, disconnect fixture from the supply circuit before opening. Keep tightly closed when in operation. When AC power is disconnected, the battery power will be live.

4. To reduce risk of fire or explosion, do not install where the marked operating temperature exceeds the ignition temperature of the hazardous atmosphere(s).

5. Do not mount near gas or electric heaters.

6.

Do not let power supply cords touch hot surfaces.

7. Do not attempt to service the battery inside this fixture. This fixture incorporates a sealed, no maintenance battery that is not field replaceable. Contact RAL for information on factory replacements.

8.

The use of accessory equipment not recommended by the manufacturer may cause an unsafe condition.

9. Do not use this equipment for other than intended use.

10.

Installation and servicing of this fixture should be performed by qualified personnel.

SAVE THESE INSTRUCTIONS

BATTERY REMOVAL

1. Turn off electrical power.

2. Remove the end caps located on each side of the fixture.

3. Pull the wires out on the side of the housing.

4. Remove the two wire nuts connecting the LED.

5. Remove the two nuts, bolts and washers located on top of either end of the housing.

6. Remove the red LED indicator assembly from the housing.

7. Protect the glass rod from damage.

8. Remove the screws holding the LED circuit board to the housing by inserting a screwdriver through the bolt holes.

9. Partially slide out the circuit boards from the right side of the ballast housing.

10. Remove the wire connector by sliding the connector out of the circuit board.

11.Remove the circuit board from the housing.

12. Remove the battery unit’s wire connector from the

13.

circuit board.

Replace the battery and reverse the order to install.

Rig-A-Lite Tel: (713)943-0340 Visit us at:

8500 Hansen Rd Fax: (713)943-8354 http://www.rigalite.com

Houston, TX 77075

Email: info@rigalite.com