1-111 Safe signalling and monitoring Safety rated limit switches and

advertisement

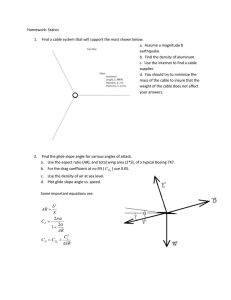

Safe signalling and monitoring Safety rated limit switches and Safety switches for hinged guards Position or limit switches are used with movable machine guards or detect the presence of materials. These switches feature positive break contacts which make them suitable for safety applications. Position Switches 1-112 Hinged switches are used to monitor the position of hinged safety guards. They prevent machine operation while the door is ajar. Hinged Switches 1-116 For more information, see our online product catalog: www.usa.schmersal.net 1-111 Position switches Z/T 235 Z/T 236 Technical data 8,5 4 4,3 20 20 22 4,3 20 20 58,5 63,5 8,5 Standards: 22 30 • Metal enclosure • Available with 2 positive break NC contacts • Snap action with constant contact pressure up to switching point • Slow action available with overlapping or staggered contacts • Wiring compartment • 1 cable entry M20 • Wide range of alternative actuators • Actuator heads can be repositioned by 4 x 90° • Angle of roller lever adjustable in 10° steps • Good resistance to oil and petroleum spirit • Metal roller available on request • EX version available • AS-Interface Safety at Work available 15 ¤ 26 30 3 15 30 30 • Thermoplastic enclosure •D ouble insulated X • Available with 2 positive break NC contacts •S nap action with constant contact pressure up to switching point •S low action available with overlapping or staggered contacts •1 cable entry M20 •W ide range of alternative actuators • Actuator heads can be repositioned by 4 x 90° • Angle of roller lever adjustable in 10° steps •G ood resistance to oil and petroleum spirit • AS-Interface Safety at Work available Approvals IEC/EN 60947-5-1 BG-GS-ET-15 Design: fixings to EN 50047 Enclosure:Z/T 235: zinc die-cast, enamel finish Z/T 236: Glass fiber reinforced thermoplastic Protection class: IP67 to EN 60529 Contact material:silver Contact type: change-over contact with double break, type Zb or 2 NC contacts, with galvanically separated contact bridges Switching principle: A IEC 60947-5-1 slow or snap action, NC contacts with positive break Connection: screw terminals Cable section: max. 2.5 mm², min. 0.75 mm² (incl. conductor ferrules) Cable entry: 1 x M20 Uimp: 6 kV connector: 0.8 kV Ui: 500 V connector: 50 V Ithe: 10 A Utilization category: AC-15, DC-13 Ie/Ue: 4 A / 230 VAC 1 A / 24 VDC connector: 4 A / 50 V Max. fuse rating: 6 A gG D-fuse Ambient temperature: −30 °C … +80 ºC Mechanical life: 20 million operations Switching frequency: max. 5,000/h Bounce duration: snap action: < 3 ms; slow action: in accordance with actuating speed Switchover time: snap action: > 5.5 ms; slow action: in accordance with actuating speed Classification: Standards: EN ISO 13849-1 B10d (NC):20,000,000 B10d (NO):1,000,000 for max. 10% ohmic contact load Mission time: 20 years B10d 0,1 x nop MTTFd nop d op x h op x 3600 s/h t cycle Ordering details Ordering details Note ➀➁ 23➂-➃Z➄-➅-➆-➇-➈ No. 13 14 11 12 13 14 21 22 21 22 23 24 No. Option ➀ Z Snap action A T Slow action A For the appropriate actuator: see page 1-115 5 Metal housing 6 Plastic housing 02 2 NC 11 1 NO / 1 NC 20 2 NO * H Slow action with staggered contacts UE with overlapping contacts ➁ ➂ ➃ ➄ 1-112 Description Option ➅ NPT ST ➆ 2310 1297 ➇ 2138 ➈ 1637 Description Cable entry M20 Cable entry NPT 1/2“ Connector M12 (A-Coding) (B-Coding) Enclosure with ­transversely slotted mounting holes Roller lever 7H for safety duties Gold-plated contacts 1 2 3 4 1 2 3 4 1 2 3 4 Caution! The versions with connector may only be used in PELV circuits to EN 60204-1. * Switches with 2 NO contacts (20) are only available for T (Slow Action) versions and are only suitable for positioning tasks. For more information, see our online product catalog: www.usa.schmersal.net Position switches Plunger / lever options M18 x 1 ¤ 10 ¤6 3,5 6 ¤ 12 ¤ 12,6 16,5 12 33 40 24 19,6 Plunger S 19,6 19,6 Plunger 4S 19,6 Plunger R 8,6 M18 x 1 3,5 ¤ 12 ¤ 14 5,3 ¤ 12 5 28 40 33 31,6 24 19,6 19,6 19,6 19,6 19,6 19,6 Plunger 4R Offset Roller Lever 1R Offset Roller K 32 25 5 22 17-23 12,8 19,6 43,5 30 19,6 19,6 Angle Roller Lever 3K 19,6 Angle Roller Lever 4K 44,85 ¤ 20 8,5 8,5 19,6 15 23 15 15 31-72 31-70 5 24,5 Angle Roller Lever K4 44,5 32,5 10 20 40 ¤ 15 10 5 43,5 ¤ 14 ¤ 22 5 19,6 19,6 Roller Lever 1H Roller Lever 7H 19,6 Roller Lever 7H-2138 40,5 ¤6 40,1 43,5 15 15 15 19,6 Roller Lever 10H 19,6 19,6 Roller Lever 12H 5 28 24,5 200 13 ¤ 15 5 ¤ 15 9,5 19,6 19,6 19,6 Roller Lever 14H For more information, see our online product catalog: www.usa.schmersal.net 1-113 Position switches Z/T 335 Z/T 336 Technical data Standards: 5,3 76 66,5 60 17 30 40,5 17 30 40,5 38 • Metal enclosure • Snap action with constant contact pressure up to switching point • Slow or snap action available with 2 positive break NC contacts to EN 60947-5-1 • Slow action available with overlapping or staggered contacts • 1 cable entry M20 • Wide range of alternative actuators • Actuator heads can be repositioned by 4 x 90° • Angle of roller lever adjustable in 10° steps • Good resistance to oil and petroleum spirit • Metal roller available on request • EX version available • AS-Interface Safety at Work available 30,5 7,3 ¤5,3 30,5 7,3 ¤5,3 66,5 60 76 9,5 9,5 5,3 38 • Thermoplastic enclosure •D ouble insulated X •S low action or snap action available with 2 positive break NC contacts to EN 60947-5-1 •S nap action with constant contact pressure up to switching point •S low action available with overlapping or staggered contacts •1 cable entry M20 •W ide range of alternative actuators • Actuator heads can be repositioned by 4 x 90° • Angle of roller lever adjustable in 10° steps •G ood resistance to oil and petroleum spirit •M etal roller available on request • AS-Interface Safety at Work available Approvals IEC/EN 60947-5-1 BG-GS-ET-15 Design: DIN EN 50041 Enclosure: 335: light-alloy die cast, paint finish 336: Glass fiber reinforced thermoplastic Protection class: IP67 to EN 60529 Contact material:silver Contact type: change-over contact with double break, type Zb or 2 NC contacts, with galvanically separated contact bridges Switching principle: A IEC 60947-5-1 slow or snap action, NC contacts with positive break Connection: screw terminals Cable section: max. 2.5 mm² (incl. conductor ferrules) Cable entry: 1 x M20 Uimp: 6 kV -03z, -12z: 4kV connector: 0.8 kV Ui: 500 V -03z, -12z: 250 V connector: 50 V Ithe: 10 A Utilization category: AC-15, DC-13 Ie/Ue: 4 A / 230 VAC 4 A / 24 VDC connector: 4 A / 50 V Max. fuse rating: 6 A gG D-fuse Ambient temperature: −30 °C … +80 ºC Mechanical life: 30 million operations Switching frequency: max. 5,000/h Bounce duration: snap action: in accordance with actuating speed; slow action: < 2ms Switchover time: snap action: < 2 ms; slow action: in accordance with actuating speed Classification: Standards: EN ISO 13849-1 B10d (NC):20,000,000 B10d (NO):1,000,000 for max. 10% ohmic contact load Mission time: 20 years B10d 0,1 x nop MTTFd Ordering details Ordering details ➀➁ 33➂-➃Z➄-➅-➆-➇-➈ No. Option ➀ Z Snap action A T Slow action A For the appropriate actuator: see page 1-117 5 Metal housing 6 Plastic housing 11 1 NO / 1 NC 02 2 NC 20 2 NO * 01/01 1 NC left / 1 NC right 12 1 NO / 2 NC** 03 3 NC** Slow action H with staggered contacts UE with overlapping ­contacts ➁ ➂ ➃ ➄ 1-114 Description No. Option Description ➅ G24 With LED ➆ NPT ST ➇ 2310 2138 ➈ 1637 Cable entry M20 Cable entry NPT 1/2“ Connector M12 (A-Coding) (B-Coding) Roller lever 7H for safety duties Gold-plated contacts nop d op x h op x 3600 s/h t cycle Note 13 14 11 12 13 14 21 22 21 22 23 24 1 2 3 4 1 2 3 4 1 2 3 4 Caution! The versions with connector may only be used in PELV circuits to EN 60204-1. * Switches with 2 NO contacts (20) are only available for T (Slow Action) versions and are only suitable for positioning tasks. ** Switches with 1 NO & 2 NC contacts (12) or 3 NC contacts (03) are only available for 335 (metal) housings with T (Slow Action) contacts. For more information, see our online product catalog: www.usa.schmersal.net Position switches Plunger / Lever options ¤ 17,2 8,5 ¤ 20 4,6 27 42,5 27,5 40,6 ¤9 27 27 Plunger S 33,5 27 Roller plunger R • Actuator type B to EN 50041 • Required actuating force: 12 N for snap action, 17 N for slow action • Actuating speed with actuating angle 0° to switch axis, max. 0.5 m/s 27 Offset roller lever 1K • Actuator type C to EN 50041 •R equired actuating force: 12 N for snap action, 17 N for slow action • Actuating speed with actuating angle 30° to switch axis: max. 0.5 m/s • Required actuating force: 12 N for snap action, 17 N for slow action • Actuating speed with actuating angle 30° to switch axis: max. 0.5 m/s ¤6 56,3 8,5 8,5 ¤ 20 49 9,5 15,5 45,5 28 200 15,5 13 ¤ 20 38 29,5 27 27 27 Angle roller lever 3K 27 27 Roller lever H • Required actuating force: 12 N for snap action, 17 N for slow action • Actuating speed with actuating angle 30° to switch axis: max. 0.5 m/s • Actuation parallel to axis of switch from below Rod Lever 10H • Actuator type A to EN 50041 •R equired actuating torque: 26 Ncm for snap action, 31 Ncm for slow action • Actuating speed with actuating angle 30° to switch axis: max. 2.5 m/s On version TVH ...-01/01z positive break only to one side. ¤ 20 8,5 31-72 8,5 31-72 ¤ 20 53 ¤ 20 53 • Only for positioning tasks • Actuator type D to EN 50041 • Plastic rod • Required actuating torque: 26 Ncm for snap action, 31 Ncm for slow action • Actuating speed with actuating angle 30° to switch axis: max. 2.5 m/s • Aluminum rod, ordering suffix -1183 Note L+ 27 15,5 25,5 15,5 13 21 27 27 27 24 VDC 14 22 3 2 YE Roller lever 7H • Only for positioning tasks • Required actuating torque: 26 Ncm for snap action, 31 Ncm for slow action • Actuating speed with actuating angle 30° to switch axis: max. 2.5 m/s Roller lever 7H-2138 • For safety tasks A, positive break • Required actuating torque: 26 Ncm for snap action, 31 Ncm for slow action • Actuating speed with actuating angle 30° to switch axis: max. 2.5 m/s L- GN 1 LED version Ordering suffix G24, Protected against incorrect polarity and voltage spikes. On version TV7H ...-01/01z-2138 positive break only to one side. For more information, see our online product catalog: www.usa.schmersal.net 1-115 Safety switch for hinged guards T.C 235 T.C 236 Technical data 22 30 M20 13,5 30 20 20 22 30 • Metal enclosure • Versions available for left-hand (T3C 235), right-hand (T5C 235) and swing-doors (T4C 235) • 1 cable entry M20 • Good resistance to oil and petroleum spirit • Actuator heads can be repositioned in steps 4 x 90° • Opening angle 180° • Stainless steel actuator • EX version available IEC/EN 60947-5-1 BG-GS-ET-15 Design: fixings to EN 50047 Enclosure: 235: light-alloy diecast, paint finish 236: Glass fiber reinforced thermoplastic Protection class: IP67 to EN 60529 Contact material:silver Contact type: change-over contact with double break Zb or 1 NC or 2 NC contacts, with galvanically separated contact bridges Switching principle: A IEC 60947-5-1 slow action, NC contact with positive break Connection: screw terminals Cable section: max. 2.5 mm², min. 0.75 mm² (incl. conductor ferrules) Cable entry: 1 x M20 Uimp: 6 kV connector: 0.8 kV Ui: 500 V connector: 50 V Ithe: 10 A Utilization category: AC-15 Ie/Ue: 4 A / 230 VAC 1 A / 24 VDC connector: 4 A / 50 V Max. fuse rating: 6 A gG D-fuse Ambient temperature: −30 °C … +80 ºC Mechanical life: > 1 million operations Switching frequency: max. 5,000/h Positive break angle: 12.5° Positive break torque: 0.185 Nm Classification: Standards: EN ISO 13849-1 B10d (NC):20,000,000 Mission time: 20 years 4,3 25 19,5 8,5 4,3 20 20 63,5 63,5 8,5 25 19,5 Standards: M20 13,5 30 • Thermoplastic enclosure •V ersions available for left-hand (T3C 236), right-hand (T5C 236) and swing-doors (T4C 236) •D ouble insulated X •1 cable entry M20 •G ood resistance to oil and petroleum spirit • Actuator heads can be repositioned in steps 4 x 90° •O pening angle 180° •S tainless steel actuator MTTFd B10d 0,1 x nop nop Approvals H Ordering details T➀C 235-➁Z-➂ No. Option Description ➀ ➁ 3 4 5 01 02 11 ➂ ST 2310 Left-hand version Swing-door version Right-hand version 1 NC 2 NC 1 NO / 1 NC Cable entry M20 Connector M12 (A-Coding) (B-Coding) Connector Note Caution! The versions with connector may 1 NO only be used in PELV circuits to EN 60204-1. 1 NC 14 11 12 21 22 21 22 1 2 3 4 1 2 3 4 2 NC 13 14 11 12 21 22 21 22 1 2 3 4 1-116 13 1 2 3 4 For more information, see our online product catalog: www.usa.schmersal.net d op x h op x 3600 s/h t cycle Safety switch for hinged guards Swing-door version (4) 8 Left-hand version (3) 43 5,1 8 43 5,1 70 10 2 8 10 2 2 19,5 31 19,5 16 5,1 31 19,5 70 43 10 16 70 16 Right-hand version (5) • Good resistance to oil and petroleum spirit • Actuator heads can be repositioned by 4 x 90° • Opening angle 180° • Good resistance to oil and petroleum spirit • Actuator heads can be repositioned in steps 4 x 90° • Opening angle 2 x 90° • Good resistance to oil and petroleum spirit • Actuator heads can be repositioned by 4 x 90° • Opening angle 180° Closed guard device = 0° in contact switch travel diagrams. This is the rest position of the switch Closed guard device = 0° in contact switch travel diagrams. This is the rest position of the switch Closed guard device = 0° in contact switch travel diagrams. This is the rest position of the switch Contacts/ Switch travel Slow action Contacts/ Switch travel Slow action Contacts/Switch travel Slow action 1 NO 1 NC T3C 235-11Z T3C 236-11Z 1 NO 1 NC T4C 235-11Z T4C 236-11Z 1 NO 1 NC T5C 235-11Z T5C 236-11Z 180° 3,5° 0 12,5° 4,5° 1 NC T3C 235-01Z T3C 236-01Z 180° 2 NC 12,5° 4,5° 0 12,5° 4,5° 0 12,5° 4,5° 90° 1 NC 2 NC 11-12 21-22 3,5° 0 3,5° 90° 13-14 12,5° 12,5° 21-22 4,5° 4,5° T4C 235-01Z T4C 236-01Z 90° 11-12 T3C 235-02Z T3C 236-02Z 180° 0 4,5° 13-14 21-22 90° 3,5° 1 NC 4,5° 0 4,5° 90° 12,5° 12,5° 11-12 T4C 235-02Z T4C 236-02Z 12,5° 4,5° 0 4,5° 90° 12,5° 12,5° 11-12 12,5° 12,5° 21-22 4,5° 4,5° For more information, see our online product catalog: www.usa.schmersal.net 21-22 13-14 T5C 235-01Z T5C 236-01Z 0 4,5° 2 NC 180° 12,5° 180° 11-12 T5C 235-02Z T5C 236-02Z 0 4,5° 12,5° 4,5° 12,5° 180° 11-12 21-22 1-117 Safety switch for hinged guards TV.S 335 Technical data Contact variants Standards: 65,3 107 ¤ 8 / ¤ 10 ¤ 14 9,5 ¤ 4,2 5 M20 7,3 ¤ 5,3 60 13 38 30 40,5 • Metal enclosure • Good resistance to oil and petroleum spirit • Actuator heads can be repositioned in steps 4 x 90° using Torx T 20 srewdriver and pin • Actuator shaft can be turned 360° • 1 cable entry M20 • LED version available • Shaft bore Ø 8 mm or 10 mm Approvals MTTFd H Ordering details TV➀S 335-➁Z-➂ No. Option Description ➀ ➁ IEC/EN 60947-5-1 EN ISO 13849-1 BG-GS-ET-15 Design: fixings to EN 50041 Enclosure: light-alloy diecast, paint finish Protection class: IP67 to EN 60529 Contact material:silver Contact type: change-over contact with double break Zb or 1 NC or 2 NC contacts, with galvanically separated contact bridges Switching principle: A IEC 60947-5-1 slow action, NC contact with positive break Connection: screw terminals or connector Cable section: (rigid/flexible): min. 0.75 mm² max. 2.5 mm² (incl. conductor ferrules) Cable entry: 1 x M20 Uimp: 6 kV connector: 0.8 kV Ui: 500 V connector: 50 V Ithe: 10 A Utilization category: AC-15, DC-13 Ie/Ue: 4 A / 230 VAC 4 A / 24 VDC connector: 4 A / 50 V Max. fuse rating: 6 A gG D-fuse (DIN EN 60269-1) Ambient temperature: −25 °C … +70 ºC Mechanical life: > 1 million operations Switching frequency: max. 1,000/h Shaft bore: Ø 8 mm / 10 mm Positive break angle: 7° Positive break torque: 0.6 Nm Classification: Standards: EN ISO 13849-1 B10d (NC):20,000,000 Mission time: 20 years 8 10 02 03 11 12 ➂ NPT ST 2310 1-118 Shaft bore Ø 8 mm Shaft bore Ø 10 mm 2 NC 3 NC 1 NO / 1 NC 1 NO / 2 NC Cable entry M20 Cable entry NPT 1/2“ Connector M12 (A-Coding) (B-Coding) B10d 0,1 x nop nop 1 NO 1 NC 354° 354° 3° 0 3° 7° 7° 13-14 21-22 2 NC 354° 354° 3° 0 3° 7° 7° 11-12 21-22 1 NO 2 NC 3 NC Connector 1 NO 1 NC 13 14 21 22 1 2 3 4 2 NC 11 12 21 22 1 2 3 4 d op x h op x 3600 s/h t cycle Note Note Closed guard device = 0° in contact switch travel diagrams. This is the rest position of switch. L+ 13 24 VDC L- 3 2 YE GN 14 1 LED version: Ordering suffix G24, only available for version with one NO and one NC contact. Protected against incorrect polarity and voltage spikes. Caution! The versions with connector may only be used in PELV circuits to EN 60204-1. • Setting assistance: Grub screw for location, shaft pre-drilled for pin • Universal joint available to compensate for axial displacement (only for shaft bore 10 mm), see the following pages 1-127. For more information, see our online product catalog: www.usa.schmersal.net Safety switch for hinged guards TESZ Technical data System components 15 36 5 ° 135 19 71 42 62 92 76 44 • Thermoplastic enclosure • Double insulated X • Simple mounting, especially on 40 mm profiles • Good resistance to oil and petroleum spirit • 2 cable entries M20 • For left or right hinged doors • Fixing holes for M6 countersunk screws to DIN 965 • The additional hinge including mounting accessories is also available separately, MTTFd B10d 0,1 x nop nop 15 5 ¤ 6,3 92 62 IEC/EN 60947-5-1 BG-GS-ET-15 Enclosure: glass fiber reinforced thermoplastic, self-extinguishing Hinge:aluminum Protection class: IP65 to EN 60529 Contact material:silver Contact type: change-over contact with double break, type Zb or 3 NC contacts Switching principle: A IEC 60947-5-1 slow action, NC contact with positive break Connection: screw terminals Cable section: max. 1 mm² (incl. conductor ferrules) Cable entry: 2 x M20 Uimp: 2.5 kV Ui: 250 V Ithe: 2.5 A Utilization category: AC-15, DC-13 Ie/Ue: 2 A / 230 VAC 1 A / 24 VDC Max. fuse rating: 2 A gG D-fuse Ambient temperature: −25 °C … +65 ºC Mechanical life: > 1 million operations Switching frequency: max. 120/h Positive break angle: 10° Classification: Standards: EN ISO 13849-1 B10d (NC):2,000,000 Mission time: 20 years ¤ 12 x 90° Standards: 44 71 Additional hinge Part numbers for extra hinges: (no switch) TESZ/S/30 for 30 mm profiles TESZ/S/35 for 35 mm profiles TES/S for 40 mm profiles TES/S/45 for 45 mm profiles d op x h op x 3600 s/h t cycle Approvals H Ordering details TESZ ➀➁➂ No. Option Description Note The opening angle has been set to 4° in factory. Contact variants 1 NO 2 NC 0 4° 10° ➀ 1102 1110 ➁ ➂ S 30 35 45 1 NO/2 NC 3 NC with extra hinge without extra hinge 30 mm profiles 35 mm profiles 40 mm profiles 45 mm profiles Until the limit of the mechanical life has been reached the angle can increase up to 10° under normal wear-out conditions. 13° 135° 11-12 21-22 33-34 3 NC 0 4° 10° For more information, see our online product catalog: www.usa.schmersal.net 135° 11-12 21-22 31-32 1-119 Safety switch for hinged guards TESF Technical data Contact variants Standards: 90 M16 x 1,5 6,1 115 100 51 41,5 4 11 21,5 25,5 75,5 • Metal enclosure • Adjustable switching angle • Opening angle 180° • Mountable on the inside and the outside of the safety guard • Screw terminals, cage clamps or connector • Simple mounting, for all common profile systems (30 … 60 mm) • Oil and petroleum resistant • 2 cable entries M16 • For left or right hinged doors IEC/EN 60947-5-1 BG-GS-ET-15 Enclosure: light-alloy diecast Protection class: IP65 to EN 60529 Contact material: AgNi10 Contact type: 2x change-over contact with double break, type Zb Switching principle: A IEC 60947-5-1 slow action, NC contact with positive break Connection: screw terminals or cage clamps or connector Cable section: max. 1 mm² (incl. conductor ferrules) Cable entry: 2 x M16 Uimp: 2.5 kV; ordering suffix ST1 and ST2: 0.8 kV Ui: 250 V Ithe: 2.5 A Utilization category: AC-15; DC-13 Ie/Ue: 2 A / 230 VAC; 1 A / 24 VDC Max. fuse rating: 2 A gG D-fuse to DIN EN 60269-1 Ambient temperature: −25 °C … +65 ºC Mechanical life: > 1 million operations Switching frequency: 120/h Positive break angle: 10° Classification: Standards: EN ISO 13849-1 B10d (NC):2,000,000 Mission time: 20 years MTTFd B10d 0,1 x nop nop 2 NO/2 NC 0° 180° 3° 10° 11-12 A 23-24 31-32 A 43-44 Screw terminals 23 24 43 44 11 12 31 32 31 32 43 44 11 12 23 24 Connector ST24.1 or ST24.2 23 24 43 44 11 12 31 32 6 5 1 2 3 4 5 6 7 8 4 3 7 1 8 2 d op x h op x 3600 s/h t cycle Approvals H Ordering details TESF ➀-➁➂➃ No. Option Description ➀ no alignment aid with alignment aid with extra hinge S without extra hinge Screw Terminals ST24.1 connector on bottom ST24.2 connector on top 0 for inside mounting 180 for outside mounting U Adjustable switch point A ➁ ➂ ➃ 1-120 Ordering details Note Contact switch t­ravel diagrams: 0° = safety guard closed. Caution! The versions ST1 and ST2 11/11 may only be used in PELV c ­ ircuits to EN 60204-1. * The f­actory-set switching angle is 3°. The positive break angle is 5°. Until the limit of the mechanical life has been reached the angle can increase up to 8° under normal wear-out conditions. For more information, see our online product catalog: www.usa.schmersal.net Safety switch for hinged guards System components 51 51 25,5 25,5 41,5 41,5 4 11 22 6,1 115 100 55 51 6,1 40 90 M16 x 1,5 System components 25,5 75,5 41,5 Bottom connector ST24.1 90 Additional hinge TESF/S 51 M16 x 1,5 11 25,5 75,5 4 22 6,1 115 100 22 41,5 Top connector ST24.2 Additional hinge TESFA/S 11 4 21,5 22 With alignment aid order version A Adjustment tool TESF-14 Ordering details Ordering details Connector M12, 8 pins, 24 VDC, bottom top With alignment aid ST24.1 ST24.2 order version A Additional hinge without alignment aid with alignment aid TESF/S TESFA/S Adjustment tool TESF-14 For more information, see our online product catalog: www.usa.schmersal.net 1-121 We make designing your system easy. Online Product Catalog www.usa.schmersal.net Images available online Every part number page has an Image tab where you can view or download JPG or EPS images of the product, dimensional drawings, switch travel diagrams, or contact diagrams. The CAD tab also has links to download CAD drawings of the part in many popular program formats, so they can be directly incorporated into CAD systems designs. 1-122